Display panel assembly structure and display device

A display panel and assembly structure technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of increasing process and production costs, easy to break, product defects, etc., to simplify the connection process and eliminate flexible circuit boards. Fractures and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

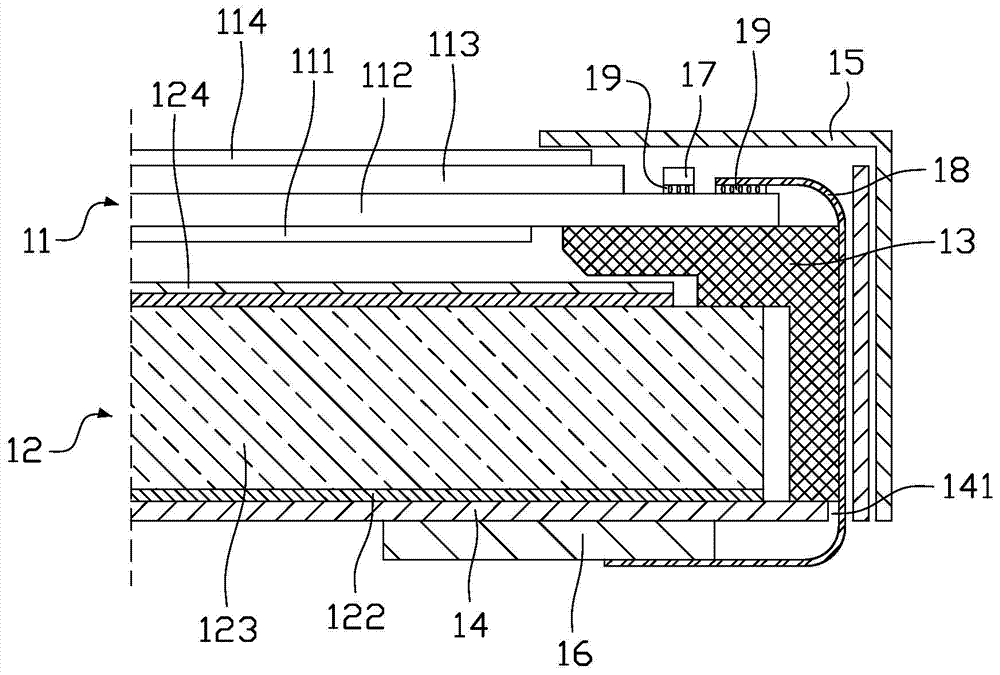

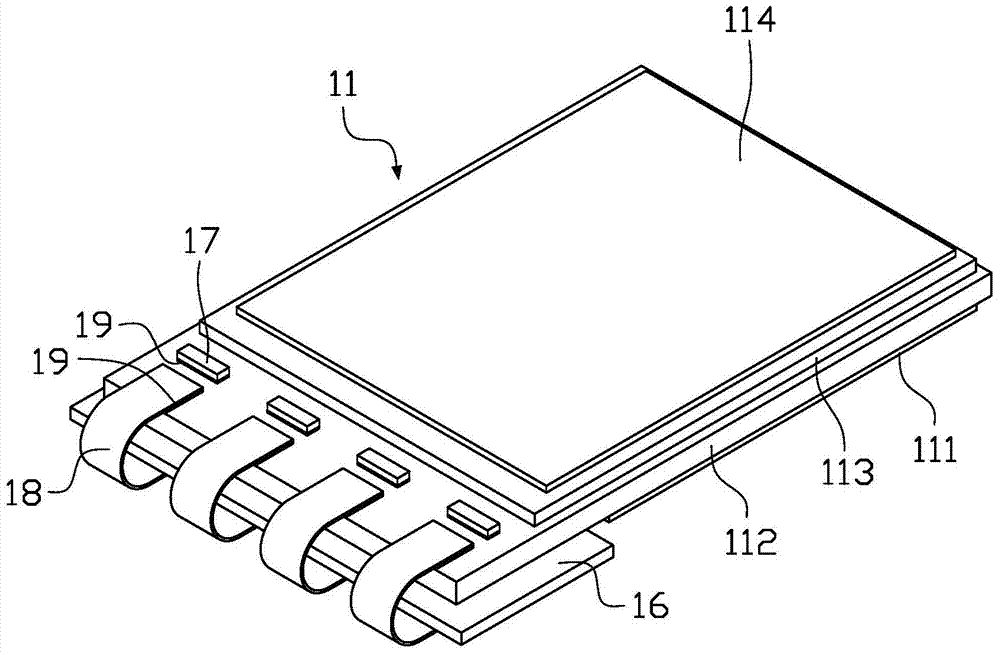

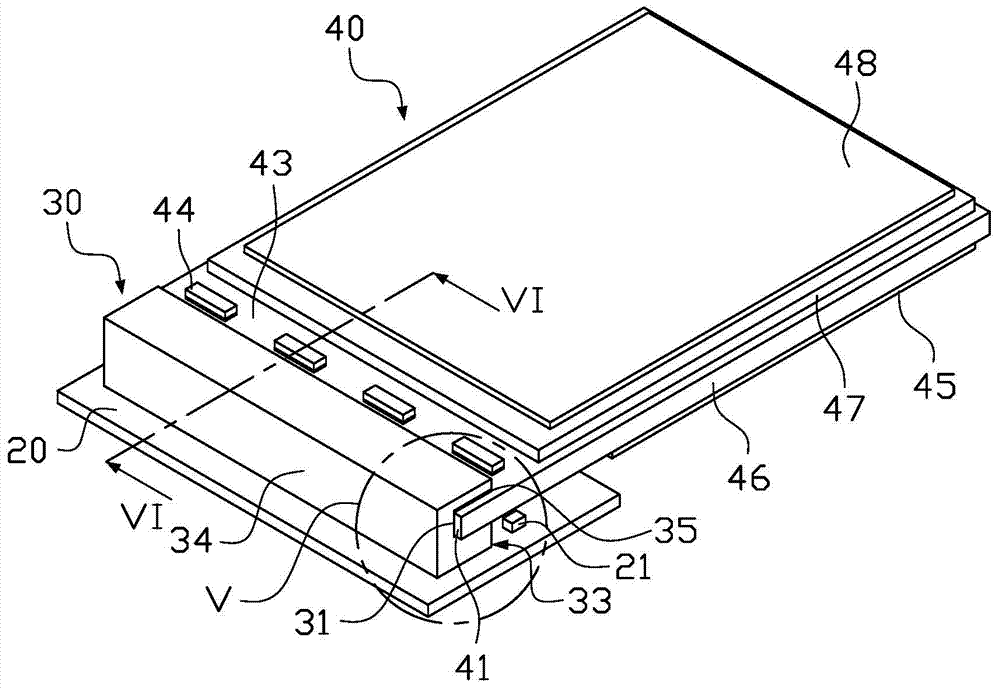

[0029] image 3 It is a structural schematic diagram of the assembly structure of the display panel in the first embodiment of the present invention, Figure 4 for image 3 Schematic diagram of the structure of the rigid circuit board in, Figure 5 for image 3 Schematic diagram of the enlarged structure of part V in the middle, Image 6 for image 3 The cross-sectional schematic diagram after being cut along the VI-VI line in , please combine Figure 3 to Figure 6 , The display panel assembly structure provided in this embodiment includes a rigid circuit board 20 , a connector 30 , and a display panel 40 . The connector 30 is fixed on the rigid circuit board 20 , and the connector 30 is provided with a slot 31 along a horizontal direction on a side surface close to the display panel 40 , and a plurality of probes 32 are provided in the slot 31 . The display panel 40 has an insertion end 41 on the side close to the connector 30, the insertion end 41 is provided with a pl...

no. 2 example

[0039] In the above first embodiment, the display panel 40 is a liquid crystal display panel as an example for illustration. However, in other embodiments of the present invention, the display panel 40 can also be other types of display panels, please refer to Figure 7 , Figure 7 It is a structural schematic diagram of the assembly structure of the display panel in the second embodiment of the present invention. In this embodiment, the display panel 40a is a flexible display panel, such as a flexible organic light emitting diode (Flexible Organic Light Emitting Diode) that is self-illuminating and does not need an additional backlight source. Light-Emitting Diode, FOLED) display panel, because the display panel 40a is flexible and rollable, it is suitable for making a flexible display device. The insertion end 41 of one side of the display panel 40a (refer to image 3 ) into the slot 31 of the connector 30a, through a plurality of probes 32 of the connector 30a (see Imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com