Multi-alloy step feed device for metallurgy smelting

A multi-alloy and metallurgical technology, applied in the field of metallurgical smelting multi-alloy step-by-step adding devices, can solve the problems of large equipment investment, complex production process and high maintenance cost, and achieve the effects of reducing production cost, simplifying adding process and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

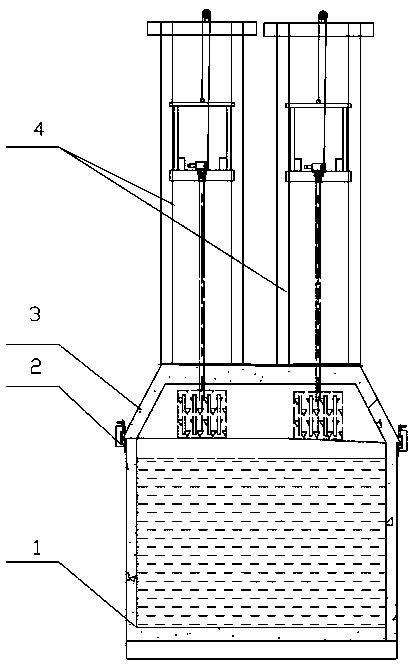

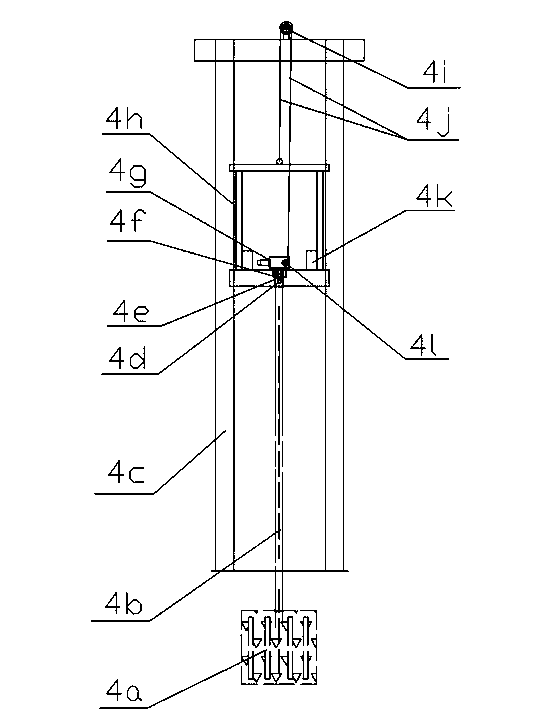

[0014] A multi-alloy step-by-step adding device for metallurgical smelting, in which more than two alloy feeders 4 are arranged on the cover 3 of the ladle 1, the cover 3 and the ladle 1 are fixed by a connecting card 2, and the alloy feeder 4 includes a bracket 4c , the carriage 4h is installed in the bracket 4c, the double output shaft belt motor speed reducer 4g and the counterweight iron 4k are arranged on the carriage 4h, and the lifting wheel 4l is installed on one of the output shafts of the double output shaft belt motor speed reducer 4g, and the other An electromagnetic clutch device 4f is installed on an output shaft, and the steel wire rope 4j is sleeved on the guide wheel assembly 4i on the top of the bracket 4c, one end of which is connected with the carriage 4h, and the other end is connected with the lifting wheel 4l, and the alloy frame 4a is fixed to the connecting rod 4b. Then, the upper end of the connecting rod 4b is connected with the shaft sleeve 4e fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com