Preparation method of distearoyl sodium tartrate diester modified talcum powder and nylon composite material

A technology of sodium stearyl tartrate and nylon composite materials, which is applied in the field of composite materials, can solve the problems of poor compatibility, low interface strength, and gaps formed at the interface, and achieve increased toughness, good compatibility, and improved dispersion uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

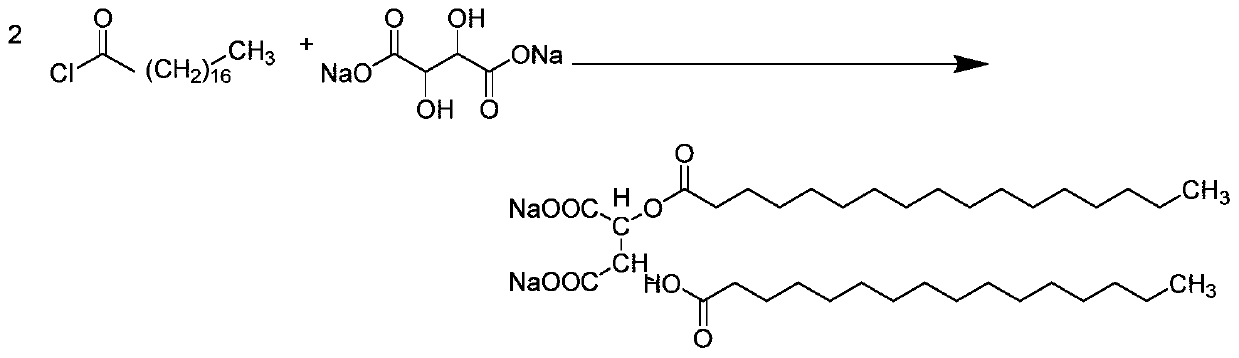

[0031] (1) Synthesis of distearoyl sodium tartrate diester surface modifier:

[0032] In a 250ml three-necked flask equipped with a stirrer, thermometer, and reflux condenser, add 1.1g of stearoyl chloride (it is easy to crystallize when stored at low temperature, and melt before use), 12ml of dichloromethane solvent, and stir to dissolve in an ice-water bath Cool for 20 minutes and mix well. Then take a 250 ml beaker, add 0.3 g of sodium tartrate and 100 ml of acetone, and stir to dissolve to obtain an acetone solution of sodium tartrate. Then, 2ml of triethylamine was slowly added dropwise to the flask, and stirred for 5 minutes under ice-water bath conditions. The freshly prepared acetone solution of sodium tartrate was gradually added dropwise to the reactor, the temperature was raised to room temperature, and the reaction was carried out for 12 hours. Suction and filter under reduced pressure 2 times, leaving the filtrate. After distillation, a large amount of white paste...

Embodiment 2

[0038] (1) Synthesis of distearoyl sodium tartrate diester surface modifier

[0039] In a 250ml three-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, add 1.1g of stearoyl chloride (it is easy to crystallize when stored at low temperature, and melt before taking it), 12ml of dichloromethane solvent, and stir in an ice water bath for 20 Cool in minutes and mix well. Then take a 250 ml beaker, add 0.3 g of sodium tartrate and 100 ml of acetone, and stir to dissolve to obtain an acetone solution of sodium tartrate. Then 2ml of triethylamine was slowly added dropwise to the flask, and stirred for 5 min under ice-water bath conditions. The freshly prepared acetone solution of sodium tartrate was gradually added dropwise to the reactor, the temperature was raised to room temperature, and the reaction was carried out for 12 hours. Suction and filter under reduced pressure twice, leaving the filtrate. After distillation, a large amount of white paste-like s...

Embodiment 3

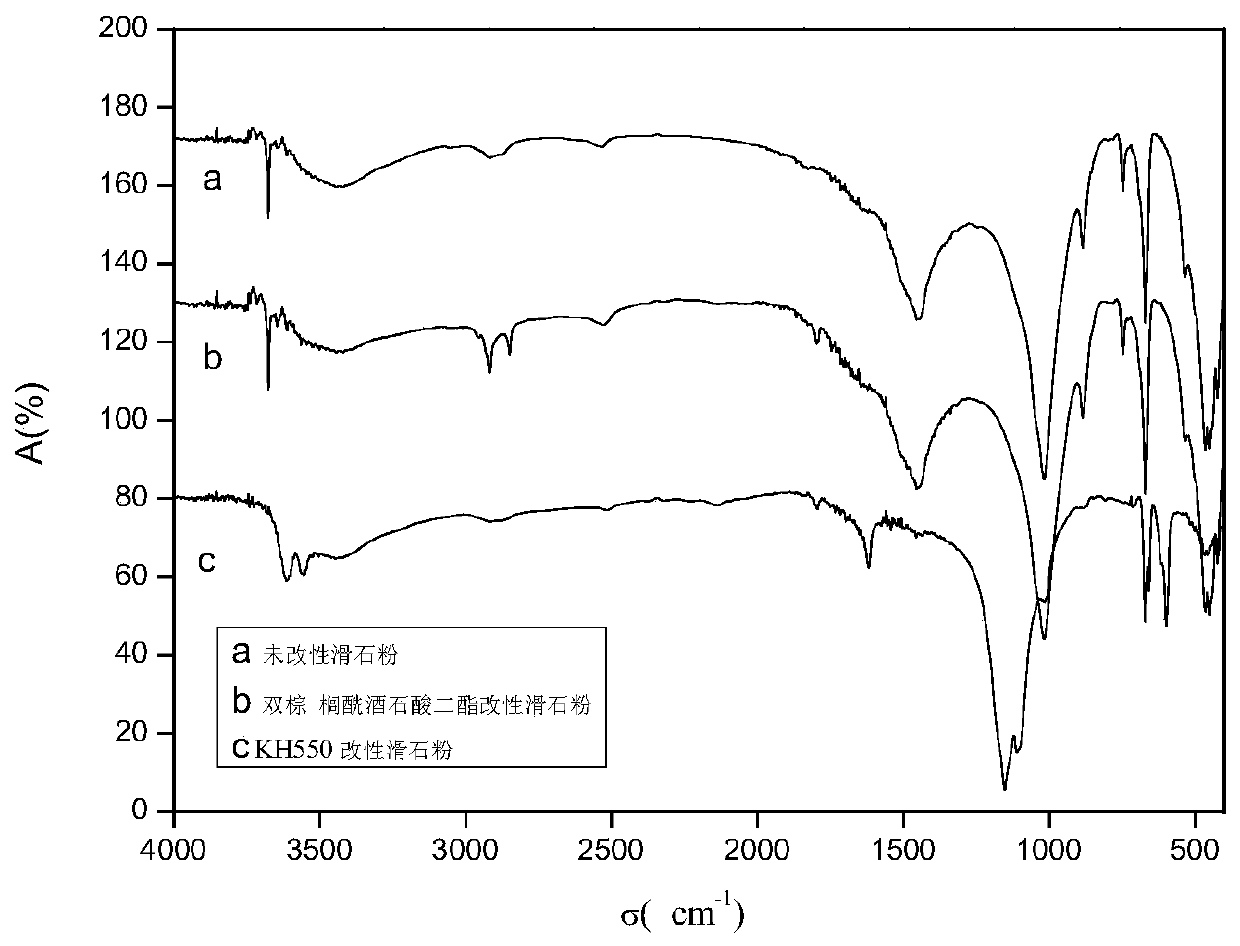

[0045] 1) Synthesis of silane coupling agent KH550 modified talc

[0046] Now take 2g of KH550 reagent, add it to a 250ml beaker, and then add 100ml of ethanol to make a uniform solution. Put 40g of talc into a 250ml three-necked flask equipped with a stirrer, thermometer and reflux condenser, take the above-mentioned synthetic silane coupling agent KH550 ethanol solution, add it in portions until the end, stir at 60℃ for 4 hours, wash, dry, and bake dry.

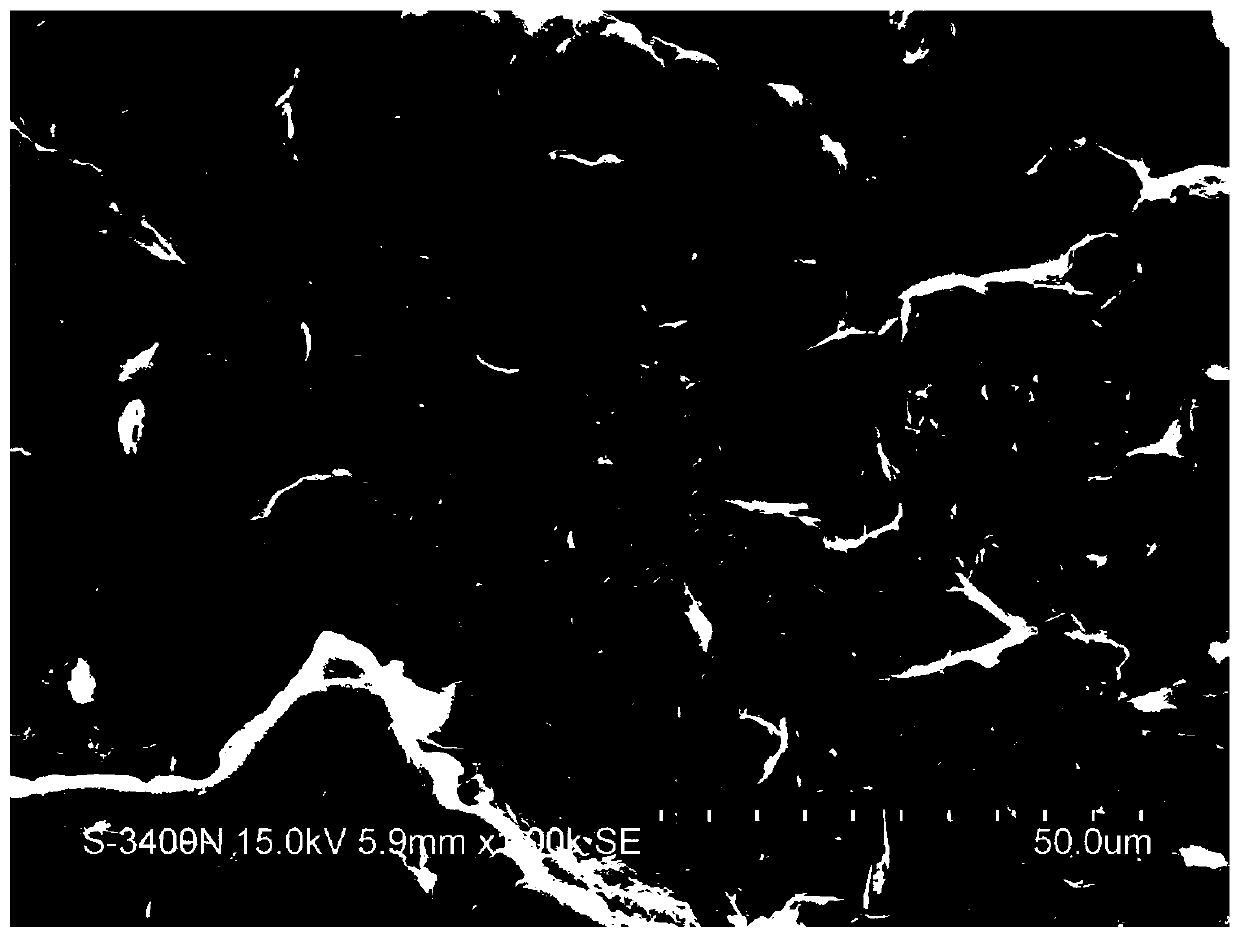

[0047] (2) Silane coupling agent KH550 modified talc and nylon anion copolymer

[0048] In a 250ml three-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a vacuum device, add 100g of caprolactam, heat to 130℃ to melt, vacuum for 20 minutes to remove water, then add 2.8g of sodium hydroxide, stir for 10min, add 2g of modified talc powder, continue to vacuum for 5 minutes, add 0.75g of TDI, react for 30 seconds, pour into the mold, place in an oven for molding, the temperature of the oven is 165°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com