A kind of preparation method of surface-modified silicon carbide based on oil-based grinding and polishing liquid

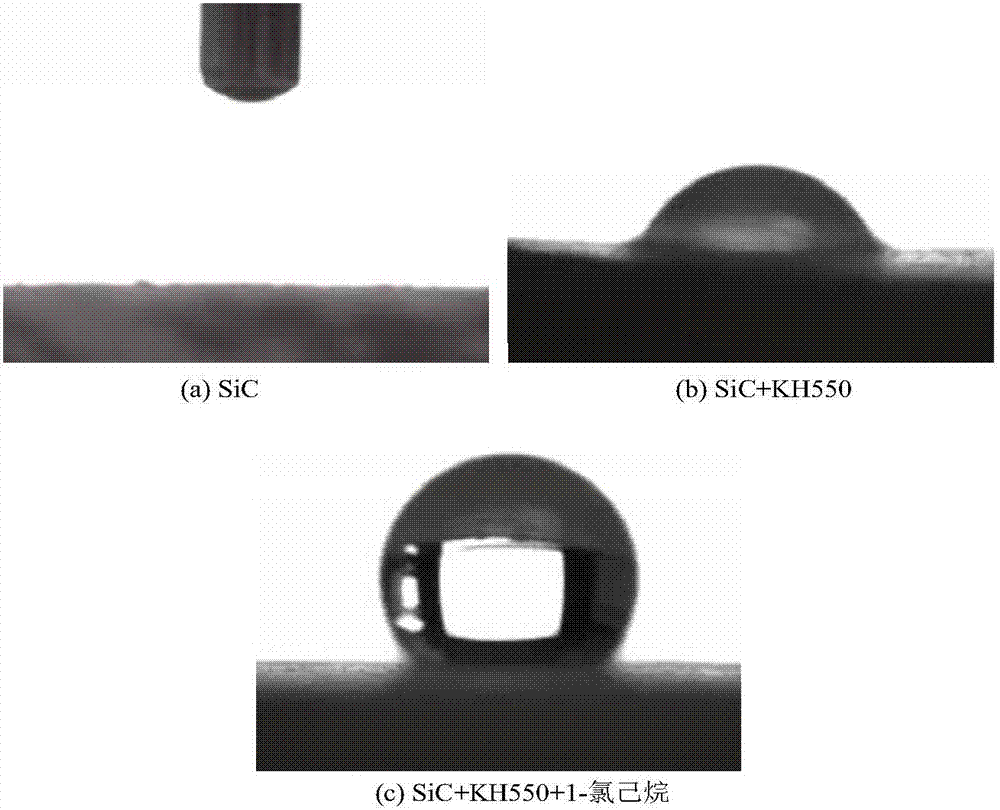

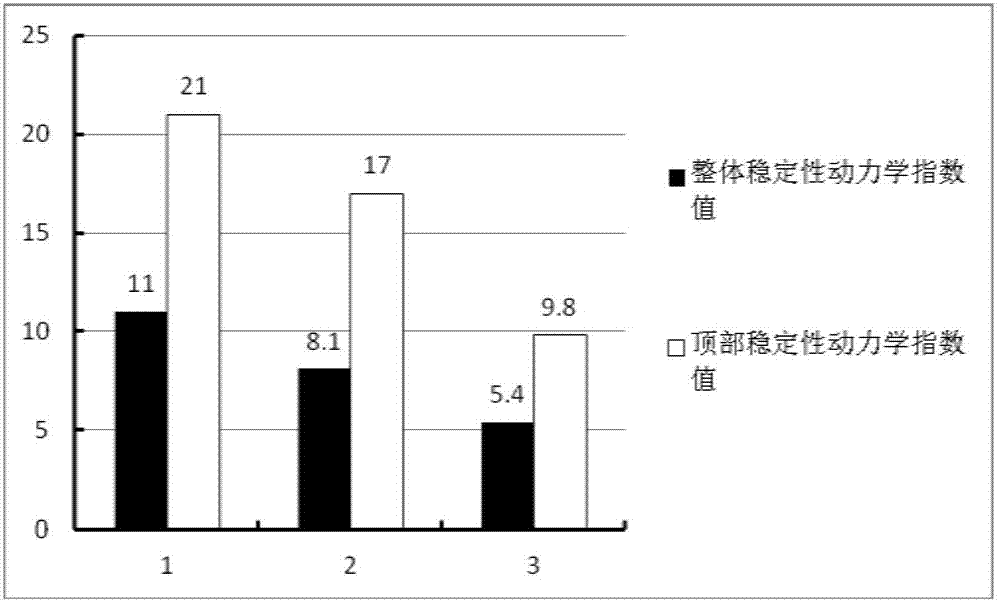

A technology of surface modification and surface modifier, applied in polishing compositions containing abrasives, chemical instruments and methods, dyed organic silicon compound treatment, etc., can solve the problem of material surface removal rate decline, shortening the service life of abrasive tools, Hinder the transportation of polishing products and other problems, and achieve the effects of reducing particle agglomeration, enhancing surface hydrophobicity, and improving lipophilicity and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

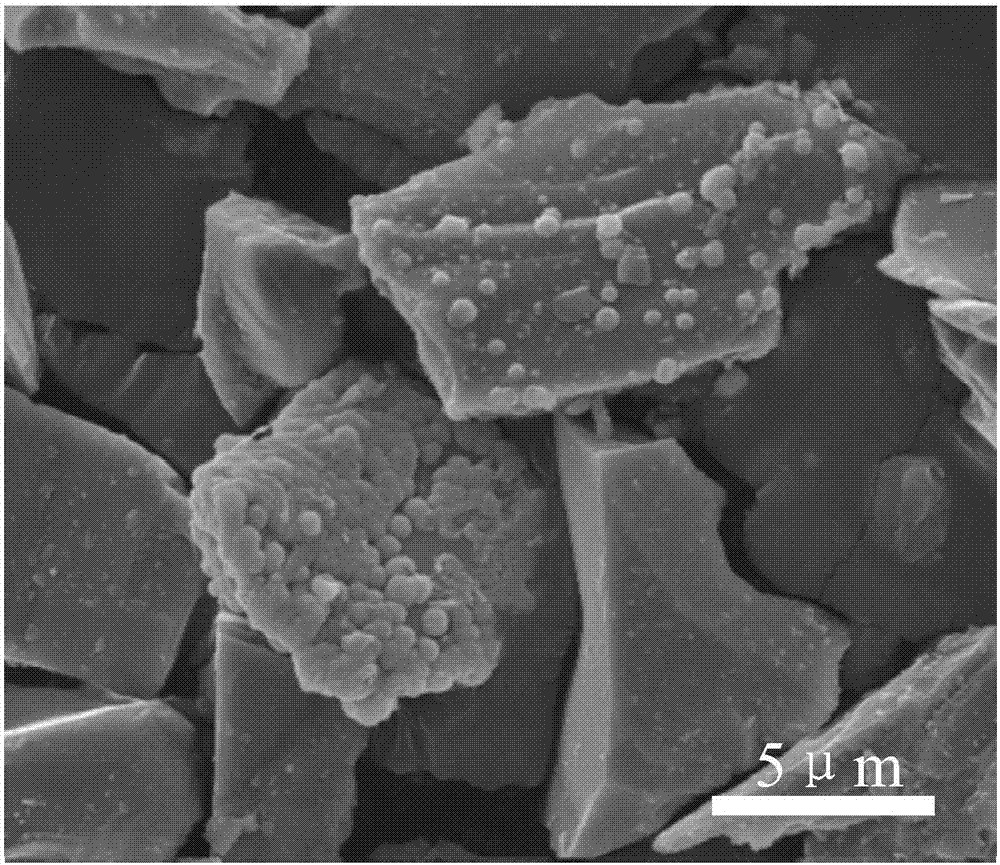

[0035] 1. Mix ammonia solution with a concentration of 5wt% and silicon carbide micropowder, ultrasonically clean for 30 minutes, stir continuously for 3 hours, filter with suction, and wash repeatedly with deionized water until neutral, and place the silicon carbide obtained by suction filtration in an oven at 100°C , dried for 24 hours, ground and set aside;

[0036] 2. Measure 50 ml of ethanol and 10 ml of deionized water, mix well, weigh 2 g of aminopropyltriethoxysilane (KH550), add it to the alcohol-water mixture, and stir with a magnetic stirrer at room temperature 30min;

[0037] 3. Transfer the solution obtained in step 2 to a three-necked flask, reflux in a water bath, raise the temperature to 90°C, add 9 grams of silicon carbide micropowder, and condense and reflux at this temperature for 4 hours;

[0038] 4. After the reaction, filter with suction and rinse with absolute ethanol for at least 3 times to eliminate the physical adsorption of aminopropyltriethoxysilan...

Embodiment 2

[0044] 1. Mix ammonia solution with a concentration of 15wt% and silicon carbide micropowder, ultrasonically clean for 30 minutes, stir continuously for 2 hours, filter with suction, and wash repeatedly with deionized water until neutral, and place the silicon carbide obtained by suction filtration in an oven at 100°C , dried for 24 hours, ground and set aside;

[0045] 2. Measure 30 ml of ethanol and 10 ml of deionized water, mix well, weigh 0.5 g of mercaptopropyltrimethoxysilane, add it to the alcohol-water mixture, and stir with a magnetic stirrer for 30 minutes at room temperature;

[0046] 3. Transfer the solution obtained in step 2 to a three-necked flask, reflux in a water bath, raise the temperature to 90°C, add 2 grams of silicon carbide micropowder, and condense and reflux at this temperature for 5 hours;

[0047] 4. After the reaction, filter with suction and rinse with absolute ethanol at least 3 times to eliminate the physical adsorption of mercaptopropyltrimetho...

Embodiment 3

[0053] 1. Mix hydrochloric acid solution with a concentration of 5wt% and silicon carbide micropowder, ultrasonically clean for 30 minutes, stir continuously for 2.5 hours, filter with suction, and wash repeatedly with deionized water until neutral, and place the silicon carbide obtained by suction filtration in an oven at 100°C medium, dry for 24 hours, grind, and set aside;

[0054] 2. Measure 27 ml of ethanol and 13 ml of deionized water, mix well, weigh 0.5 g of diethylenetriaminopropyltrimethoxysilane, add it to the alcohol-water mixture, and stir for 30 minutes at room temperature with a magnetic stirrer ;

[0055] 3. Transfer the solution obtained in step 2 to a three-necked flask, reflux in a water bath, raise the temperature to 90°C, add 7.6 g of silicon carbide micropowder, and condense and reflux at this temperature for 5 hours;

[0056] 4. After the reaction, filter with suction and rinse with absolute ethanol at least 3 times to eliminate the physical adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com