Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good refractoriness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

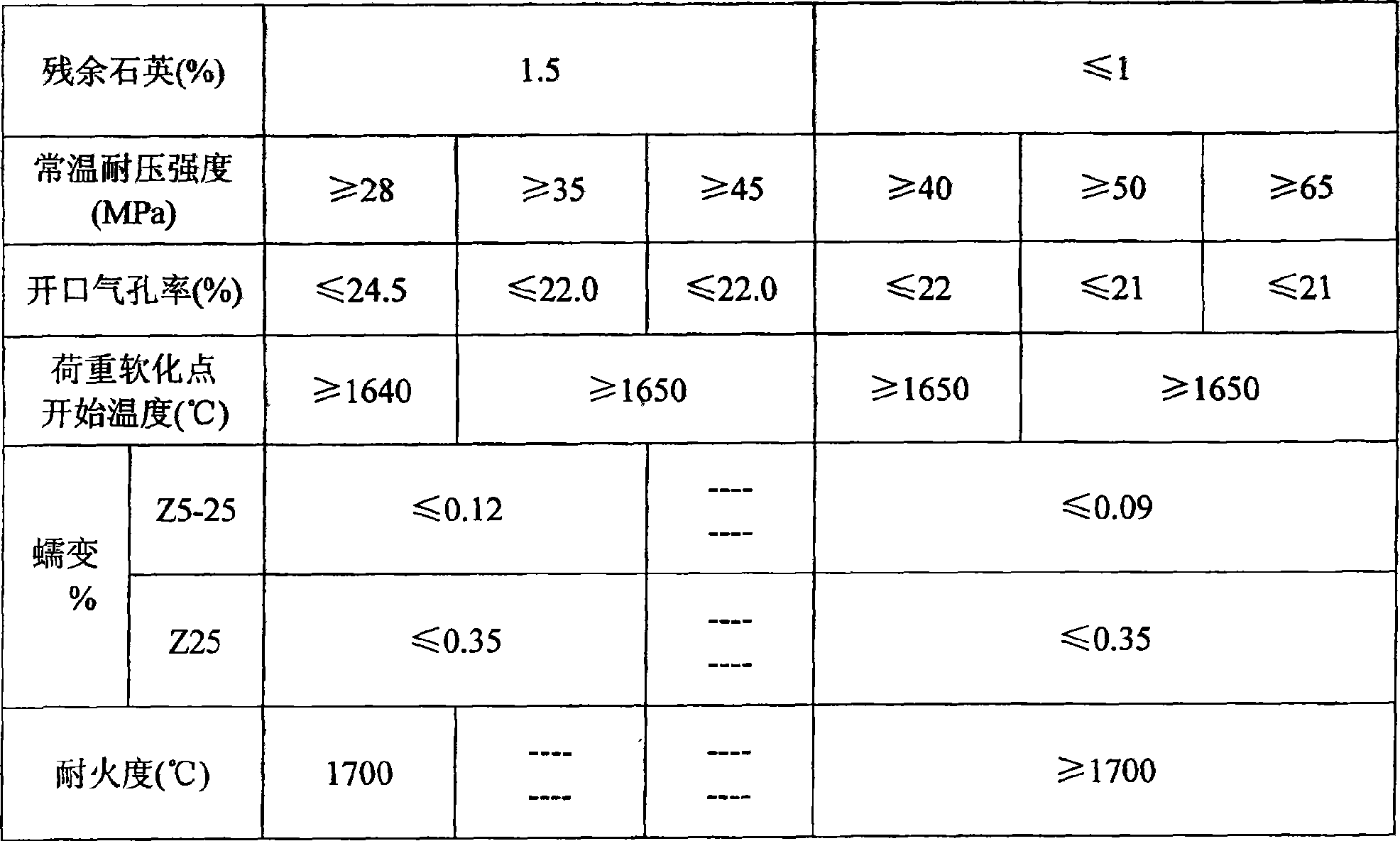

Silicon brick for 7.63-meter coke oven

The invention relates to the corhart technical field, in particular to quartz bricks for 7.63m coking chamber. The invention overcomes the drawbacks of the prior quartz bricks for 7.63m coking chamber that as difference exists in the quality and choice of the corhart, the particle fineness and size distribution of the material are unreasonable, iron content is above the standard. The weight percentage compositions of the formulation of the invention are as follows: twenty-five percent to thirty-five percent of silica coarse power, forty-one percent to forty-seven percent of silica middle power, ten percent to twenty percent of fine powder formed by fifty percent of silicon and residual fifty percent of silica brick, and ten percent to twenty percent of residual silica brick. The material further comprises accessories of one point nine percent to two point one percent of mineralizer mixed by manganese powder and potassium feldspar according to a proportion of one to one, seven point five percent to eight point five percent of lime cream and zero point nine percent to one point one percent of paper pulp. The invention is superior over the prior quartz bricks of the prior 7.63m coking chamber in terms of physicochemical indexes of the silica brick made by the formulation of the invention, such as chemical composition, compressive strength, porosity and refractability, etc., particularly in terms of lower content of bengala ( Fe2O3). The invention has the advantages of rich source of the material, reasonable fineness of aggregate and size distribution.of particles. The quartz brick can meet the design and complication degree of and dimensions of shapes of bricks for the 7.63 coking chamber and is suitable for mass production of the coking chamber.

Owner:山西盂县西小坪耐火材料有限公司

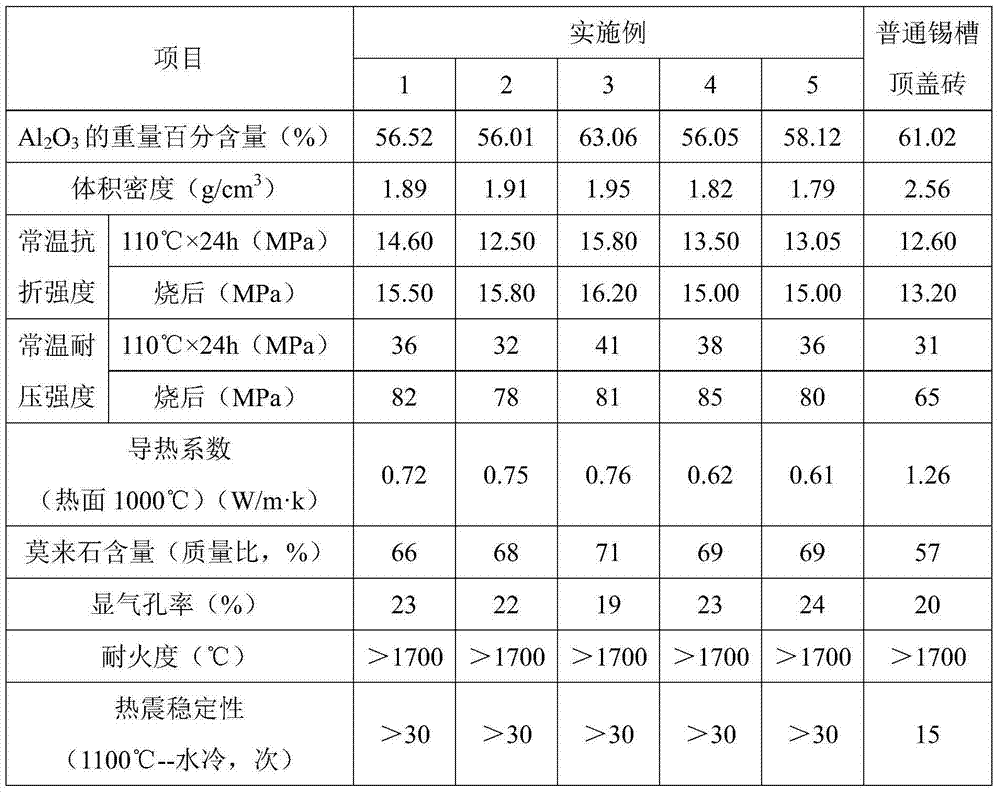

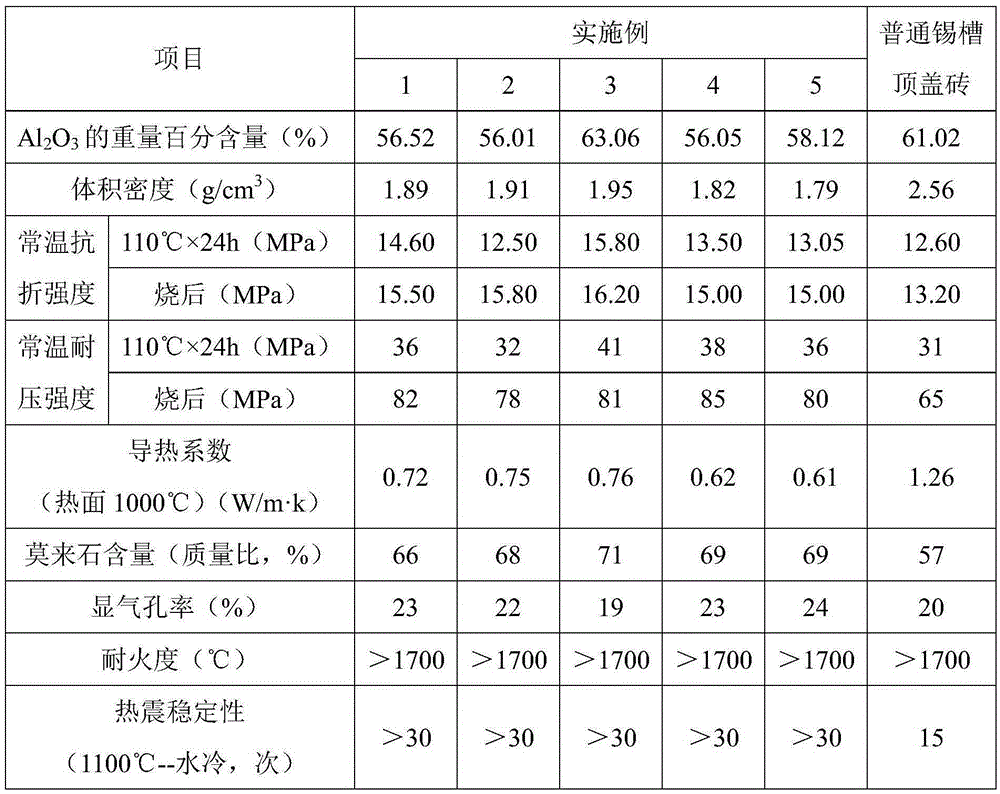

Low-thermal-conductivity mullite tin bath combined top cover brick

The invention discloses a low-thermal-conductivity mullite tin bath combined top cover brick prepared from the following raw materials by the mass percentage: 40.5%-65% of a mullite aggregate, 8%-15% of calcium aluminate cement, 4%-10% of a silica micropowder, 10%-18% of an alumina micropowder, 5%-13% of a mullite fine powder, 2%-3% of a mineralizing agent, and 0.1%-0.5% of a water reducing agent. The low-thermal-conductivity mullite tin bath combined top covering brick has the advantages of small thermal conductivity coefficient, small proportion, light weight, high strength, good thermal shock resistance, high refractoriness (greater than 1700 DEG C) and the like; the tin bath combined top cover brick is used in a top cover of a tin bath, greatly reduces the kiln body weight, and reduces the kiln body heat capacity while saving cost; the tin bath combined top cover brick has good thermal shock resistance, and has the service life of a kiln improved greatly; and the tin bath combined top cover brick has the advantages of small thermal conductivity coefficient, good thermal insulation effect and little heat loss, significantly improves the thermal utilization efficiency, saves energy, greatly reduces the energy consumption, and is suitable for popularization and application.

Owner:HENAN ZHONGYUAN SPECIAL REFRACTORY

Torpedo ladle lining repair gunning mix

The invention relates to a torpedo ladle lining repair gunning mix, belonging to the technical field of torpedo ladles for transporting molten iron. The torpedo ladle lining repair gunning mix comprises the following components in percentage by weight: 45-60% of brown fused alumina particle, 10-20% of silicon carbide particle, 1-5% of kyanite powder, 1-5% of Gangxi earth, 1-10% of active alpha-Al2O3 powder, 1-7% of silicon micropowder, 1-5% of metallic silicon powder, 0-5% of ball pitch, 0-5% of amorphous graphite and 2-10% of pure calcium aluminate cement. The raw materials are weighed according to the particle sizes and proportions and uniformly mixed in a mixer. The torpedo ladle lining repair gunning mix has favorable refractoriness, oxidation resistance and slag iron permeation and corrosion resistance at the torpedo ladle service temperature of 1400-1530 DEG C.

Owner:SHOUGANG CORPORATION

Silicon brick for 7.63-meter coke oven

The invention relates to the corhart technical field, in particular to quartz bricks for 7.63m coking chamber. The invention overcomes the drawbacks of the prior quartz bricks for 7.63m coking chamber that as difference exists in the quality and choice of the corhart, the particle fineness and size distribution of the material are unreasonable, iron content is above the standard. The weight percentage compositions of the formulation of the invention are as follows: twenty-five percent to thirty-five percent of silica coarse power, forty-one percent to forty-seven percent of silica middle power, ten percent to twenty percent of fine powder formed by fifty percent of silicon and residual fifty percent of silica brick, and ten percent to twenty percent of residual silica brick. The material further comprises accessories of one point nine percent to two point one percent of mineralizer mixed by manganese powder and potassium feldspar according to a proportion of one to one, seven point five percent to eight point five percent of lime cream and zero point nine percent to one point one percent of paper pulp. The invention is superior over the prior quartz bricks of the prior 7.63m coking chamber in terms of physicochemical indexes of the silica brick made by the formulation of the invention, such as chemical composition, compressive strength, porosity and refractability, etc., particularly in terms of lower content of bengala ( Fe2O3). The invention has the advantages of rich source of the material, reasonable fineness of aggregate and size distribution.of particles. The quartz brick can meet the design and complication degree of and dimensions of shapes of bricks for the 7.63 coking chamber and is suitable for mass production of the coking chamber.

Owner:山西盂县西小坪耐火材料有限公司

Ceramsite sand with dedusting ash as well as preparation method and application thereof

ActiveCN109020607ASmall bulk densityGood shape factorCeramic materials productionCeramicwareHigh resistanceExpanded clay aggregate

The invention discloses ceramsite sand with dedusting ash as well as a preparation method and application thereof. The ceramsite sand is prepared from the following components in parts by weight: 70-80 parts of fly ash, 10-15 parts of cement, 1-5 parts of VAE glue powder and 1-5 parts of silicon ash. The ceramsite sand with dedusting ash replaces conventional sand to prepare coated sand; firstly,the ceramsite sand with dedusting ash is small in stacking density, good in angular coefficient and large in specific surface area under the equivalent weight condition; the consumption of adhesive inpreparation of the coated sand is low; a better coating effect is achieved in the process of preparing the coated sand; mullite is taken as a main crystal phase of the prepared ceramsite sand; the ceramsite sand has extremely high resistance to high temperature and good thermal stability; the size accuracy of castings can be ensured; the preparation method of the ceramsite sand with dedusting ashis simple; a large amount of energy does not need to be consumed in the preparation process; compared with other common raw sand of the coated sand, the ceramsite sand with dedusting ash is low in cost.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

Casting sand for casting sand mold and preparing method of casting sand

ActiveCN105665614AExcellent refractorinessGood collapsibilityFoundry mouldsFoundry coresVolcanic ashParaffin oils

The invention discloses casting sand for casting a sand mold and a preparing method of the casting sand and relates to the technical field of sand mold casting. The casting sand is prepared from, by weight part, 100-120 parts of silica sand, 15-20 parts of ceramic micro powder, 10-15 parts of volcanic ash, 10-15 parts of carclazyte, 8-12 parts of vermiculite powder, 8-12 parts of paraffin oil, 6-10 parts of alginic acid trimethylene glycol ester, 5-8 parts of asbestos powder, 5-8 parts of hydroxy propyl cellulose, 4-6 parts of xanthan gum, 3-5 parts of a silane coupling agent, 3-5 parts of graphite powder, 2-3 parts of nanometer zirconia, 1-2 parts of nanometer zinc powder and 50-60 parts of ethyl alcohol. The casting sand has good refractoriness, thermal stability, fluidity, breathability and liquid metal permeability resistance, molding of the sand mold and the mold core is facilitated, in addition, collapsibility is good after the casting sand is used, repeated use can be achieved, the casting cost is reduced, and therefore economic benefits are improved.

Owner:ANHUI SOLID FOUNDRY CO LTD

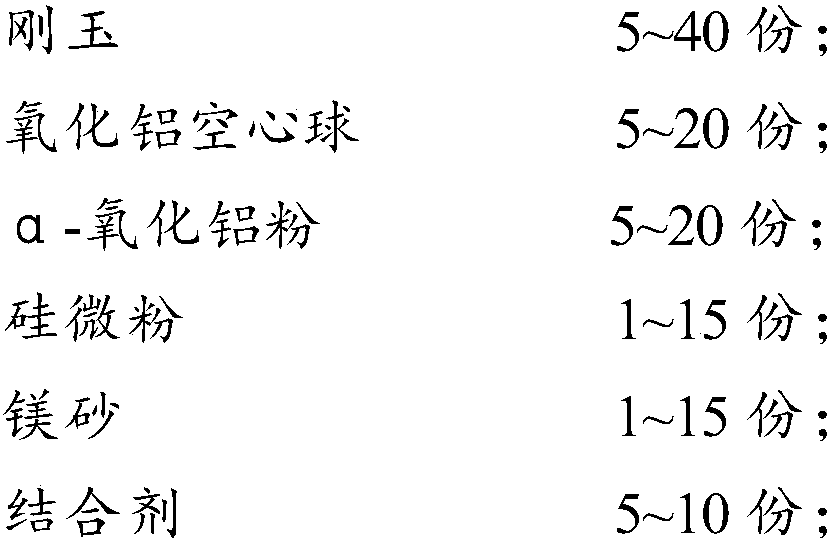

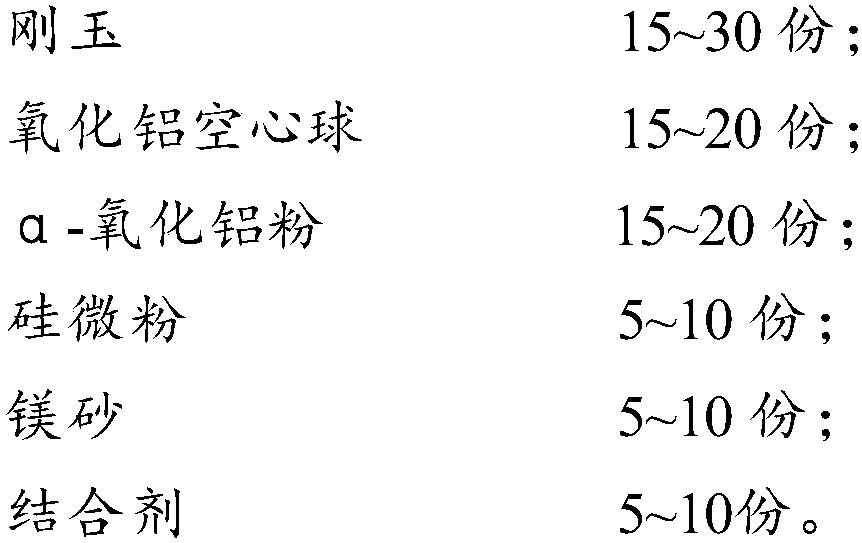

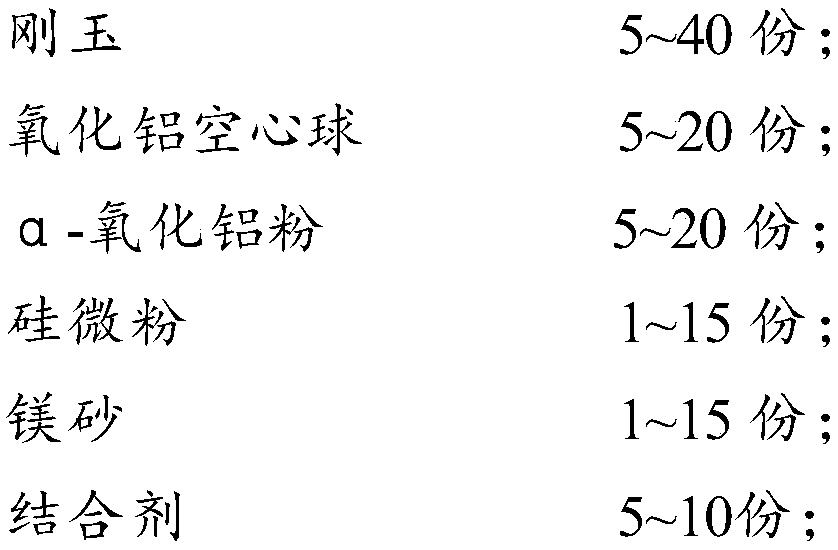

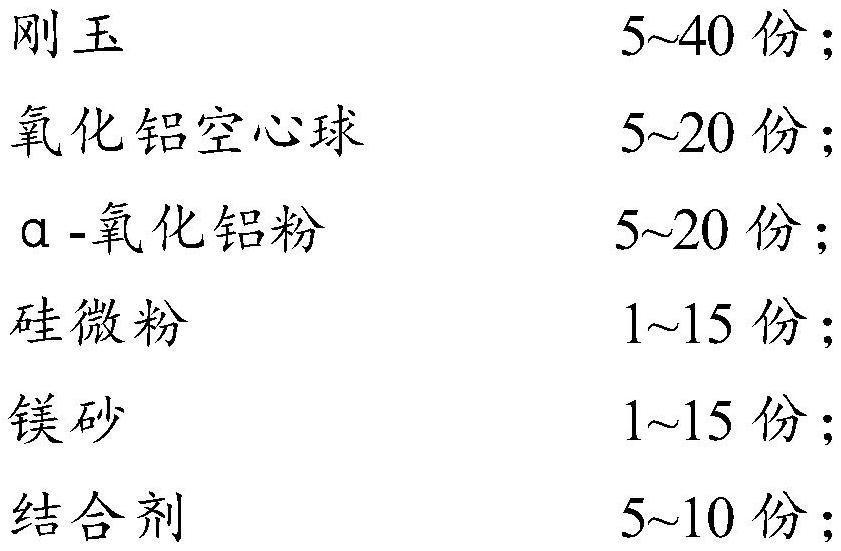

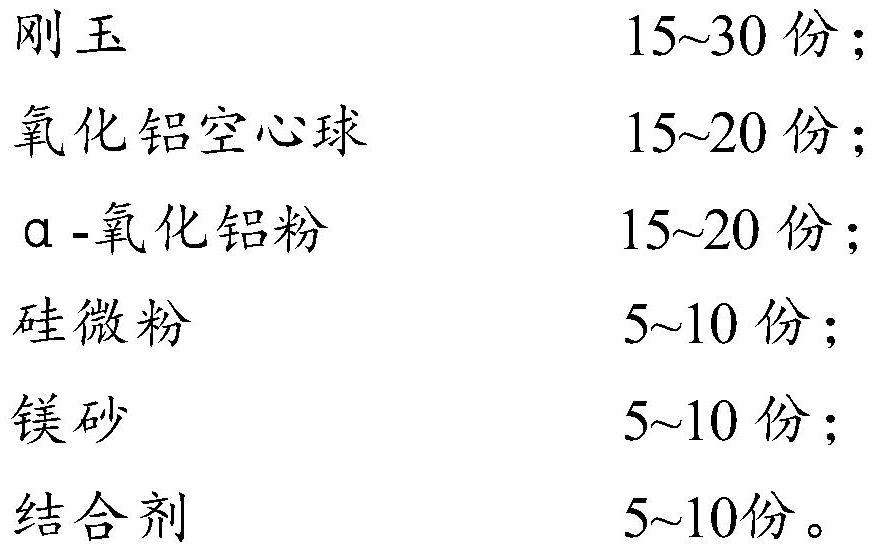

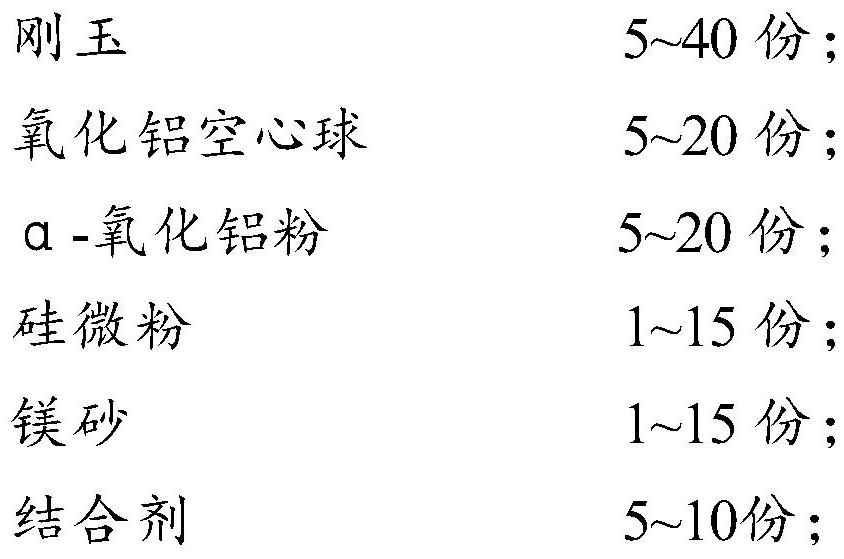

Fireproof self flowing casting material

The invention provides a fireproof self flowing casting material, which is prepared from the following raw materials in parts by weight: 5 to 40 parts of corundum, 5 to 20 parts of aluminum oxide hollow balls, 5 to 20 parts of alpha-aluminum oxide powder, 1 to 15 parts of silicon micro powder, 1 to 15 parts of magnesia and 5 to 10 parts of bonding agent, wherein the bonding agents are silica sol and silane coupling agents. Through the matching of the specific ingredients and dosage, the performance such as flowability, refractoriness, strength and the like of the casting material can be obviously improved, so that the service life of the casting material is prolonged.

Owner:HUNAN RAMON SCI & TECH

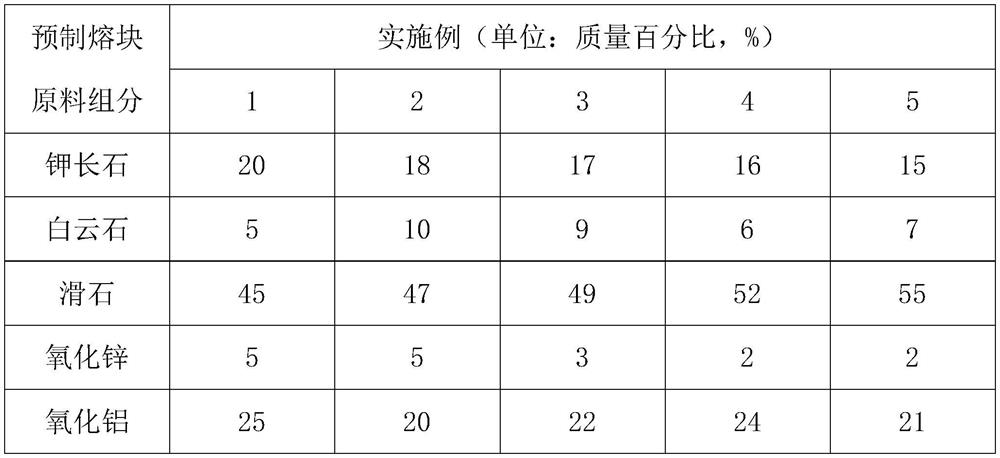

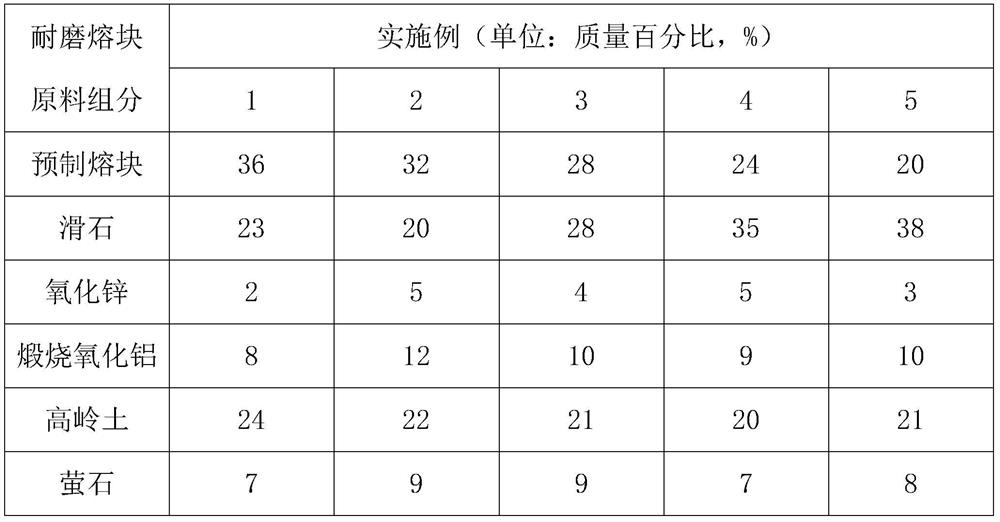

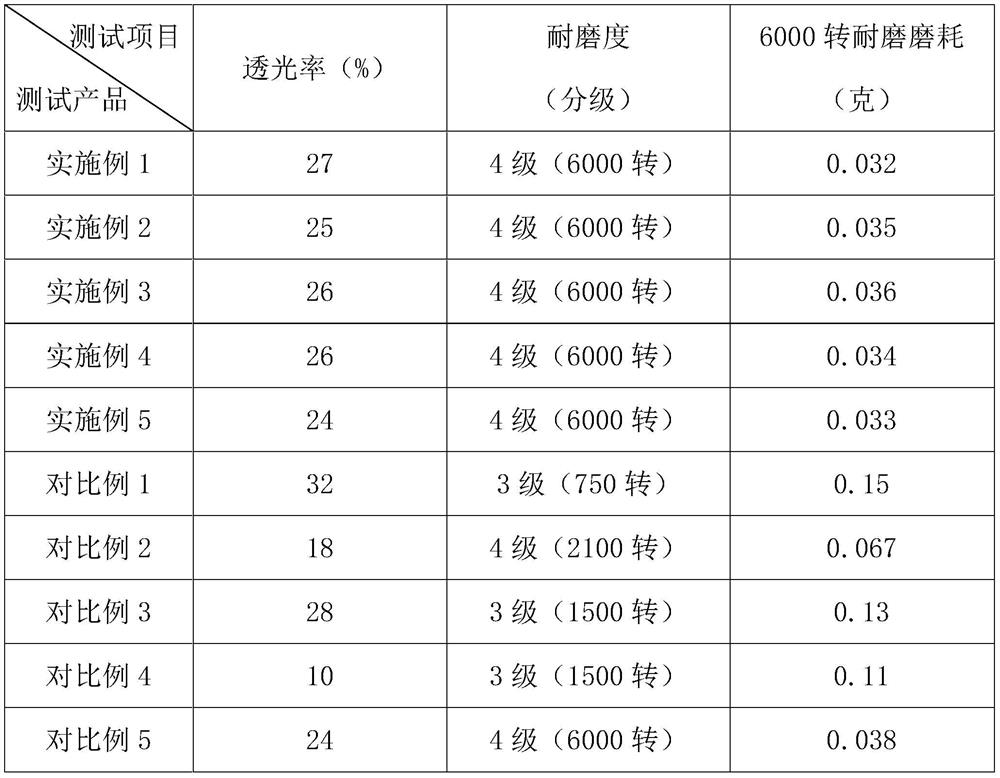

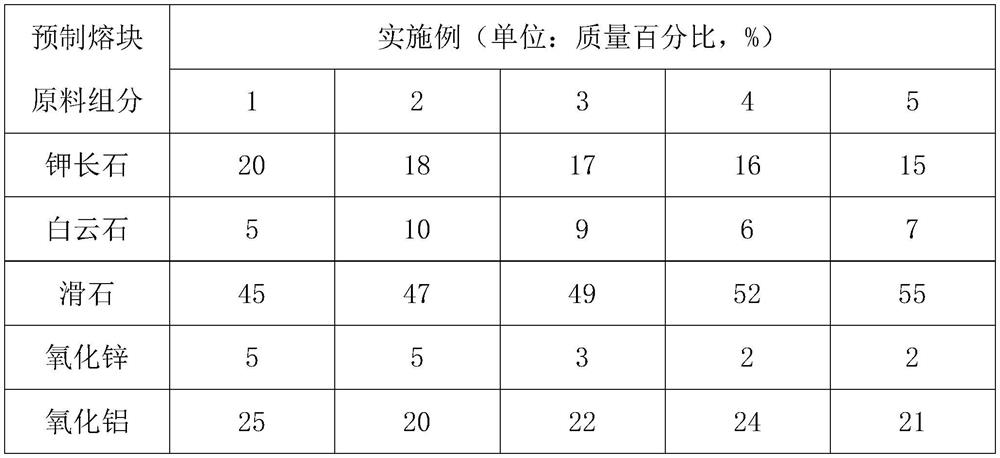

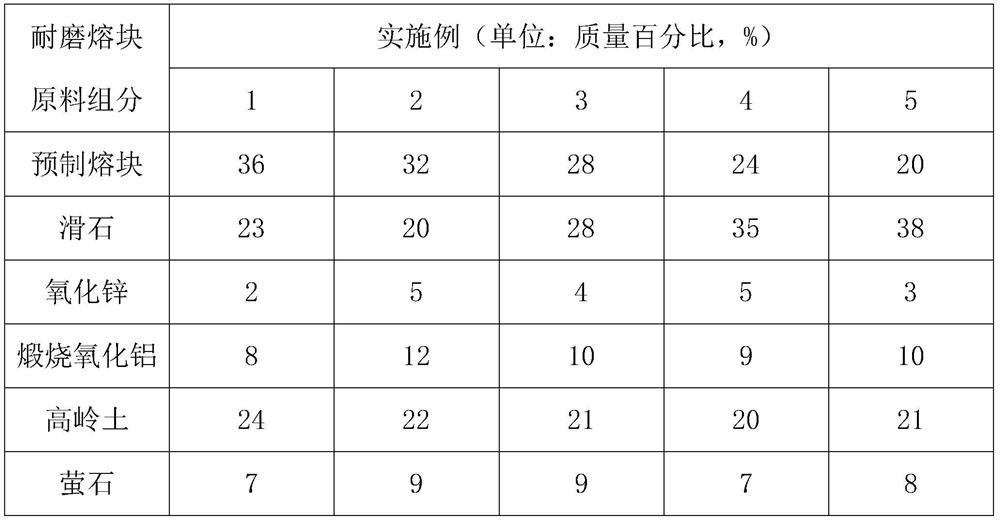

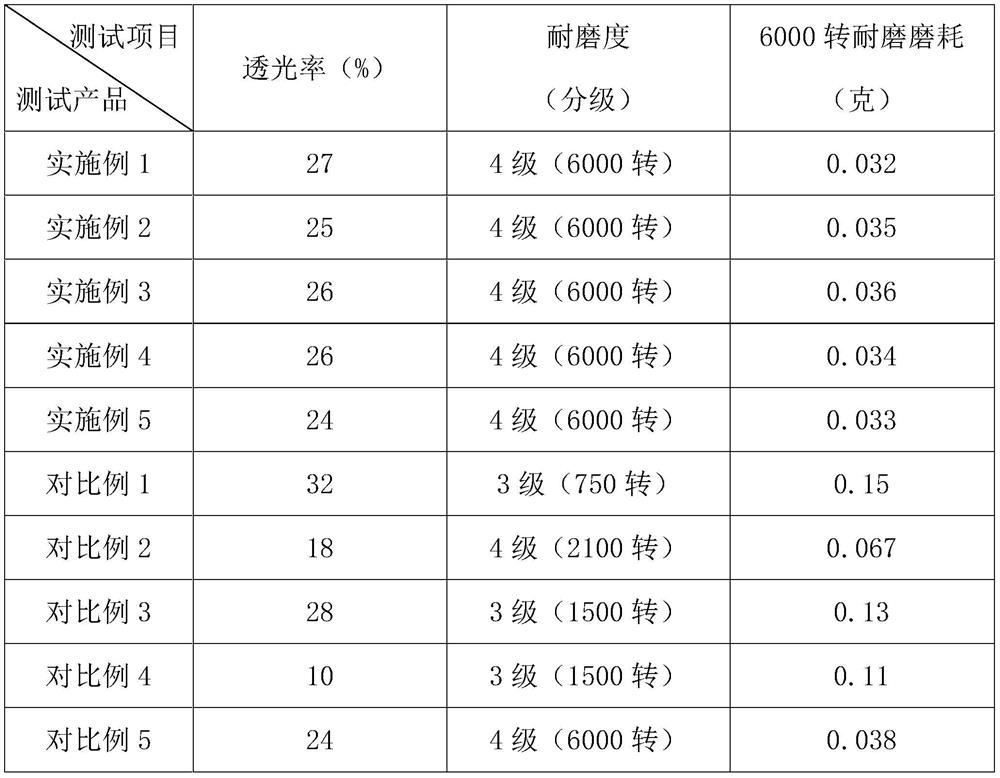

Wear-resistant frit, preparation method of frit and glaze using frit

The invention discloses a wear-resistant frit, a preparation method of the frit and a glaze using the frit, and the wear-resistant frit is prepared from the following raw materials in percentage by mass: 20-36% of prefabricated frit, 20-38% of talc, 2-5% of zinc oxide, 8-12% of calcined aluminum oxide, 20-24% of kaolin and 7-9% of fluorite. The prefabricated frit is prepared from the following rawmaterials in percentage by mass: 15 to 20 percent of potassium feldspar, 5 to 10 percent of dolomite, 45 to 55 percent of talc, 2 to 5 percent of zinc oxide and 20 to 25 percent of aluminum oxide. The wear-resistant frit is good in transparency and good in wear resistance, the preparation method of the wear-resistant frit is simple, all the raw material components are fully fused in the high-temperature firing process, and the prepared wear-resistant frit is high in transparency and good in wear resistance. The glaze using the wear-resistant frit has the advantages of favorable wear resistance of the glaze layer, favorable surface gloss of the glaze surface and favorable light transmission property.

Owner:佛山市东鹏陶瓷发展有限公司 +2

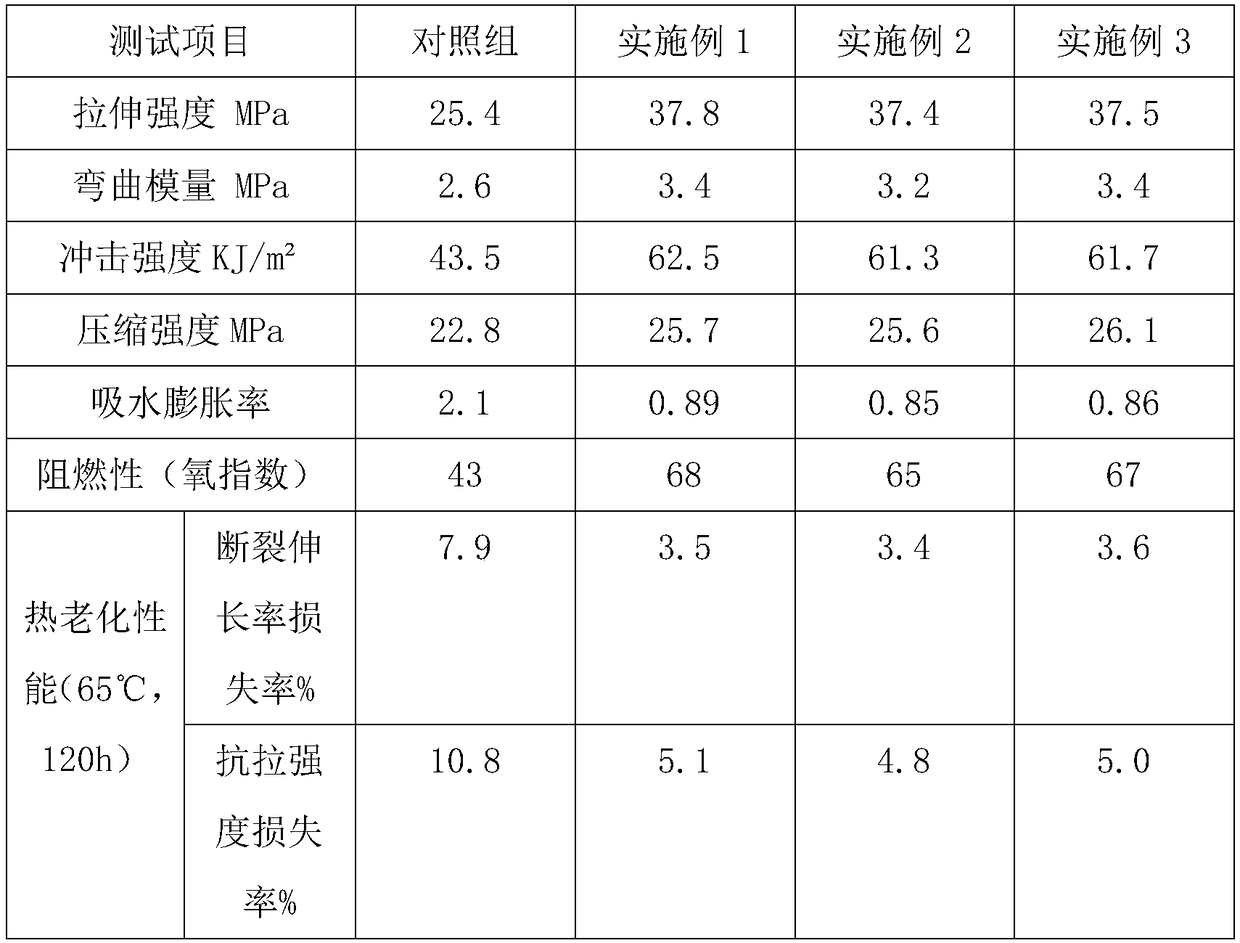

Pressure-resistant and anti-cracking wood-plastic composite with high strength

The invention relates to the technical field of polymer composites, in particular to a pressure-resistant and anti-cracking wood-plastic composite with high strength. The wood-plastic composite is prepared from the following components: polypropylene resin, a polyolefin thermoplastic elastomer, a compatilizer, wood flour, metamorphic asbestos fiber, magnesium hydroxide, a lubricant, a silane coupling agent, dibutyl phthalate, dibasic lead phosphite and an ageing resister, wherein the wood flour chooses fir powder or pine powder with water content lower than 3%, and is subjected to high-pressure impregnation with a flame retardant solution before use; the flame retardant solution is prepared from silica sol, ammonium polyphosphate, sodium octoborate tetrahydrate and aluminum carbonate by adding water; the compatilizer is maleic anhydride grafted polypropylene; the lubricant is polyethylene wax; the ageing resister contains an antioxidant and an ultraviolet light absorber in the same mass ratio. The wood-plastic composite has high strength, outstanding pressure resistance and cracking resistance and good heat stability, and is not prone to ageing or deformation.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Refractory brick high in refractoriness under load and preparation method thereof

The invention discloses a refractory brick high in refractoriness under load and a preparation method thereof. The refractory brick is prepared from, by weight, 12-19 parts of enstatite, 21-28 parts of fused magnesite, 14-22 parts of dawsonite, 22-34 parts of high silicon vanadium tailings, 6-12 parts of boron phosphate, 18-30 parts of molten blast furnace slag, 10-15 parts of colloidal graphite powder, 5-10 parts of tungsten silicide, 36-48 parts of high-alumina cement, 16-28 parts of silicate cement slurry, 15-25 parts of silicon manganese slag, 8-14 parts of polyvinylpyrrolidone and 5-10 parts of waste sugarcane molasses. By the raw materials of fused magnesite, enstatite and dawsonite matching with colloidal graphite powder, tungsten silicide and the like, refractoriness under load of the refractory brick is enhanced obviously under the condition that refractoriness of the brick body is unaffected. The refractory brick is good in fire resistance, high in refractoriness under load and high-temperature strength, strong in thermal stability, easy to process and long in service life.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

Preparation process of slag pot isolator

The invention relates to a preparation process of a slag pot isolator, belonging to the technical field of smelting. The preparation process comprises the following steps: (1) adding 65-75 percent of regenerated scrap grains and 25-35 percent of alumina cement into mixing agitation equipment; (2) additionally adding 0.01-0.03 percent of water reducing agent, 0.1-0.5 percent of additive and 12-15 percent of liquid wedding agents into the mixing agitation equipment; (3) smelting the materials for 5-8 minutes in a mixing way under the condition that the outdoor temperature is 5 DEG C-25 DEG C; (4) vibrating the smelted mixing materials to be flat by a vibrating spear; (5) shaping products by self fixing so that the products can be demolded; (6) naturally maintaining; (7) roasting and selecting the products to obtain products which accord with the strength requirement to prevent the products from being burst; and (8) checking the roasted products to obtain the slag pot isolator according to a physicochemical index specification value and an outline dimension standard corresponding the products. With the preparation process of the slag pot isolator, waste bricks are recovered to be circularly mixed into the preparation materials, and the technical index and the property of the prepared slag pot isolator is the same as that of a slag pot isolator prepared by fresh materials, thereby the invention achieves good popularization and application effect.

Owner:上海盛江特种耐火材料有限公司

High-temperature wear-resistant coating material and preparation method thereof

The invention discloses a high-temperature wear-resistant coating material which comprises 18-25 parts of 3-5mm black corundum, 6-10 parts of 1-3mm black corundum, 6-10 parts of 1-3mm silicon carbide, 15-25 parts of 0-1mm silicon carbide, 10-15 parts of silicon carbide powder, 25-30 parts of mullite powder, 4-8 parts of Gangxi sludge and 8-12 parts of aluminum sulfate solution. The preparation method comprises the following steps: uniformly mixing the black corundum and silicon carbide; adding the aluminum sulfate solution into the mixture, and uniformly mixing; and adding the silicon carbide powder, mullite powder and Gangxi sludge into the mixture, and stirring uniformly. The coating material has the advantages of high adhesion property, high toughness, favorable wear resistance and excellent thermal shock stability, can effectively resist erosion of solid particles and corrosion of flue gas under high-temperature conditions, can effectively lower the heat loss of the furnace wall, and enhances the overall heat efficiency of heat engineering equipment. The high-temperature wear-resistant coating material has better fire resistance, permanent linear change rate, wear resistance and the like than the traditional wear-resistant castable and plastic material. The wear-resistant coating material is simple for laying and convenient for maintenance, and can greatly lower the construction and maintenance cost and enhance the economic benefits.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

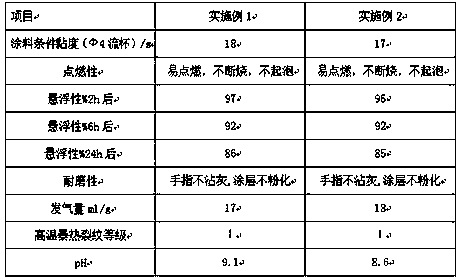

Low-cost environmentally-friendly alcohol-based cast iron coating and preparation method thereof

ActiveCN108145070AGood suspensionGood refractorinessFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention relates to a low-cost environmentally-friendly alcohol-based cast iron coating and a preparation method thereof. The low-cost environmentally-friendly alcohol-based cast iron coating comprises 46-55% of bauxite, 3-9% of quartz powders, 3-6% of mullite powders, 3-6% of pyrophyllite powders, 2.43-3.14% of sodium bentonite, 1.92-3.82% of expandable graphite, 0.38-0.65% of rosin, 0.38-0.58% of low viscosity polyvinyl butyral, and 27-31% of alcohol. According to the low-cost environmentally-friendly alcohol-based cast iron coating and the preparation method thereof, an easy-peeling coating is formed after pouring, the surface of the obtained casting is smooth and clean, and the dimensional accuracy is high; compared with traditional cast iron coating, the content of graphite is reduced from 100% to less than 4%, black pollution is reduced, obvious price advantage is obtained, raw material resources are extensive, cost performance is high, and the low-cost environmentally-friendly alcohol-based cast iron coating has broad application prospects.

Owner:HUBEI UNIV OF TECH

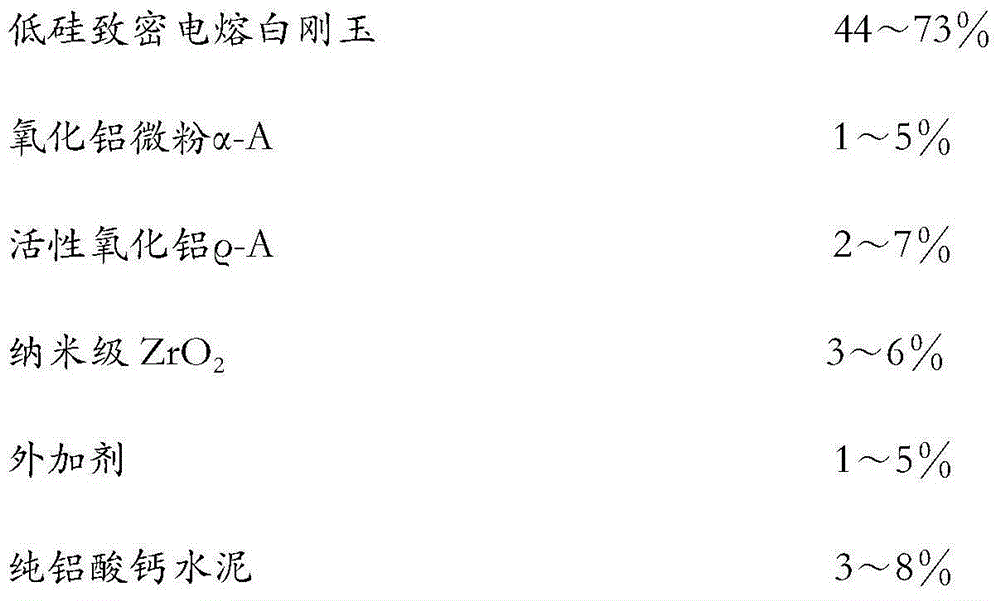

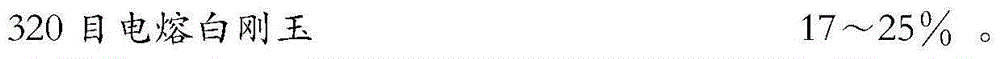

High-aluminum low-silicon casting material

The invention discloses a high-aluminum low-silicon casting material. The high-aluminum low-silicon casting material comprises the following components in percentage by weight: 44-73% of low-silicon compact electrofusion white alundum, 1-5% of aluminum oxide micro powder alpha-A, 2-7% of active aluminum oxide rho-A, 3-6% of nanometer-level ZrO2, 1-5% of an additive, 3-8% of pure calcium aluminate cement and 17-25% of 320-mesh electrofusion white alundum. The high-aluminum low-silicon casting material disclosed by the invention is high in strength, good in toughness and small in linear variation under high temperature environment.

Owner:港泰耐火材料(江苏)有限公司

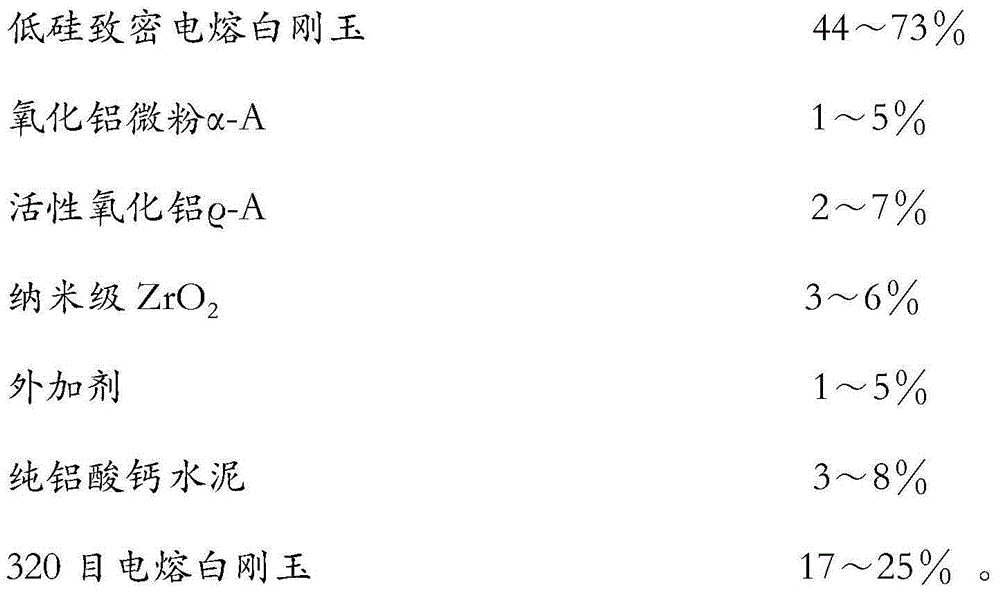

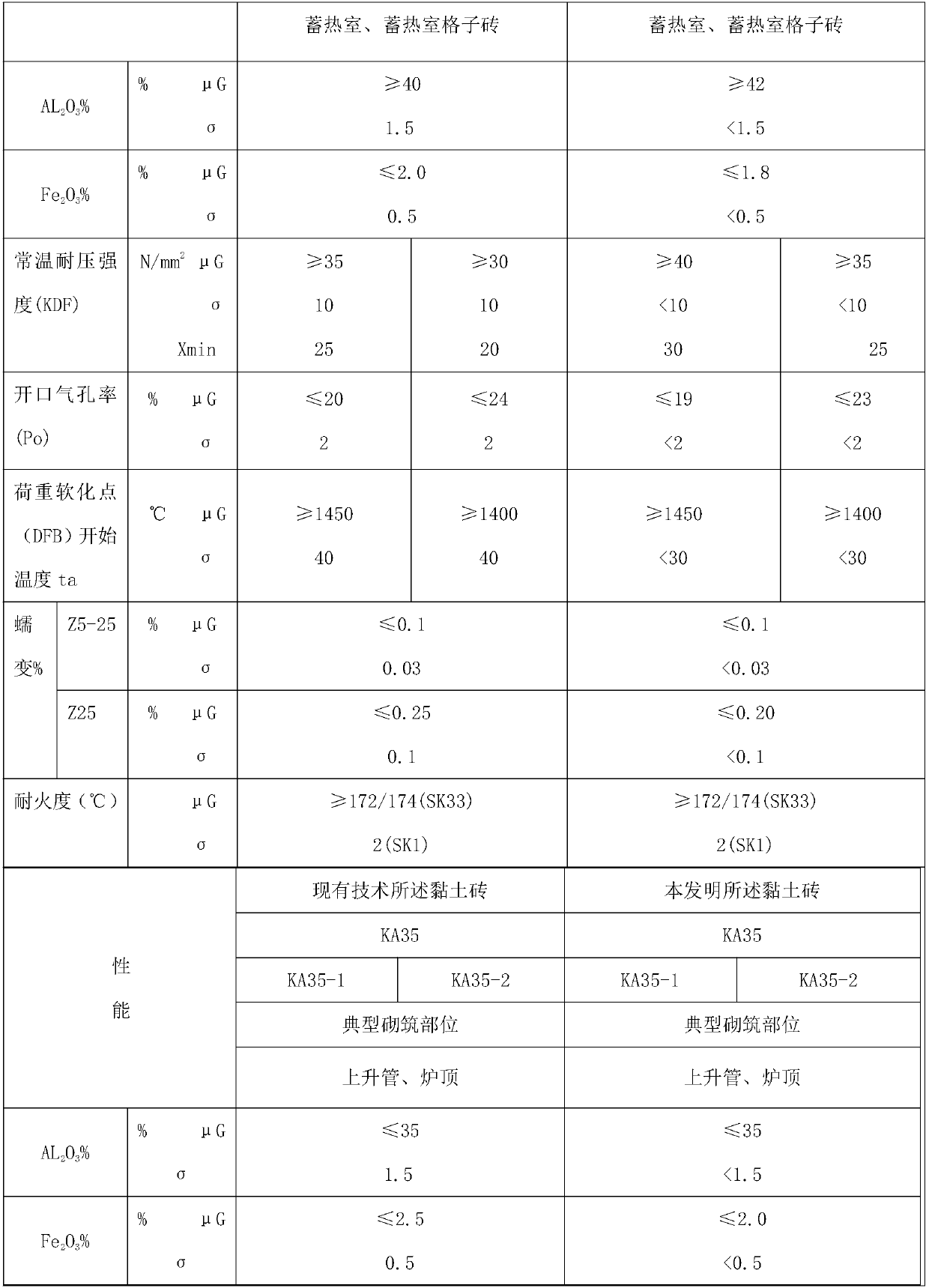

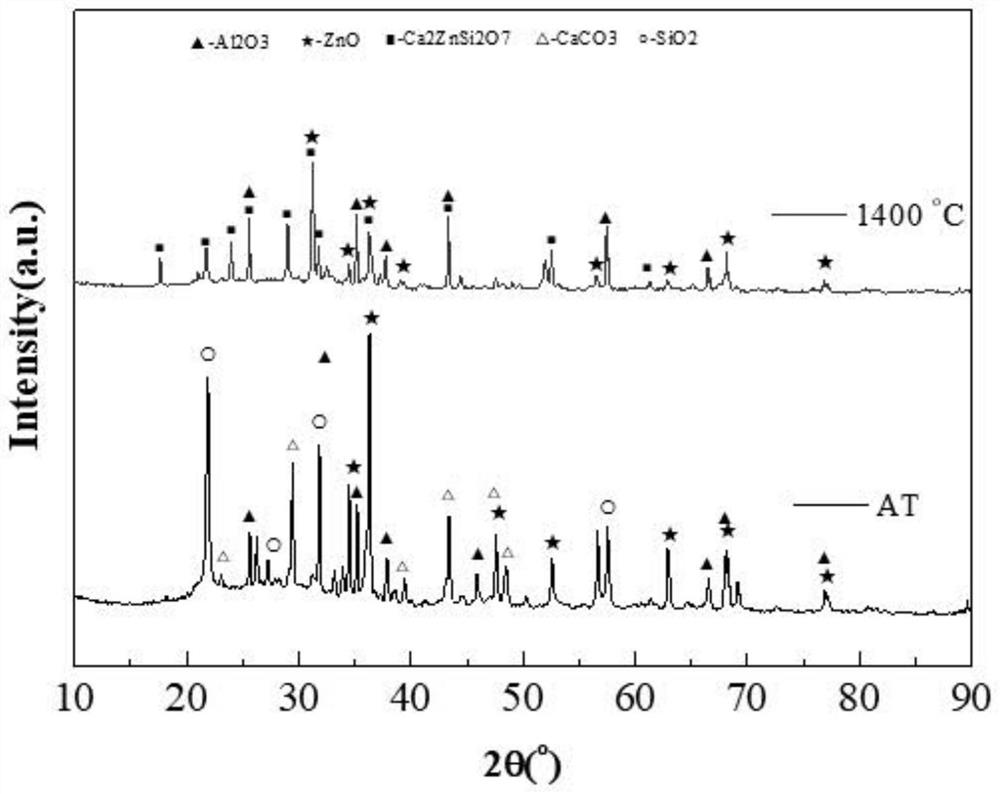

Clay bricks for 6.25M coke oven

InactiveCN107827446AExtensive sources of raw materialsAggregate fineness and particle size distribution are reasonableAluminiumClay soil

The invention belongs to the technical field of refractory materials, and particularly relates to clay bricks for a 6.25M coke oven. The clay bricks are composed of, by weight, 25-35 parts of bauxiteclinker coarse powder, 20-30 parts of bauxite clinker medium powder, 5-10 parts of bauxite clinker fine powder and 30-40 parts of soft clay fine powder. Physiochemical indexes like chemical analysis,pressure-resistance strength, porosity and refractoriness of the clay bricks prepared according to a formula are better than those of existing clay bricks for 6.25m coke ovens, and especially Fe2O3 content is obviously low. The clay bricks have the advantages of extensive raw material source and reasonable aggregate fineness and particle size distribution, meet requirements on design, complexity and appearance size of coke oven brick type and are suitable for requirements of coke oven large-scale production.

Owner:山西盂县西小坪耐火材料有限公司

Fireproof sheet honeycomb ceramic automobile exhaust purification material and preparation method thereof

InactiveCN106116554AHigh compressive strengthGood chemical stabilityGas treatmentHeterogenous catalyst chemical elementsNano al2o3Cordierite

The invention discloses a fireproof sheet honeycomb ceramic automobile exhaust purification material and a preparation method thereof. The fireproof sheet honeycomb ceramic automobile exhaust purification material is characterized by being prepared from, by weight, 10-15 parts of floating beads, 40-50 parts of cordierite, 1-3 parts of TiO2, 1-3 parts of clay, 4-8 parts of sodium carbonate, 10-15 parts of stearic acid, a proper amount of a 1 mol / L HNO3 solution, 50-60 parts of nanometer aluminum oxide sol, 1-3 parts of 1 mol / L La(NO3)3, 1-2 parts of a 1 mol / L Sr(NO3)2, 0.5-1 part of a 1 mol / L Co(NO3)2, 2-6 parts of a 1 mol / L critic acid and 100-200 parts of deionized water. By means of ZrO2 powder and CrO2 powder, the comprehensive performance of a honeycomb ceramic carrier is enhanced, and the honeycomb ceramic carrier has the advantages of being high in compressive strength, resistant to high temperature, good in chemical stability, high in corrosion resistance and the like; due to the load La-Sr-Co-O catalyst, the automobile exhaust purification efficiency is improved; meanwhile, the honeycomb ceramic carrier is made into the sheet shape, installation and replacement are convenient, meanwhile, the cost is saved, sufficient utilization of resources are promoted, and the current environment-friendly trend is met.

Owner:安庆市花蕾纺织材料有限公司

Preparation method of anti-shrinkage high-refractoriness refractory mortar

The invention discloses a preparation method of anti-shrinkage high-refractoriness refractory mortar, and belongs to the technical field of refractory material preparation. According to the preparation method of the anti-shrinkage high-refractoriness refractory mortar, first river sand is taken as a raw material, crushed and screened to obtain river sand powder, then the river sand powder and brown sugar water are mixed and dried to obtain a drying object, then the drying object is subjected to carbonization and high-temperature sintering to obtain silicon carbide, then oriental topaz and kyanite are mixed and subjected to ball-milling to obtain a mixed fine material, potassium carbonate, then zirconia and diammonium hydrogen phosphate are taken as raw materials, solid phase sintering is conducted to obtain zirconium phosphate potassium powder, finally the silicon carbide, the mixed fine material, zirconium phosphate potassium and strontium nitrate are taken as powder materials, phenolic resin and ethylene glycol are taken as binding agents to prepare the anti-shrinkage high-refractoriness refractory mortar.

Owner:刘群艳

Refractory brick with high breaking strength and preparation method of refractory brick

InactiveCN107032800AImprove fire resistanceExcellent overall performanceCorrosion resistantMagnesium

The invention discloses a refractory brick with high breaking strength and a preparation method of the refractory brick. The refractory brick is prepared from raw materials in parts by weight as follows: 39-48 parts of municipal sludge, 12-18 parts of a tanning extract, 21-32 parts of blast furnace fly ash, 14-26 parts of steel slag, 16-27 parts of calcium silicate tailings, 7-14 parts of sodium humate, 15-20 parts of asbestos wool, 13-19 parts of waste tempered glass, 8-14 parts of magnesium aluminum silicate, 18-30 parts of vermiculite tailings, 22-29 parts of waste aluminum silicate, 21-27 parts of waste concrete, 10-15 parts of gypsum whiskers and 16-24 parts of pyrophyllite. The asbestos wool, the waste tempered glass, the gypsum whiskers and other materials which are fire-proof, corrosion-resistant, wear-resistant and high in strength are added to the refractory brick, the breaking strength of the refractory brick can be improved, the refractoriness, corrosion resistance and wear resistance of the refractory brick can be improved, and the service life of the refractory brick is greatly prolonged.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

Coating, preparation method thereof and method for spraying coating on metal mold cavity

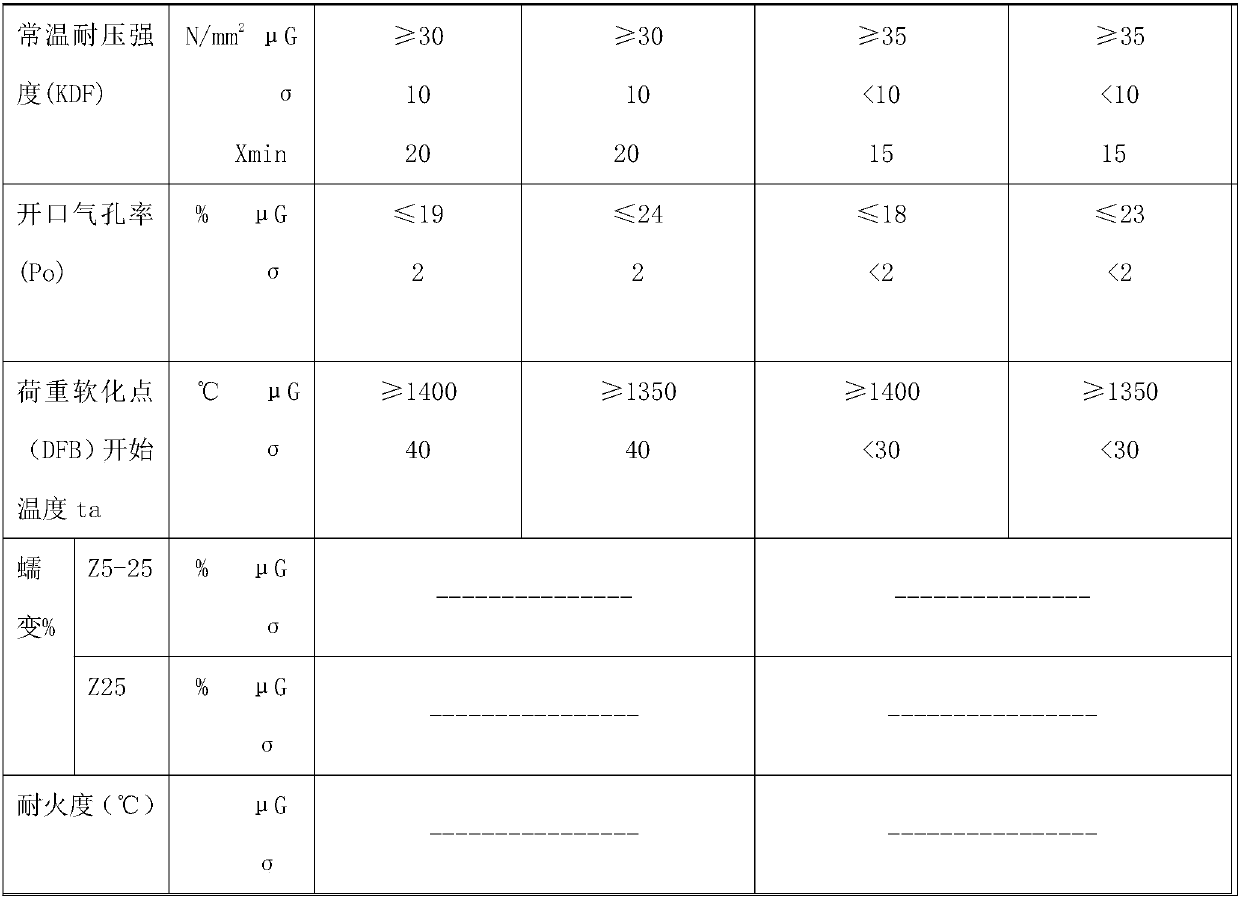

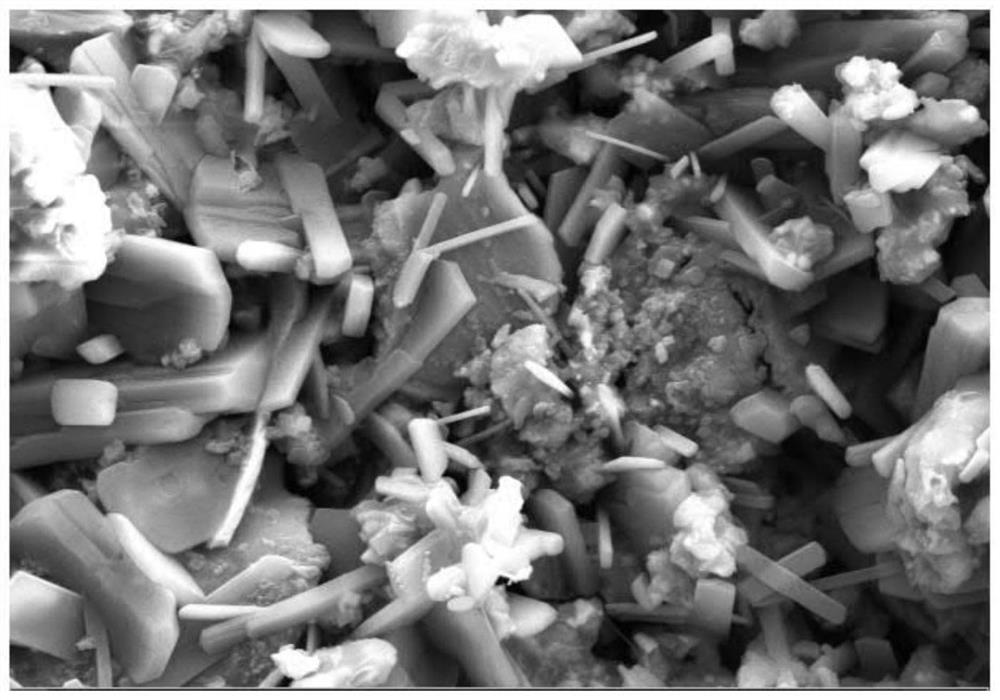

ActiveCN114231063AImprove high temperature resistanceGood refractorinessFireproof paintsMetal moldOxide zinc

The invention discloses a coating, a preparation method thereof and a method for spraying the coating on a metal mold cavity, and belongs to the technical field of coatings. The coating is prepared by mixing the following raw materials in parts by weight: 20-30 parts of a main material, 3-5 parts of an adhesive and 40-60 parts of water, the main material comprises refractory aggregate, glass powder, calcium carbonate and zinc oxide in a weight ratio of (10-14): (2-6): (3-6): (1-3). The coating has good high temperature resistance and can be firmly adhered to the surface of a cavity of a metal mold.

Owner:SONGSHAN LAKE MATERIALS LAB +1

A formulation of water-based lost foam coating for low-temperature high-strength ductile iron

ActiveCN108057840BGood hangabilityImprove uniformityFoundry mouldsFoundry coresWater basedAluminum magnesium silicate

The invention provides a formula of water-based lost foam paint for low-temperature high-strength ductile iron. The formula comprises refractory aggregate, an adhesive, a suspension agent, a surface active agent and a carrier; the refractory aggregate comprises diatomaceous earth, zircon powder, forsterite powder and flake graphite; the adhesive comprises polyving akohol and silica sol; the suspension agent comprises lithium-based bentonite and aluminum-magnesium silicate; and the surface active agent comprises a water-based defoamer, a wetting agent and a penetrating agent. The paint preparedaccording to the formula has excellent sag resistance, uniformity, thermal stability and metal oxidative corrosion resistance, and castings cast through the paint have excellent surface finish and clear outlines.

Owner:TIANJIN NINGKANG TECH

A kind of dedusting ash ceramsite sand and its preparation method and application

ActiveCN109020607BSmall bulk densityGood shape factorCeramic materials productionCeramicwareExpanded clay aggregateMullite

The invention discloses ceramsite sand with dedusting ash as well as a preparation method and application thereof. The ceramsite sand is prepared from the following components in parts by weight: 70-80 parts of fly ash, 10-15 parts of cement, 1-5 parts of VAE glue powder and 1-5 parts of silicon ash. The ceramsite sand with dedusting ash replaces conventional sand to prepare coated sand; firstly,the ceramsite sand with dedusting ash is small in stacking density, good in angular coefficient and large in specific surface area under the equivalent weight condition; the consumption of adhesive inpreparation of the coated sand is low; a better coating effect is achieved in the process of preparing the coated sand; mullite is taken as a main crystal phase of the prepared ceramsite sand; the ceramsite sand has extremely high resistance to high temperature and good thermal stability; the size accuracy of castings can be ensured; the preparation method of the ceramsite sand with dedusting ashis simple; a large amount of energy does not need to be consumed in the preparation process; compared with other common raw sand of the coated sand, the ceramsite sand with dedusting ash is low in cost.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

Preparation method of ball clay special for 75-degree white ultrathin building ceramic rock plate

ActiveCN114477952AHigh refractorinessHigh whitenessCeramic materials productionClaywaresLeuciteKaolin clay

The invention discloses a preparation method of ball clay special for a 75-degree white ultrathin building ceramic rock plate, which comprises the following steps: mixing kaolin, black clay, leucite and white afrodite, crushing, sieving, adding into a sulfuric acid solution, carrying out double-frequency ultrasonic wave alternate oscillation treatment, filtering, washing with water, drying, adding water into the obtained powder to prepare slurry, and drying to obtain the ball clay special for the 75-degree white ultrathin building ceramic rock plate. Sequentially carrying out primary magnetic separation impurity removal, secondary magnetic separation impurity removal and tertiary magnetic separation impurity removal on the obtained slurry, then adding sodium formaldehyde sulfoxylate and phthalimido peroxyhexanoic acid, carrying out double-frequency ultrasonic alternate oscillation treatment, then adding sodium carboxymethyl inulin and dodecyl sulfate diethanolamine salt, and carrying out high-speed ball milling, filtering, drying, crushing and sieving to obtain a finished product. Carrying out wet compression molding on the prepared powder to prepare pressed powder, sintering the prepared pressed powder, and cooling to normal temperature. The ball clay prepared by the invention has excellent refractoriness and whiteness, and completely meets the use requirements of 75-degree white ultrathin building ceramic rock plates.

Owner:佛山市南海科友陶瓷原料有限公司

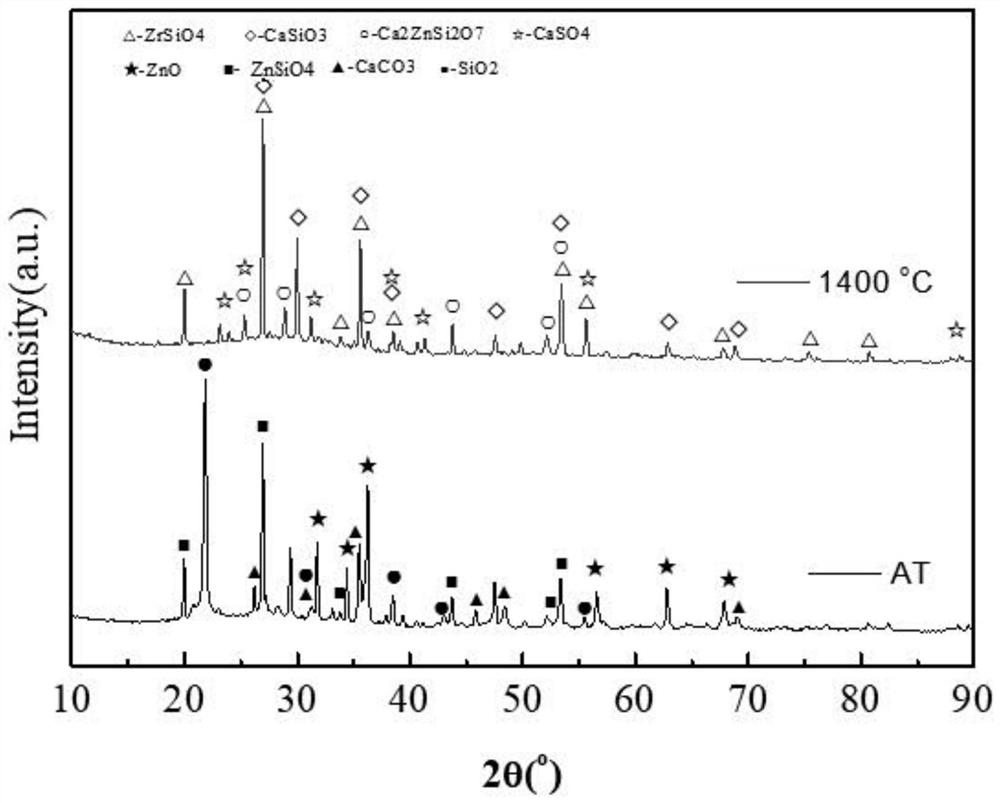

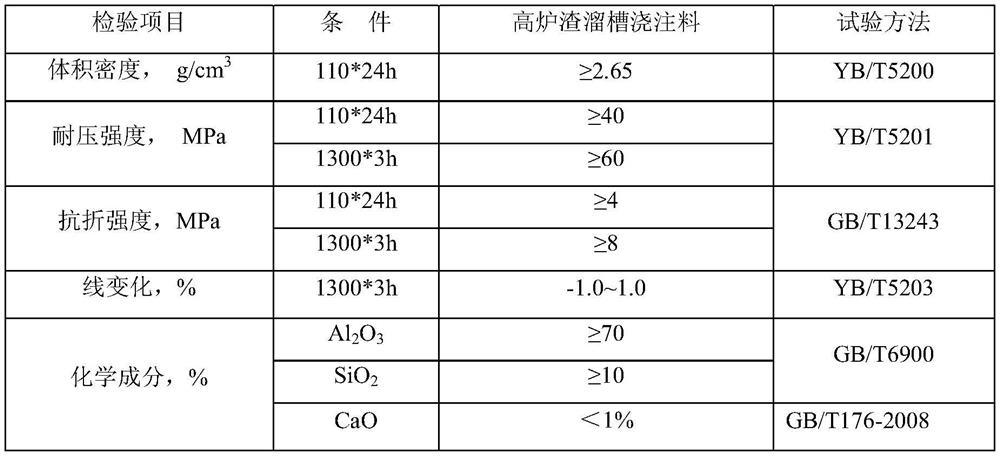

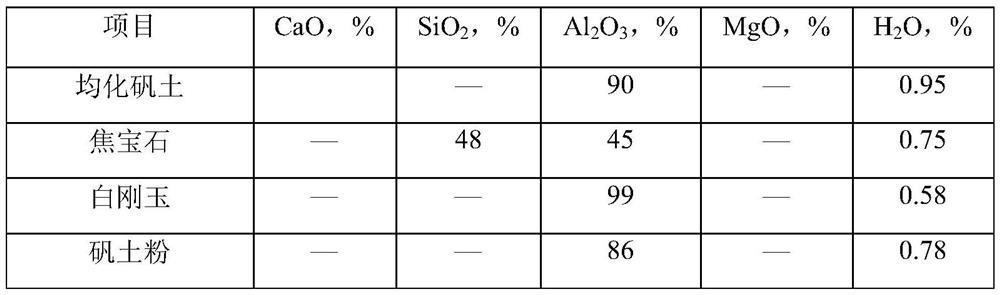

Castable for blast furnace slag chute and preparation method thereof

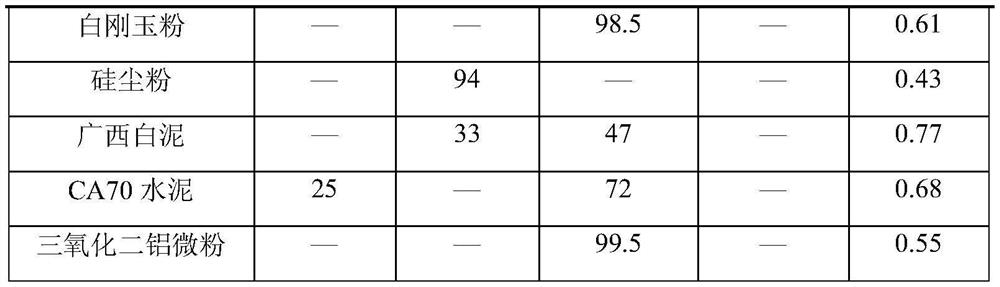

The invention belongs to the technical field of refractory materials, and particularly relates to a blast furnace slag chute castable and a preparation method thereof. The raw material of the blast furnace slag chute castable is composed of the following components by weight: 8mm<homogenized alumina particle size≤12mm, 20-23%, 3mm<homogenized alumina particle size≤8mm, 17-20%, 1mm ≤ 8~12% for coke gemstone particle size ≤ 3mm, 9~11% for 0mm < white corundum particle size ≤ 1mm, 9~10% for bauxite powder with particle size ≤ 0.074mm, and 9~10% for white corundum powder with particle size ≤ 0.044mm 8~10%, particle size ≤0.005mm, Al2O3 micropowder is 8~10%, particle size≤0.074mmCA-70 cement is 5~10%, particle size≤0.074mm, silica dust powder is 1~3%, particle size≤0.074mm Diameter ≤0.074mm Guangxi white mud 2-3%; plus 0.1-0.3% industrial grade sodium hexametaphosphate, 0.3-0.6% stainless steel fiber, 0.03-0.06% explosion-proof fiber by the total weight of the above raw materials. The blast furnace slag chute castable has the characteristics of good anti-sticking performance, high strength, stable thermodynamic performance and the like.

Owner:GANGCHENG GRP LIANGSHAN RUIHAI IND

A refractory self-flowing castable

Owner:HUNAN RAMON SCI & TECH

A low thermal conductivity mullite tin bath combined top cover brick

The invention discloses a low-thermal-conductivity mullite tin bath combined top cover brick prepared from the following raw materials by the mass percentage: 40.5%-65% of a mullite aggregate, 8%-15% of calcium aluminate cement, 4%-10% of a silica micropowder, 10%-18% of an alumina micropowder, 5%-13% of a mullite fine powder, 2%-3% of a mineralizing agent, and 0.1%-0.5% of a water reducing agent. The low-thermal-conductivity mullite tin bath combined top covering brick has the advantages of small thermal conductivity coefficient, small proportion, light weight, high strength, good thermal shock resistance, high refractoriness (greater than 1700 DEG C) and the like; the tin bath combined top cover brick is used in a top cover of a tin bath, greatly reduces the kiln body weight, and reduces the kiln body heat capacity while saving cost; the tin bath combined top cover brick has good thermal shock resistance, and has the service life of a kiln improved greatly; and the tin bath combined top cover brick has the advantages of small thermal conductivity coefficient, good thermal insulation effect and little heat loss, significantly improves the thermal utilization efficiency, saves energy, greatly reduces the energy consumption, and is suitable for popularization and application.

Owner:HENAN ZHONGYUAN SPECIAL REFRACTORY

Preparation method of water-based lost foam casting coating

InactiveCN110814275AGood adhesionImprove dry strengthFoundry mouldsFoundry coresFoundryUltimate tensile strength

The invention discloses a preparation method of a water-based lost foam casting coating. According to the preparation method of the water-based lost foam casting coating, a coating layer and a castingare easy to strip, sand sticking is avoided, sand is easy to remove, the cleaning workload of the casting can be reduced, the water-based lost foam casting coating has the characteristics of good room-temperature and high-temperature comprehensive performance, high temperature resistance, scouring resistance, no cracking, low gas evolution, high coating strength, good air permeability and the like, and has good suspension property, coating property, thixotropy and leveling property, titanium tetrachloride is adopted for hydrolysis bonding, and bad defects can be avoided, so that the surface smoothness of the casting is good, and the process requirements of casting manufacturers are met.

Owner:HEXIAN KEJIA VALVE CASTING

Evanescent mold ammeter shell

InactiveCN107377878AGood release effectEasy to fillFoundry mouldsFoundry coresLiquid metalFire resistance

The invention belongs to the field of electrical equipment and discloses an evanescent mold ammeter shell. The evanescent mold ammeter shell is prepared and obtained according to the following process that EPS beads are subjected to foaming once and then are poured into a mold cavity, a model is formed through expansion under the action of high-temperature steam, is put into a precoated sand mold, is solidified through sand jetting and heating, is immersed into fireproof paint prepared in advance, and is taken out, and the surface of the model is evenly coated with the fireproof paint; liquid metal is poured into a mold, and a casting is formed after cooling; after the casting is formed, a sand shell without the outer surface is formed so as to obtain the needed metal shape which is exposed completely; and residual sand grains and an oxide skin on the surface of the casting are removed, and the evanescent mold ammeter shell is obtained. The evanescent mold ammeter shell is complete in structure, filling of all corners is good, and fire resistance is good.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

A kind of low-cost environment-friendly alcohol-based cast iron coating and preparation method thereof

ActiveCN108145070BGood suspensionGood refractorinessFoundry mouldsFoundry coresSodium BentoniteMullite

Owner:HUBEI UNIV OF TECH

A kind of regenerated brick for carbon kiln and its preparation method

ActiveCN108395264BGood refractorinessHigh compressive strengthCeramic materials productionClaywaresSODIUM METAPHOSPHATEFiber

The invention discloses a regenerated brick for a carbon kiln and a preparation method thereof, and relates to the technical field of regenerated bricks and its preparation. The regenerated bricks include raw materials in the following percentages by weight: carbon kiln repair waste bricks 60-80%, high alumina powder 10-20%, pure calcium aluminate cement 4-16%, silicon micropowder 4-5%, three Sodium polyphosphate 0.05-0.15%, sodium hexametaphosphate 0.05-0.15%, explosion-proof fiber 0.05-0.17% and additive 3-4%; the production method is to mix and stir the raw materials into a mixed slurry, cast and mold, demould, Dry it at a constant temperature of 25-35°C. The regenerated bricks of the present invention solve the problems of difficult disposal of carbon kiln waste bricks and high energy consumption and high cost of making regenerated bricks by optimizing raw material preparation and production methods, and realize green recycling of resources and energy saving and environmental protection. In the case of sintering, the refractoriness, compressive strength, high-temperature flexural strength and other properties of the regenerated bricks produced are good, and all meet the use standards.

Owner:GUANGXI QIANGQIANG CARBON CO LTD

A kind of wear-resistant frit, preparation method of frit and glaze using same

The invention discloses a wear-resistant frit, a preparation method of the frit and a glaze using the same. A wear-resistant frit is calculated according to the mass percentage, and its raw materials include the following components: prefabricated frit 20-36%, 20-38% of talc, 2-5% of zinc oxide, 8-12% of calcined alumina, 20-24% of kaolin and 7-9% of fluorite; calculated according to mass percentage, the raw materials of the prefabricated frit include the following components : Potassium feldspar 15-20%, dolomite 5-10%, talc 45-55%, zinc oxide 2-5% and aluminum oxide 20-25%. The wear-resistant frit has good transparency and good wear resistance. The preparation method of the wear-resistant frit is simple, and each raw material component is fully melted during the high-temperature firing process. The prepared wear-resistant frit is The block has high transparency and good wear resistance. Using the glaze material of the wear-resistant frit, the glaze layer has good wear resistance, and the glaze surface has good surface gloss and good light transmission performance.

Owner:佛山市东鹏陶瓷发展有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com