A refractory self-flowing castable

A castable and refractory technology, applied in the field of refractory materials, can solve the problems of reducing the service life of castables, poor fluidity, poor temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

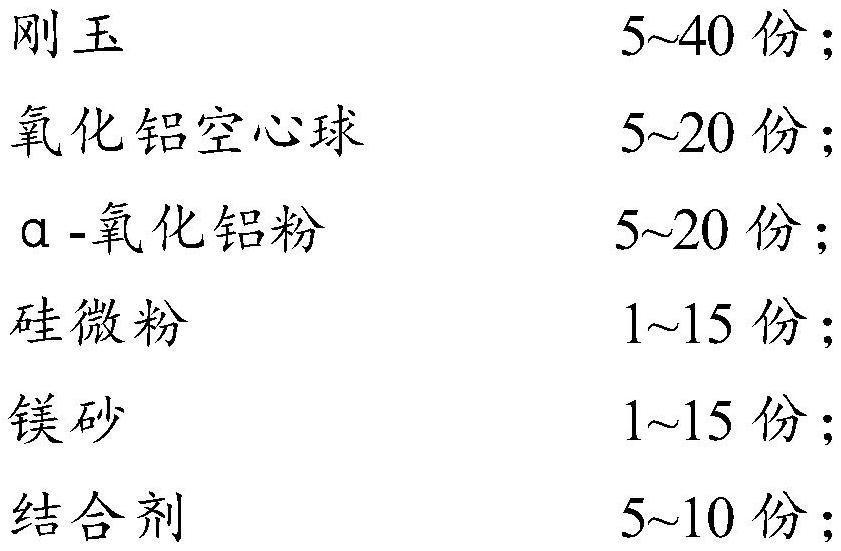

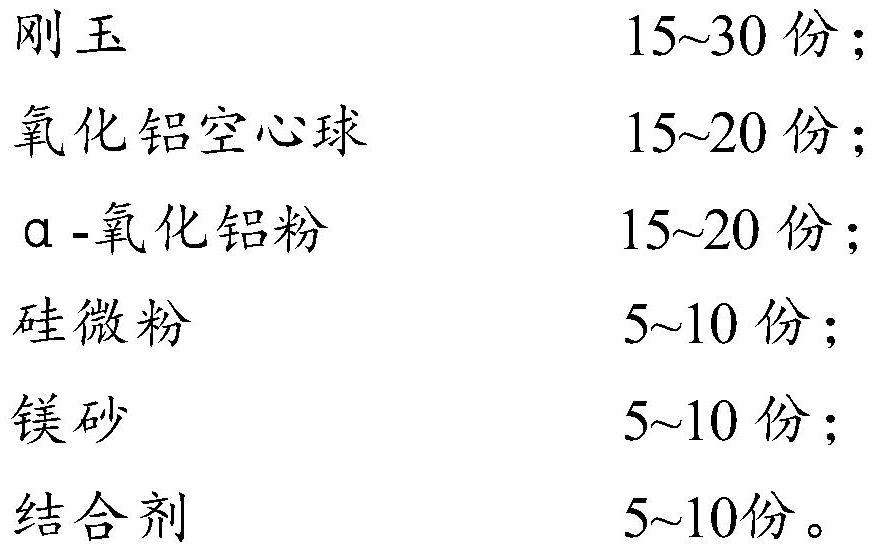

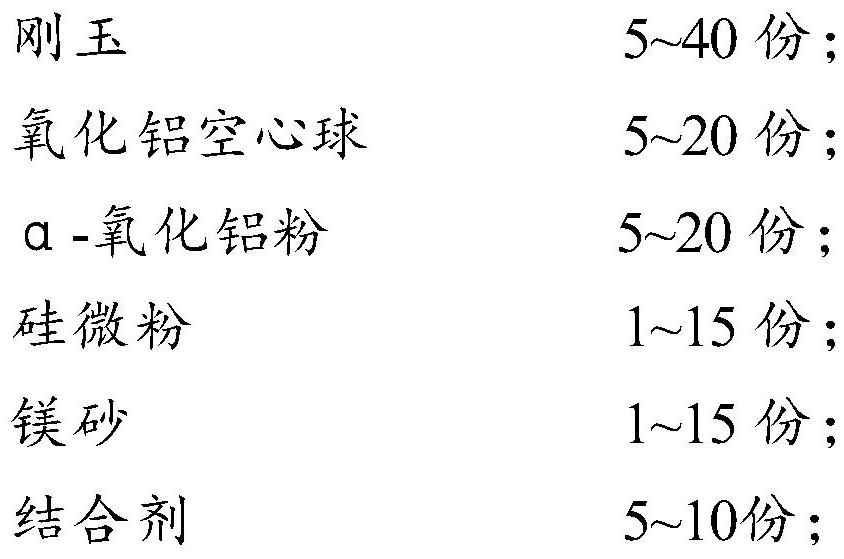

Method used

Image

Examples

Embodiment 1

[0043] 1.1 Sample preparation

[0044] raw material:

[0045] 25 parts of sintered corundum, 18 parts of alumina hollow spheres (particle size 0.2mm), 18 parts of α-alumina powder (particle size 500 mesh), 8 parts of silicon micropowder, 8 parts of fused magnesia (particle size 400 mesh), 6 parts of binder (the mass ratio of silica sol:trimethoxysilane is 10:0.1).

[0046] Preparation:

[0047] Sintered corundum, aluminum oxide hollow spheres, α-alumina powder, silicon micropowder, and fused magnesia are weighed and mixed, then poured into a mixer, and then a binder is added and stirred evenly to obtain a refractory self-flowing castable.

[0048] 1.2 Performance test

[0049] The self-flow value of the obtained refractory castable was tested at 20°C (tested according to the self-flow method specified in the national standard GB / T 3003-2006), the test results are shown in Table 1, and Table 1 is the castable obtained from the practical examples and comparative examples of t...

Embodiment 2

[0052] 15 parts of sintered corundum, 15 parts of alumina hollow spheres (particle size 0.1mm), 15 parts of α-alumina powder (particle size 325 mesh), 5 parts of silicon micropowder, 5 parts of fused magnesia (particle size 200 mesh), 5 parts of binder (the mass ratio of silica sol:triethoxysilane is 10:0.08).

[0053] Prepare according to the formula of Example 1 to obtain a refractory self-flowing castable.

[0054] According to the performance test method of Example 1, the performance test of the obtained refractory self-flowing castable was carried out, and the test results are shown in Table 1.

Embodiment 3

[0056] 30 parts of sintered corundum, 20 parts of alumina hollow spheres (particle size 0.3 mm), 20 parts of α-alumina powder (particle size 800 mesh), 10 parts of silicon micropowder, 10 parts of fused magnesia (particle size 600 mesh), 10 parts of binder (the mass ratio of silica sol:γ-glycidyl etheroxypropyl trimethoxysilane is 10:0.12).

[0057] Prepare according to the formula of Example 1 to obtain a refractory self-flowing castable.

[0058] According to the performance test method of Example 1, the performance test of the obtained refractory self-flowing castable was carried out, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com