Wear-resistant frit, preparation method of frit and glaze using frit

A frit and raw material technology is applied in the field of preparation methods and glazes using the same to achieve the effect of improving wear resistance, good wear resistance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of described wear-resistant frit comprises the following steps:

[0034] The step of preparing the prefabricated frit: mixing the raw materials of the prefabricated frit according to the ratio, firing at high temperature, quenching in water to obtain the prefabricated frit, powdering the prefabricated frit, sieving, and drying;

[0035] The steps of preparing the wear-resistant frit: mixing the raw materials of the wear-resistant frit according to the ratio, firing at high temperature, and quenching in water to obtain the wear-resistant frit.

[0036] By first preparing the prefabricated frit, the prefabricated frit obtained through high-temperature firing process is added as a raw material to the raw material of the wear-resistant frit, because the chemical composition contained in the prefabricated frit is close to cordierite The chemical composition introduced into the wear-resistant frit is beneficial to the precipitation of cordierite crystal...

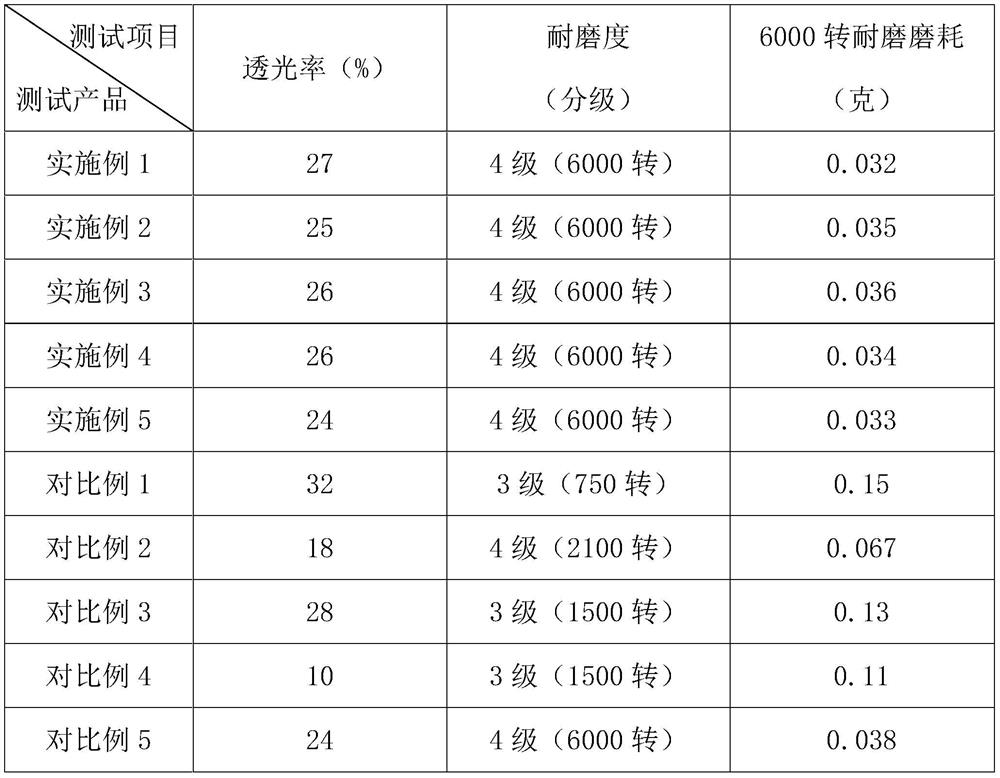

Embodiment 1~5

[0065] A wear-resistant frit is prepared according to the following steps:

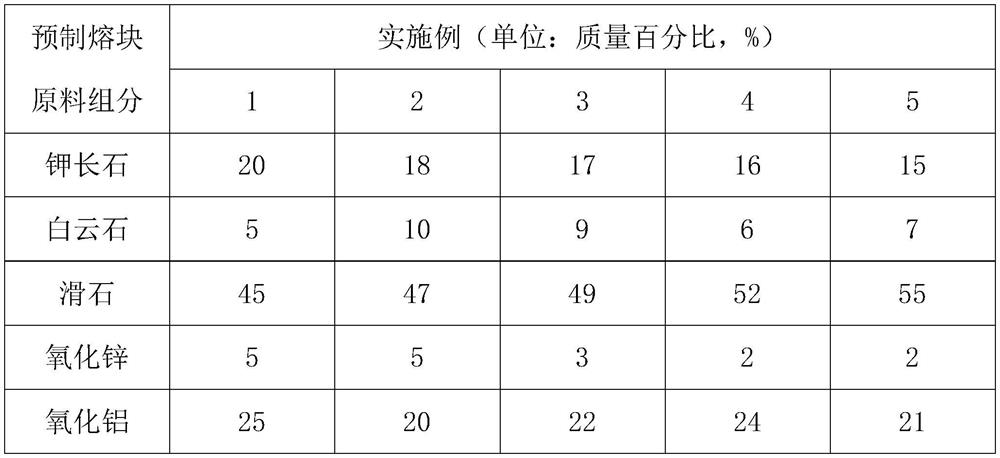

[0066] (1) Steps for preparing prefabricated frit: mix the raw materials of prefabricated frit according to the ratio in Table 1, and perform high-temperature firing (wherein, the temperature curve of high-temperature firing is from room temperature to 1100°C, which takes 100 minutes and the heating rate 11°C / min; it takes 60 minutes to rise from 1100°C to 1530°C, and the heating rate is 7.2°C / min; keep at 1530°C for 25 minutes), quench in water to obtain prefabricated frit, and prefabricated frit is powdered and sieved (get 180 mesh sieves), drying;

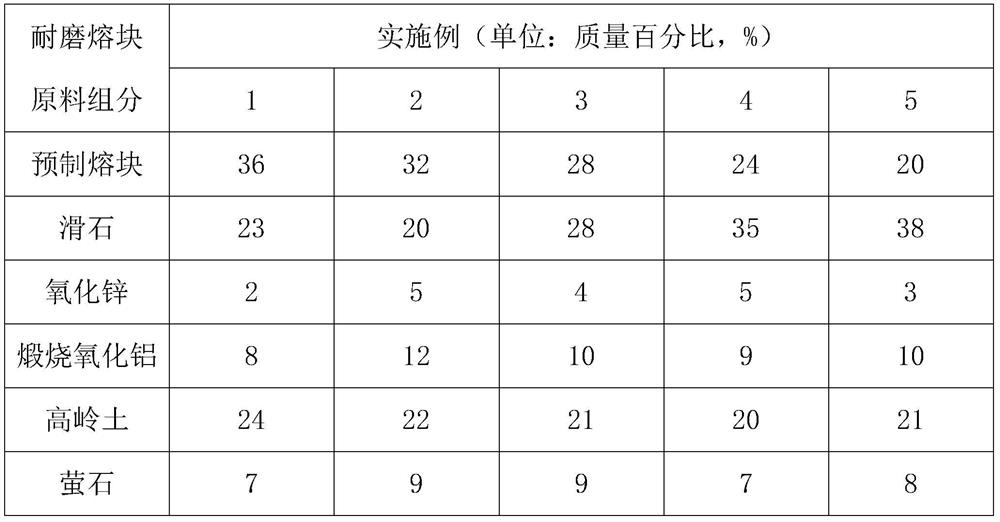

[0067] (2) Steps for preparing wear-resistant frit: mix the raw materials of wear-resistant frit according to the ratio in Table 2, and perform high-temperature firing (from normal temperature to 1100°C, it takes 100min, and the heating rate is 11°C / min; It takes 60 minutes to rise from 1100°C to 1530°C, and the heating rate is 7.2°C / min; hold at 1530°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com