Castable for blast furnace slag chute and preparation method thereof

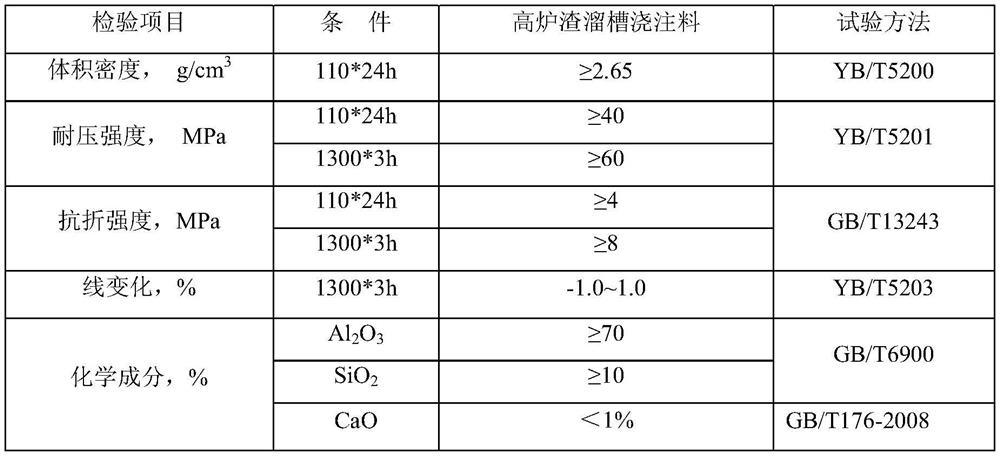

A blast furnace slag and castable technology, which is applied in the field of refractory materials involved in blast furnace slag treatment, can solve the problems of slag sticking, low service life, iron sticking, etc., and achieve the effects of high refractoriness, high strength and good thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of castable for blast furnace slag chute comprises the following steps:

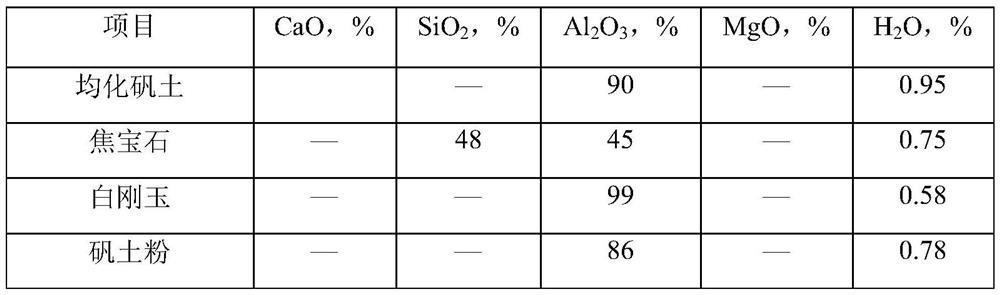

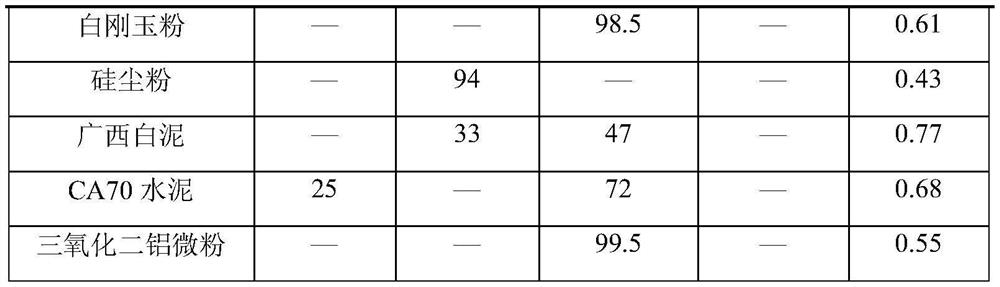

[0028] a. According to the requirements, control raw materials homogenized bauxite, coke gem, white corundum, bauxite powder, white corundum powder, aluminum oxide powder, CA70 cement, silica dust powder, Guangxi white mud, admixture sodium hexametaphosphate, stainless steel Content and particle size of steel fiber and explosion-proof fiber;

[0029] b. Send the aggregate part of 12mm-1mm into the drum mixer according to the ratio for mixing and stirring. After mixing and stirring for a certain period of time, add bauxite powder, white corundum powder, aluminum oxide powder, Ca70 cement, Silica dust powder, Guangxi white mud, admixture sodium hexametaphosphate, stainless steel fiber and explosion-proof fiber are stirred.

[0030] According to the actual production volume, put the above aggregate particles into a drum mixer for mixing and stirring. After mixing and stirring ...

Embodiment 1

[0048] 21 parts by weight of qualified 8mm-12mm homogenized alumina, 19 parts by weight of 3-8mm homogenized alumina, 11 parts by weight of burnt gems, and 10 parts by weight of white corundum are sent into a drum mixer for mixing and stirring. After mixing and stirring for 2 minutes, add 9 parts by weight of bauxite powder, 9 parts by weight of white corundum powder, 9 parts by weight of aluminum oxide micropowder, 8 parts by weight of Ca70 cement, 2 parts by weight of silica dust powder, 2 parts by weight of Guangxi white mud and Add 0.2 parts by weight of industrial grade sodium hexametaphosphate, 0.4 parts by weight of stainless steel fiber, and 0.04 parts by weight of explosion-proof fiber into the drum mixer for mixing and stirring. After mixing and stirring for 4 minutes, pass the mixed material through the tee Put the valve feeding device into a dry ton bag, pack it at 500kg / bag, fasten the opening mark and put it in storage for standby, take samples to test the physica...

Embodiment 2

[0054] 22 parts by weight of 8mm-12mm homogenized alumina, 18 parts by weight of homogenized alumina of 3-8mm, 12 parts by weight of burnt gems, and 9 parts by weight of white corundum are sent into the drum mixer for mixing and stirring. After mixing and stirring for 2 minutes, add 10 parts by weight of bauxite powder, 8 parts by weight of white corundum powder, 10 parts by weight of aluminum oxide micropowder, 7 parts by weight of Ca70 cement, 2 parts by weight of silica dust powder, 2 parts by weight of Guangxi white mud and Add 0.2 parts by weight of industrial grade sodium hexametaphosphate, 0.3 parts by weight of stainless steel fiber, and 0.05 parts by weight of explosion-proof fiber into the drum mixer for mixing and stirring. After mixing and stirring for 4 minutes, pass the mixed material through the tee Put the valve feeding device into a dry ton bag, pack it at 500kg / bag, tie the opening mark and put it in storage for standby, take samples to test the physical and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com