A low thermal conductivity mullite tin bath combined top cover brick

A technology of mullite tin and low thermal conductivity, applied in the field of refractory materials, can solve the problems of large heat capacity, poor thermal insulation performance and thermal shock resistance, fast heat dissipation, etc., and achieve low thermal conductivity, good thermal insulation effect and high refractoriness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

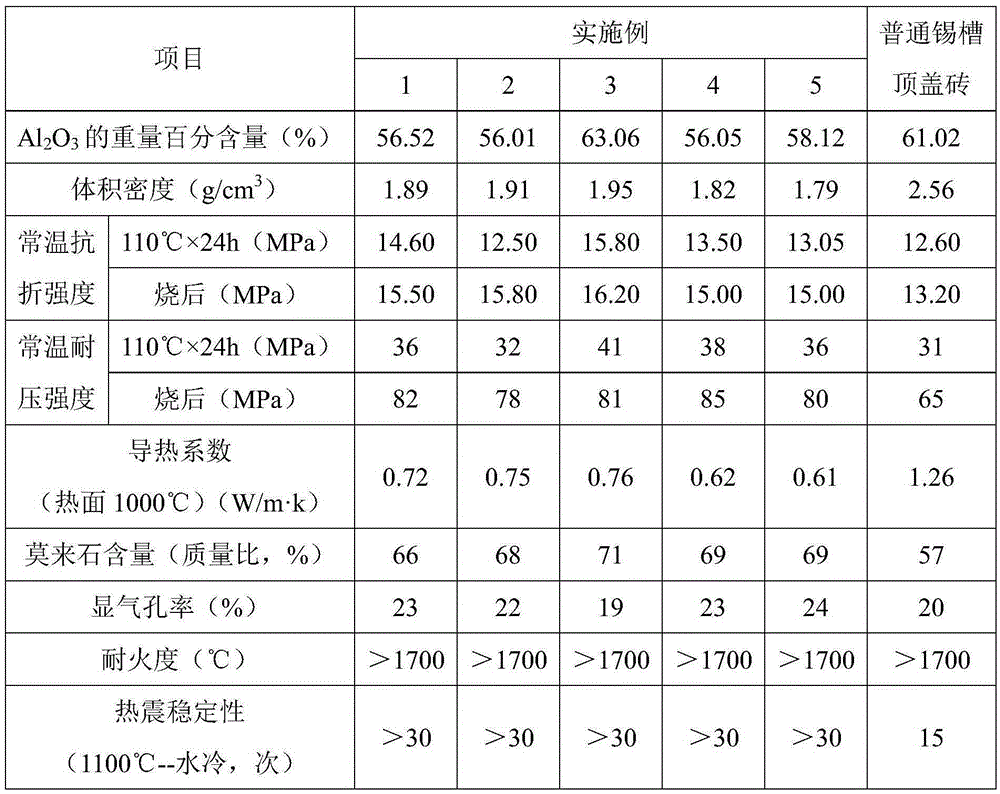

Examples

Embodiment 1

[0022] The low thermal conductivity mullite tin bath combined roof brick of this embodiment is made of the following raw materials in mass percentage: 52% of high-purity mullite aggregate, 15% of pure calcium aluminate cement, 8% of high-purity silica powder, α-alumina fine powder 10%, high-purity mullite fine powder 12%, sillimanite 2.8%, sodium tripolyphosphate 0.2%.

[0023] Wherein, the raw material specifications are as follows: in the mullite aggregate, Al 2 o 3 The mass percentage content ≥ 48%, Fe 2 o 3 The mass percentage content of ≤0.6%, Na 2 O and K 2 The sum of the weight percentages of O ≤ 0.6%; the particle size of the mullite aggregate is 0.088-8mm, and the bulk density is 1.90g / cm 3 , Barrel pressure strength ≥ 80Mpa, apparent porosity 20%, average pore diameter D50 ≤ 50μm, mass percentage of mullite phase ≥ 55%. In the calcium aluminate cement, Al 2 o 3 The mass percentage content of ≥80%, Fe 2 o 3 The mass percentage content of calcium aluminate ce...

Embodiment 2

[0026] The low thermal conductivity mullite tin bath combined roof brick of this embodiment is made of the following raw materials in mass percentage: 55% of high-purity mullite aggregate, 9.9% of pure calcium aluminate cement, 10% of high-purity silica powder, α-alumina fine powder 18%, high-purity mullite fine powder 5%, andalusite 2.0%, sodium hexametaphosphate 0.1%.

[0027] Wherein, the raw material specifications are as in Example 1, the difference is that: the bulk density of the mullite aggregate is 1.95g / cm 3 , The apparent porosity is 15%.

[0028] The preparation method of the low thermal conductivity mullite tin bath combined top cover brick in this embodiment is as follows: the concave mold is used to form the formula ingredients, the mixture is made by adding water and stirred, the mold is poured and formed by vibration, after demoulding, the standard curing is performed, and then the mold is heated at 110 ° C. It is dried under the hood, and then fired at a hig...

Embodiment 3

[0030] The low thermal conductivity mullite tin bath combined roof brick of this embodiment is made of the following raw materials in mass percentage: 50% of high-purity mullite aggregate, 12% of pure calcium aluminate cement, 5% of high-purity silica powder, α-alumina fine powder 18%, high-purity mullite fine powder 12%, andalusite 1.0%, sillimanite 1.7%, sodium hexametaphosphate 0.3%.

[0031]Wherein, the raw material specifications are as in Example 1, except that the bulk density of the mullite aggregate is 2.0 g / cm3, and the apparent porosity is 15%.

[0032] The preparation method of the low thermal conductivity mullite tin bath combined top cover brick in this embodiment is as follows: the concave mold is composed of the formula ingredients, the mixture is made by adding water and stirred, the mold is poured and formed by vibration, after demoulding, it is maintained under natural conditions, and then Drying at 110°C, and then firing at a high temperature in a downdraft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com