Preparation method of water-based lost foam casting coating

A lost foam casting and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve problems such as pores and other defects, poor mechanical properties, and limit the development and application range of lost foam aluminum alloy casting technology. Improve the yield, easy to operate, and prevent the collapse of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

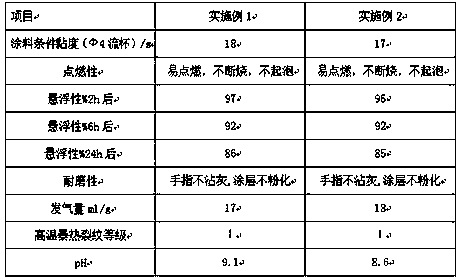

Embodiment 1

[0018] A method for preparing a water-based lost foam casting coating, comprising the following steps: (1) First, 23 parts of alcohol with a mass fraction of 95%, 8 parts of distilled water, 5 parts of acetic acid with a mass fraction of 3%, and 13 parts of hydrochloric acid with a mass fraction of 5% Add to the hydrolyzer in turn, stir for 5 minutes to make it evenly mixed; Add 13 parts of titanium tetrachloride to the hydrolyzer at one time, continue to stir for 1 hour to make it fully hydrolyzed, during the hydrolysis process, the temperature is controlled at 50 ° C, cooled , when the temperature drops below 30°C, filter it with gauze, cover and seal it to obtain a titanium tetrachloride hydrolyzate; (2) Soak 19 parts of diatomaceous earth in 6% acetic acid for 10 minutes, wash with deionized water, and then use Soak in 5% edible alkaline water solution for 30min, then wash with deionized water until neutral, then calcined at 650°C for 3 hours, add 0.5 part of oleic acid ami...

Embodiment 2

[0025] A method for preparing a water-based lost foam casting coating, comprising the following steps: (1) First, 23 parts of alcohol with a mass fraction of 95%, 8 parts of distilled water, 2 parts of acetic acid with a mass fraction of 3%, and 13 parts of hydrochloric acid with a mass fraction of 5% Add to the hydrolyzer one by one, stir for 10 minutes to make it evenly mixed; Add 13 parts of titanium tetrachloride to the hydrolyzer at one time, continue to stir for 1.5 hours to make it fully hydrolyzed, during the hydrolysis process, the temperature is controlled at 50 ° C, cooled , when the temperature drops below 30°C, filter it with gauze, cover and seal it to obtain a titanium tetrachloride hydrolyzate; (2) Soak 19 parts of diatomaceous earth in 6% acetic acid for 20 minutes, wash with deionized water, and then use Soak in 5% edible alkaline water for 30 minutes, then wash with deionized water until neutral, then calcined at 650°C for 3 hours, add 0.7 part of oleic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com