Coating, preparation method thereof and method for spraying coating on metal mold cavity

A technology for metal molds and coatings, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of coating adhesion defects and other problems, and achieve the effects of improving production tempo, good high temperature resistance, and improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present application embodiment also provides a method of preparing a coating comprising: mixing the material to water, and then mixed with an adhesive.

[0036] The main material can be mixed with water to make the components to disperse in water, and then mix with the adhesive can make each component even more even in the coating.

[0037] In some embodiments, the step of mixing the material and water comprises: mixing the material with a portion of the water into a paste, and then mixed with the remaining water.

[0038] This type can make the components in the main material more uniformly dispersed in water. Alternatively, a paste of water is 5 to 10 parts by mixing with the material.

[0039] When the suspension is included in the raw material, the material is mixed with water, and then mixed with the suspension, mixed with the adhesive.

[0040] Since the suspension is a solid, after mixing the material and water, the suspension can be mixed in water, and then mixe...

Embodiment 1

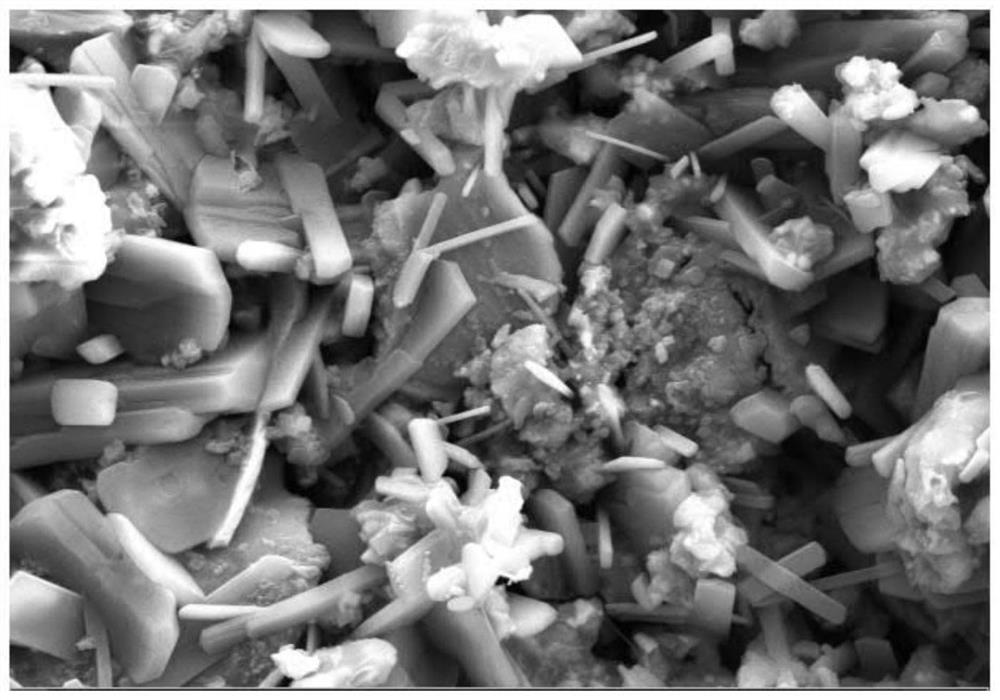

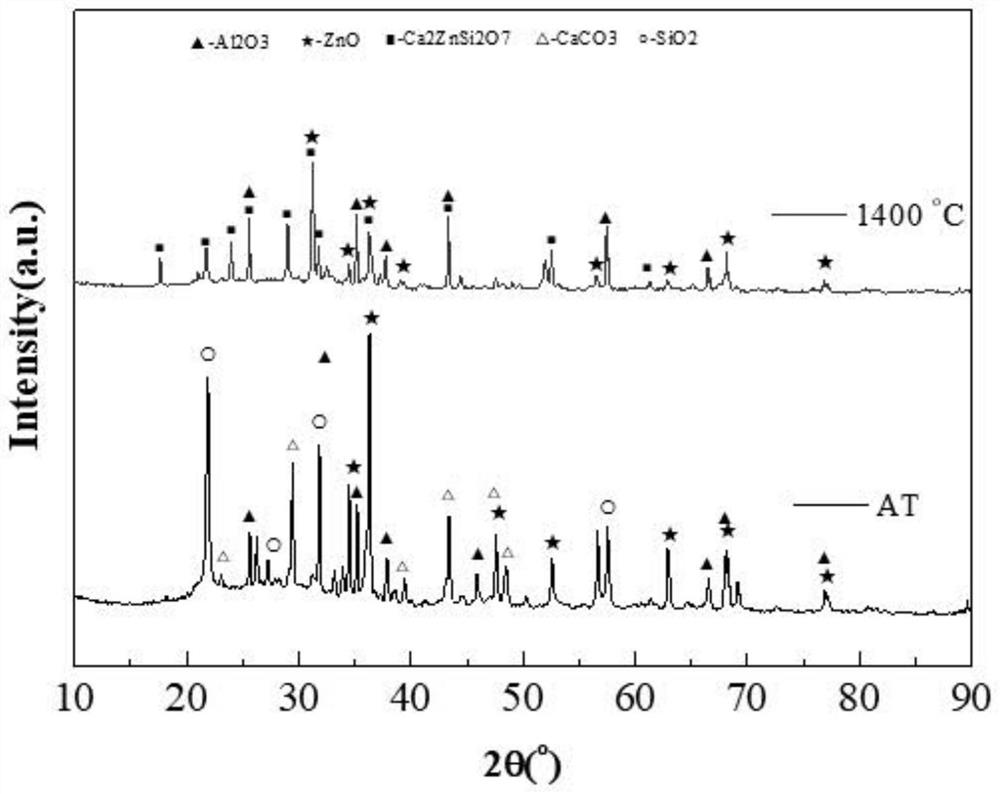

[0050] This embodiment provides a coating which is made of a raw material, wherein the raw material comprises 1 g of magnesium silicate aluminum, water glass 3g, deionized water 50g, and dissection. The main material is: 10 g of alumina powder, 3g of diatomite, 2g of glass powder, light calcium carbonate 3g and zinc oxide 2g.

[0051] The method of preparing the coating comprises mixing the material and mixed with a mixture of 8 g of water to form a paste, and then the remaining water was added to stir for 10 min, and the mixture was stirred with magnesium silicate, then the mixture was stirred for 5 min, Make paint.

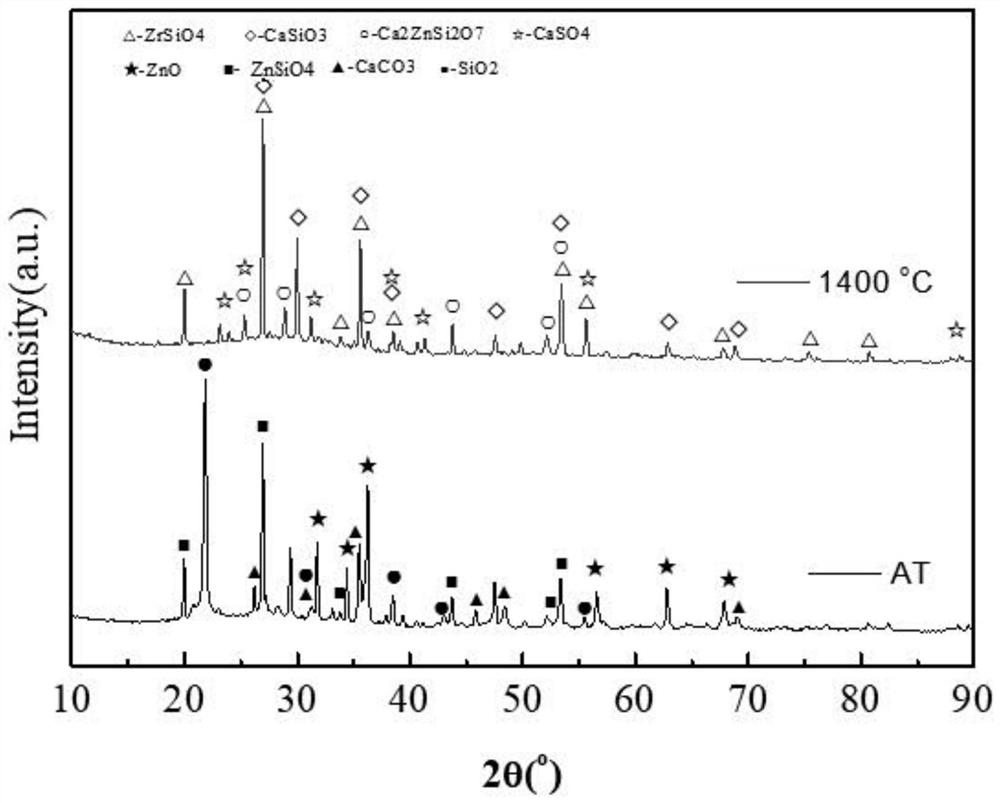

Embodiment 2

[0053] This embodiment provides a coating and a preparation method thereof, and the preparation method is also the same as in Example 1. The coating material of the present embodiment differs only that the aluminum oxide powder of Example 1 will be replaced. Zirconium powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com