Fireproof self flowing casting material

A castable and refractory technology, applied in the field of refractory materials, can solve the problems of poor thermal stability, reduced service life and destructive performance of castables, and achieve the effects of good thermal stability, improved service life and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

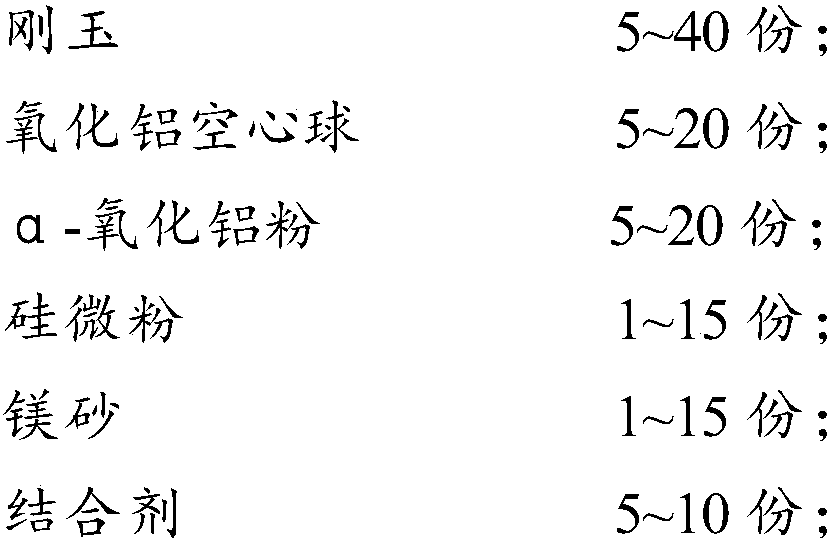

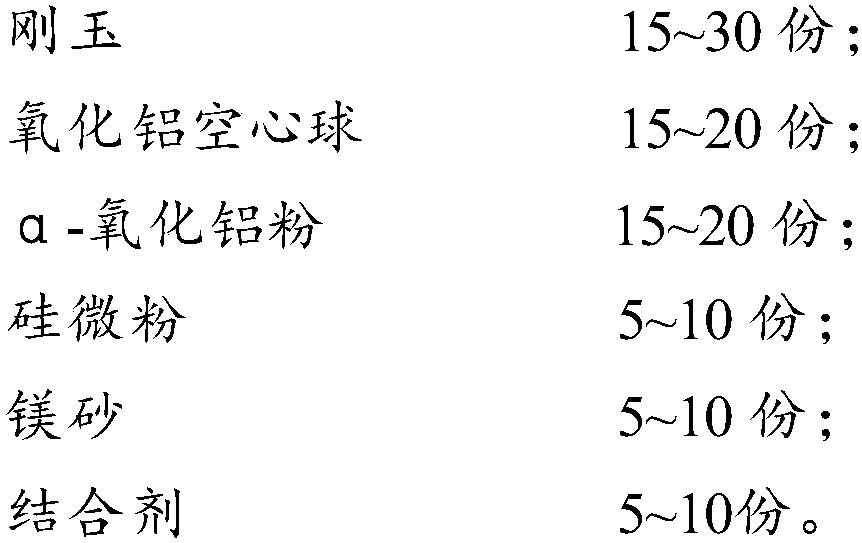

Method used

Image

Examples

Embodiment 1

[0043] 1.1 Sample preparation

[0044] raw material:

[0045] 25 parts of sintered corundum, 18 parts of alumina hollow spheres (particle size 0.2mm), 18 parts of α-alumina powder (particle size 500 mesh), 8 parts of silicon micropowder, 8 parts of fused magnesia (particle size 400 mesh), 6 parts of binder (the mass ratio of silica sol:trimethoxysilane is 10:0.1).

[0046] Preparation:

[0047] Sintered corundum, aluminum oxide hollow spheres, α-alumina powder, silicon micropowder, and fused magnesia are weighed and mixed, then poured into a mixer, and then a binder is added and stirred evenly to obtain a refractory self-flowing castable.

[0048] 1.2 Performance test

[0049] The self-flow value of the obtained refractory castable was tested at 20°C (tested according to the self-flow method specified in the national standard GB / T 3003-2006), the test results are shown in Table 1, and Table 1 is the castable obtained from the practical examples and comparative examples of t...

Embodiment 2

[0052] 15 parts of sintered corundum, 15 parts of alumina hollow spheres (particle size 0.1mm), 15 parts of α-alumina powder (particle size 325 mesh), 5 parts of silicon micropowder, 5 parts of fused magnesia (particle size 200 mesh), 5 parts of binder (the mass ratio of silica sol:triethoxysilane is 10:0.08).

[0053] Prepare according to the formula of Example 1 to obtain a refractory self-flowing castable.

[0054] According to the performance test method of Example 1, the performance test of the obtained refractory self-flowing castable was carried out, and the test results are shown in Table 1.

Embodiment 3

[0056] 30 parts of sintered corundum, 20 parts of alumina hollow spheres (particle size 0.3 mm), 20 parts of α-alumina powder (particle size 800 mesh), 10 parts of silicon micropowder, 10 parts of fused magnesia (particle size 600 mesh), 10 parts of binder (the mass ratio of silica sol:γ-glycidyl etheroxypropyl trimethoxysilane is 10:0.12).

[0057] Prepare according to the formula of Example 1 to obtain a refractory self-flowing castable.

[0058] According to the performance test method of Example 1, the performance test of the obtained refractory self-flowing castable was carried out, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com