Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Good fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic resin with high toughness

The invention discloses acrylic resin with high toughness, which comprises the following components according to the weight portion: 50-75 of acrylic resin, 5-35 of polyethylene resin, 5-35 of compatilizer, 0.2-1 of processing materials, 4-15 of filling agent and 0.3-1 of dispersing agent, wherein the acrylic resin is one or the composition of more than two of isotactic PP, syndiotactic PP, block co-polymerized polypropylene or random co-polymerized polypropylene, and melting flow index of the acrylic resin is (0.4-30)g / 10min. The invention aims at overcoming the defects of the prior art, and providing the acrylic resin with rich source, low price, high elongation at break, strong temperature toleration, high softening point, excellent impact property, fatigue and bending resisting properties and wide application.

Owner:广东智汇赛特新材料有限公司

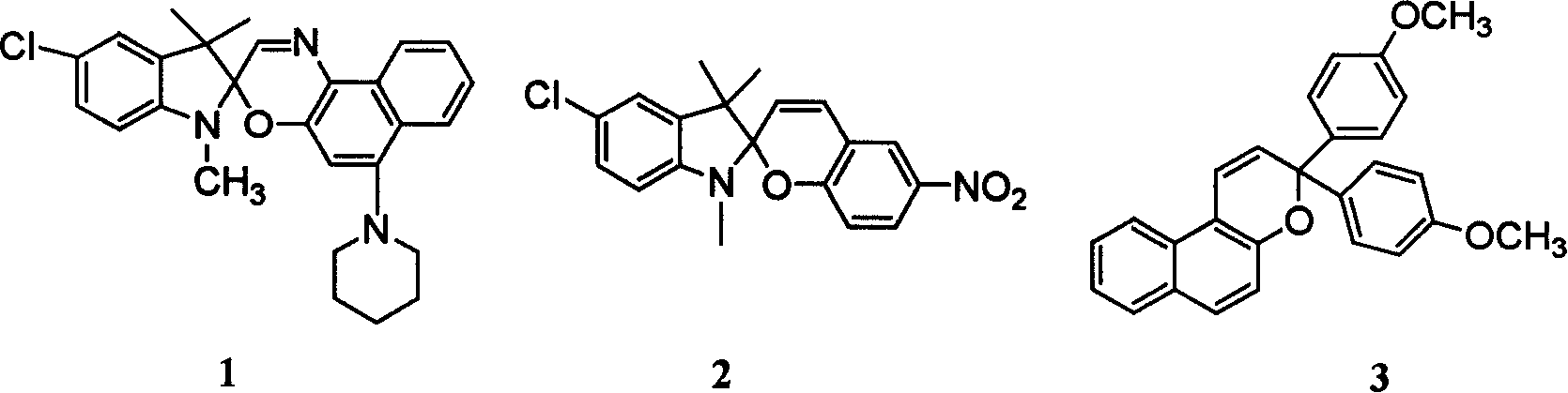

Organic photochromic composite nano materials and method for preparing same

InactiveCN1629250AGood fatigue resistanceExtended service lifeLuminescent compositionsHindered amine light stabilizersHalogen

The invention relates to an organic photochromic composite nano materials and method for preparing same, wherein the material has the structural formula of [R1]-[M]-[R2][R3], wherein [M] is naphtha or benzoxazine, spiro-pyrans and naphthopyrans chemical functional group, [R1] is straight chain alkyl, alkoxy, halogen, halogenated alkyl, nitro, [R2] is alkoxy, cycloalkyl, oxygen-containing, nitrogen-containing heterocycte, halogen, nitro. [R3] is straight chain alkyl, branched chain alkyl, hydroxyalkyl, carboxylic alkyl. The carrier can employ PVB resin, polystyrene resin, polymethyl methacryate, acetyl butyryl cellulose, PET resin powder, or polyvinyl pyrrolidon resin. The material also includes anti-oxidant, hindered amine light stabilizer, and single state oxygen quencher.

Owner:NANKAI UNIV

Polycarbonate composite material with modified calcium sulfate whisker and preparation method thereof

The invention relates to a polycarbonate composite material with modified calcium sulfate whisker and a preparation method thereof. The calcium sulfate whisker-modified polycarbonate composite material comprises the following raw materials by weight parts: 100 parts of polycarbonate, 15 to 20 parts of polystyrene, 15 to 25 parts of calcium sulfate whisker, 0.1 to 0.4 part of antioxidant 1010, 1 to 4 parts of polyfluortetraethylene and 1 to 3 parts of titanic acid ester coupling agent. The preparation method comprises the following steps: calcium sulfate whisker and titanic acid ester coupling agent are activated for 3 to 6 minutes in a high-speed mixer; the rest raw materials are mixed for 6 to 8 minutes with the modified calcium sulfate whisker in the high-speed mixer; and then the obtained mixture is granulated by melting through a double-screw extruder. The polycarbonate composite material with the modified calcium sulfate whisker has good fatigue resistance and low notch sensitivity and is particularly suitable for manufacturing television shells, precise instrument shells, automotive interior trims, instrument structural components and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

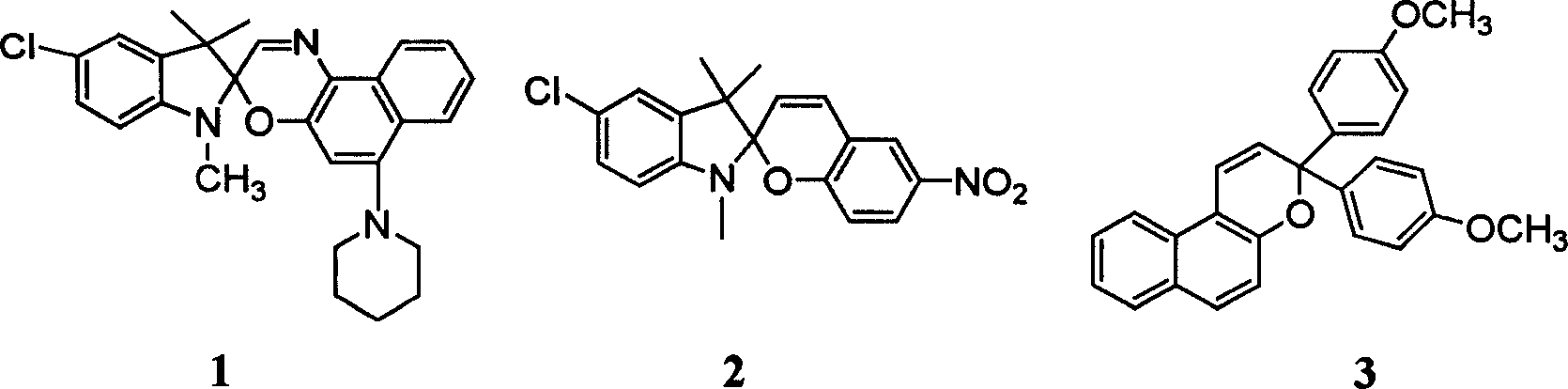

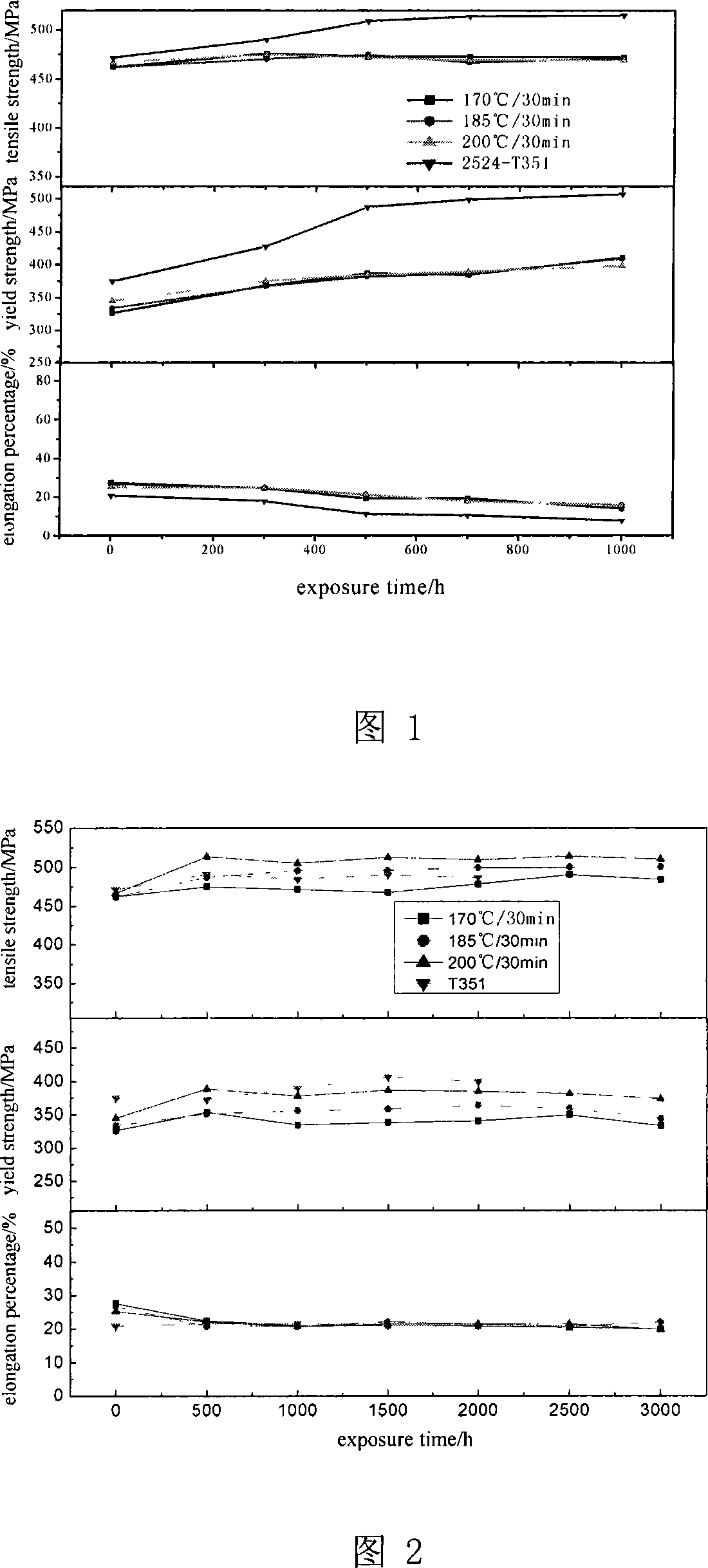

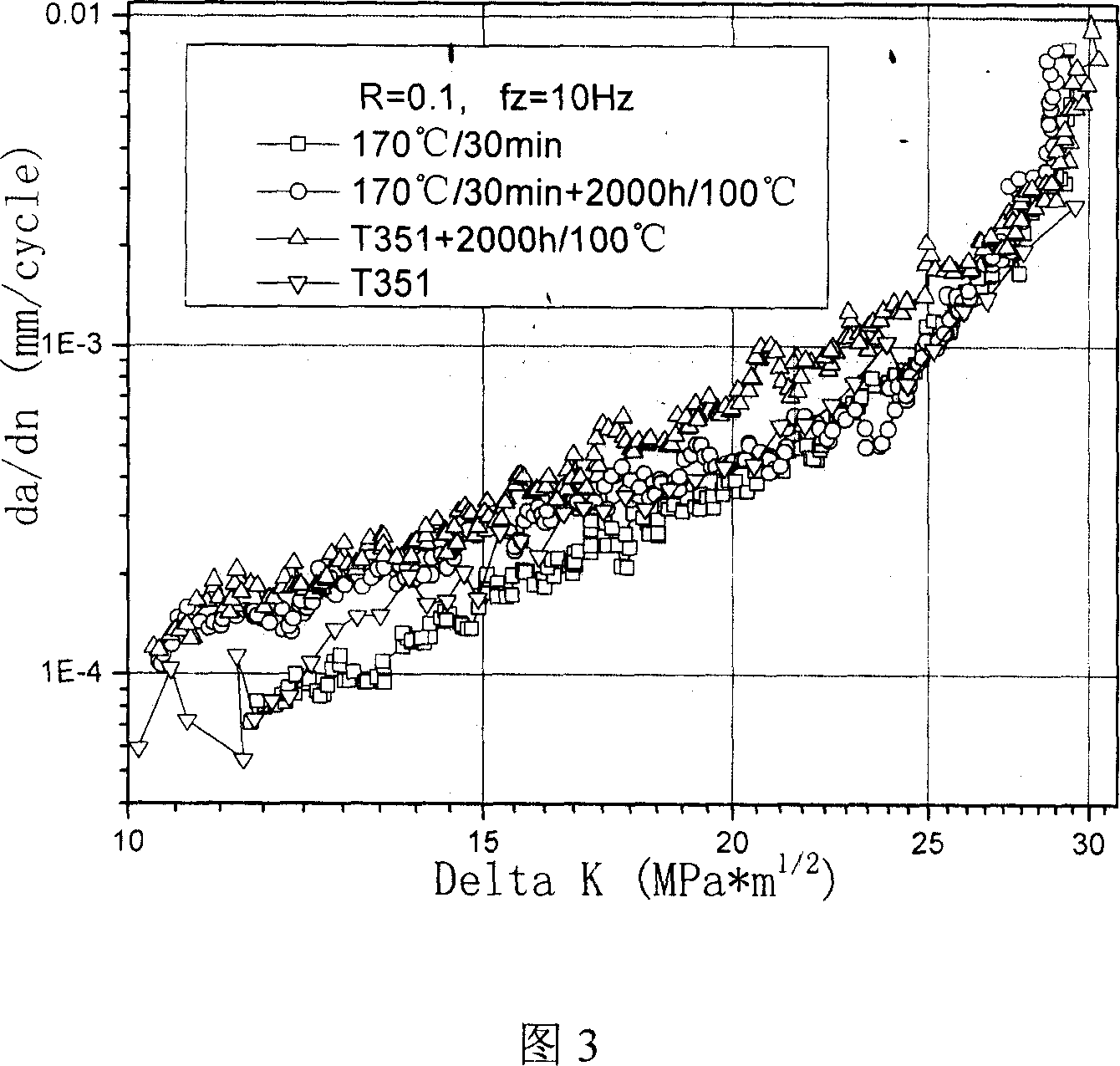

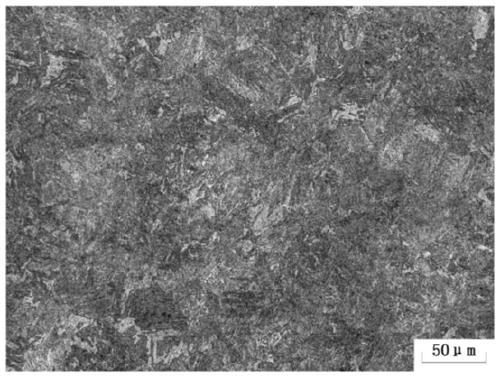

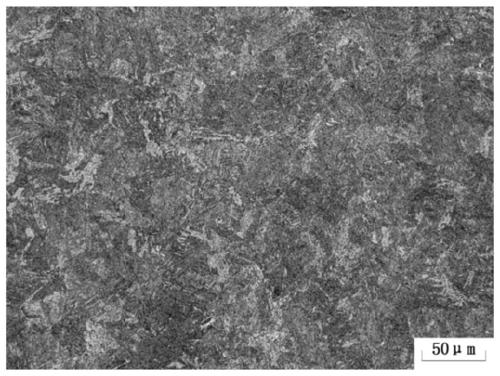

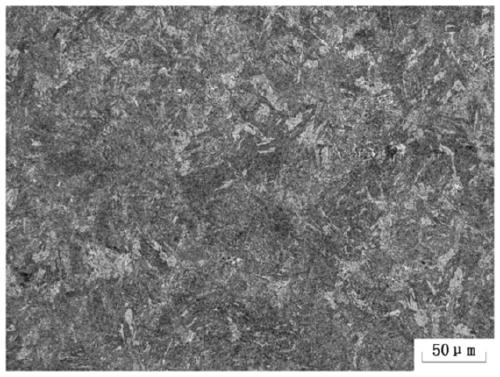

Treatment method for providing aluminum alloy with high thermal stability anti-fatigue microstructure

The present invention discloses one heat treating process for aluminum alloy to obtain anitfatigue microstructure with high heat stability. The treating process for aluminum alloy plate includes the first solution treatment at 490-500 deg.c, and the subsequent artificial ageing treatment at 170-200 deg.c for 20-60 min. The heat treating process makes the Al-Cu-Mg alloy obtain reinforcing GPB structure in relatively large size, excellent antifatigue performance, delayed degradation of the antifatigue performance and anitfatigue microstructure with high heat stability.

Owner:CENT SOUTH UNIV

Manometer layered silicate clay modified phenolic resin and preparation method thereof

The invention discloses a preparation method of a nanometer layered silicate clay modified phenolic resin. The preparation method comprises the following steps: (1) performing organic modification on the nanometer layered silicate clay; (2) preparing modified phenol; (3) adding the modified phenol prepared in the step (2), methyl aldehyde and a basic catalyst into a reactor, uniformly stirring, warming to begin reaction, after the reaction is finished, according to the viscosity of materials, replenishing water or performing vacuum dewatering, so as to enable the viscosity of the materials to reach 300-3000 cps to obtain the nanometer clay modified phenolic resin. According to the invention, the nanometer layered silicate clay is adopted to modify the phenolic resin, and a composite material manufactured and formed after the phenolic resin and a corresponding acid curing agent are compounded with fiber materials, and cured at 25-80 DEG C is stable in reaction to fire, has excellent F / S / T performance, reaches 1a level of a BS6853 test, and also has excellent performance such as high mechanical strength, fatigue durability, heat resistance and strong acid corrosion resistance.

Owner:陈精明

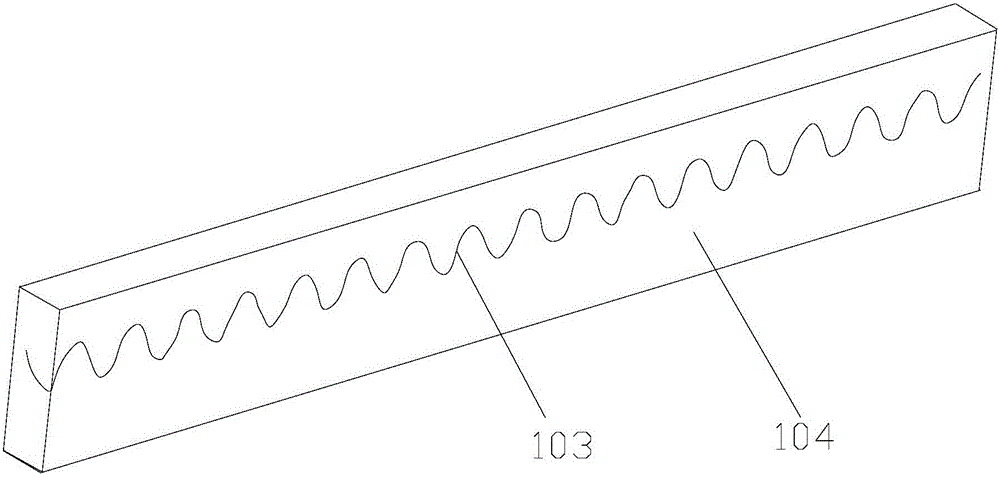

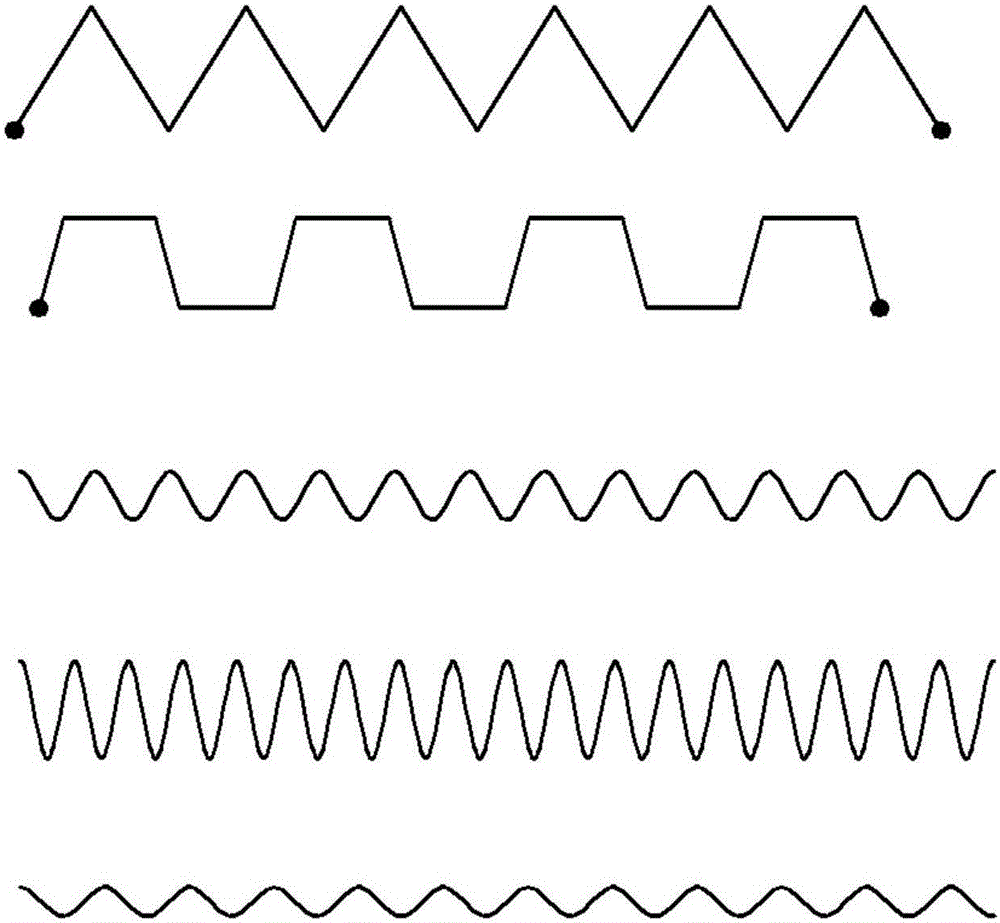

Flexible stretchable and washable conductive connecting piece

ActiveCN105895199AGood flexibilityGood fatigue resistanceConductive layers on insulating-supportsEngineeringConductive materials

The invention discloses a flexible stretchable and washable conductive connecting piece. The flexible stretchable and washable conductive connecting piece is a composite conductive connecting piece formed by combination of a conductive material and a non-conductive material, the conductive material and the non-conductive material are simultaneously stretched and reset, and the electrical property remains unchanged. The conductive material and the non-conductive material are processed into the conductive connecting piece in the form of a fabric through a combined weaving process according to a wire arranging method, or the conductive connecting piece in the form of the fabric is sealed in an elastic base material made of the non-conductive material to fabricate the composite conductive connecting piece, or the conductive material is directly buried in the elastic base material to fabricate the composite conductive connecting piece. The flexible stretchable and washable conductive connecting piece has the advantages of good flexibility, wash resistance and excellent fatigue durability, and can be stretched substantially, the cyclic load and a resistance value after washing are small in change, the electric signal transmission is stable and reliable, good adhesion to the surface of a human body can be achieved, and the flexible stretchable and washable conductive connecting piece can replace a metal wire and a printed circuit to be applied to intelligent clothes and intelligent wearable devices.

Owner:ZHUHAI ADVANPRO TECH

Production technique of antifatigue aluminum alloy section

The invention discloses a production technique of an antifatigue aluminum alloy section. The alloy comprises the following elements in percentage by mass: 3.5-4.2% of Cu, 1.2-1.8% of Mg, 0.4-0.8% of Mn, 0.10-0.15% of Zn, 0.1-0.2% of,Sb0.2-0.3% of Ti, 0.35-0.45% of Zr, 0.08-0.12% of Fe, 0.04-0.06% of Si, 0.03-0.05% of Ge, 0.02-0.03% of Bi, 0.04-0.08% of RE, 0.002-0.003% of B and the balance of Al. The contents of Fe, Si and other impurity elements are lowered to improve the fracture toughness, fatigue resistance and stress corrosion resistance of the alloy; and the rare earth metal elements, including Pr, Nd and La, in the modifier can form high-thermohardening-property complex component compounds in the aluminum alloy which are reticularly distributed on the grain boundary or among the dendrite, thereby refining the structure, effectively preventing the base transformation and movement of crystal boundaries, and further obviously enhancing the high temperature properties of the alloy.

Owner:ANHUI HUANYU ALUMINUM

Treatment method for brass texture antifatigue aluminum alloy panel

The invention relates to a treatment method for a brass texture antifatigue aluminum alloy panel, which is characterized in that multiple times of warm rolling is performed on an aluminum alloy hot rolling material until reaching the designed thickness of the aluminum alloy panel, and after annealing treatment and solution treatment, short-term artificial aging is performed. According to the invention, a treatment process of multiple times of warm rolling and annealing is adopted; by virtue of warm rolling, grains of the alloy can be effectively refined, the return process of alloy can be promoted, deformation energy storage can be reduced, and recrystallization can be inhibited; and by virtue of primary annealing treatment, annealing temperature and heat insulation time can be controlled, grains cannot grow up, and a deformation texture can be retained, thus obtaining a relatively strong deformation texture. The treatment method is simple in process method and convenient to operate, can effectively improve the composition and the volume fraction of the texture in an aluminum alloy matrix, can effectively prolong the fatigue life of the aluminum alloy on the premise of ensuring that aluminum alloy strength and ductility meet alloy performance requirements, is suitable for industrial application, and provides a feasible technical solution for preparation of aluminum alloy material for aviation and spaceflight.

Owner:湖南润泰新能源科技有限公司

Polyamide, polyamide composition, and molded article

ActiveUS20150175744A1Excellent high temperature strengthGood fatigue resistanceSpecial tyresDiaminePolyamide

A polyamide comprising a unit containing at least one (a) alicyclic dicarboxylic acid and a unit containing a (b) diamine having 8 or more carbon atoms, wherein the polyamide satisfies the following conditions (1) and (2): (1) a sulfuric acid relative viscosity ηr at 25° C. is 2.3 or more; and (2) Mw (weight average molecular weight) / Mn (number average molecular weight) is 4.0 or less.

Owner:ASAHI KASEI CHEM CORP

Aramid tire cord and manufacturing method thereof

ActiveUS20110048604A1Good fatigue resistanceHigh travel performanceArtificial filament physical treatmentPneumatic tyre reinforcementsAutomotive engineeringTensile strain

Disclosed is aramid tire cord and a method for manufacturing the same, wherein the aramid tire cord has superior properties on initial modulus change rate, tensile strain, initial modulus and strength retention rate, wherein the initial modulus change rate is not more than 5% after the aramid tire cord is repetitively extended 10 times at 120° C. under the condition that the load corresponding to 10% of the strength at break is applied thereto. Thus, the aramid tire cord of the present invention has the most optimal modulus, optimal crystallization constant and optimal crystalline orientation constant so that the aramid tire cord is superior in its initial modulus change rate, tensile strain and initial modulus retention rate, to thereby obtain good fatigue resistance. Thus, if the aramid tire cord of the present invention is used for a tire-reinforcing material, it is possible to obtain high traveling performance by preventing the property deterioration during the high-speed traveling with repetitively-occurring sequence of high temperature and high pressure.

Owner:KOLON IND INC

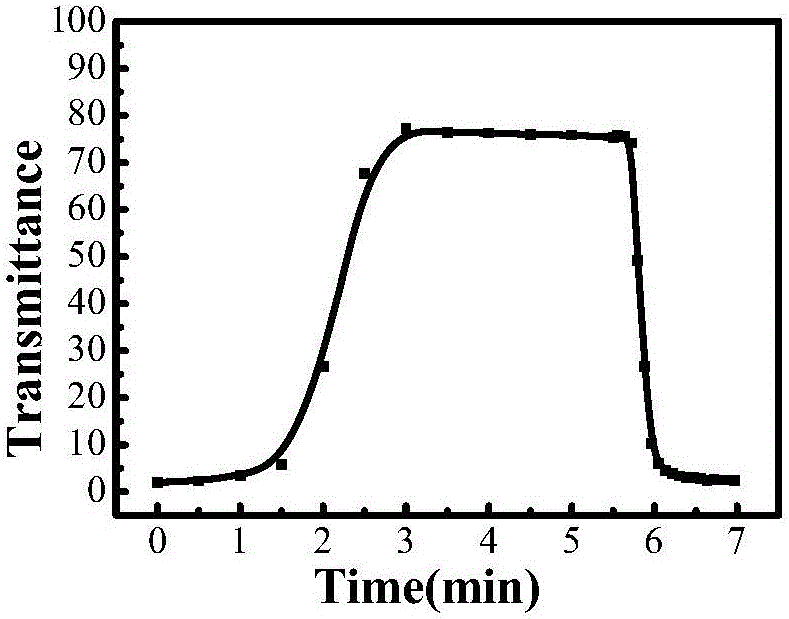

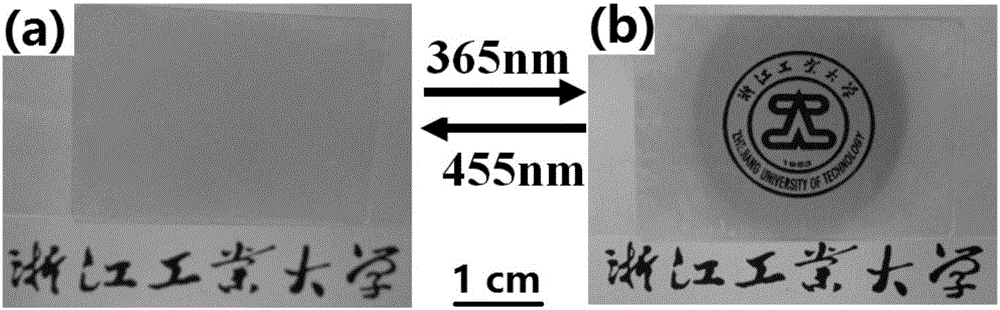

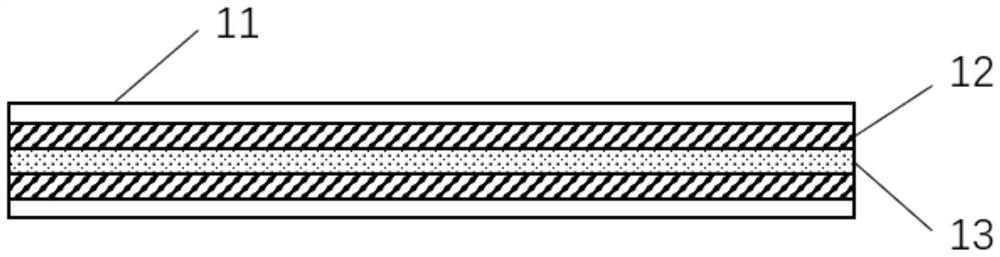

Stretchable photoresponse liquid crystal light scattering display screen and manufacturing method thereof

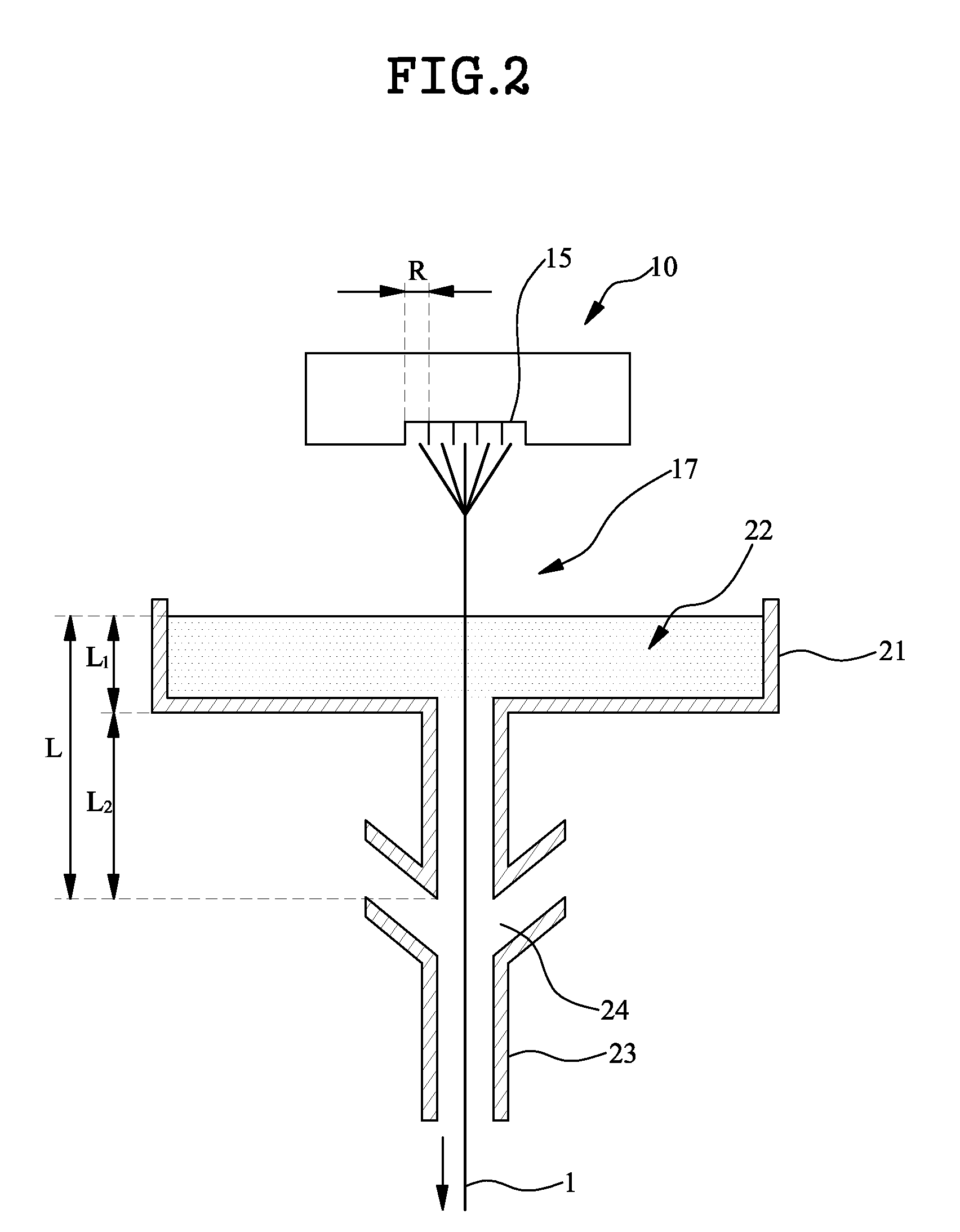

ActiveCN105137640AGood fatigue resistanceSimple preparation processLiquid crystal compositionsNon-linear opticsPolyurethane membraneImage contrast

The invention discloses a stretchable photoresponse liquid crystal light scattering display screen and a manufacturing method thereof. The stretchable photoresponse liquid crystal light scattering display screen is manufactured by coating azobenzene-containing liquid crystal physical gel on the surface of a stretchable membrane and then covering another stretchable membrane on the surface of the azobenzene-containing liquid crystal physical gel. The azobenzene-containing liquid crystal physical gel comprises the following components by weight percent: 89.7-98.9% of liquid crystal matrix compound, 1-8.7% of azobenzene compound and 0.1-1.6% of gelator, and the stretchable membrane is a polyurethane membrane or a PDMS membrane. The stretchable photoresponse liquid crystal light scattering display screen disclosed by the invention is simple in manufacturing process, has photoresponse, long stability time under visible light, good tensile property, and good anti-fatigue performance, can be repeatedly used, and has the characteristics of wide view, high luminance and high image contrast.

Owner:ZHEJIANG UNIV OF TECH

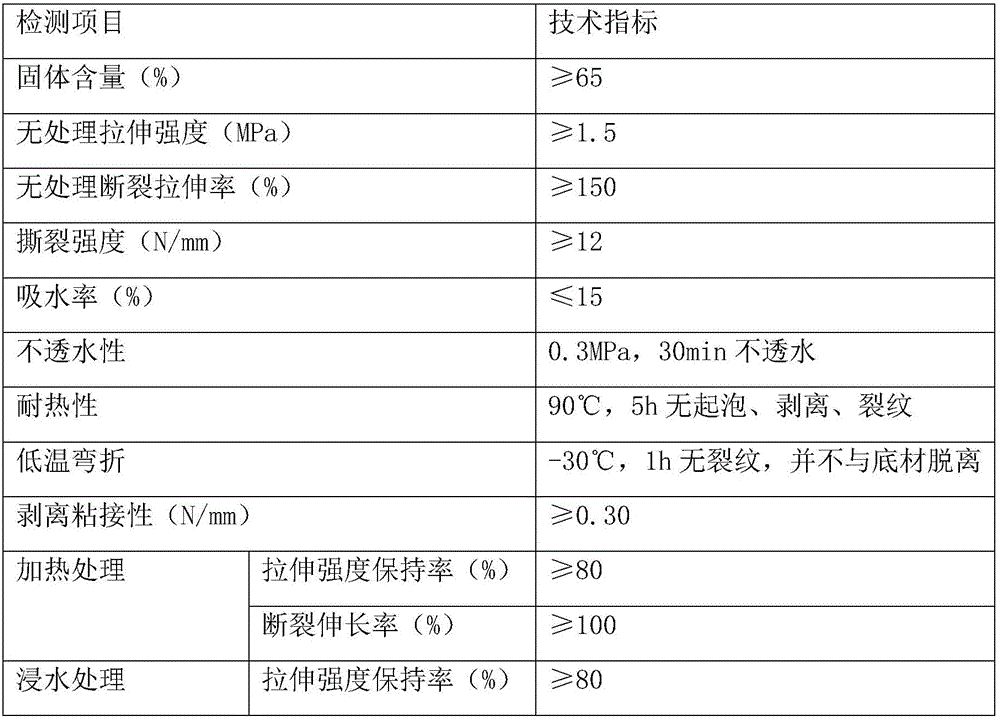

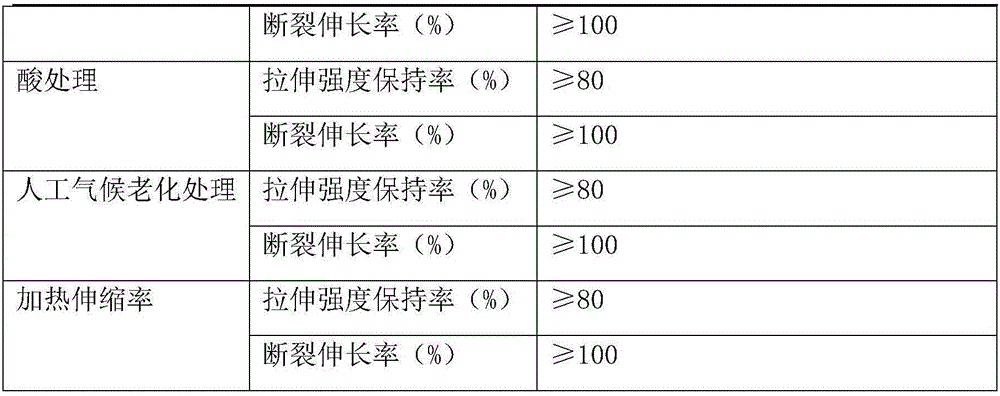

Special roof-spraying waterproof material

ActiveCN106221450AImprove adhesionImprove sealingFireproof paintsAntifouling/underwater paintsEpoxyLow speed

The invention discloses a special roof-spraying waterproof material. The special roof-spraying waterproof material is prepared from, by weight, 400-550 parts of emulsion, 80-120 parts of silica powder, 300-400 parts of calcite powder, 40-60 parts of rutile titanium dioxide, 30-50 parts of deionized water, 2-4 parts of dispersing agent, 2-4 parts of defoaming agent, 1.5-2.5 parts of preservative, 0.8-1.2 parts of ultraviolet light absorber and 0.8-1.2 parts of anti-aging agent. A preparing method of the special roof-spraying waterproof material includes the steps that the silica powder, the calcite powder, the rutile titanium dioxide, the deionized water, the dispersing agent, the defoaming agent, the preservative, the ultraviolet light absorber and the anti-aging agent are stirred to be even at a high speed, the emulsion is added at a low speed, the mixture is stirred to be even, and the special roof-spraying waterproof material is obtained through filtering. The emulsion is acrylic emulsion or a mixture of acrylic emulsion and aliphatic-series waterborne polyurethane emulsion or a mixture of acrylic emulsion and waterborne epoxy resin emulsion. The special roof-spraying waterproof material is mainly used for water resisting of roofs.

Owner:成都市嘉洲新型防水材料有限公司

Preparation method of PVC foam glove

The invention relates to a preparation method of a PVC foam glove. The method comprises the steps of: S1: preparing a material A: mixing 30-55 parts of PVC resin powder, 35-65 parts of a plasticizer,0.2-4 parts of a stabilizer, 0.3-8 parts of a viscosity reducer and 0.2-5 parts of a foaming agent, and fully stirring the substances to obtain a material A, and conducting standing for 15-50h for standby use; S2: preparing a material B: firstly adding 0.1-5 parts of butyronitrile powder into 35-65 weight parts of the material A, then adding 0.1-3 parts of PVC resin powder, 0.1-3 parts of a foaming aid and 0.1-2 parts of an anti-sagging agent, and conducting further stirring, finally pouring 5-25 parts of water and 3-20 parts of oil agent, stirring the substances evenly, then conducting standing for 4h or more for standby use; S3: impregnating a glove blank in the material B, and carrying out rubber dripping and homogenizing; and S4: performing drying and plasticizing to obtain the wear-resistant PVC foam glove. The method provided by the invention can prepare the PVC foam glove with breathability, softness, comfortable hand feel, excellent wear resistance, tear resistance and punctureresistance, improves the comprehensive performance of the PVC glove and expands the scope of application.

Owner:SHANDONG XINGYU GLOVES

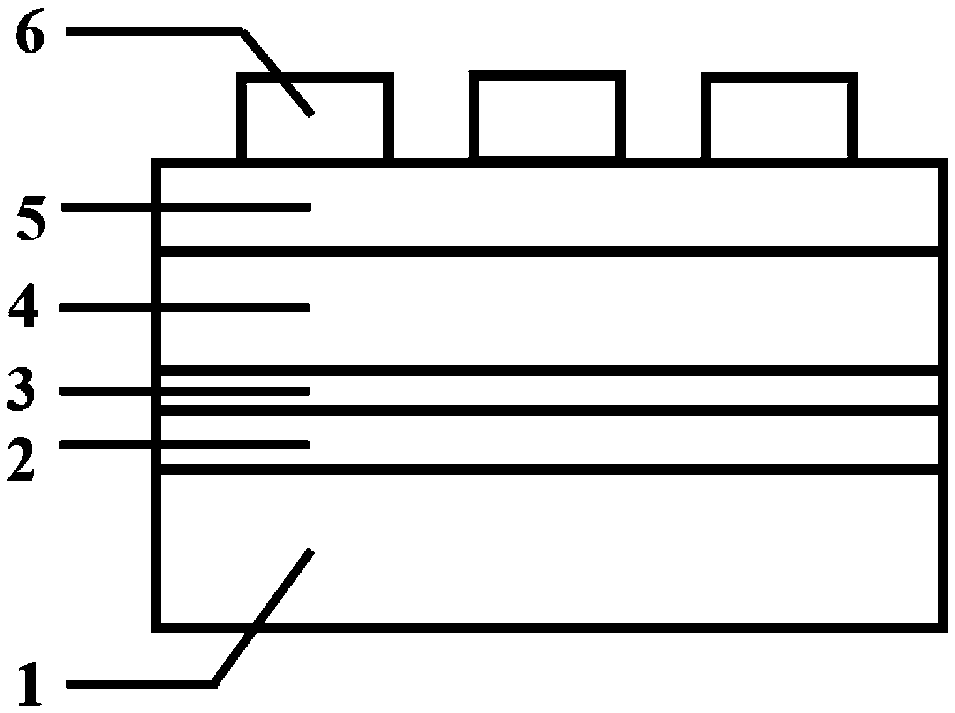

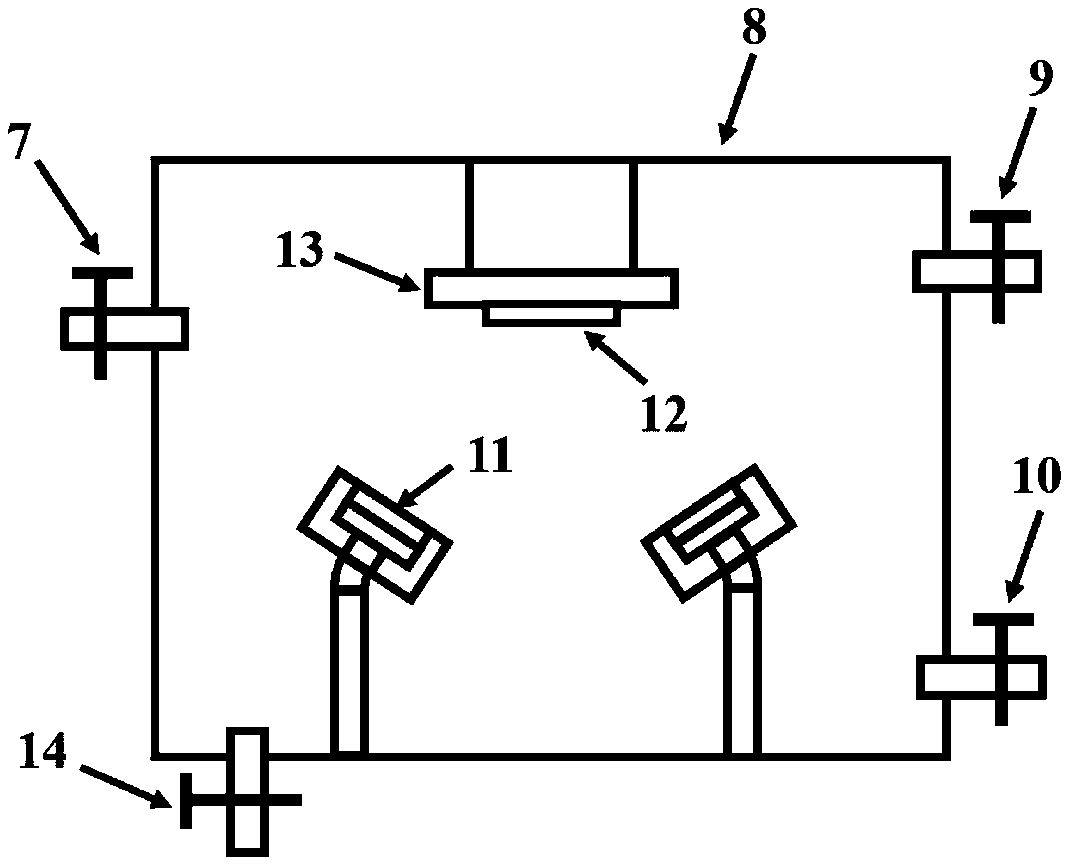

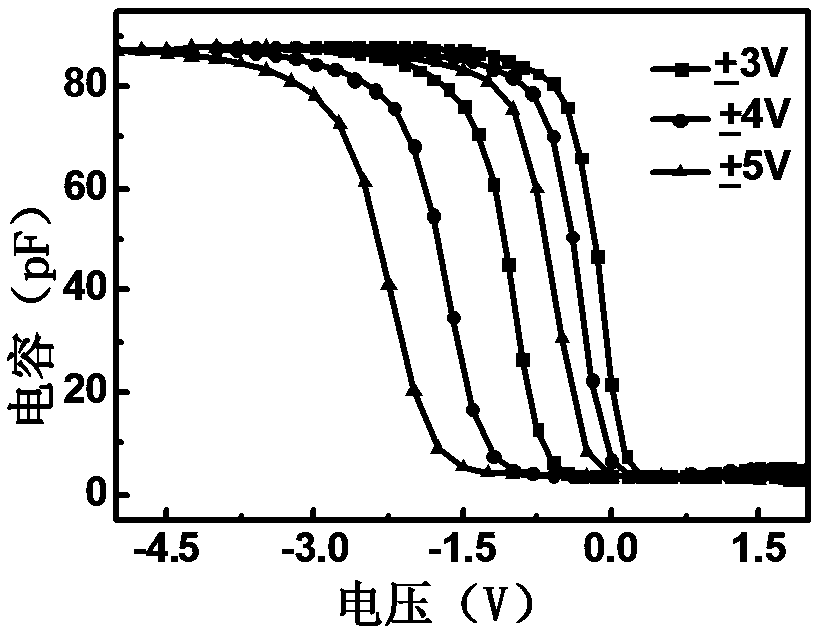

Low power consumption charge trapping type storage device based on graphene oxide quantum dots and preparation method thereof

ActiveCN107768379AReduce operating voltageGood fatigue resistanceSolid-state devicesSemiconductor devicesBlock layerBlocking layer

The invention provides a low power consumption charge trapping type storage device based on graphene oxide quantum dots and a preparation method thereof. The storage device is structurally composed ofan Si substrate, an SiO2 tunneling layer, a GQODs / Zr0.5Hf0.5O2 trapping layer, an SiO2 blocking layer and a Pd top electrode in sequence. The preparation method comprises the following steps: carrying out cleaning corrosion on the Si substrate, carrying out high temperature annealing growth on the SiO2 tunneling layer, uniformly paving a GQODs layer on the SiO2 tunneling layer by using an SC-1B spin coater, and plating a trapping layer, a blocking layer and an electrode film layer on an existing structure through a magnetron sputtering method. Relative to a general charge trapping type storage device, the storage device has the advantages of relatively low operating voltage, high fatigue resistance, data storage durability, large storage window, little charge leakage, low power consumption, low cost and the like, is extremely applicable for being applied to electronic equipment, and has certain market application values.

Owner:HEBEI UNIVERSITY

Shock-reducing rubber

InactiveCN104610591AImprove shock absorptionImprove sound insulationManufacturing technologyPolymer science

The invention discloses shock-reducing rubber and relates to the technical field of manufacturing of rubber products. The shock-reducing rubber is prepared from the following raw materials in parts by weight: 90-100 parts of natural rubber, 6-10 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of an accelerator TE, 2-2.5 parts of sulfur, 2.5-3 parts of an anti-aging agent 4020 and 35-45 parts of carbon black. The shock-reducing rubber is high in both elasticity and viscosity and has the advantages of good shock-reducing, sound-insulation and buffer properties, excellent heat resistance and fatigue resistance, small possibility in aging and long service life.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

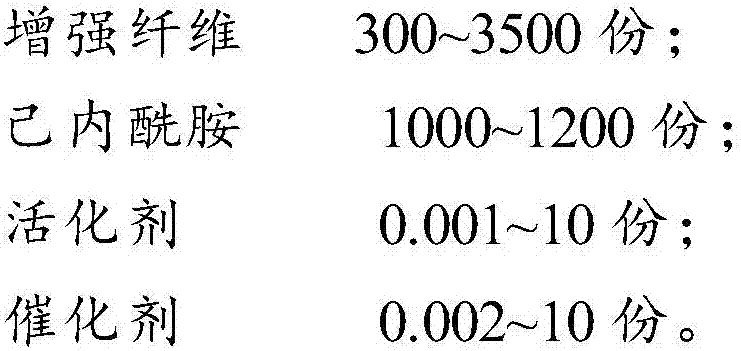

Automobile-cantilever-beam supporting system and preparing method thereof

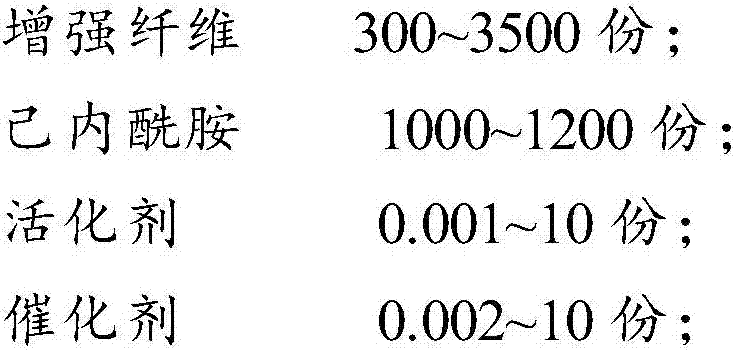

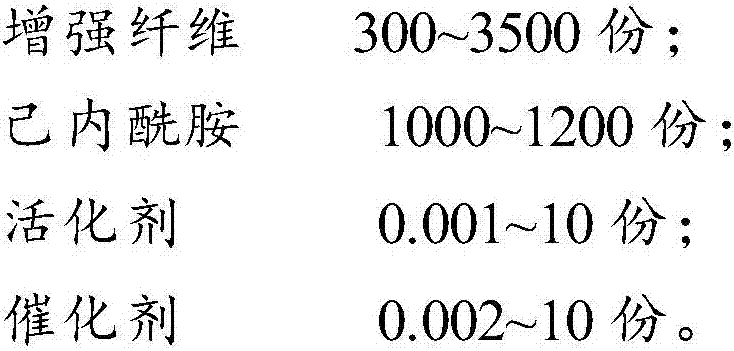

The invention provides an automobile-cantilever-beam supporting system. The automobile-cantilever-beam supporting system comprises an automobile-cantilever-beam supporting rod piece and an automobile-cantilever-beam supporting fixing end. The automobile-cantilever-beam supporting rod piece is prepared from, by weight, 300-3,500 parts of reinforced fibers, 1,000-1,200 parts of caprolactam, 0.001-10 parts of an activating agent and 0.002-10 parts of a catalyst; the automobile-cantilever-beam supporting fixing end is prepared from, by weight, 1,000-1,200 parts of caprolactam, 0.001-10 parts of an activating agent and 0.002-10 parts of a catalyst. According to the automobile-cantilever-beam supporting system, the specific-ratio reinforced fibers, caprolactam, activating agent and catalyst are used as the supporting rod piece in cooperation with the specific-ratio supporting fixing end, and therefore the automobile-cantilever-beam supporting system is prepared. Nonmetal is used as a raw material, the obvious lightweight effect is achieved, and meanwhile the mechanical performance and the anti-fatigue performance are better.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Niobium-containing axle for urban rails and subways and heat treatment technology thereof

InactiveCN111270168AHigh strengthGood fatigue resistanceFurnace typesHeat treatment furnacesPhysicsMetallurgy

The invention provides a niobium-containing axle for urban rails and subways and a heat treatment technology thereof. The axle is prepared from the components of: 0.34 0.39% of C, 0.20 0.35% of Si, 1.40 1.60% of Mn, 0.25 0.45% of Cr, 0.10 0.20% of Ni, 0.10 0.20% of Mo, 0.015 0.050% of Nb, 0.0010 0.0050% of Ca, 0.0015 0.0030% of B, less than or equal to 0.010% of P, less than or equal to 0.008% ofS, less than or equal to 0.0010% of T[O], 0.015 0.035% of Als, and the balance of Fe and other unavoidable impurities. According to niobium-containing axle for urban rails and subways and the heat treatment technology thereof, the heat treatment technology of "normalizing + tempering (quenching + tempering at high temperature)" is adopted, and the axle has the advantages of low cost, high strengthand excellent fatigue resistance.

Owner:MAANSHAN IRON & STEEL CO LTD

Composite electrochromic material as well as preparation method and application thereof

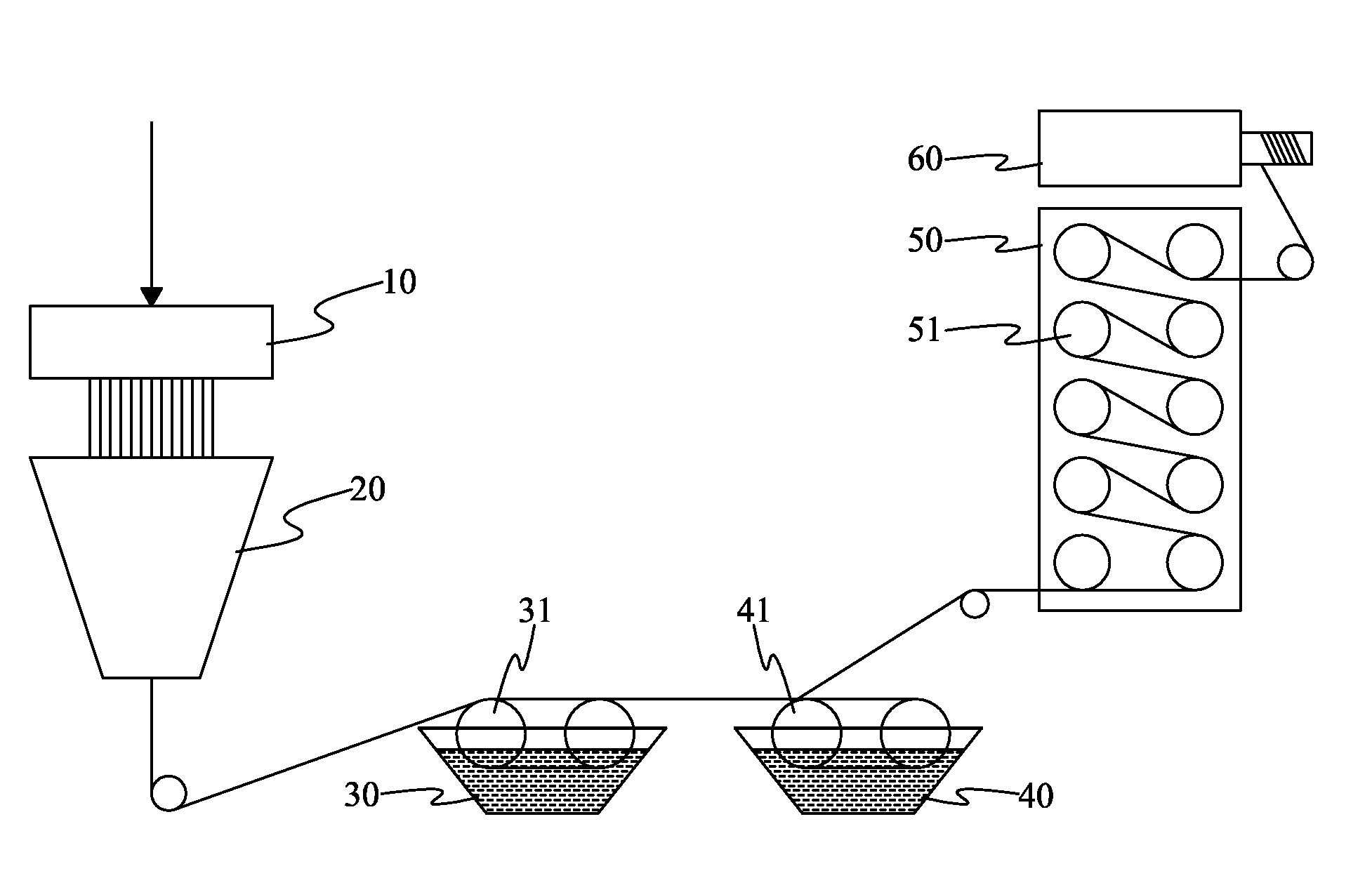

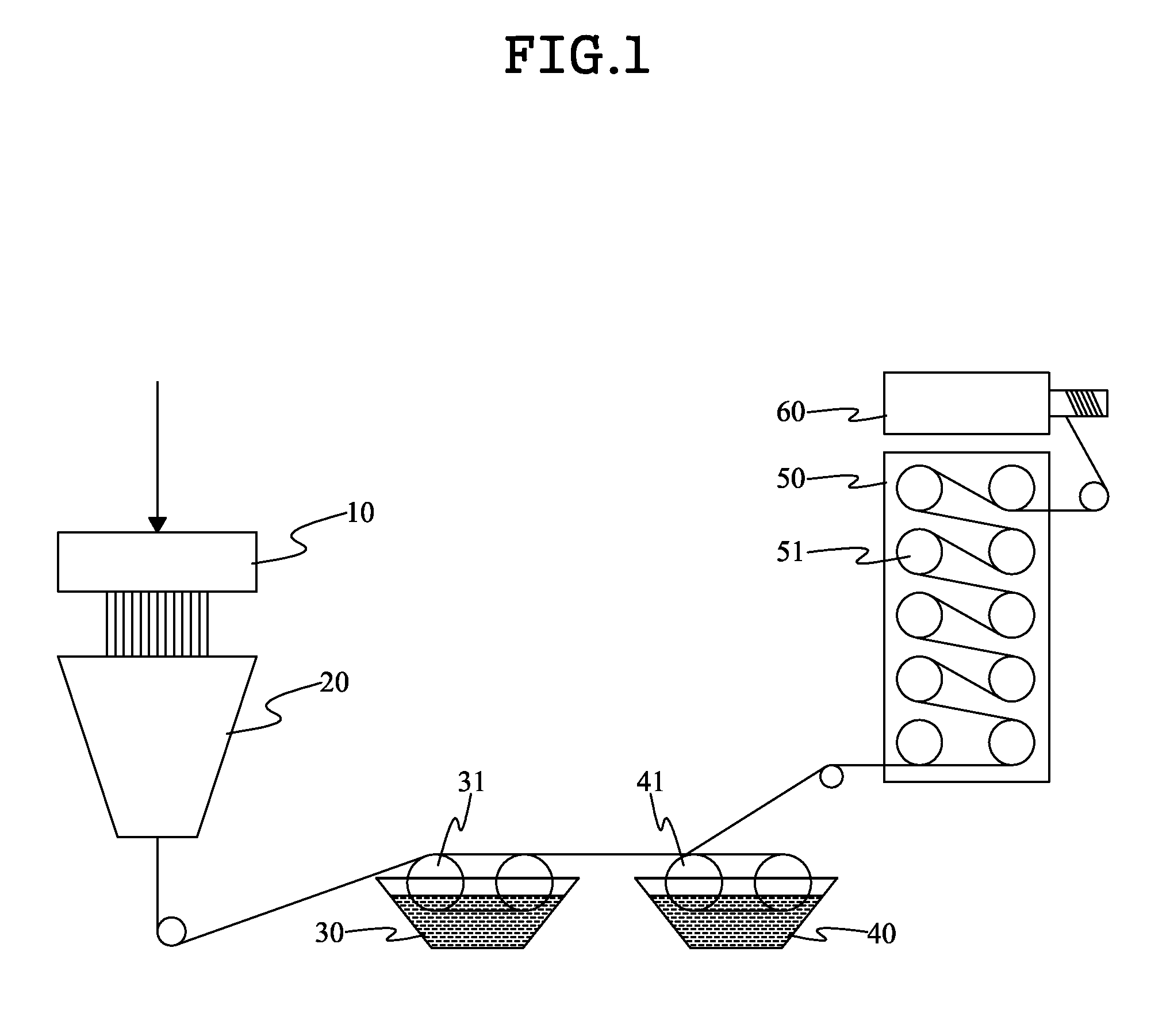

ActiveCN113106570AReduce thicknessDoes not affect flexibilityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberSpinning

The invention discloses a composite electrochromic material as well as a preparation method and application thereof. The composite electrochromic material comprises a core layer, a skin layer with an electrochromic function and a light-permeable flexible high polymer material protection layer which are sequentially arranged, wherein the core layer material comprises a conductive mixture with fluidity; the conductive mixture comprises liquid metal and a carboxylated carbon nanotube; and the mass ratio of the carboxylated carbon nanotube to the liquid metal is (2-5): 100, the length of the carboxylated carbon nanotube is 15-30 [mu]m, the inner diameter of the carboxylated carbon nanotube is 6-10 nm, and the outer diameter of the carboxylated carbon nanotube is 12-20 nm. The preparation method comprises the following steps of performing spinning by adopting a three-channel nozzle co-extrusion method to prepare hollow double-layer fiber which comprises a skin layer and a protective layer and is provided with a cavity, and injecting the conductive mixture into the cavity of the hollow double-layer fiber. The material has excellent deformability, a stable and sensitive color changing function and a controllable deformation degree, still has a relatively stable color changing function under the condition of serious deformation, is good in fatigue resistance and is suitable for preparing intelligent textiles.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Shock-reducing rubber

The invention discloses a shock-reducing rubber, and relates to the technical field of rubber product manufacture. The shock-reducing rubber is prepared from the following raw materials in parts by weight: 90-100 parts of chloroprene rubber, 5-8 parts of zinc oxide, 1-1.5 parts of stearic acid, 0.7-1 part of accelerants M, 2-3 parts of anti-aging agents A, 1-2 parts of anti-aging agents 4010 NA and 30-40 parts of carbon black. The shock-reducing rubber disclosed by the invention has the advantages of high-elasticity state, high-viscosity state, good shock-reducing property, sound-insulating property and buffer property, good heat resistance and fatigue resistance, low possibility in aging and long service life.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

Making method of anti-fatigue copper alloy wire for automobile elastic element

The invention discloses a making method of an anti-fatigue copper alloy wire for an automobile elastic element. The anti-fatigue copper alloy wire comprises 2-4wt% of Al, 1.2-2.4wt% of Sn, 0.5-1.5wt% of Ni, 0.6-0.12wt% of Zn, 0.4-0.8wt% of Sb, 0.25-0.35wt% of Bi, 0.03-0.06wt% of As, 0.015-0.025wt% of B, 0.01-0.02wt% of Pd, 0.005-0.015wt% of Ru, 0.02-0.03wt% of Er, 0.015-0.025wt% of Tb, 0.005-0.01wt% of P, and the balance Cu and inevitable impurities. The cooper alloy wire has the advantages of good fatigue resistance, no fracture after long term use, long service life, good wear resistance, high mechanical strength, high fatigue ageing resistance, low processing cost and the like.

Owner:安徽新辰汽车制造有限公司

Rubber cushion pad

The invention relates to a rubber cushion pad. The rubber cushion pad consists of the following components in parts by weight: 80 to 90 parts of natural rubber, 20 to 30 parts of polyurethane rubber,20 to 30 parts of talcum powder, 10 to 20 parts of silica-alumina carbon black, 3 to 5 parts of lignocellulose, 1 to 3 parts of sulphur, 3 to 5 parts of zinc oxide, 0.5 to 0.9 part of stearic acid, 1to 3 parts of an anti-aging agent, 4 to 6 parts of high aromatic oil and 2 to 4 parts of paraffin, wherein the anti-aging agent is a mixture of a p-phenylenediamine anti-aging agent and a di-hydro-quinoline anti-aging agent, and the mass ratio of the p-phenylenediamine anti-aging agent to the di-hydro-quinoline anti-aging agent is (1.3 to 1.9): 1. The rubber cushion pad has the advantages that therubber cushion pad takes natural rubber and polyurethane rubber as main raw materials, lignocellulose and the anti-aging agent are added into the main raw materials, and the raw materials have synergistic effect, so that the prepared rubber cushion pad has the characteristics of abrasion resistance, low creep, fatigue resistance and good cushioning effect.

Owner:江苏海迅铁路器材集团股份有限公司

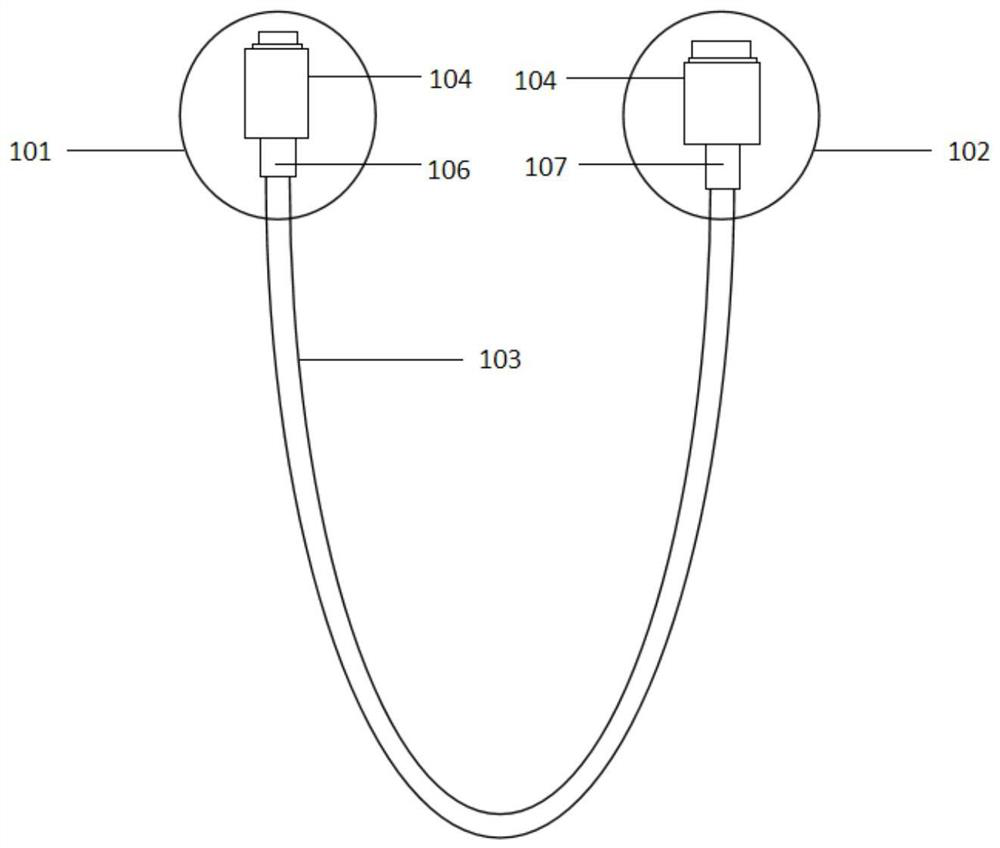

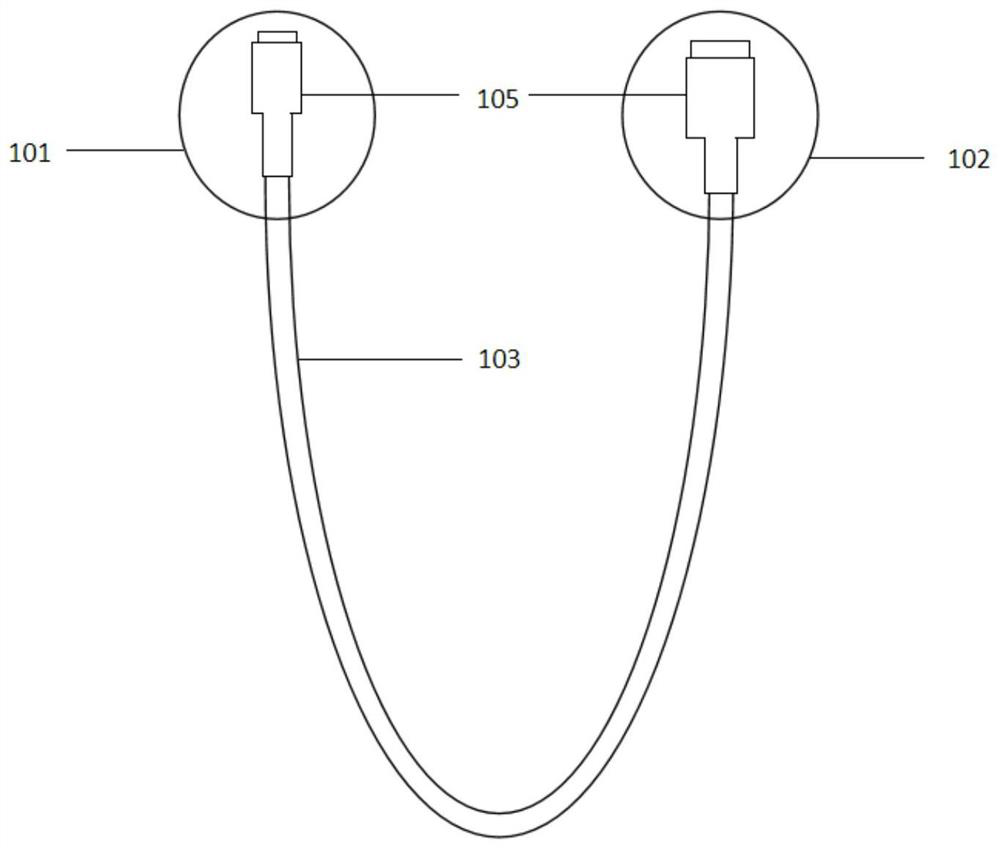

High-tension-bearing data line and preparation method thereof

InactiveCN113214595ATightly boundImprove rigidityCoupling device connectionsContact member manufacturingWeather resistanceEngineering

The invention relates to the field of data lines, in particular to a high-tension-bearing data line which comprises a power end connector and a data end connector, the power end connector and the data end connector each comprise a chip, an inner mold layer and an outer mold layer, and the inner mold layers are made of ABS / PC / TPV composite materials; and the ABS / PC / TPV composite material is prepared from the following raw materials: ABS, PC, TPV, a lubricant, a functional auxiliary agent and a compatilizer. The prepared data line is not easy to break when being bent and stretched, can bear large tensile force, has good weather resistance, wear resistance and aging resistance, and is long in service life.

Owner:深圳市麦沃电子科技有限公司

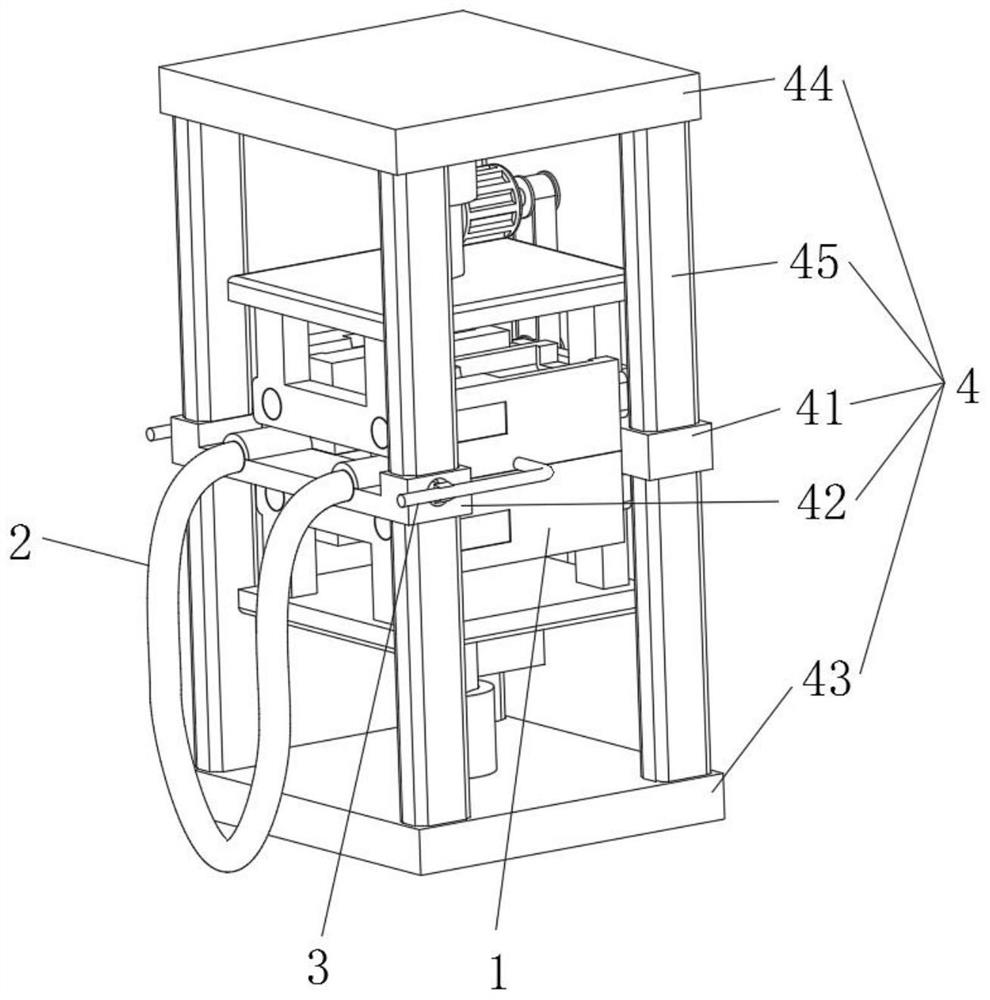

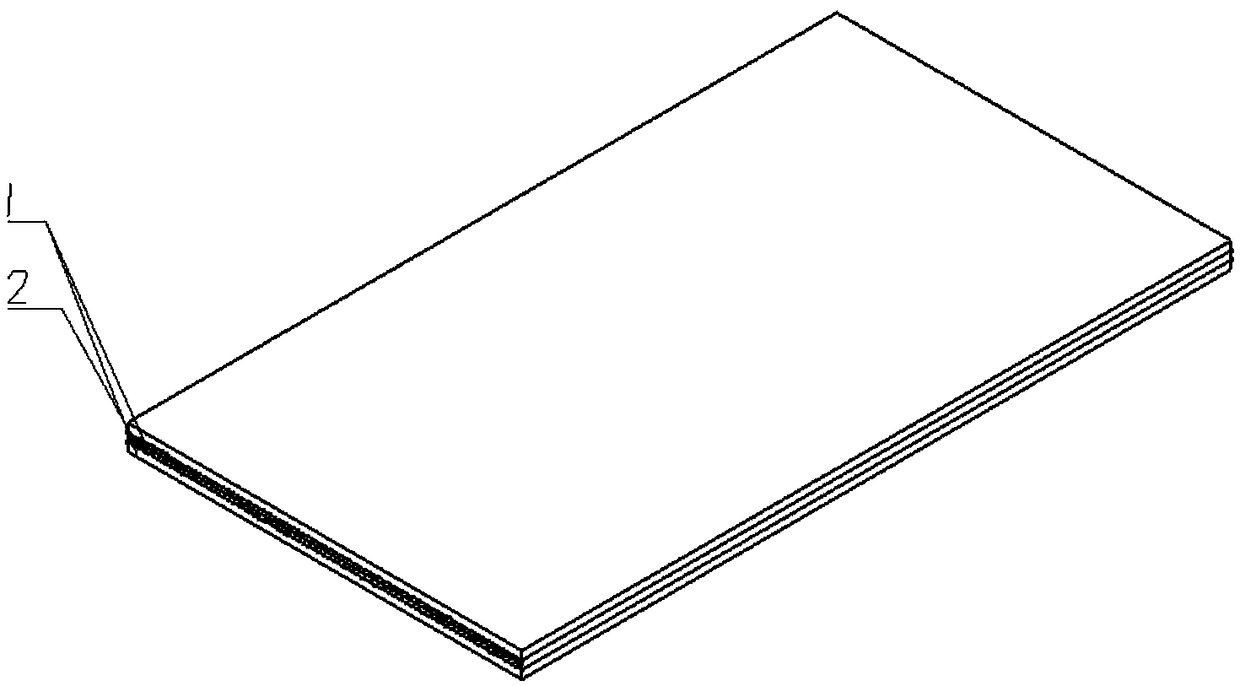

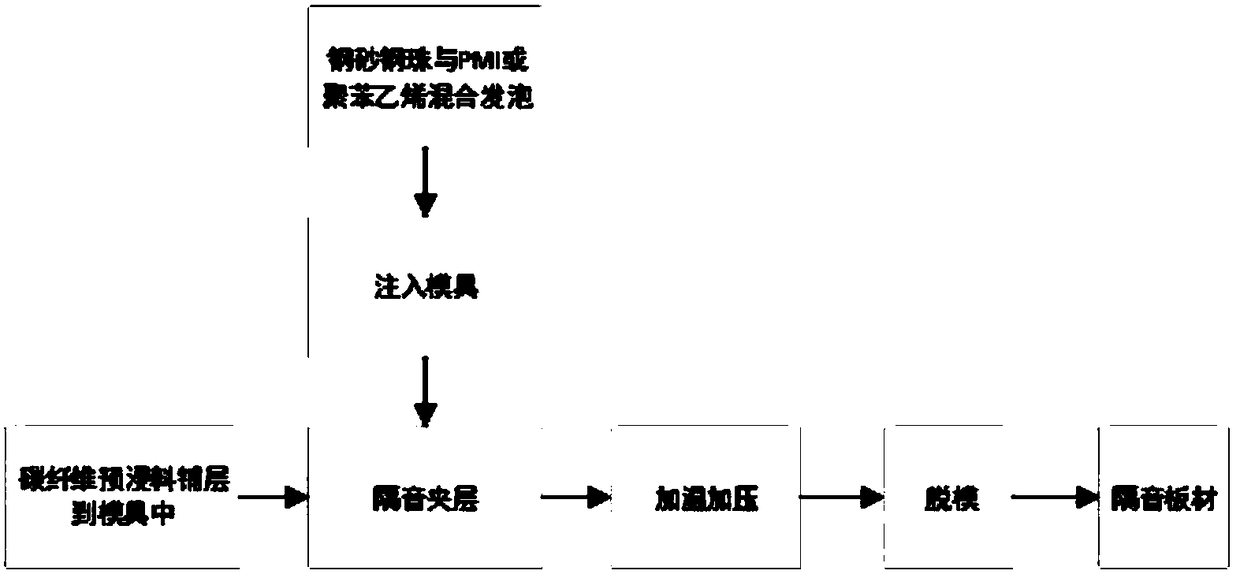

Carbon fiber interlayer composite acoustic panel and preparation method and application thereof

PendingCN108705821AImprove ride experienceGood fatigue resistanceLamination ancillary operationsSynthetic resin layered productsAcoustic boardMaterials processing

The invention relates to a carbon fiber interlayer composite acoustic panel and a preparation method and application thereof. The carbon fiber interlayer composite acoustic panel comprises a carbon fiber upper surface skin layer, a carbon fiber lower surface skin layer and at least one sound insulation and vibration insulation composite interlayer arranged between the carbon fiber upper surface skin layer and the carbon fiber lower surface skin layer; the sound insulation and vibration insulation composite interlayer is manufactured from a foaming foam board containing steel grit or steel balls. According to the sound insulation effect requirement, the thickness of the sound insulation composite interlayer is designed, the material preparation ratio of the sound insulation interlayer is changed, adjustment is performed, the specific sound insulation requirement is met by regulating the ratio of steel grit or steel balls to the foam layer, the more vibration insulation interlayers are embedded, the better the sound insulation effect is, the sound insulation material processing technology is simple and easy to implement, design can be performed according to the appearance, the high designability is achieved, and integrated molding can be achieved. The sound insulation material can be used for non-main-force-bearing protective components such as side walls, end walls, roofs and door plates of high-speed trains.

Owner:CRRC IND INST CO LTD

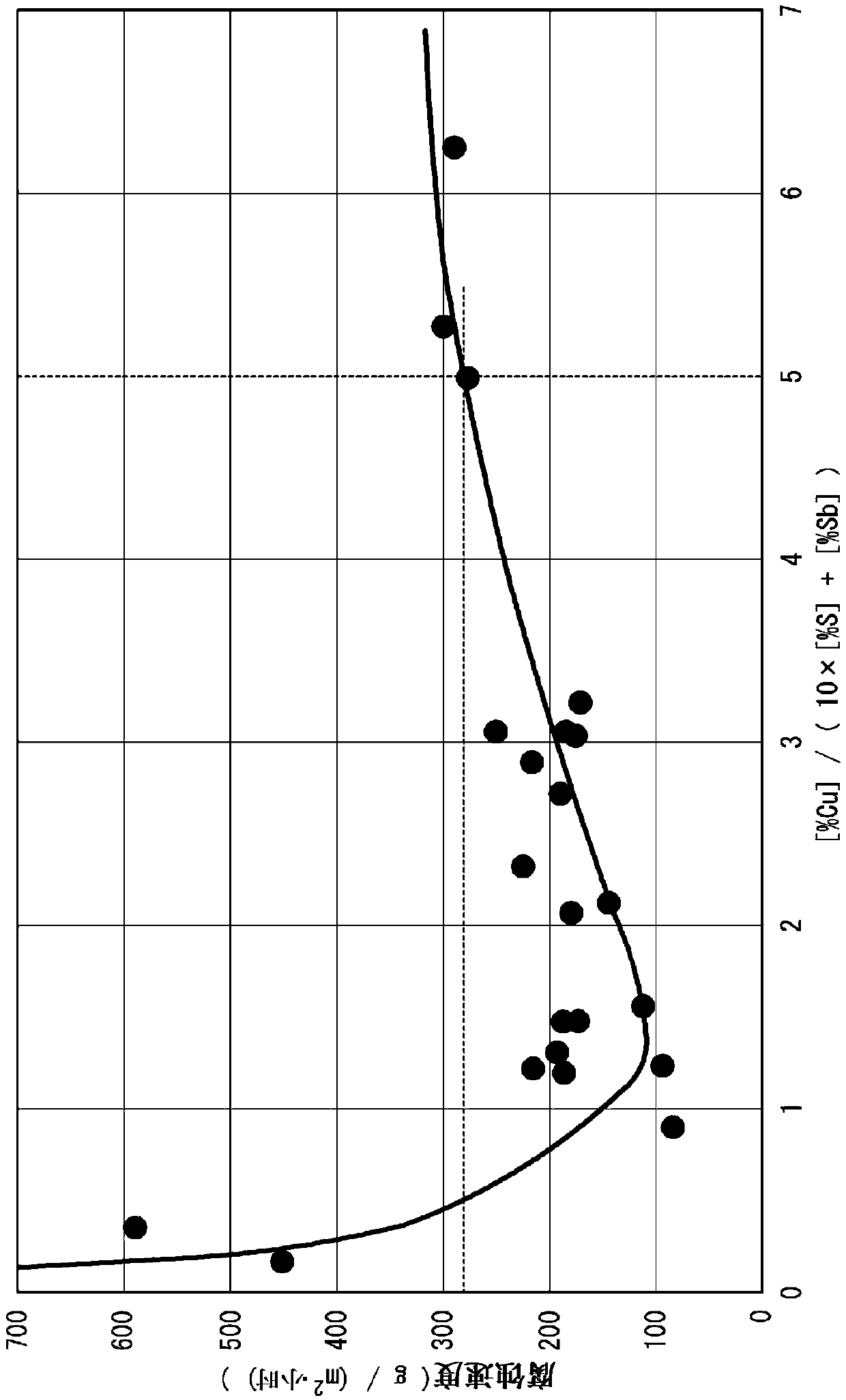

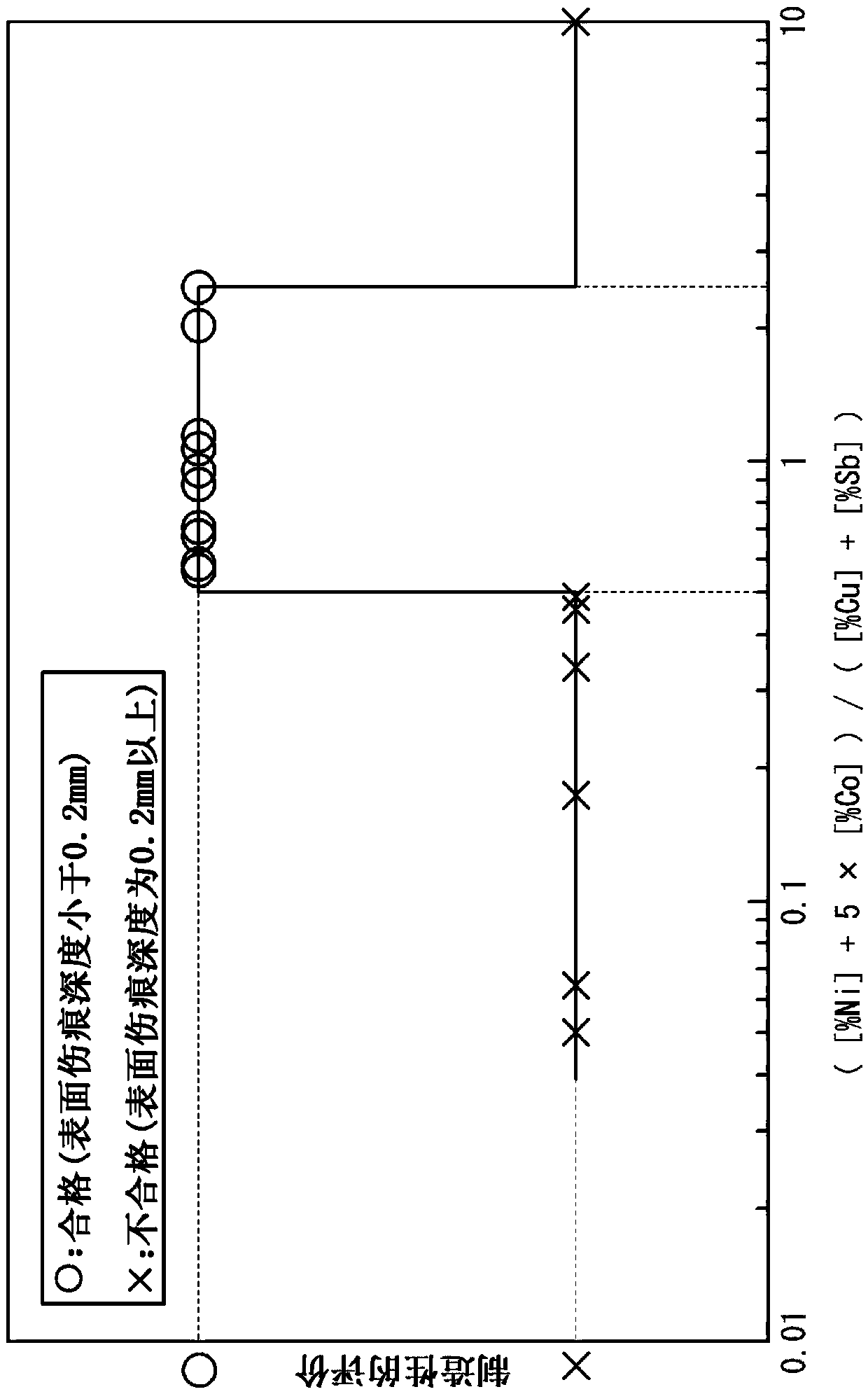

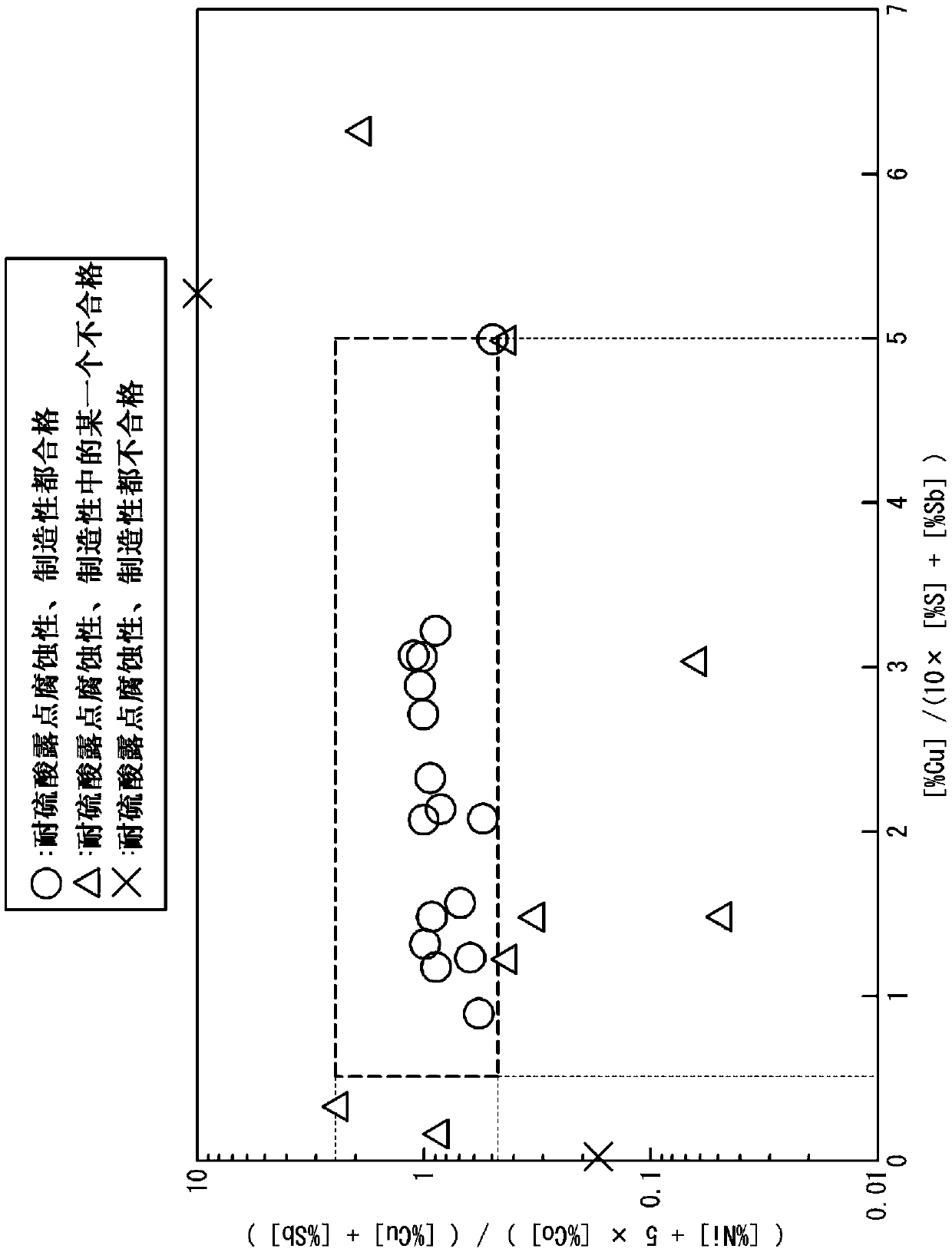

Sulfuric acid dew point corrosion-resistant steel

ActiveCN109642287AExcellent resistance to sulfuric acid dew point corrosion and manufacturabilityGood fatigue resistanceFurnace typesHeat treatment furnacesCorrosion resistantDew point

This sulfuric acid dew point corrosion-resistant steel has a prescribed component composition, and the content of S, Cu and Sb in said component composition satisfy expression (1) below and the content of Cu, Ni, Sb and Co satisfy the relation of expression (2) below. 0.50 <= [%Cu] / (10x[%S]+[%Sb]) <= 5.00 (1) 0.50 <= ([%Ni]+5x[%Co]) / ([%Cu]+[%Sb]) <= 2.50 (2), wherein [%S], [%Cu], [%Ni], [%Co] and [%Sb] are the content (mass%) of S, Cu, Ni, Sb and Co, respectively, in the component composition.

Owner:JFE STEEL CORP

Bearing material obtained through loose sintering and having ultralow porosity and manufacturing method thereof

The invention discloses a bearing material obtained through loose sintering and having the ultralow porosity and a manufacturing method thereof. The bearing material comprises, by weight, 70-85% of -140+200-mesh copper alloy particles and 15-30% of -600-mesh copper alloy particles, thus has the ultralow porosity and pore size, and achieves the high mechanical strength and the excellent anti-fatigue performance, and thus the bearing material having the ultralow porosity can be preferably used for manufacturing a connecting rod bushing and the like of an engine. Because of lead-free copper alloysintering, human health and environmental protection requirements are met.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

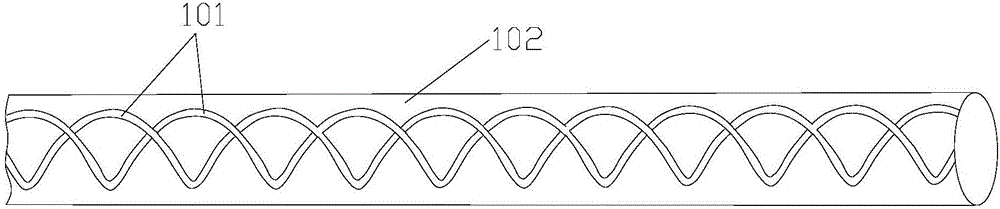

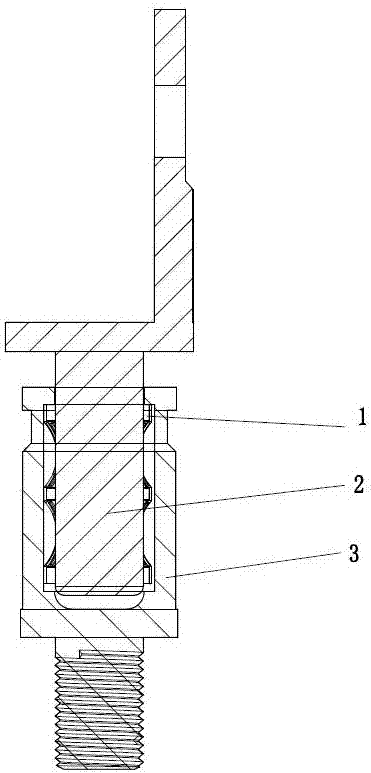

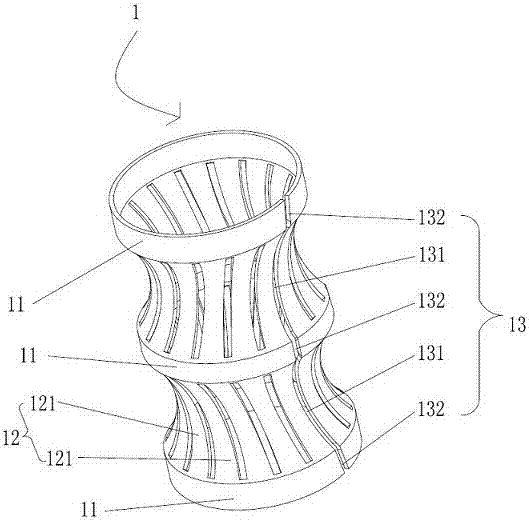

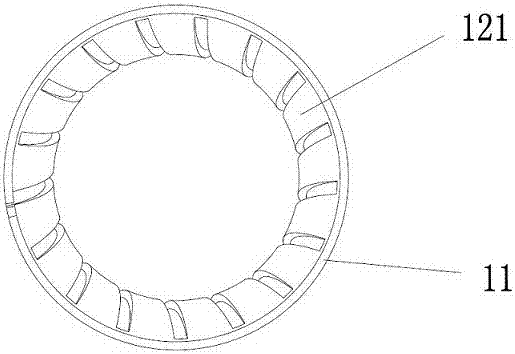

Crown spring jack connecting part

InactiveCN107039813AGood fatigue resistanceExtended service lifeCoupling contact membersElectricityEngineering

The invention proposes a crown spring jack connecting part, and relates to the technical field of electric connectors. The connecting part is used for manual maintenance of the connection between a plug and a jack in a switch or an electric connector. The connecting part is made of a phosphor copper material. The connecting part is shaped like bamboo. A crown spring jack comprises a plurality of annular base bodies and a plurality of elastic piece groups. The annular base bodies are arranged in parallel, and each two adjacent annular base bodies are connected through one elastic piece group to form one connection unit. Each connection unit is shaped like a waist drum. The internal surface of the central part of each elastic piece group is used for the contact connection with the plug. The external surfaces of the annular base bodies are used for the contact connection with the internal surface of the jack. Each elastic piece group consists of a plurality of elastic pieces, and the elastic pieces extend from one annular base body to the next annular base body in an inclined manner. According to the invention, the connecting part provided by the invention can enable the contact between the plug and the jack to be good, and the elasticity can be valid perpetually. Meanwhile, the connecting part is good in conductivity, and cannot generate arc in a working process.

Owner:深圳市品川新能源连接器件有限公司

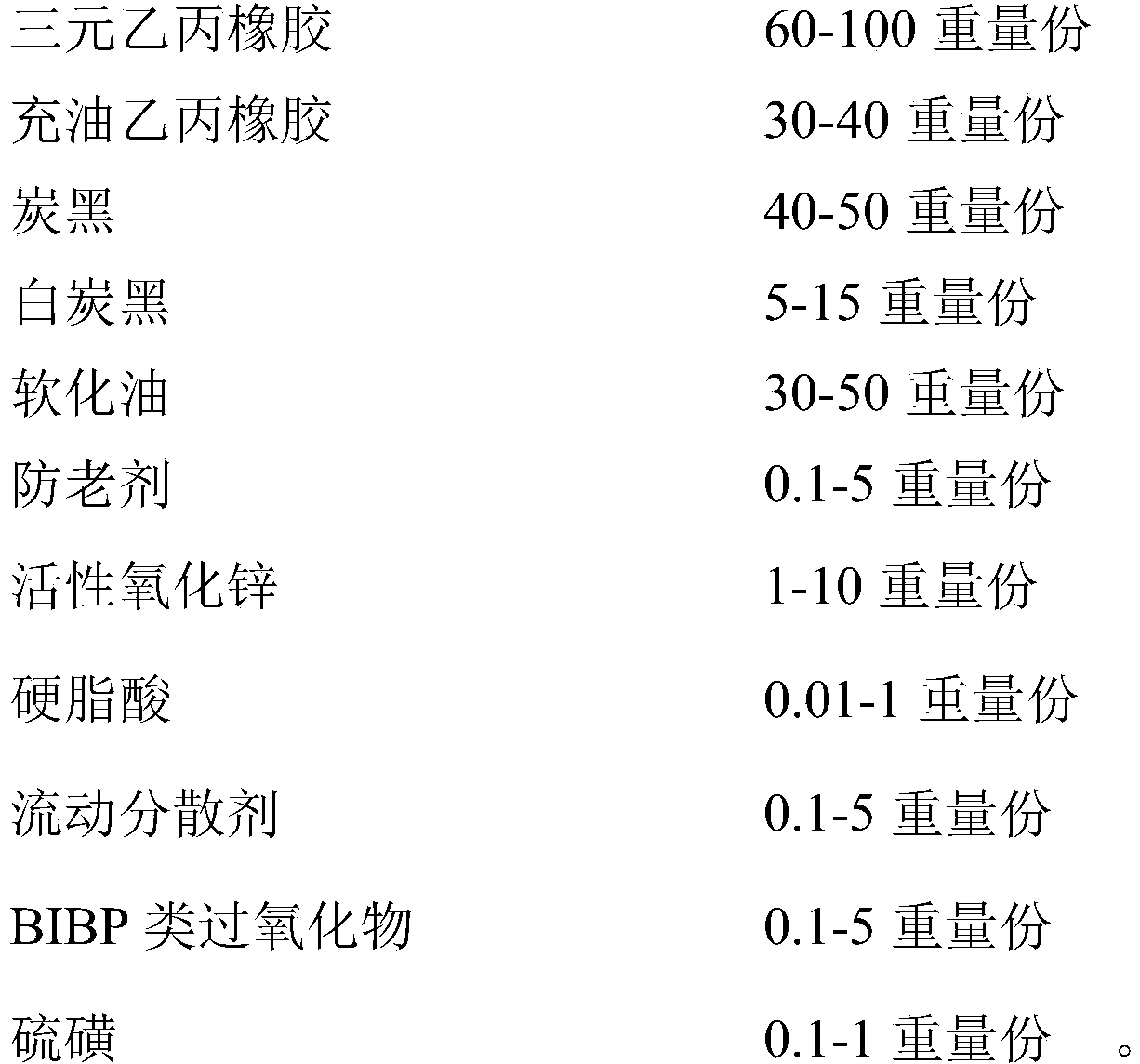

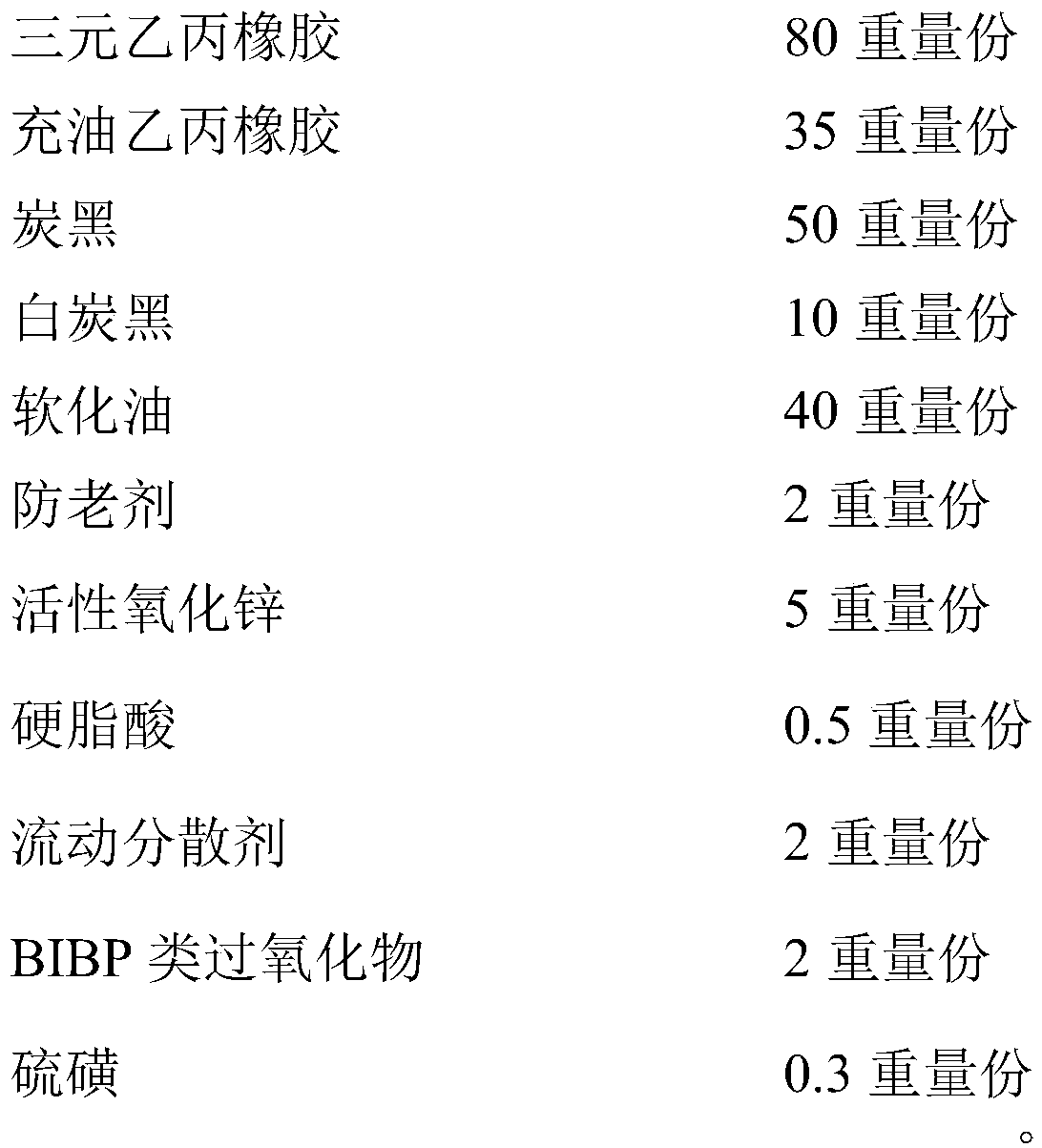

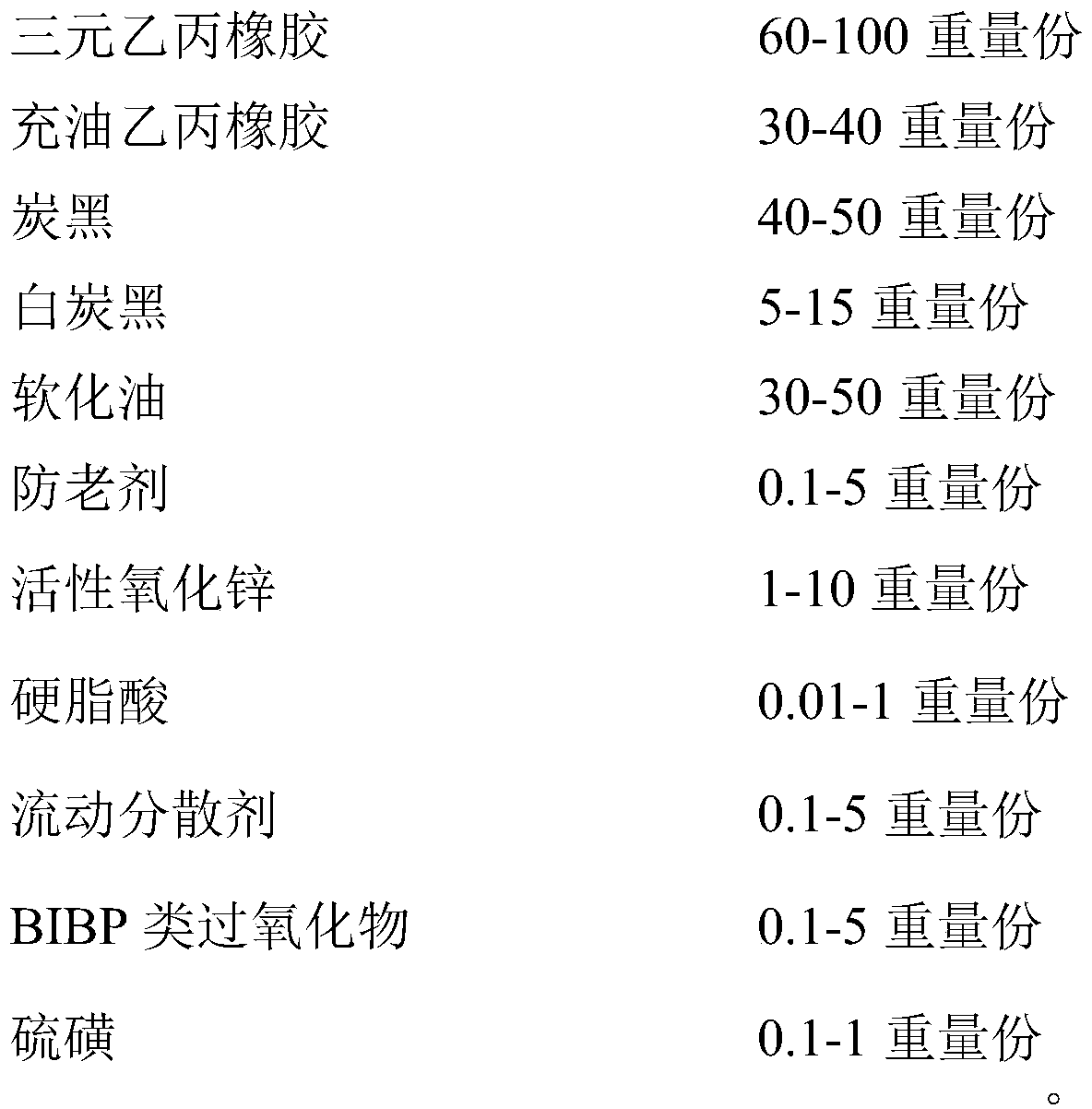

Rubber material as well as preparation method and application thereof

InactiveCN110551343AGood fatigue resistanceGood material strength and tear resistanceCarbon blackOxide

The invention relates to a rubber material as well as a preparation method and application thereof. The rubber material is composed of the following raw materials in parts by weight: 60-100 parts of ethylene-propylene-diene rubber, 30-40 parts of oil-filled ethylene propylene rubber, 40-50 parts of carbon black, 5-15 parts of white carbon black, 30-50 parts of softening oil, 0.1-5 parts of anti-aging agent, 1-10 parts of activated zinc oxide, 0.01-1 part of stearic aicd, 0.1-5 parts of flowing dispersant, 0.1-5 parts of BIBP peroxide and 0.01-1 part of sulfur. The rubber material is obtained by internally mixing and open-milling all the raw materials after mixing the raw materials sequentially in batches. The rubber material is designed according to a unique formula, so that the ratio of dynamic stiffness to static stiffness of the material is smaller than 3, the preparation demand of an elastic buffering part can be met, meanwhile, the static stiffness is within the range of 25+ / -3 N / mm, and the rubber material is good in fatigue resistance and high in material strength and tear resistance.

Owner:厦门市金汤橡塑有限公司

Graphene modified polycarbonate composite material and preparation process thereof

InactiveCN112341783AGood fatigue resistanceLow notch sensitivityPolycarbonatePolytetrafluoroethylene

The invention discloses a graphene modified polycarbonate composite material and a preparation process thereof. The graphene modified polycarbonate composite material is mainly prepared from, by weight, 100 parts of polycarbonate, 10-12 parts of polystyrene, 10-12 parts of graphene, 10-12 parts of calcium sulfate whiskers, 0.1-0.4 part of antioxidant 1010, 1-4 parts of polytetrafluoroethylene and1-3 parts of titanate coupling agent. The invention further discloses a preparation process of the graphene modified polycarbonate composite material. According to the preparation method, the grapheneis firstly adopted to modify the calcium sulfate whiskers, so that the length-diameter ratio of the calcium sulfate whiskers is further improved, the diameter of the calcium sulfate whiskers is reduced, and the compatibility and the interface bonding force of the calcium sulfate whiskers and a matrix can be further improved. The graphene modified polycarbonate composite material disclosed by theinvention is good in fatigue resistance, low in notch sensitivity and particularly suitable for manufacturing shell materials and the like.

Owner:桃江县缘湘聚文化传媒有限责任公司

Environment-friendly pervious concrete and preparation method thereof

InactiveCN111925170AWide variety of sourcesEasy to prepareCeramicwareMicrosphereAcetic acid ammonium salt

The invention discloses environment-friendly pervious concrete. The environment-friendly pervious concrete is characterized in that the environment-friendly pervious concrete comprises the following components in parts by weight: 20-30 parts of cement, 0.5 to 1.5 parts of aluminum oxide nanotubes, 2 to 5 parts of N-(trimethoxysilyl propyl) ethylenediamine triacetic acid ammonium salt modified nanoaluminum powder, 60 to 70 parts of rough aggregate, 0.5 to 1.5 parts of nano porous hollow cage-shaped titanium oxide, 1 to 2 parts of porous polysaccharide microspheres, 0.1 to 0.4 part of sodium sulfonate-based hyperbranched poly (amine-ester) and 20 to 30 parts of water. The invention further discloses a preparation method of the environment-friendly pervious concrete. The environment-friendlypervious concrete disclosed by the invention is excellent in mechanical property, good in fatigue resistance and water permeability, good in comprehensive performance, wear resistance and durability,and safe and environment-friendly to use.

Owner:韩昌龙

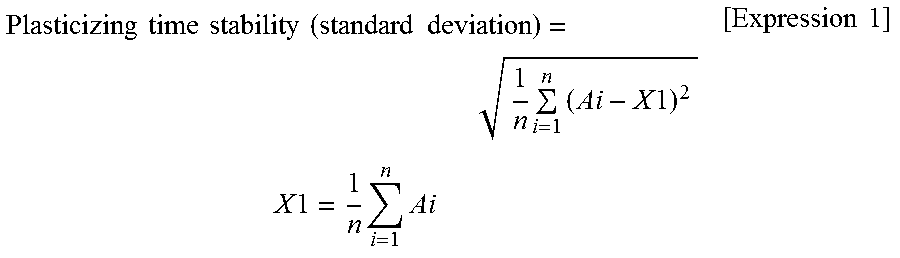

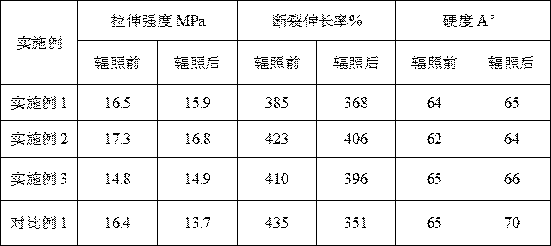

Preparation method of fatigue-resistant and irradiation-resistant diaphragm sizing material

The invention discloses a preparation method of a fatigue-resistant and irradiation-resistant diaphragm sizing material. EPDM (ethylene-propylene-diene monomer) rubber, NBR (nitrile-butadiene rubber),a reinforcing filling agent, a vulcanizing agent, a vulcanization accelerator, an activator, a plasticizer, an anti-aging agent, an anti-irradiation aid, a binder and an anti-fatigue agent are plasticized and mixed. The prepared diaphragm sizing material has excellent fatigue resistance and has the flexure times up to 250,000 times or above. The tensile strength, elongation at break and hardnesschange rate are substantially reduced after 935 KGy irradiation, the irradiation resistance of the diaphragm sizing material is improved, and the sizing material can be used for producing various irradiation-resistant rubber products and widely applied to environments with high-energy radiation in the fields of aerospace, nuclear industry, electronic communication, chemical engineering, medicine,ships and the like and has very good social benefits and economic benefits.

Owner:JIANGSU SHENTONG VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com