Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "No fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic resin with high toughness

The invention discloses acrylic resin with high toughness, which comprises the following components according to the weight portion: 50-75 of acrylic resin, 5-35 of polyethylene resin, 5-35 of compatilizer, 0.2-1 of processing materials, 4-15 of filling agent and 0.3-1 of dispersing agent, wherein the acrylic resin is one or the composition of more than two of isotactic PP, syndiotactic PP, block co-polymerized polypropylene or random co-polymerized polypropylene, and melting flow index of the acrylic resin is (0.4-30)g / 10min. The invention aims at overcoming the defects of the prior art, and providing the acrylic resin with rich source, low price, high elongation at break, strong temperature toleration, high softening point, excellent impact property, fatigue and bending resisting properties and wide application.

Owner:广东智汇赛特新材料有限公司

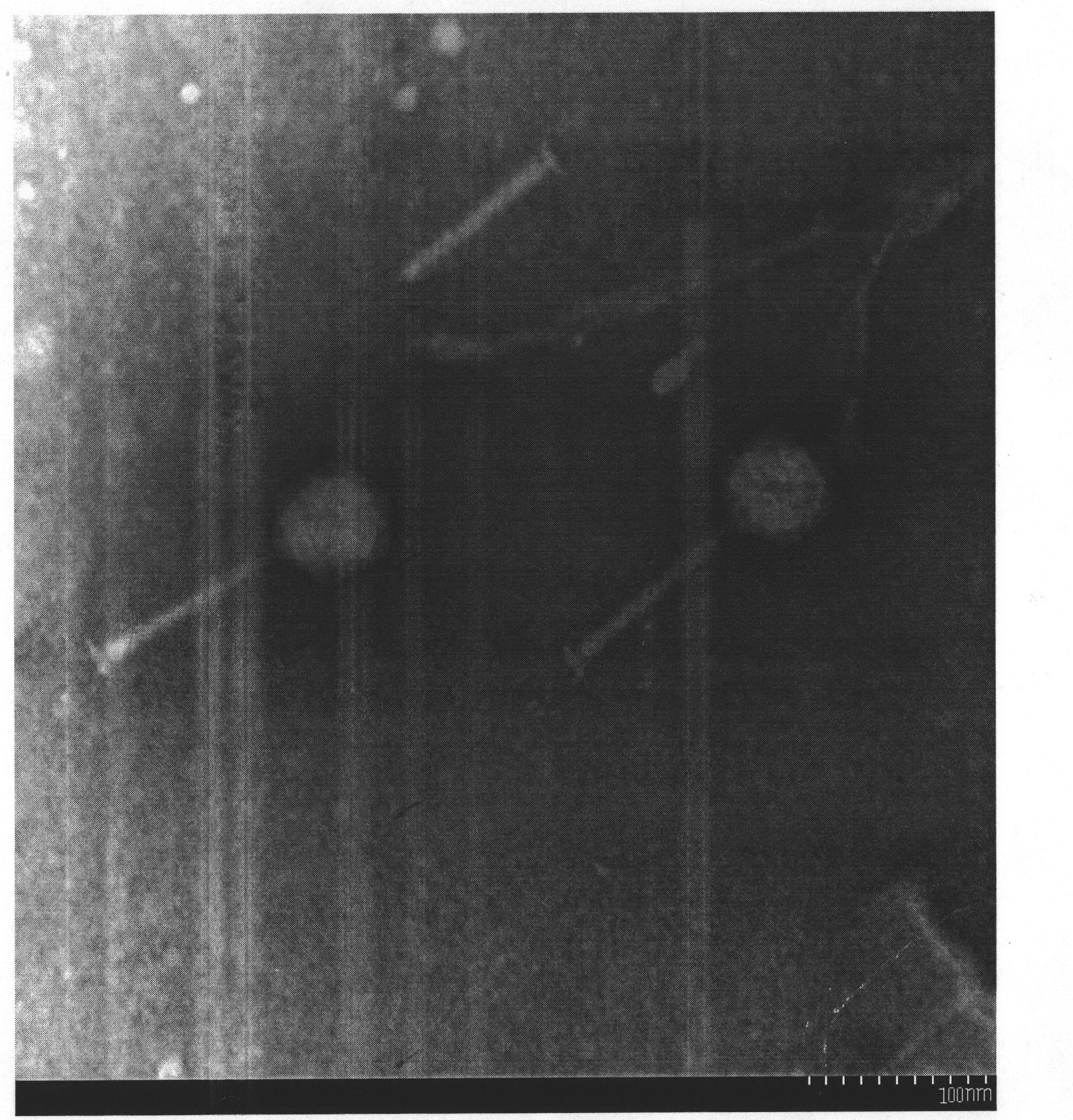

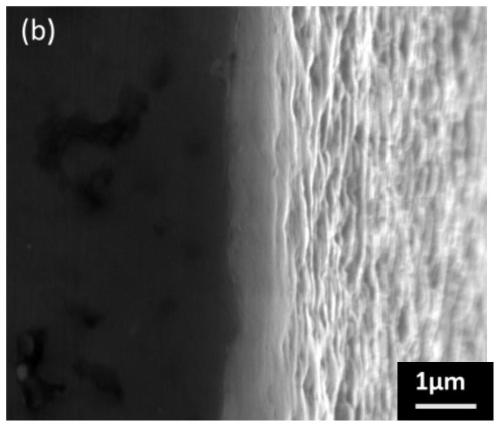

Method for preparing polyacrylonitrile-based carbon fiber precursor fiber

ActiveCN101161880AConducive to smoothHigh tensile strengthMonocomponent synthetic polymer artificial filamentWet spinning methodsElastic modulusAmmonium hydrogen sulfite

The invention provides a preparation method for polyacrylonitrile base carbon fiber protofilament. ammonium persulfate-ammonium sulfite or ammonium hydrogen sulfite is used as the aqueous phase suspension copolymerization of a initiation system for preparing polyacrylonitrile base carbon fiber protofilament which uses polymers as raw materials; polymers are made into 16-20Wt percent of slurry at -18-0 DEG C, vacuumized to 40-95 Kpa and dissolved for 1-2 hours at 40-55 DEG C; then spinning stock solution at 70-80 DEG C is extruded into a spinning pipe in coagulation bath via a spinneret to be shaped, and PAN nascent fiber is obtained through the minus elongation of the coagulation bath; the PAN nascent fiber has desolventize flushed away by hot water, and is simultaneously stretched, oiled, dried for densification, baked and elongated to obtain PAN base protofilament, and the tensile strength is no lower than 6.60N / dtex; the carbon fiberstrength is 3.30-4.01Gpa, and the elastic modulus is 210-262Gpa. The main technical indexes of the present invention are equivalent to the similar products in America, Japan and other countries.

Owner:吉林碳谷碳纤维股份有限公司

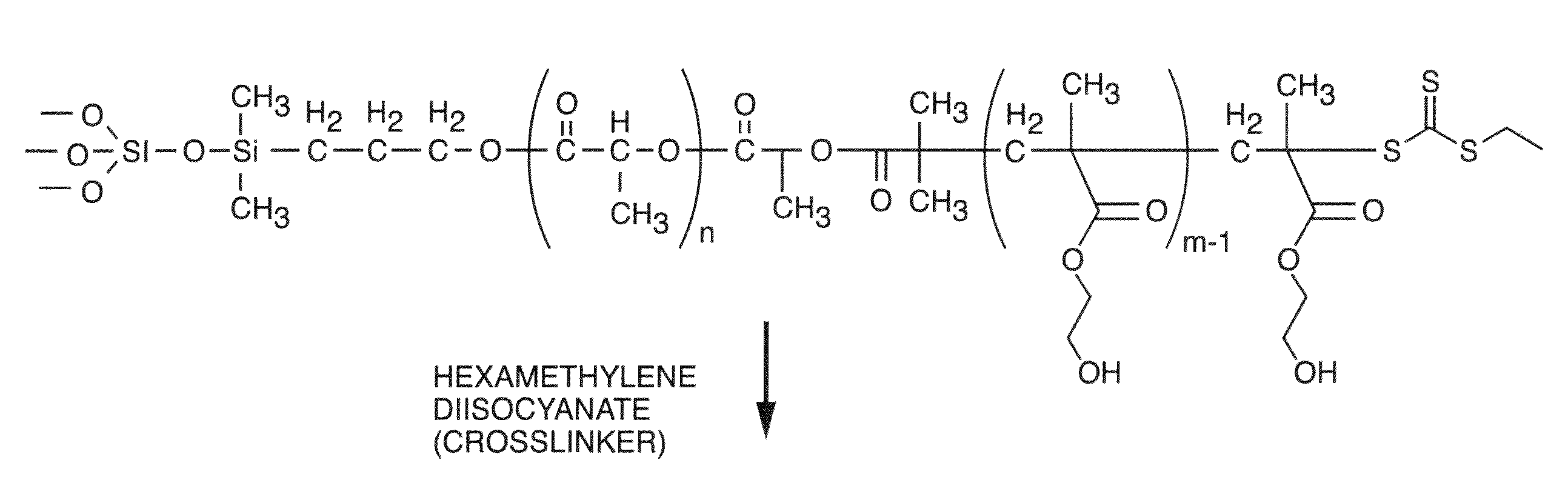

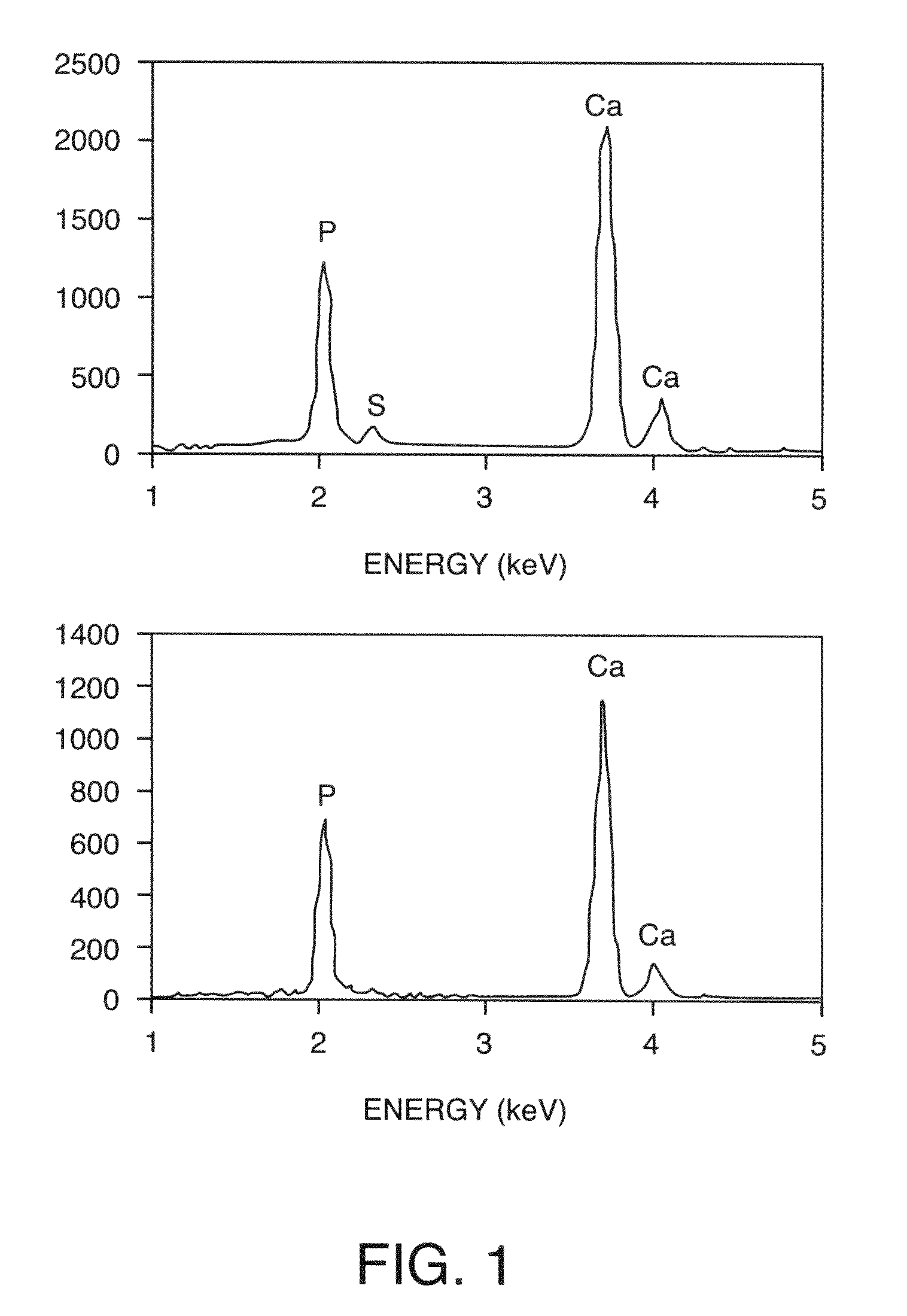

Polymer Compositions For Biomedical And Material Applications

The invention relates to composite materials that contain a polymer matrix and aggregates, and in some embodiments, methods of making, and methods of using these materials. Preferably, the aggregates are calcium phosphate aggregates. Preferably, the material is resistant to fracture. In further embodiments, the materials are used in surgical procedures of bone replacement. In further embodiments, the materials contain polyhedral silsesquioxanes and / or biodegradable segments. In further embodiments, the polymer matrix comprises biomolecules.

Owner:MASSACHUSETTS MEDICAL SCHOOL UNIV OF

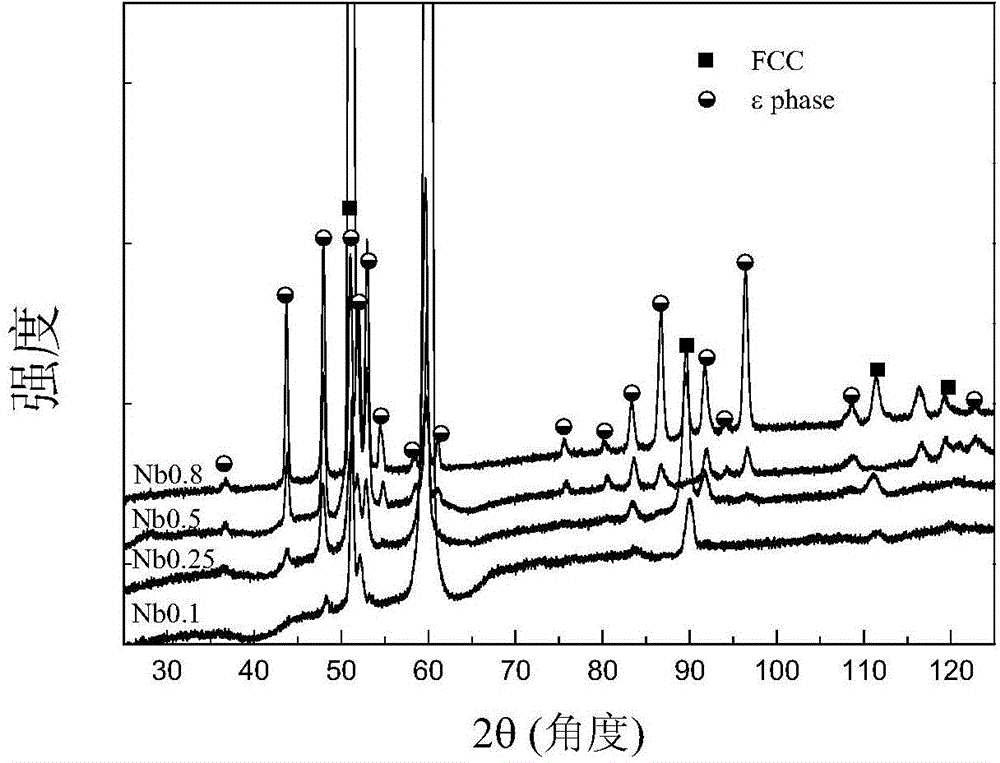

CrFeCoNiNbx high-entropy alloy and preparation method thereof

The invention discloses a CrFeCoNiNbx high-entropy alloy and a preparation method thereof. The CrFeCoNiNbx high-entropy alloy comprises Cr, Fe, Co, Ni and Nb, wherein x ranges from 0.1 to 0.8; the content of Nb is 2.4%-16.7%; Cr, Fe, Co, and Ni are equal in content; and the proportion is mole percentage. An Nb element is added to a Cr-Fe-Co-Ni quaternary alloy, a precipitated phase is formed in single FCC (face-centered cubic) solid solution phase, precipitation strengthening is performed, and the high-entropy alloy has a face-centered cubic structure, high hardness, high strength, good compression plasticity and better mechanical properties.

Owner:东莞市三航军民融合创新研究院

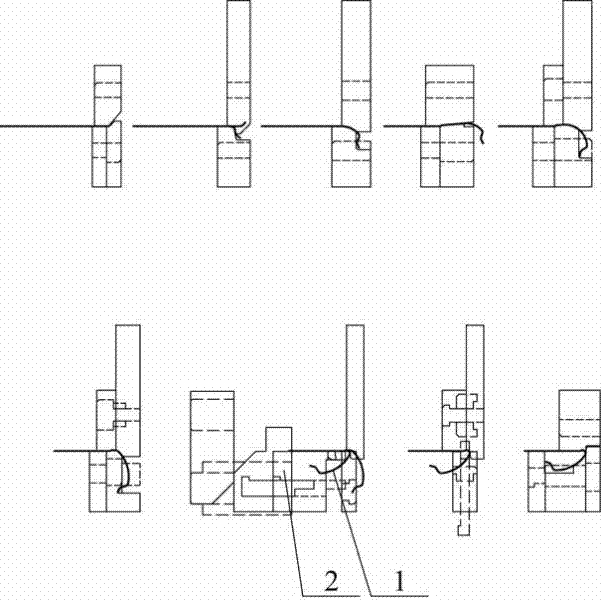

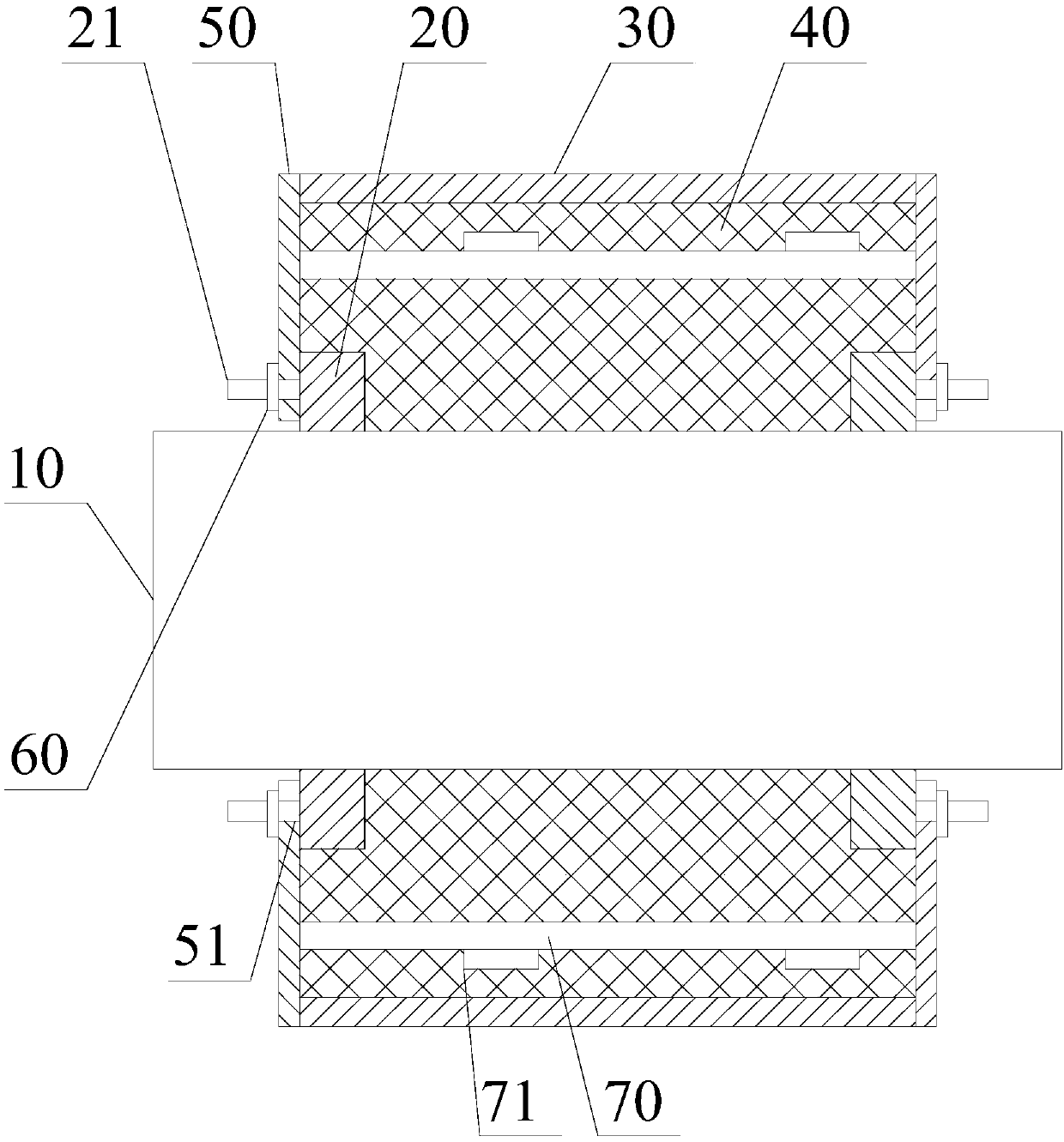

Forming method and forming device for battery shell

ActiveCN101259498AImprove yieldReduce sizeLamination ancillary operationsSynthetic resin layered productsResistElectrical battery

The invention provides a forming method of battery shell which is charactered in that: a forming sheet (S), which includes a resin film layer as an outside layer, a resin film layer as an inner layer and an aluminium foil layer between two film layers, is punch formed to required shape by a punch forming mould composed of a die (2), a former block (1) and a crease-resist pressure pad component (5). According with the forming method, in a deep pulling / processing process that punch forming is realized by the forming sheet with special lamination structure used as forming material, the crease-resist pressure pad pressure generated by the crease-resist pressure pad can be adjusted suitably according with forming shape size, deepness also likes. Consequently, more deep process can be processed easily and suitable range of forming shape is enlarged, and a deep pulling process without crease is processed.

Owner:株式会社力森诺科包装

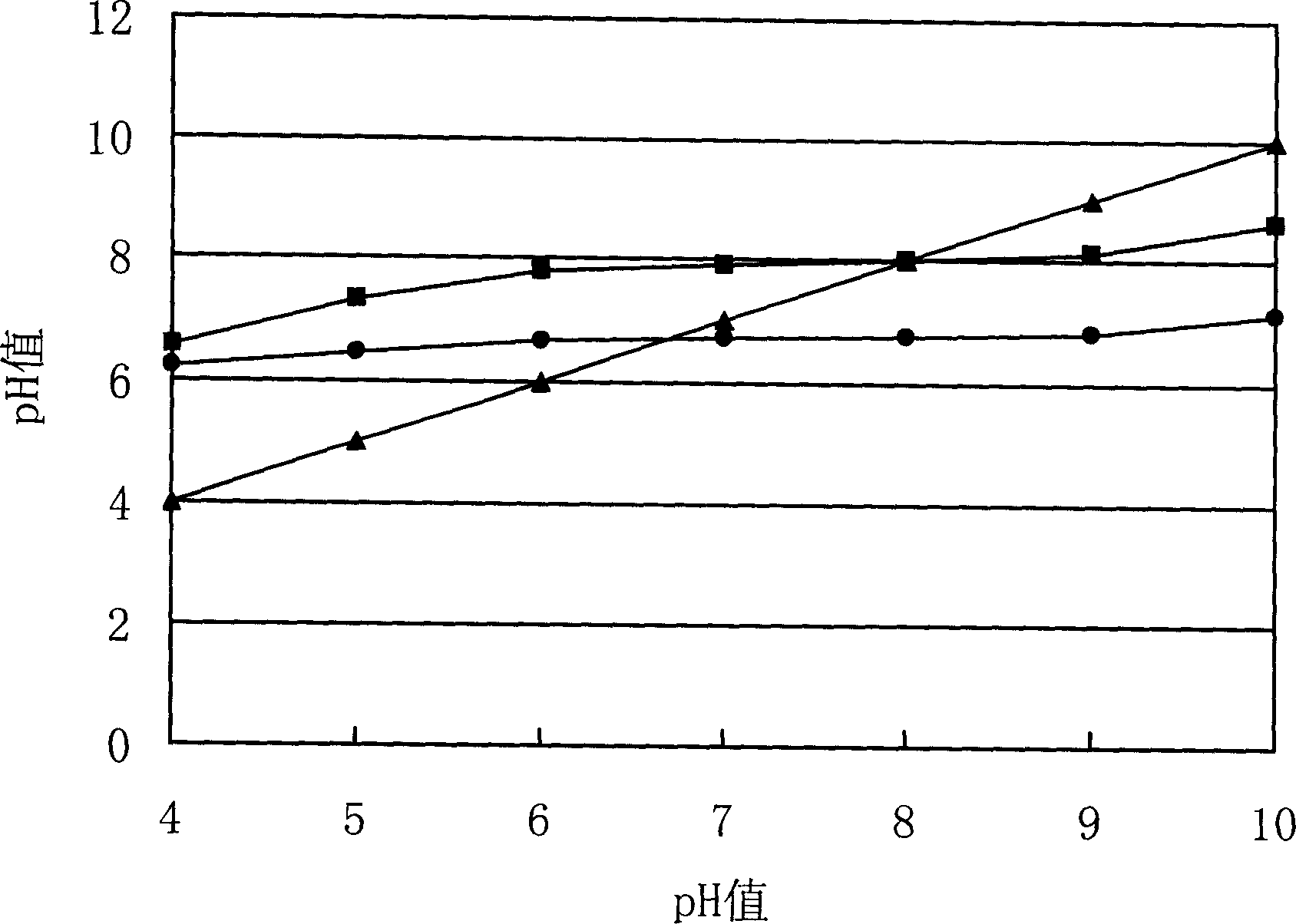

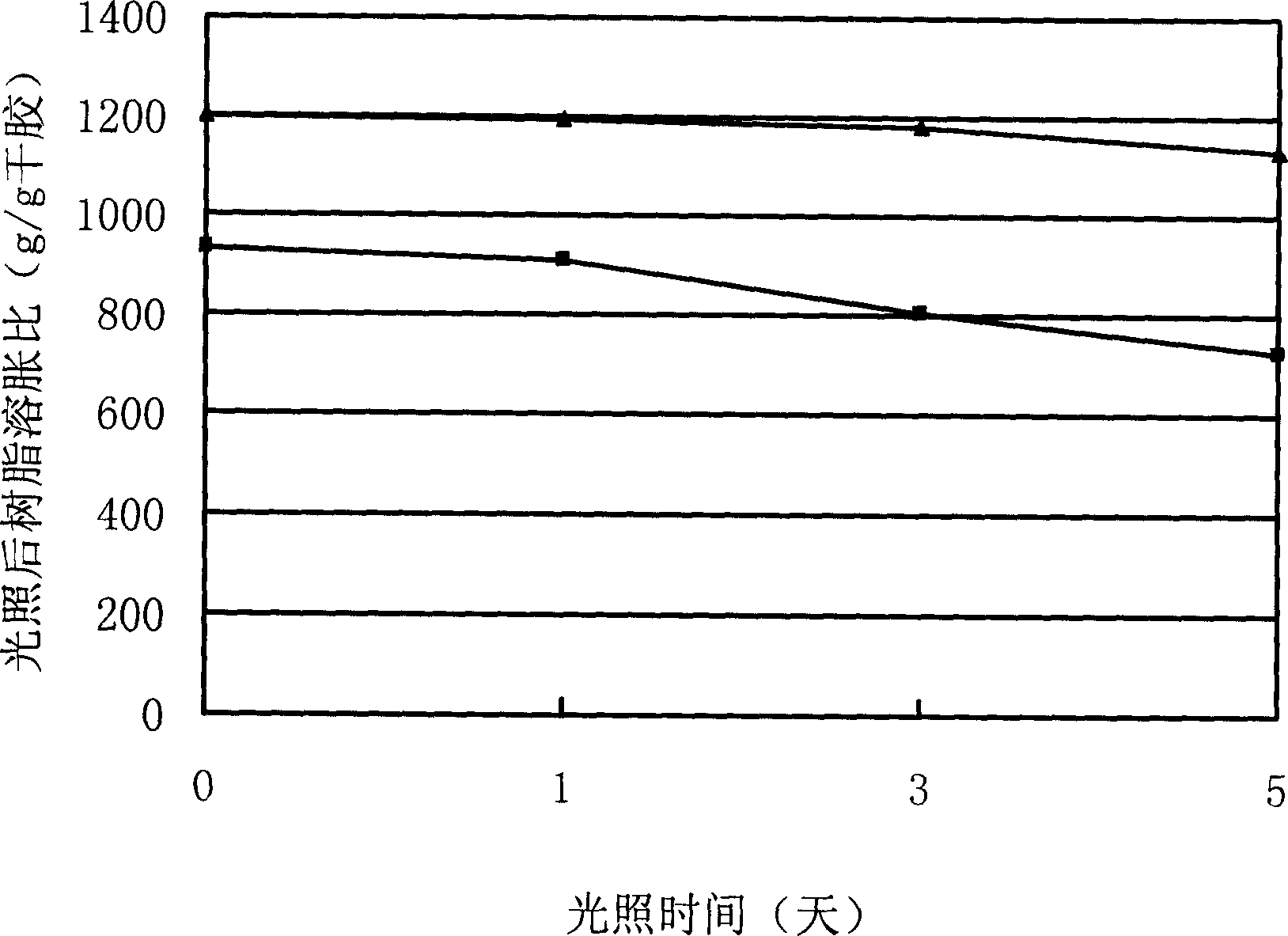

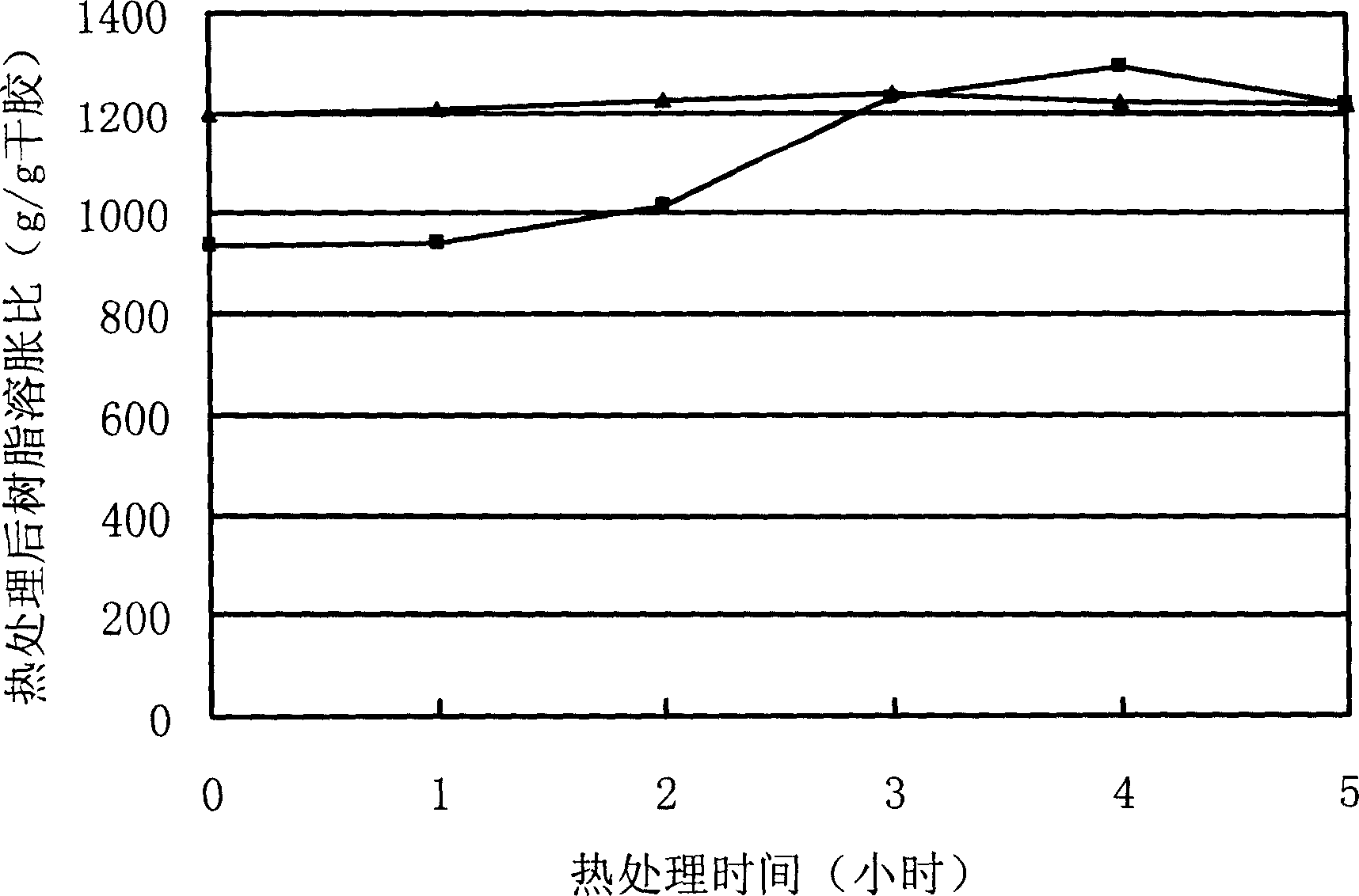

Method for preparing poly-aspartic-acid resin

This invention relates to a preparation method for poly-asparagic acid resin, which takes poly-pyrrolidine dione as the raw material to make crosslink poly-pyrrolidine dione with method of non-even phase suspended emulsion crosslink or non-even phase suspension crosslink and processes poly-asparagic acid resin by hydrolyzation characterizing that the crosslink poly-pyrrolidine dione is prepared by multi-section crosslink reaction, in which, the crosslinker is fed in for 2-4 times in equal volume and equal time interval, the crosslink poly-pyrrolidine dione and the resin are aged and crystallized and quickly dried, A ageing and crystallization process for 1-10 days under room temperature, B, quick drying process is carried out under -54-40deg.C.

Owner:BEIJING UNIV OF CHEM TECH

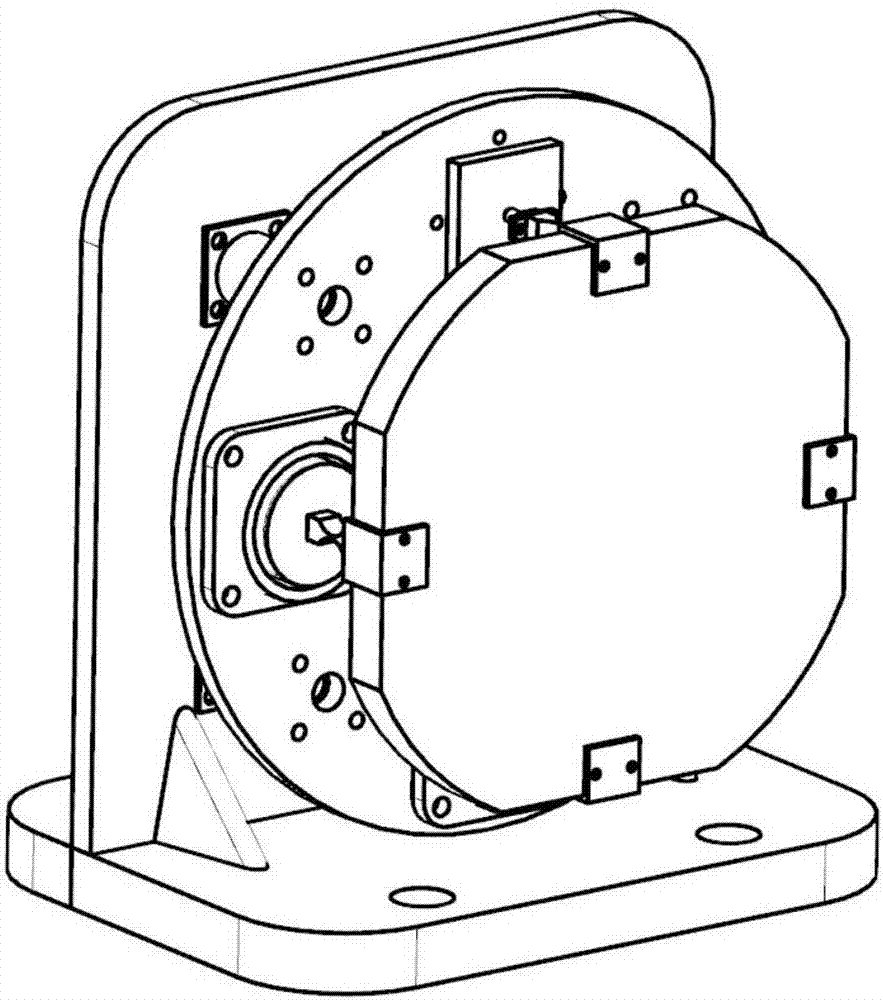

Fast steering mirror system connected with universal flexible hinge in high-precision aim-stabilization system

The present invention provides a fast steering mirror system connected with a universal flexible hinge in a high-precision aim-stabilization system. A set of voice coil motors are taken as drivers to drive the high-frequency motion of a steering mirror; a set of optical grating micrometers are taken as angular position sensors to perform real-time feedback of angular position signals; and a universal flexible hinge bears the scheme of two-degree-of-freedom motion of the steering mirror. The motion features of the steering mirror are employed to design the material composition and structure form of the voice coil motors and the universal flexible hinge so as to solve the compensation problem of the optical system two-level stable loop residual errors on the premise of using the least drivers and the simplest bearing mechanism.

Owner:西安应用光学研究所

Transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic

ActiveCN105198443AConducive to initial sintering densificationFacilitate the realization of initial sintering densificationCeramic sinteringBoron nitride

The invention discloses a transition phase assisted low-temperature sintering method of boron nitride multi-phase ceramic and relates to a sintering method of boron nitride multi-phase ceramic. The invention aims at solving the problems that the crystal grains of the prepared multi-phase ceramic are coarse and the mechanical performance is poor for a reason that the sintering temperature of the existing boron nitride multi-phase ceramic. The method comprises the following steps: 1) preparing composite sintering assistant powder; 2) preparing composite powder; 3) increasing the temperature of the composite powder under a vacuum or inert atmosphere condition, increasing pressure and then decreasing the temperature to obtain the boron nitride multi-phase ceramic. The compactness of the boron nitride multi-phase ceramic prepared by adopting the method disclosed by the invention can reach more than 95 percent, the crystal grains of the material are fine and the comprehensive mechanical performance is excellent. The invention belongs to the field of preparation of boron nitride multi-phase ceramics.

Owner:HARBIN INST OF TECH

Tap hole clay for recycled material high blast furnace and preparation method thereof

The invention belongs to the field of blast furnace iron making and particularly relates to tap hole clay for a blast furnace which replaces the conventional dense raw materials and coke powder by recycled materials and a preparation method thereof. The formula of the tap hole clay comprises the following components in percentage by weight: 55 to 70 percent of recycled material, 14 to 23 percent of clay, 2 to 5 percent of asphalt, 2 to 5 percent of sericite and 12 to 16 percent of binding agent. The dense raw materials such as dense corundum, high-alumina aggregate, an SiC raw material and the like and the coke powder are replaced by the recycled materials, so that mineral resources are saved, a large amount of energy is saved, waste discharge can be reduced effectively, the production cost of the tap hole clay is lowered and remarkable economic and social benefits are achieved.

Owner:通化耐博新材料股份有限公司

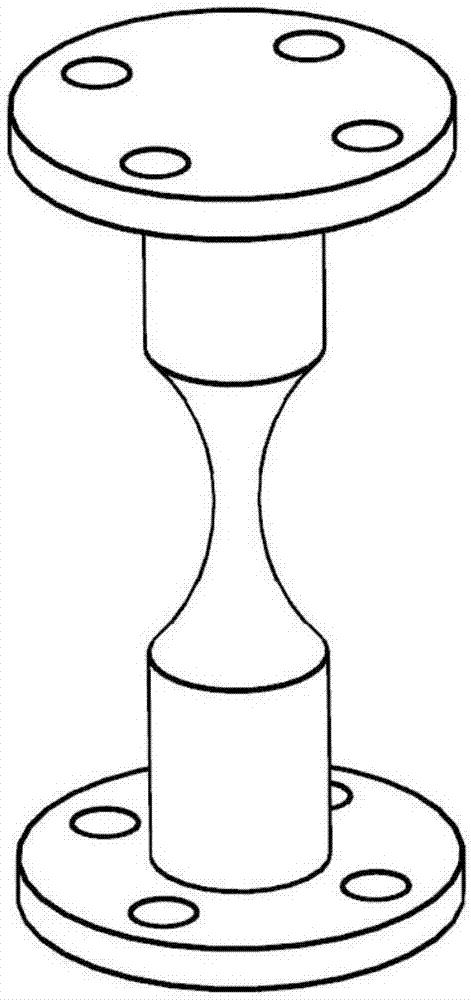

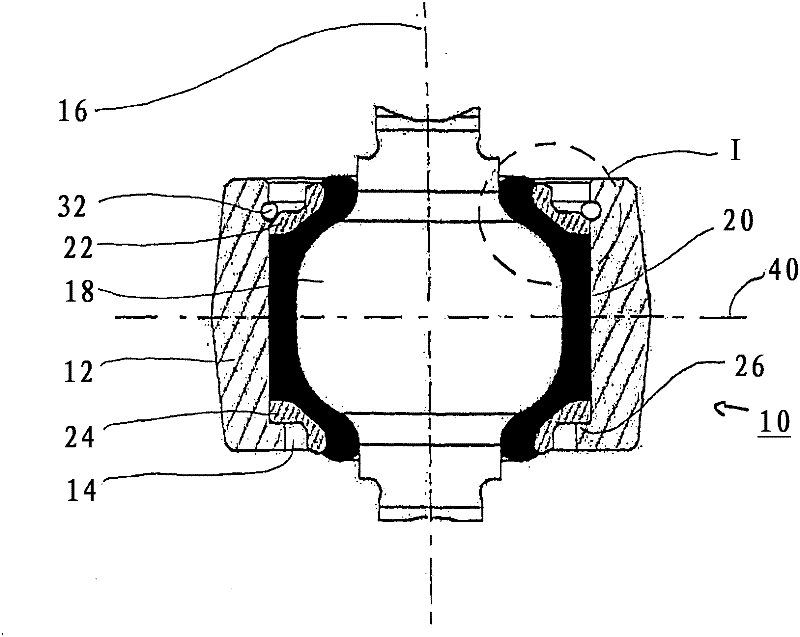

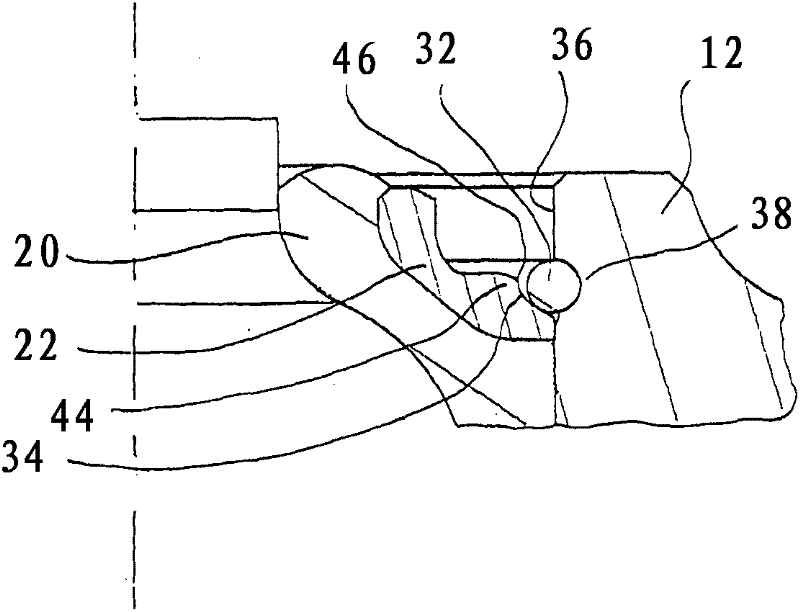

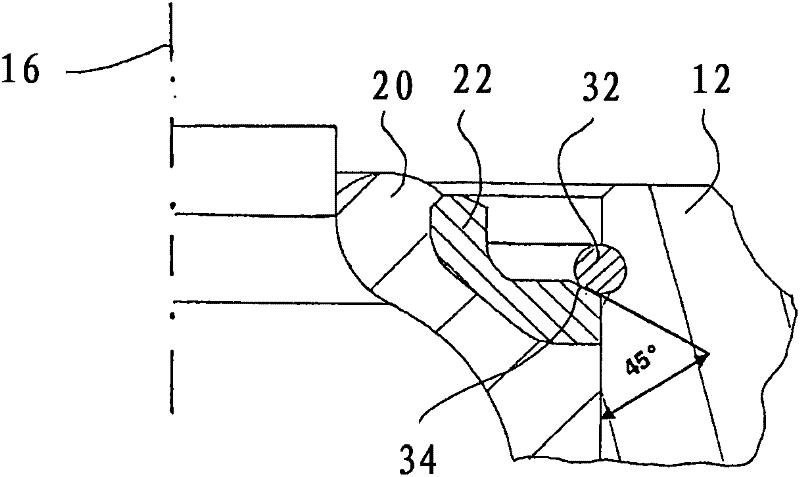

Elastomeric joint

The invention relates to an elastomeric joint (10), having a housing (12) with a through opening (14) which extends axially along the longitudinal axis (16) of the elastomeric joint, a pivot (18) which extends through the through opening (14) of the housing (12), an elastomer body (20) which is fastened to the pivot (18) and is arranged radially between the pivot (18) and the housing (12), and with at least one supporting ring (22) which is fastened to the elastomer body (20) on one end side of the through opening (14), wherein a wire ring (32) locks the supporting ring (22) with respect to the housing (12), with the result that the pivot (18) is held in the housing (12) in an axially secured manner.

Owner:THK RHYTHM AUTOMOTIVE GMBH

3D direct writing zirconium oxide colloid ink

The invention relates to 3D direct writing zirconium oxide colloid ink, which comprises the following raw materials: zirconium oxide particles, a solvent, a binder, an acid agent, an alkali agent anda dispersant, wherein the particle size of the zirconium oxide particles is 0.05-2 [mu]m, the solid content of the zirconium oxide particles in the ink is 40-56 vol%, the dispersant is one or a variety of materials selected from polyacrylic acid, polyvinyl acid, ammonium polyacrylate, polyethyleneimine, polyacrylate, polyvinyl acid salt and polycarboxylate, the dispersant accounts for 0.1-4 wt% ofthe mass of the zirconium oxide particle dry powder, the amount of the acid does not exceed 0.1% of the mass of the ink, the amount of the alkali does not exceed 0.1% of the mass of the ink, and a molar ratio of the hydrogen ion to the hydroxide ion in the acid agent and the alkali agent is (0.01-4):1. According to the present invention, with the application of the 3D direct writing zirconium oxide colloid ink to print at the room temperature, the high solid content can be provided while the 3D direct writing zirconium oxide colloid ink can be outflow from the fine spraying nozzle and the clogging cannot occur, the 3D direct writing zirconium oxide colloid ink can be rapidly cured into the fine wire with a certain strength so as to be used for various modeling, and the 3D direct writing zirconium oxide colloid ink has good rheological property.

Owner:CENT SOUTH UNIV

Boron nitride multiphase ceramic, and sintering method and application thereof

ActiveCN107721433AConducive to initial sintering densificationFacilitate the realization of initial sintering densificationBoron nitrideCeramic

The invention relates to a boron nitride multiphase ceramic, and a sintering method and application thereof. The sintering method comprises the following steps: 1, preparing the powder of a compositesintering aid; 2, preparing composite powder; and 3, subjecting the composite powder to heating, pressurizing and cooling successively under vacuum or in an inert atmosphere to obtain the boron nitride multiphase ceramic. The invention also relates to application of the boron nitride multiphase ceramic prepared by using the method as a side sealing board material. The boron nitride multiphase ceramic prepared by using the method has a density of more than 95%, a small grain size and excellent comprehensive mechanical properties.

Owner:HARBIN INST OF TECH

Grate bar and preparation method thereof

InactiveCN101935805AHigh strengthImprove toughnessProcess efficiency improvementElectric furnaceThermal fatigueEconomic benefits

The invention discloses a grate bar and a preparation method thereof, which belongs to the technical field of heat-resisting materials. The grate bar comprises the following chemical components in percentage by mass: 1.2 to 1.6 percent of C, 15.0 to 20.0 percent of Cr, 2.3 to 2.8 percent of Al, 4.5 to 5.0 percent of Si, 0.05 to 0.15 percent of Ti, 0.05 to 0.15 percent of Nb, 0.08 to 0.20 percent of RE, 0.06 to 0.15 percent of Mg, less than 0.6 percent of Mn, less than 0.04 percent of S, less than 0.05 percent of P and the balance of Fe, wherein the total mass of the Ti and the Nb is more than or equal to 0.20 percent and less than or equal to 0.28 percent. The grate bar of the invention can be produced by electric furnace and is formed by lost foam casting; the grate bar has high strength, high toughness, high inoxidizability and high thermal fatigue resistance, and can be used on large sintering machine trolley for more than 2 years; and when the grate bar is used, the labor intensity of workers can be relieved, the production efficiency of the sintering machine can be improved, and great social and economic benefit can be created.

Owner:BEIJING UNIV OF TECH

Preparation method of drug-resistant pseudomonas aeruginosa broad-host range phage

InactiveCN101962631AEasy to prepareGood separation and purification effectViruses/bacteriophagesAntibiotic YCulture mediums

The invention discloses a preparation method of drug-resistant pseudomonas aeruginosa broad-host range phage, which relates to a preparation method of phage and solves the problem of poor separation and purification effect in the traditional separation method of the pseudomonas aeruginosa phage. The method comprises the following steps: 1, selecting a sewage sample; 2, preparing a lysis solution; 3, carrying out mixed cultivation on the lysis solution and a pseudomonas aeruginosa host cell suspension to obtain a mixed solution; 4, preparing a single phage plaque; and 5, inoculating the phage into a pseudomonas aeruginosa-containing culture medium, culturing until the pseudomonas aeruginosa is completely dissolved, and finally filtering. The preparation method of pseudomonas aeruginosa phage has the advantages of simple operation, good separation and purification effect and no phage breakage. The prepared drug-resistant pseudomonas aeruginosa broad-host range phage can be used for manufacturing autoimmune (vaccines) biological agents for treating diseases caused by the infection of drug-resistant pseudomonas aeruginosa, can be especially used as a topical spray for treating epidermal infectious diseases, and can avoid the drug-resistant pseudomonas aeruginosa produced by the use of antibiotics.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

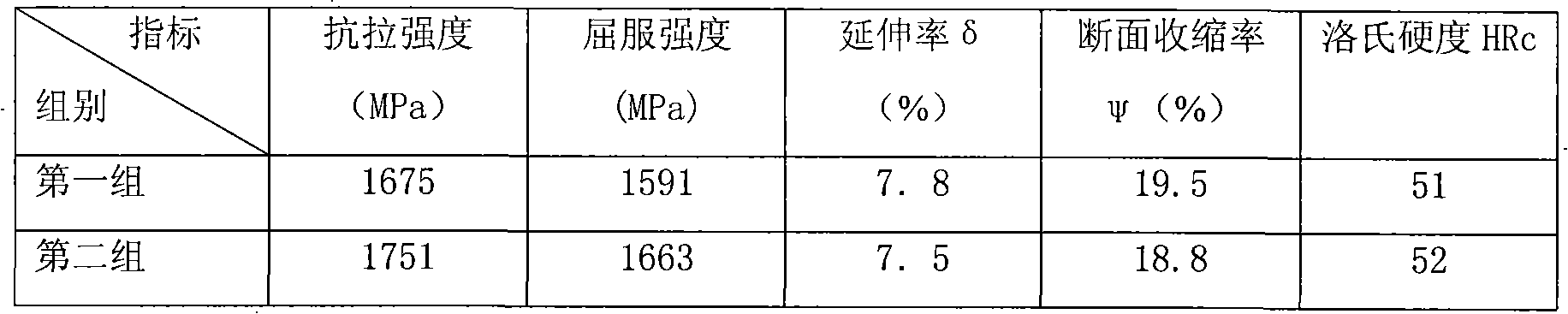

Dipper tooth material

InactiveCN101525725AEnhanced comprehensive mechanical properties of strength and toughnessImprove product technical quality levelSoil-shifting machines/dredgersDipperChromium

The invention discloses a dipper tooth material, comprising the following components by weight percentage: 1.5-2.2% of chromium, 1.0-1.7% of silicon, 0.8-1.5 % of manganese, 0.10-0.40% of molybdenum, 0.22-0.28% of carbon, 0.03-0.07% of aluminum, and iron being the rest. Compared with previous material, the dipper tooth material of the invention is improved substantially in terms of overall mechanical properties such as intensity and toughness, thus, to a certain degree, solving the problem of the existing product that fracture occurs due to insufficient intensity and roughness of the material when in use, thereby improving technical quality and level of the product. In addition, after numerous tests, the dipper tooth produced by the material of the invention witnesses no fracture, thus meeting the requirements of the market on high-strength and high tenacity dipper tooth.

Owner:NINGBO TONGDA PRECISION CASTING

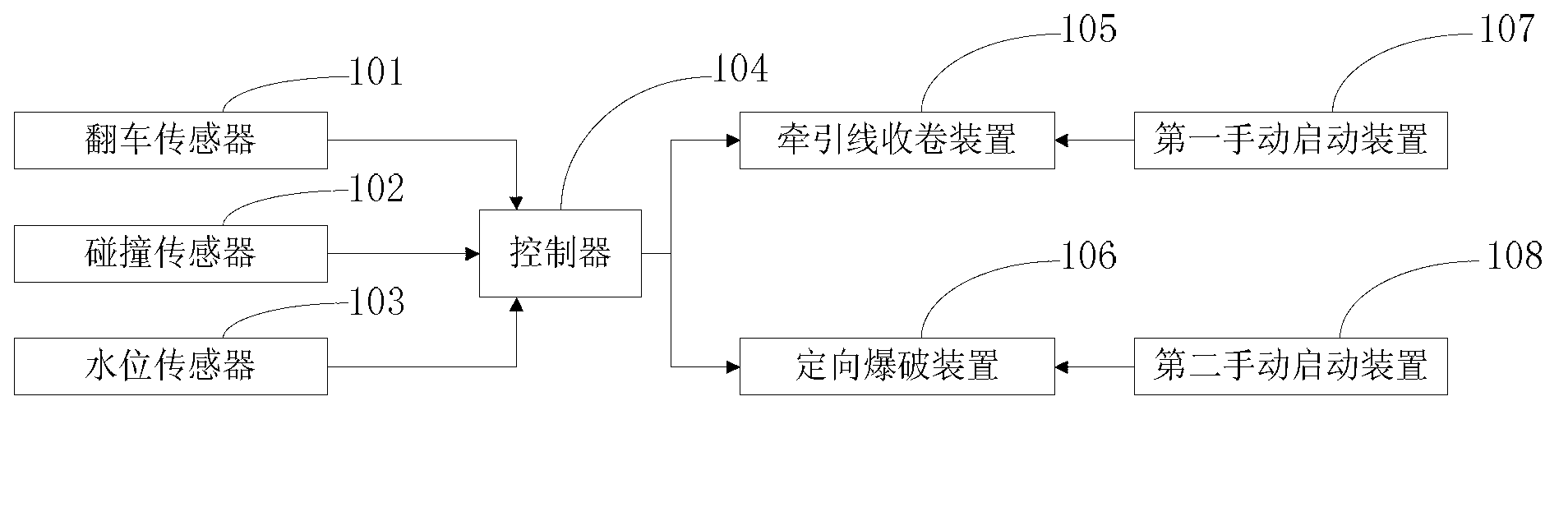

Traction-type vehicle window glass breaking device and method

ActiveCN103223914AReduced Chance of InjuryReduce debris generationPedestrian/occupant safety arrangementAutomotive engineeringEngineering

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

A goaf local filling supporting structure under a hard roof condition and a construction method thereof

The invention discloses a goaf local filling supporting structure body under a hard roof condition and a construction method thereof, and belongs to the technical field of rock stratum motion controlin coal mining. The supporting structure body comprises a filling body located in the goaf, lateral supporting bodies disposed on two sides of the filling body and isolation bodies. Each lateral support body comprises a concrete filled steel tube pier column, an anti-falling supporting leg and a flexible yielding component. The concrete filled steel tube pier column is a main supporting structure.The concrete-filled steel tube pier column is manufactured by pouring concrete grout into a seamless steel tube, the anti-falling supporting legs are arranged in the middle of the concrete-filled steel tube pier column, and each isolation body comprises a gangue bag wall built between the adjacent concrete-filled steel tube pier columns, a flexible side protection steel plate erected in a mannerof being tightly attached to the pier column and a waterproof plastic curtain hung on one side of the steel plate. Sufficient and long-term supporting resistance can be provided for overlying rock roofs, especially hard roofing rock stratums, in the goaf, and it is guaranteed that an elastic nuclear area exists in the center of the structure for a long time.

Owner:SHANDONG UNIV OF SCI & TECH

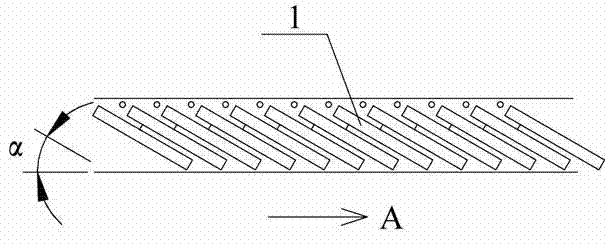

Stamping method for improving elasticity of spring piece

InactiveCN102327955AIncrease elasticityExtended service lifeShaping toolsStripping-off devicesEngineering

The patent discloses a stamping method for improving the elasticity of a spring piece and relates to the technical field of cold stamping of metal. The stamping method is designed against the problems that the direct arrangement way is adopted for material arrangement during the existing production of the spring pieces, thereby causing the waste of materials and the phenomenon of weak elasticity of the spring pieces. The stamping method comprises the following steps of: (1) blanking: using a die to blank a metal plate which needs to be subjected to pre-processing in an oblique arrangement way so as to prepare a blanking finished product; (2) forming: performing bending forming on the blanking finished product after blanking so as to prepare the spring piece; and (3) stripping: blowing the spring piece out of the die. The stamping method is particularly suitable for processing the spring pieces for various types of batteries.

Owner:SUZHOU RISING CREATION PRECISION TOOLS

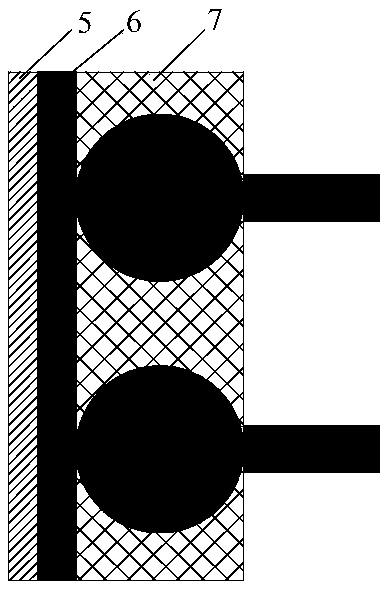

Fan-shaped high-flexibility robot cable

InactiveCN106158082AReduce weightImprove roundnessFlexible cablesFlexible conductorsElastomerEngineering

The invention discloses a fan-shaped high-flexibility robot cable which comprises a cable core, wherein the cable core is formed by a filling cotton rope at center, first, second and third fan-shaped insulated wire core layers and waterproof layers which are twisted toward the left side; the first, second and third fan-shaped insulated wire core layers are arranged on the exterior of the filling cotton rope by taking the filling cotton rope as the center of circle; the waterproof layers are extruded on the exteriors of the fan-shaped insulated wire core layers; a non-woven fabric is wound toward the right side on the exterior of the cable core; an elastomer PVC jacket is extruded on the non-woven fabric. The fan-shaped high-flexibility robot cable has the characteristics of simple structure, light weight, high flexibility, high stretching resistance, bending resistance, torsion resistance, and the like.

Owner:WUXI JIANGNAN CABLE

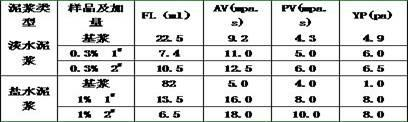

Fluid loss agent and production method thereof

The invention relates to an acrylamide salinity and heat tolerance fluid loss agent for drilling mud. A production method comprises the following steps: weighing a certain amount of each monomer according to feeding ratio, putting dissolved methacrylic acid into a reaction container, heating to 45+5 DEG C, adding N, N-dimethylacrylamide dissolved by water, adding more water to specified proportion, heating to 130 DEG C, stirring for 20 minutes, finally adding acrylamide, stirring, after sealing general N for 230 minutes, adding 0.5 percent of sodium thiosulfate initiator, regulating pH to 8.5 through potassium hydroxide, continuously reacting for 6 hours, stop reacting, and cooling to room temperature to obtain a greenish black product. The invention provides the acrylamide salinity and heat tolerance fluid loss agent and the production method thereof, so that the defect that the conventional fluid loss agent has poor salinity and heat tolerance is overcome, and better filtration reducing property can be realized event under the condition of 120 percent of saline basic mud and 150 DEG C hot rolling.

Owner:扬州润达油田化学剂有限公司

Method for manufacturing wires and bar of rare earth metal with high lanthanum being mixed into and wires and bar of rare earth alloy containing aluminum, barium, calcium and magnesium

A technology for preparing the high-La RE metal mixture wire or rod and RE alloy wire or rod containing Al, Ba, Ca and Mg includes such steps as loading the cast RE ingot or block and KCl as convering agent into the crucible in RE electric furnace, adding Al, Ba, Ca and Mg in intermediate alloy mode, removing slag, casting ingot at 1000-1150 deg.C, preheating the ingot and die, and die pressing by hydraulic press.

Owner:武钢集团有限公司

Processing technology for sousing beefsteaks with vegetable juice

The invention belongs to the technical field of food processing and discloses a processing technology for sousing beefsteaks with vegetable juice. The technology comprises the following steps: 1) unfreezing and trimming feedstock beeves; 2) injecting material liquid into the trimmed beeves; 3) subjecting the injected beeves to primary roll-kneading and then slicing, adding an enzyme solution, andthen, carrying out secondary roll-kneading; 4) subjecting the secondary-roll-kneaded beeves to encapsulation, deaeration and punching; 5) subjecting encapsulated cutlets to a reaction for 5 to 12 hours at the temperature of 0 DEG C to 4 DEG C or for 2 to 4 hours at a temperature below 12 DEG C, and then, subjecting reacted cutlets to quick freezing; 6) subjecting the quick-frozen cutlets to slow unfreezing, removing encapsulation bags, and then, carrying out slicing; and 7) subjecting the slices obtained in the step 6) to quick freezing, bagging, checkout, boxing and warehousing. The beefsteaks prepared by the processing technology disclosed by the invention are rich in taste, bright in color and luster and fresh and tender in texture and are not prone to carbon black during frying.

Owner:河南伊赛牛肉股份有限公司

Method for producing fibers used for twisted threads

InactiveCN104862793AImprove spinnabilityHigh breaking strengthArtificial thread manufacturing machinesSpinning head liquid feederFiberYarn

The invention discloses a method for producing fibers used for twisted threads. According to the method, MMWPE resin, HDPE resin, nanometer SiO2, an auxiliary agent, an agitator, a yarn separating machine, a yarn withdrawal machine, a single screw extruder and a twice-drafting electrical heating drafting machine are adopted, and the method is characterized in that the MMWPE resin, the HDPE resin, the nanometer SiO2 and the auxiliary agent are stirred to be uniform with the agitator, nano-modified compound granules are obtained, the nano-modified compound granules are melt and extruded through the single screw extruder, newly-generated yarn obtained through the extrusion is subjected to cooling and pre-drafting through a cooling water tank and a first drafting roller, pre-drafted yarn is subjected to hot drafting for twice through a high temperature first drafting water bath and a second drafting roller as well as a high temperature second drafting water bath and a third drafting roller, and after the drafting, fiber tows are reeled through the yarn withdrawal machine which uses a moment electric motor; the fiber tows are separated into the fibers used for the twisted threads through the yarn separating machine under the yarn separation tensile force, and the yarn separation tensile force is controlled to be 12%-21% of the fiber breaking force.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

High-frequency quenching process of n-type collision pin

ActiveCN103540724AImprove efficiencyExcellent performanceFurnace typesIncreasing energy efficiencyQuenchingHigh frequency

The invention discloses a high-frequency quenching process of an n-type collision pin. The process comprises the following steps: putting; heating; oil quenching; and tempering. Through treatment of the process disclosed by the invention, various performances of the n-type collision pin are excellent through detection without rupture phenomenon, thereby improving the safety performance to a greater extent.

Owner:上海朋泰机械科技有限公司

A kind of crfeconinbx high-entropy alloy and preparation method thereof

The invention discloses a CrFeCoNiNbx high-entropy alloy and a preparation method thereof. The CrFeCoNiNbx high-entropy alloy comprises Cr, Fe, Co, Ni and Nb, wherein x ranges from 0.1 to 0.8; the content of Nb is 2.4%-16.7%; Cr, Fe, Co, and Ni are equal in content; and the proportion is mole percentage. An Nb element is added to a Cr-Fe-Co-Ni quaternary alloy, a precipitated phase is formed in single FCC (face-centered cubic) solid solution phase, precipitation strengthening is performed, and the high-entropy alloy has a face-centered cubic structure, high hardness, high strength, good compression plasticity and better mechanical properties.

Owner:东莞市三航军民融合创新研究院

Connecting material for connecting silicon carbide material, and application thereof

InactiveCN110357650AReduce seamless connection temperatureAchieve seamless connectionCarbon compoundsRare-earth elementGrain boundary

The invention discloses a connecting material for connecting a silicon carbide material, and an application thereof. The connecting material comprises a rare earth carbon silicide, the chemical formula of the rare earth carbon silicide is Re3Si2C2, and Re being a rare earth element. The invention also discloses a use of the rare earth carbon silicide in the connection of the silicon carbide material, and a connecting method of the silicon carbide material. The rare earth carbon silicide is arranged at the connecting interface of the silicon carbide material to be connected, and is heated to 1000-1800 DEG C to combine the silicon carbide material to be connected into an integral body. The characteristic that the rare earth carbon silicide and the silicon carbide are converted into a liquidphase by a high-temperature eutectic reaction is utilized to effectively reduce the seamless connection temperature of the silicon carbide, the formation of the liquid phase is favorable for the densification sintering of the silicon carbide at the connecting interface, a part of liquid phase rare earth is extruded and volatilized under the action of a pressure, and the remaining liquid phase rareearth diffuses to the silicon carbide matrix along the grain boundary, so the seamless connection of silicon carbide is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Turning tool special for copy turning of non-metallic materials

ActiveCN106180759AReduce cutting heatExtended economic lifeCutting insertsTurning toolsTool marksMetallic materials

A turning tool special for copy turning of non-metallic materials comprises a tool apron which is provided with a movable guide rod and a spring. The movable guide rod is of a tubular structure; a drive rod is installed inside the movable guide rod; and the drive rod can slide in the movable guide rod. A turning tool is mounted on one side of the drive rod, and comprises a tool body. A hard alloy blade is installed on the head of the tool body. During turning, the hard alloy blade adopts a large working front angle gamma which is equal to 24 degrees and meanwhile adopts a working rear angle alpha, wherein the value range of the alpha is 7-9 degrees; the copying effect achieved by the spring and a copying roller is combined, and thus cutting heat can be lowered obviously; the economic service life of the turning tool can be prolonged by 10-12%; and meanwhile, vibration generated in the turning process can be reduced, and tool marks or corrugates on the machining surface are avoided.

Owner:SHANDONG NORTH MODERN CHEM IND

Machining process of shaft of drive motor of new energy automobile

The invention relates to a machining process of a shaft of a drive motor of a new energy automobile. The machining process includes the steps that (1), a blank is manufactured, wherein feeding is carried out according to process requirements; (2), the blank is subjected to annealing treatment; (3), three gears of outer circles are roughly turned on the blank; (4), the surface of the blank is lubricated; (5), an internal spline is manufactured through cold extruding; (6), a second positioning hole is formed in the other end differing from the end where the internal spline is arranged; (7), machining is carried out according to the process requirements; and (8), after the end where a second center hole is formed is subjected to anti-carburization treatment, threads are machined in the end. The machining process has the following beneficial effects that the coaxiality of the axis of the internal spline and the axes of all the gears of outer circles is greatly improved, and the deviation degree can be controlled within 3.5 mm.

Owner:瑞安市悦华汽车单向器有限公司

Protective tunnel energy absorption composite supporting system

PendingCN114483086ANo fractureNo collapseUnderground chambersTunnel liningSupporting systemEnergy absorption

The invention belongs to the technical field of tunnel protection, and particularly relates to a protective tunnel energy absorption composite supporting system. The energy-absorbing composite supporting system comprises anchor rods or anchor cables, an energy-absorbing layer and a steel truss. The anchor rods or the anchor cables are arranged on the inner wall of the tunnel in a driving mode and used for supporting the tunnel. The energy absorption layer is tightly attached to the inner wall of the tunnel, and the energy absorption layer is used for absorbing impact energy transmitted to the energy absorption layer by the tunnel; the steel truss is tightly attached to the energy absorption layer and used for supporting the interior of the tunnel. The energy-absorbing composite supporting system can effectively absorb impact energy under the action of blasting impact and earthquakes, it is guaranteed that an existing energy-absorbing composite supporting system does not have the phenomena of breakage, collapse, instability and the like, it is guaranteed that a tunnel can be effectively supported all the time, and then the safety of the tunnel is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Axle protection structure

InactiveCN107662452APrevent penetrationImprove securityShaftsAxle unitsInterference fitWear resistant

The invention discloses an axle protection structure, which comprises an axle, a fixed ring, a protective tube, a filling layer and a connecting flange; One side of the shaft extends axially outward to form a plurality of fixed rods; the fixed rods on the two fixed rings are located on the sides of the two fixed rings away from each other; the connecting flange is sleeved on the axle, and a through hole is opened on the connecting flange , the fixed rod goes through the through hole; the connecting flange is fixed on the fixed ring through the nut threaded with the fixed rod; the protective tube is set on the axle, and the two ends of the protective tube are respectively fixedly connected with the two connecting flanges; Between the outer surface of the axle and the inner surface of the protection cylinder, the filling layer is wear-resistant rubber. The invention can slow down the loss of driving force of the vehicle after the axle breaks, and prevent the fragments produced by the breakage of the axle from penetrating the fuel tank.

Owner:CHONGQING ZHANRUI AUTOMOBILE FITTING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com