Fluid loss agent and production method thereof

The technology of a fluid loss reducing agent and its production method is applied in the field of acrylamide anti-salt, anti-temperature and anti-fluidizing agent, which can solve the problems of poor anti-salt and anti-temperature effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 20 parts of methacrylic acid and 2 parts of water into a three-necked flask, heat to 50°C until the methacrylic acid is completely dissolved, then add 20 parts of N,N-dimethylacrylamide aqueous solution dissolved in 2 parts of water, pour slowly into a three-necked flask, supplemented with 16 parts of water, raised the temperature to 130°C, and stirred for 20 minutes, then added 40 parts of acrylamide, and sealed it with N 2 After 30 min, add 0.5% sodium thiosulfate initiator, adjust the pH to 8.5 with potassium hydroxide, and continue the reaction for 6 hours before stopping the reaction.

Embodiment 2

[0025] Add 20 parts of methacrylic acid and 2 parts of water into a three-necked flask, heat to 50°C until the methacrylic acid is completely dissolved, then add 15 parts of N,N-dimethylacrylamide aqueous solution dissolved in 2 parts of water, and pour slowly Put it into a three-necked flask, add 11 parts of water, raise the temperature to 130°C, and stir for 20 minutes, then add 40 parts of acrylamide, 10 parts of dodecyldimethylbenzyl ammonium chloride, and seal it with N 2 After 30 min, add 0.5% sodium thiosulfate initiator, adjust the pH to 8.5 with potassium hydroxide, and continue the reaction for 6 hours before stopping the reaction.

Embodiment 3

[0027] In the 2.5m equipped with stirrer, condensing reflux device, thermometer and heating mantle 3 In the stainless steel reaction kettle, after heating up to 50°C, add 40 Kg of water and 300 Kg of methacrylic acid, after stirring for 20 minutes, add 400 Kg of N,N-dimethylacrylamide, continue stirring for 20 minutes, and then add 320 Kg of water , while stirring, the temperature was raised to 130°C, after 30min, nitrogen gas was introduced for 30min, sealed, 5Kg sodium thiosulfate and 750Kg acrylamide, 200g potassium hydroxide were added, and kept at 130 + React at 5°C for 6 hours. You can get the finished product.

[0028] After testing, it has the following properties:

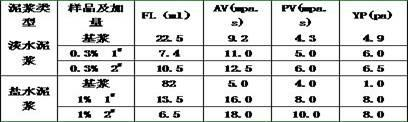

[0029] Table 1 Comparison of filter performance of acrylamide fluid loss reducer

[0030]

[0031] Table 2 Comparison of anti-high temperature filter vector performance of acrylamide fluid loss reducer mud

[0032] mud composition fresh water base pulp 0.2%1 # +Fresh water base sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com