Stamping method for improving elasticity of spring piece

A spring sheet and elastic technology, which is applied in the field of metal cold stamping, can solve the problems of wasting materials and weak product elasticity, and achieve the effects of ensuring technical requirements, prolonging service life, and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

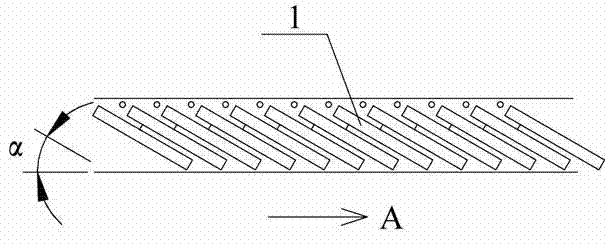

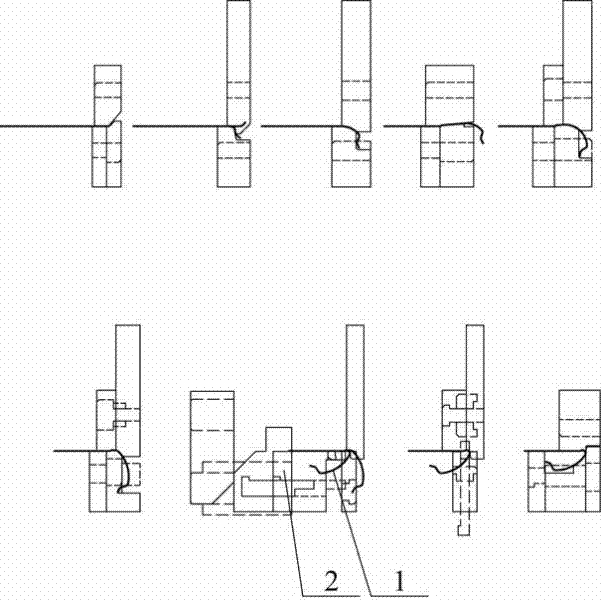

[0022] to combine figure 1 and figure 2 Illustrate a kind of stamping method that improves spring leaf elasticity of the present invention, comprises the steps:

[0023] (1) Blanking: the mold punches the pre-processed metal sheet in an oblique manner to make the blanking finished product;

[0024] (2) Forming: Bending and forming the blanked finished product after blanking to make a spring piece 1;

[0025] (3) Demoulding: Blow the spring piece 1 out of the mold.

[0026] The oblique arrangement means that the setting direction of the mold forms an included angle with the grain direction of the pre-processed metal sheet, and the included angle is 15°-80°, preferably 30°.

[0027] The mold used for stamping includes a matching punch and die. The punch includes a blanking upper die and a bending upper die. The bending upper die is fixed at the corresponding position of the punch according to the stamping process sequence. The concave mold includes a blanking concave mold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com