Preparation method of fatigue-resistant and irradiation-resistant diaphragm sizing material

A fatigue-resistant and radiation-resistant technology, which is applied in the field of preparation of fatigue-resistant radiation diaphragm rubber compound, can solve the problems of diaphragm leakage, stack jumping, and the influence of stable operation of nuclear power plants, and achieve excellent fatigue resistance performance and elongation at break. The effect of reducing and improving radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

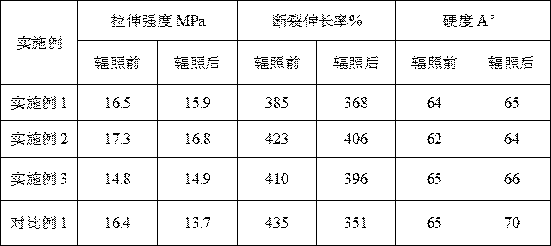

Examples

Embodiment 1

[0025] A method for preparing a fatigue-resistant and radiation-resistant diaphragm compound, the specific steps are as follows:

[0026] (1) Masticating: Masticate 70 parts of EPDM rubber and 30 parts of nitrile rubber on an open mill, adjust the roller distance to 1.5-4mm, control the roller temperature at 40-50°C, and masticate for 15 minutes to make mastication glue.

[0027] (2) Mixing: Mixing adopts two-stage mixing process. In the first stage of mixing, first put the plasticized rubber into the internal mixer to press the top bolt, mix for 1 minute, then open the top bolt, and add carbon black N330 55 parts of white carbon black, 5 parts of zinc oxide, 2 parts of stearic acid, 12 parts of dioctyl phthalate, 1.5 parts of anti-aging agent RD, 1 part of anti-aging agent 4020, 1 part of anti-aging agent MB, four 25 parts of trilead oxide, 5 parts of cerium oxide, 2.5 parts of binder RS and 3 parts of carbon nanotubes, kneading for 4 minutes, controlling the debinding tem...

Embodiment 2

[0029] A method for preparing a fatigue-resistant and radiation-resistant diaphragm compound, the specific steps are as follows:

[0030] (1) Mastication: Masticate 40 parts of EPDM rubber and 60 parts of nitrile rubber on an open mill, adjust the roller distance to 1.5-4mm, control the roller temperature at 40-50°C, and masticate for 10 minutes to make mastication glue.

[0031] (2) Mixing: Mixing adopts a two-stage mixing process. In the first stage of mixing, first put the plasticized rubber into the internal mixer, press the top bolt, and mix for 0.5 minutes, then open the top bolt and add charcoal 25 parts of black N550, 20 parts of carbon black N770, 8 parts of white carbon black, 5 parts of zinc oxide, 3 parts of stearic acid, 8 parts of paraffin oil, 5 parts of liquid butadiene, 1 part of anti-aging agent RD, anti-aging agent 4020 1 part in total, 1 part of anti-aging agent BLE, 1 part of microcrystalline wax, 40 parts of trilead tetraoxide, 2.5 parts of boron carbide...

Embodiment 3

[0033] A method for preparing a fatigue-resistant and radiation-resistant diaphragm compound, the specific steps are as follows:

[0034] (1) Masticating: Masticate 100 parts of EPDM rubber on an open mill, adjust the roller distance to 1.5-4mm, control the roller temperature at 40-50°C, and masticate for 12 minutes to make plasticized rubber.

[0035] (2) Mixing: Mixing adopts two-stage mixing process. In the first stage of mixing, put the plasticized rubber into the internal mixer, press the top bolt, and mix for 1.5 minutes, then open the top bolt and add charcoal 30 parts each of black N330 and carbon black N990, 5 parts of white carbon black, 8 parts of zinc oxide, 3 parts of stearic acid, 18 parts of paraffin oil, 1 part of anti-aging agent RD, 1 part of anti-aging agent BLE, 1 part of anti-aging agent MC, cerium oxide 5 parts, 3 parts of dysprosium oxide, 2.5 parts of boron nitride, 2.8 parts of binder RS and 5 parts of carbon nanotubes, banburying for 4 minutes, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com