Crown spring jack connecting part

A technology of connectors and crown springs, which is applied in the direction of connections, parts of connection devices, contact parts, etc., can solve problems such as arc generation, potential safety hazards, and fatigue damage of insert structures, so as to improve service life, stability and Good durability and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

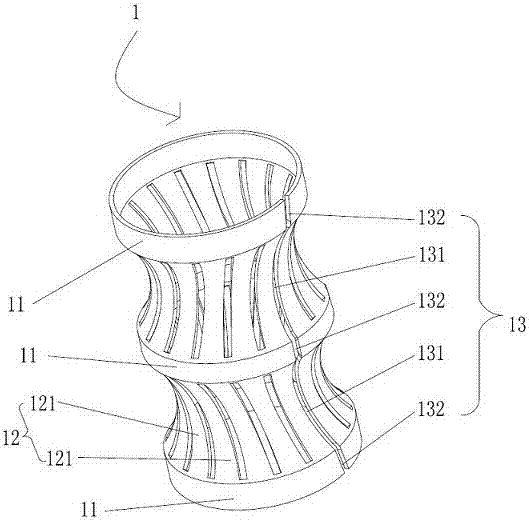

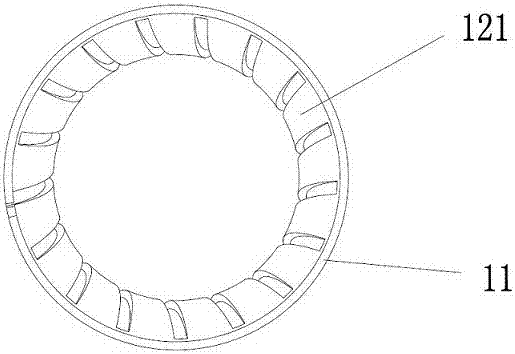

[0025] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

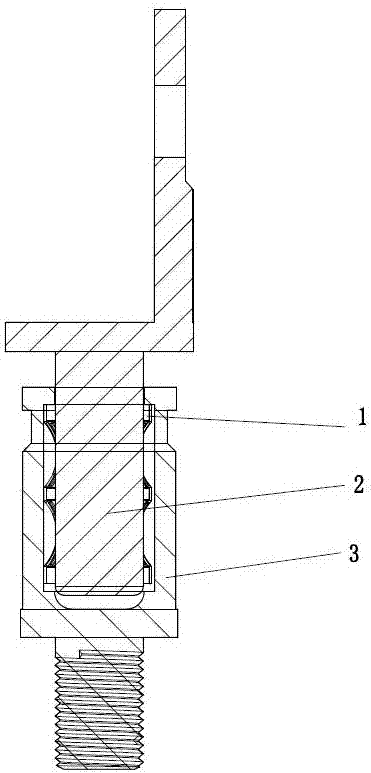

[0026] Please refer to figure 1 , The crown spring socket connector 1 provided by the specific embodiment of the present invention is used for the connection between the plug 2 and the socket 3 in a manual maintenance switch or an electrical connector. The crown spring socket connector 1 is arranged between the plug 2 and the socket 3 for preventing poor contact between the plug 2 and the socket 3 .

[0027] In this embodiment, the crown spring socket connector 1 is made of phosphor bronze, which has good ductility, current carrying capacity, electrical conductivity and impact resistance, so that the plug 2 and the jack 3 can perform operations such as live plugging and exceeding the rated current impact, without electric sparks, and at the same time, the crown spring soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com