Sulfuric acid dew point corrosion-resistant steel

A technology that resists sulfuric acid and corrodes steel, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of easy segregation, reduced productivity, and increased cost, and achieves excellent resistance to sulfuric acid dew point corrosion, as well as manufacturability and fatigue resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0139] Steel having the composition shown in Table 1 (the balance being Fe and unavoidable impurities) was smelted in a converter and cast into a slab with a thickness of 200 mm by continuous casting. After cooling this steel slab, it heated again to 1200 degreeC, and hot-rolled it, and produced the hot-rolled steel plate of thickness 4.5mm.

[0140] It should be noted that in hot rolling, the rolling reduction was set to 97.75%, the finish rolling temperature was set to 850°C, the coiling temperature was set to 560°C, and the average cooling temperature from 800°C to 650°C The speed is set as shown in Table 2.

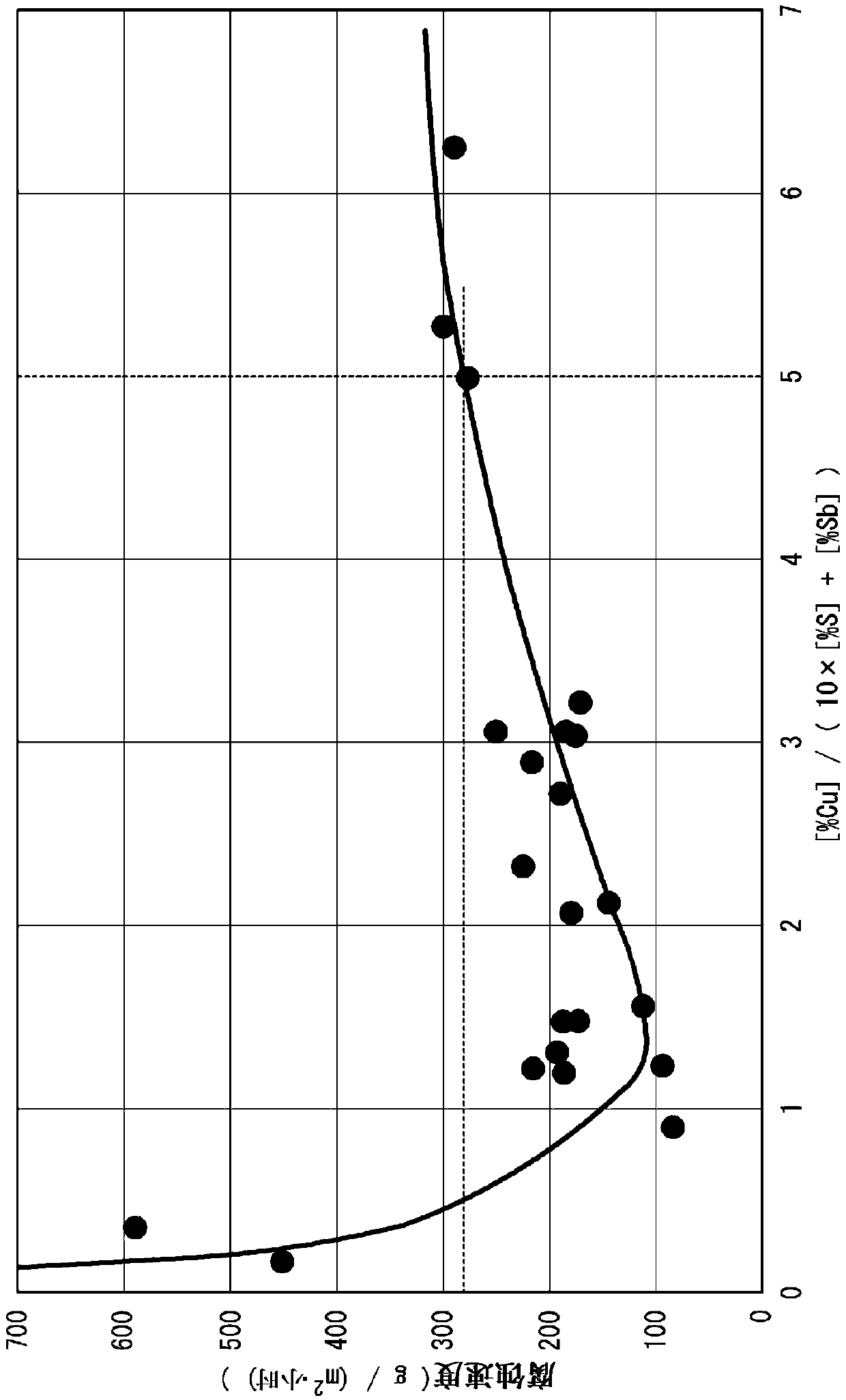

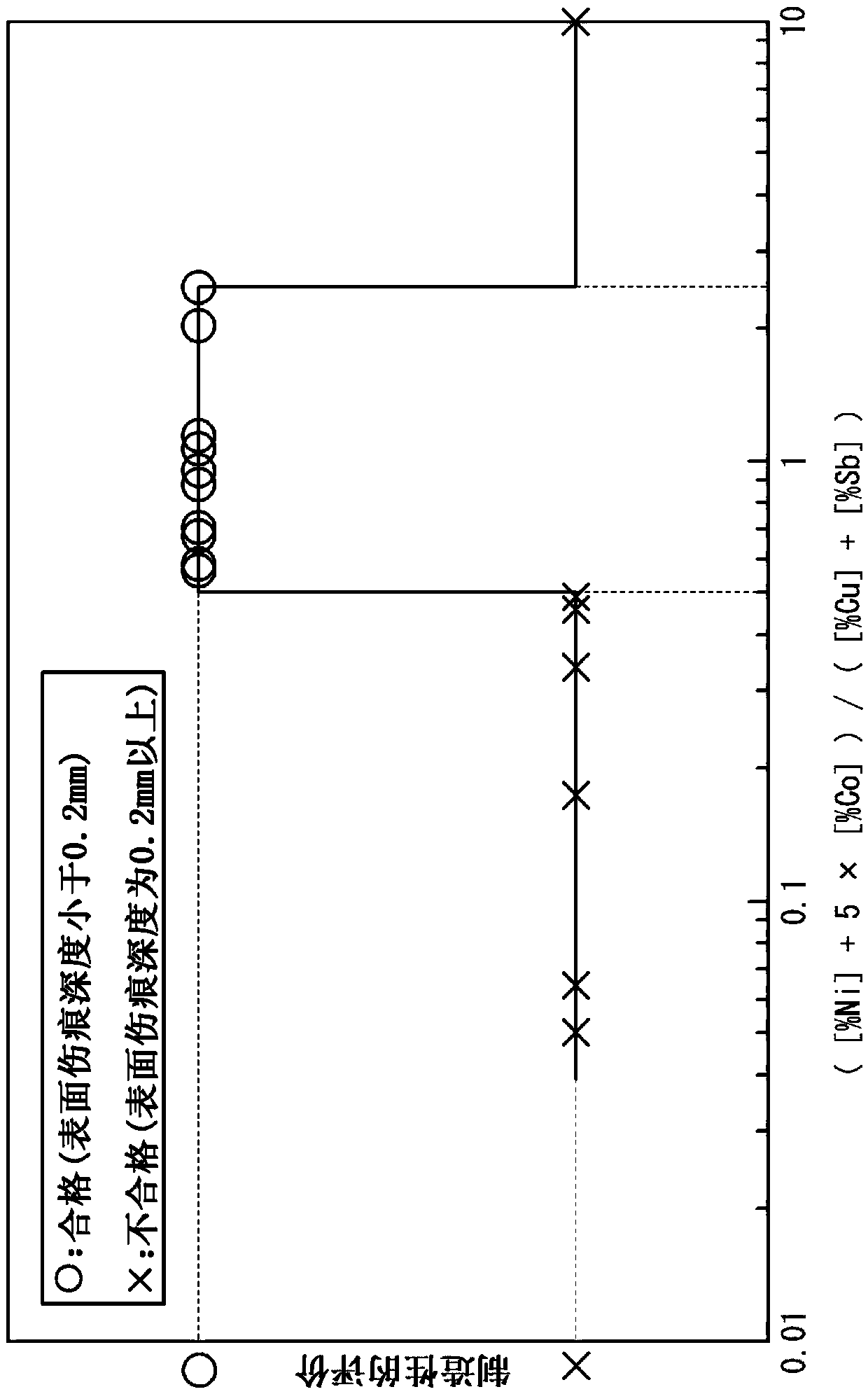

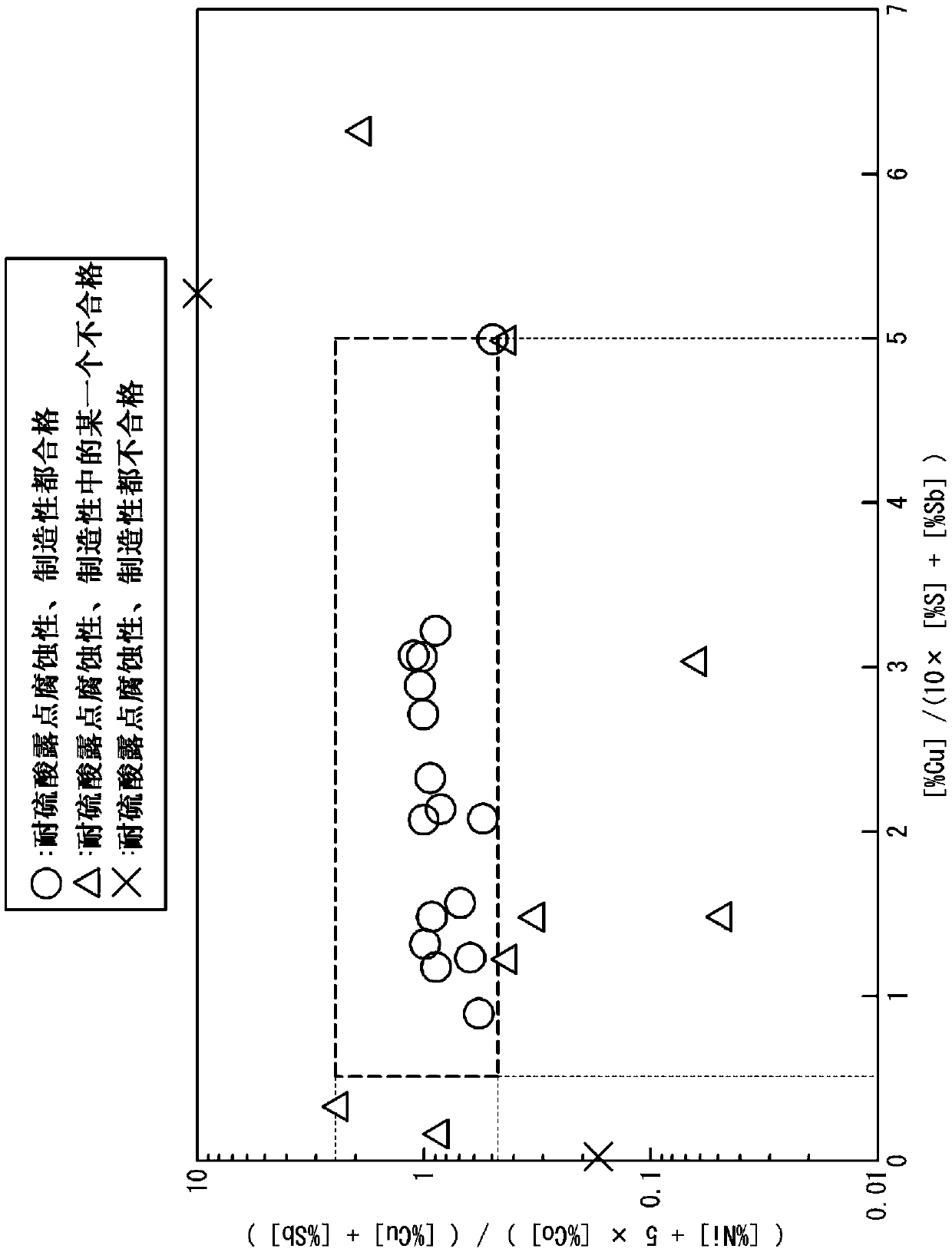

[0141] For the hot-rolled steel sheet thus obtained, the area ratio of each phase in the steel structure and the Vickers hardness were measured, and the sulfuric acid dew point corrosion resistance, manufacturability, bendability, and fatigue resistance were measured by the methods shown below. Evaluation. These results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatigue strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com