Stretchable photoresponse liquid crystal light scattering display screen and manufacturing method thereof

A light scattering and display technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of low contrast and non-stretchability, and achieve the effects of good fatigue resistance, high brightness, and wide field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

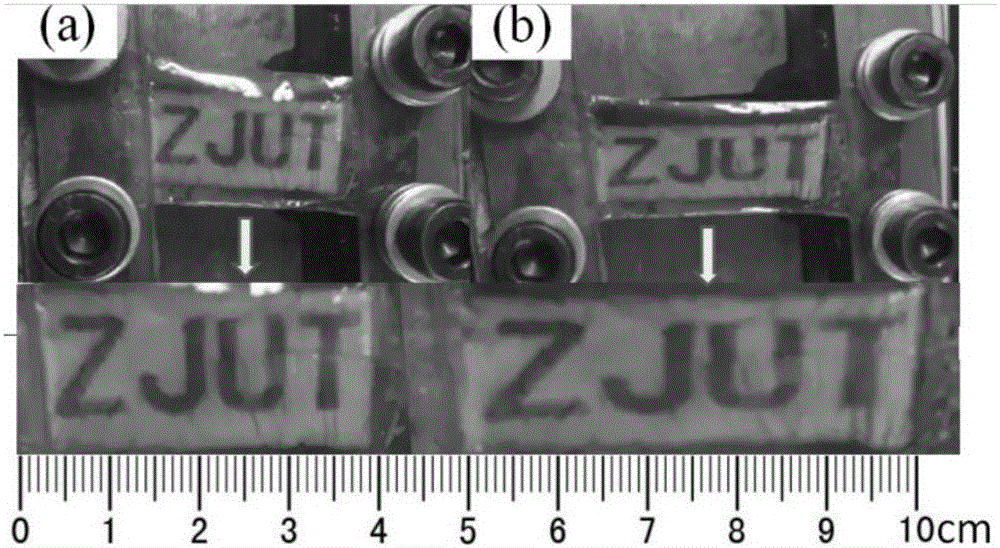

[0027] Example 1: Light-responsive stretchable liquid crystal light-scattering display

[0028] (1) Preparation of polyurethane film

[0029] Clear polyurethane 95A (purchased from Shanghai Zhixin Technology Co., Ltd.) 1.0g and polyurethane Clear 95B (purchased from Shanghai Zhixin Technology Co., Ltd.) 1.5g was mixed thoroughly at room temperature (25°C), and placed in a vacuum desiccator at room temperature for 12 minutes for defoaming to obtain a non-foaming prepolymer with certain fluidity. Quickly introduce it into a mold (76mm×25mm×3mm) made of glass slides, wherein the thickness of the mold is controlled by double-sided adhesive tape to 3mm, and the thickness of the film is 1mm. After the transfer was completed, the prepolymer was cured at 150°C for 10 minutes at high temperature, and then peeled off with a blade while it was still hot to obtain a polyurethane film matrix, which was cut into a polyurethane film with a size of 65mm×23mm×1mm.

[0030] (2) Light-respo...

Embodiment 2

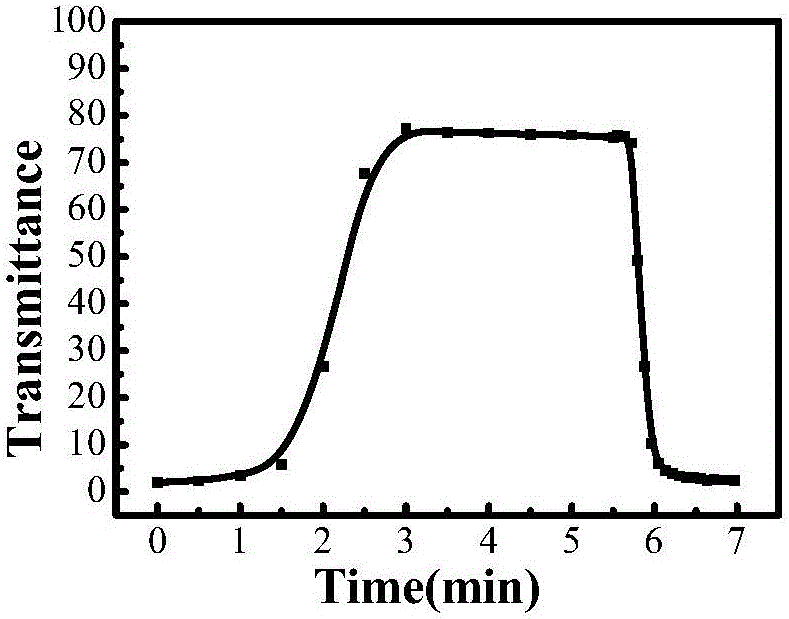

[0033] Embodiment 2: Measurement of light transmittance of liquid crystal physical gel

[0034] At 150°C, add 4.7wt% 4,4'-diethoxyazobenzene and 0.5wt% gel factor (compound of formula (IX)) to 94.8wt% 5CB liquid crystal, 150°C oil bath Mix well and wait until they are mutually soluble to prepare liquid crystal physical gel 0.5wt% POSS-G1-BOC / 5wt% 2Azo2 / 5CB. The liquid crystal physical gel was poured into a mold box (30mm×20mm×2.5mm) made of glass slides, and the thickness of the liquid crystal physical gel layer was controlled to be 0.5mm. After irradiating the liquid crystal physical gel layer with ultraviolet light with a wavelength of 365nm for 5.5 minutes, the light transmittance of the liquid crystal physical gel showed an "S" type change with time, as shown in Fig. figure 2 shown. At 0-1.0min, the liquid crystal molecules still maintain the anisotropic phase, and the light transmittance hardly changes at this time. At 1.0-3.0min, the azobenzene compound molecules con...

Embodiment 3

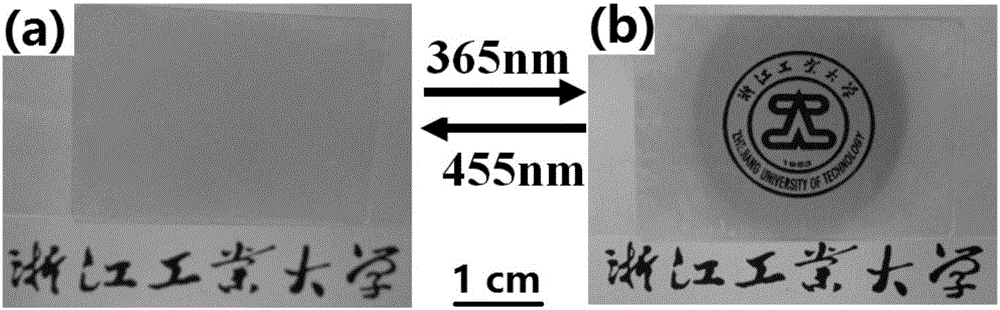

[0036] Example 3: Changes in the display screen image before and after the liquid crystal physical gel is irradiated with ultraviolet / blue light

[0037] At 150°C, add 4.7wt% 4,4'-diethoxyazobenzene and 0.5wt% gel factor (compound of formula (IX)) to 94.8wt% 5CB liquid crystal, 150°C oil bath Mix well and wait until they are mutually soluble to prepare a liquid crystal physical gel 0.5wt% POSS-G1-BOC / 5wt% 2Azo2 / 5CB, and pour it into a mold box (40mm×25mm×2.2mm) made of glass slides , controlling the thickness of the liquid crystal physical gel layer to be 0.2 mm. Liquid crystal physical gel before and after UV / blue light irradiation (UV light: 35.4mW / cm 2 , 10min; blue light: 26.5mW / cm 2 , 3min) The display image changes as follows image 3 shown. Such as image 3 As shown in (a), the liquid crystal physical gel as a whole scatters the incident light, showing an opaque state, and the school logo of "Zhejiang University of Technology" cannot be seen. However, when the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com