Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213results about How to "Good degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

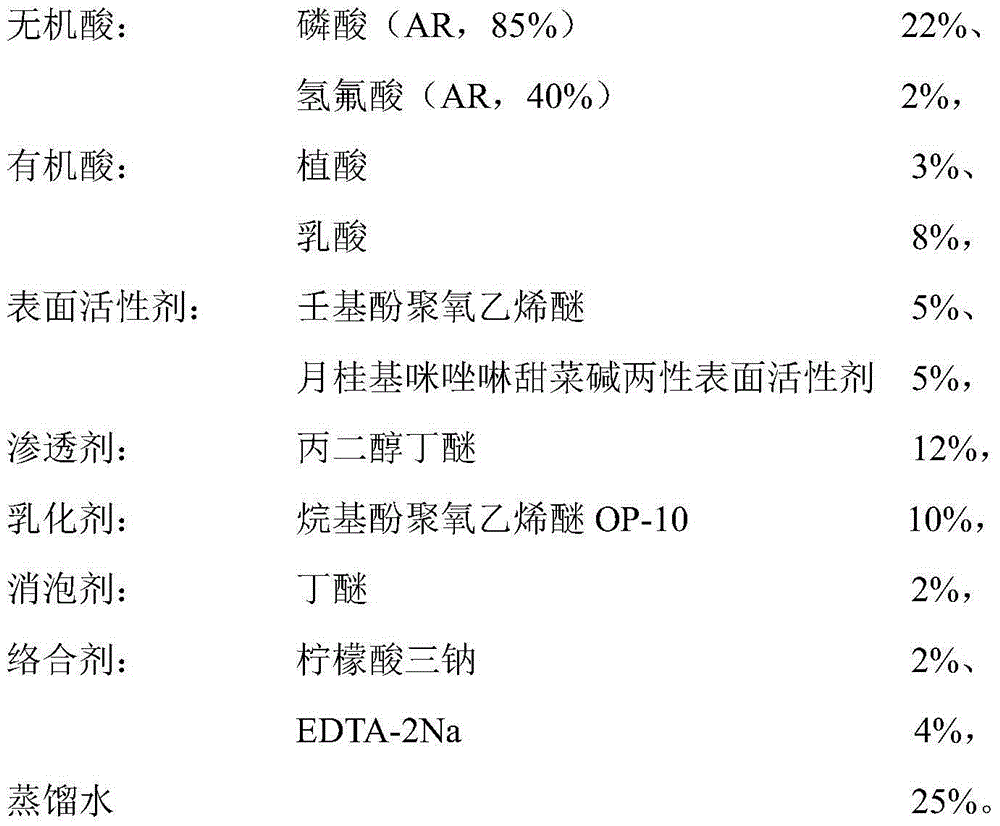

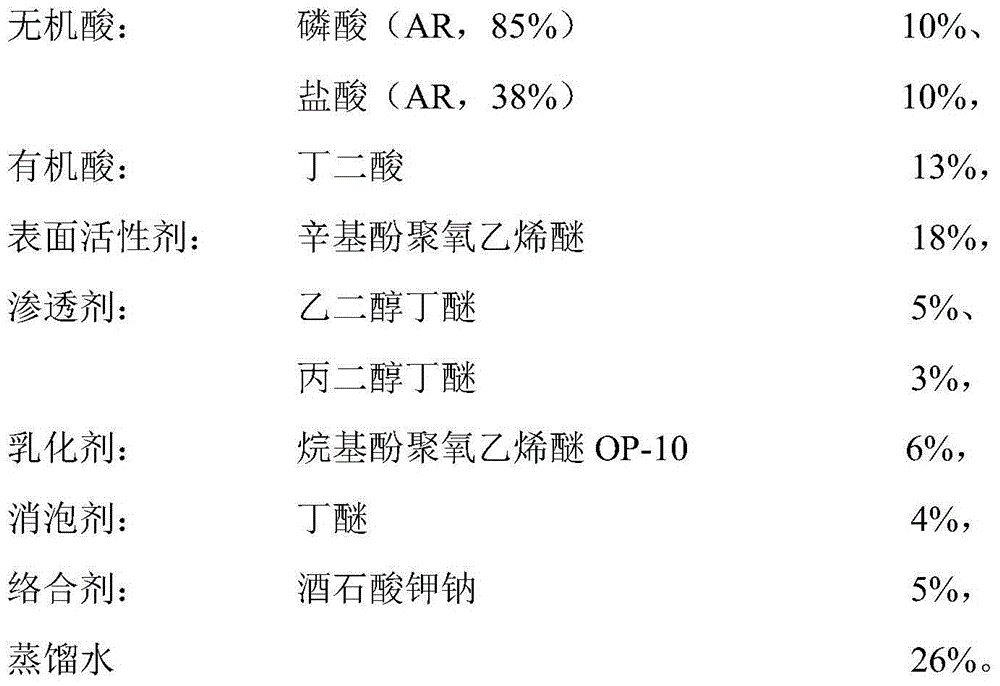

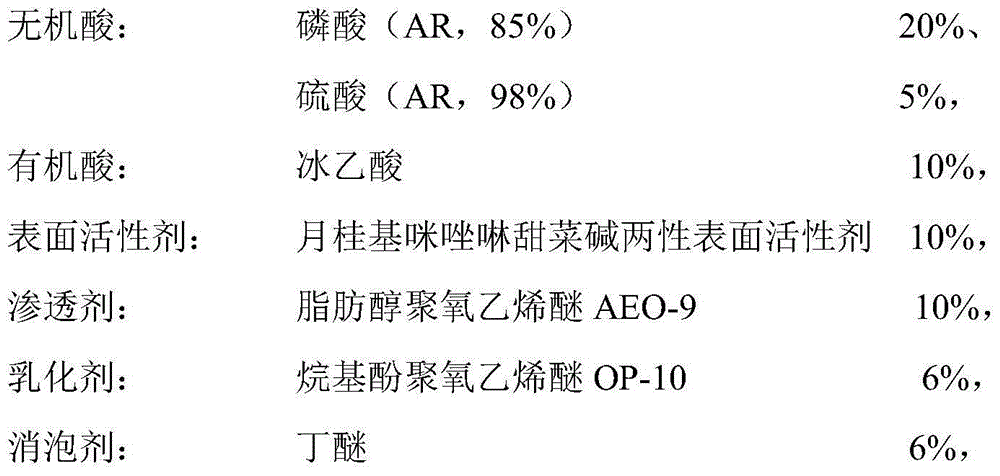

Environment-friendly aluminum cleaning agent and preparation method thereof

The invention discloses an environment-friendly aluminum cleaning agent and a preparation method thereof. The cleaning agent is composed of the following components in percentage by weight: 20% to 25% of inorganic acid, 10% to 20% of organic acid, 10% to 18% of surfactant, 8% to 15% of osmotic agent, 6% to 18% of emulsifier, 2% to 8% of antifoaming agent, 5% to 8% of complexing agent, and 25% to 30% of water. In the provided cleaning agent, the using amount of hydrochloric acid, sulfuric acid, and nitric acid is reduced, the aluminum parts are washed by medium-strong acids and organic acids, and the cleaning agent has a very good oil stain and rust removing ability. The cleaning agent is acidic, the pH value of the cleaning agent is 2.1 to 5.6, and the cleaning agent can well remove the oxide scale on the aluminum surface. Because the acidity of the organic acids is weak, the over-corrosion on work tools and acid volatilization, which can harm the workers' health, are effectively avoided, and the cleaning effect is not influenced at the same time. Moreover the adopted organic acids are easy to decompose, and thus the cleaning agent is environment-friendly.

Owner:PINGGAO GRP +1

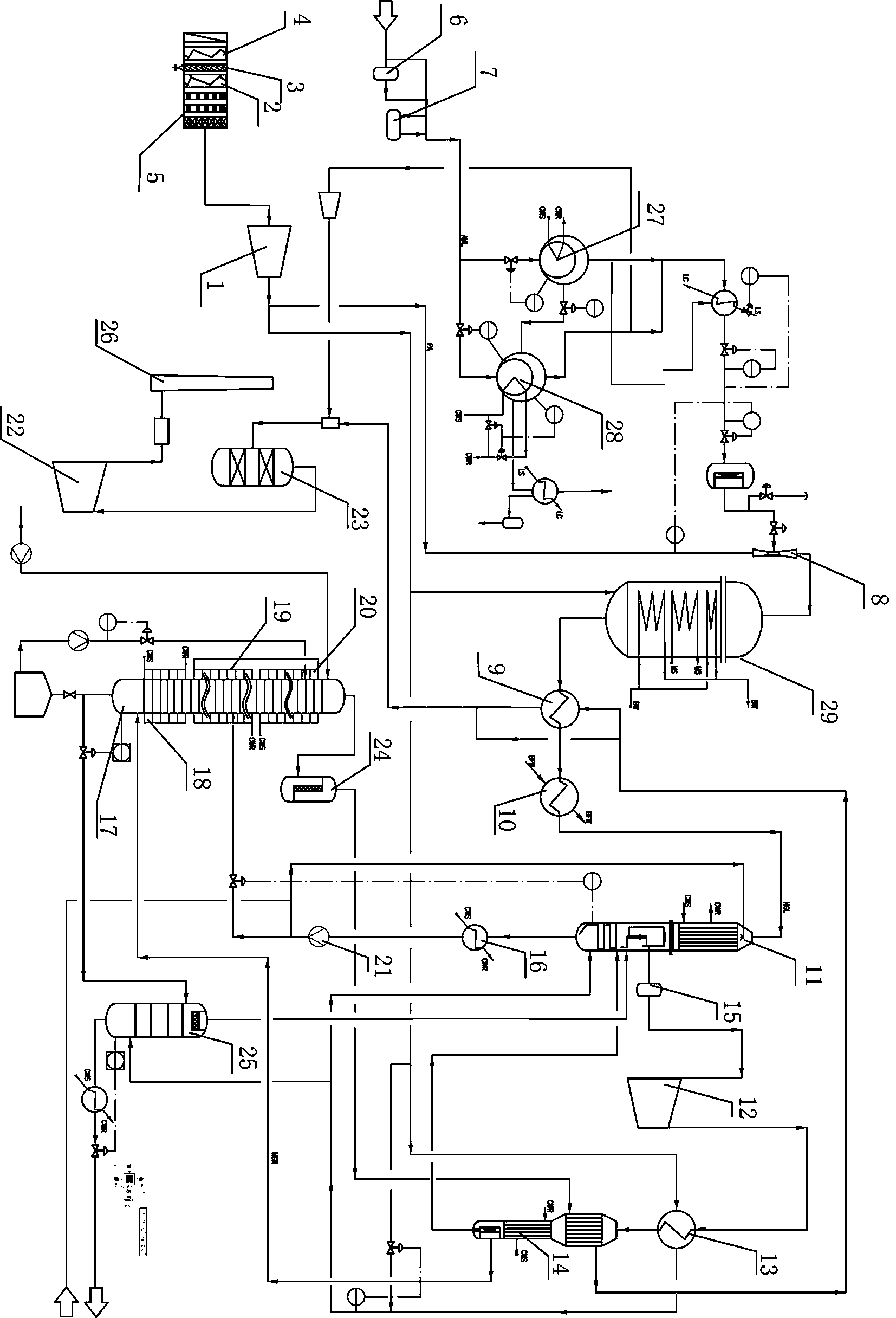

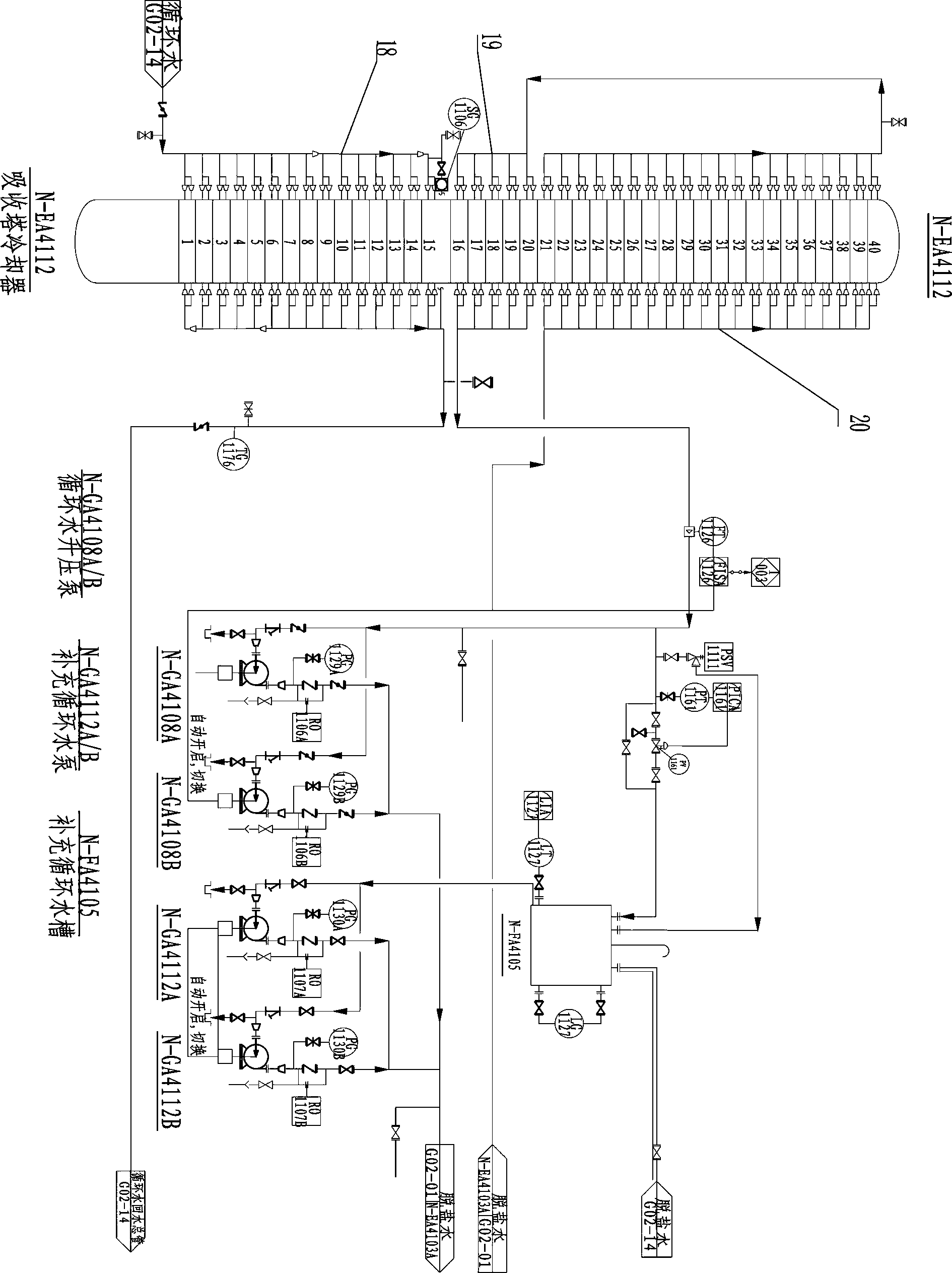

Method and device for preparing high-concentration dilute nitric acid

The invention discloses a method and device for preparing high-concentration dilute nitric acid. The method comprises the following steps: carrying out ammonia-air mixing, ammoxidation, condensation separation and fine separation on air subjected to impurity removal and dehumidification and liquid ammonia subjected to impurity removal, oil removal and evaporation, absorbing in an absorption tower in which 40 tower plates are arranged, meanwhile, carrying out cooling heat exchange by a three-stage water circulation technique to obtain the high-concentration dilute nitric acid of which the concentration is not lower than 68-70%. The method and device effectively enhance the nitric acid absorption efficiency, enhance the concentration of the dilute nitric acid, and can better satisfy the demands of modern industry for high-concentration dilute nitric acid.

Owner:TIANJI COAL CHEM IND GROUP

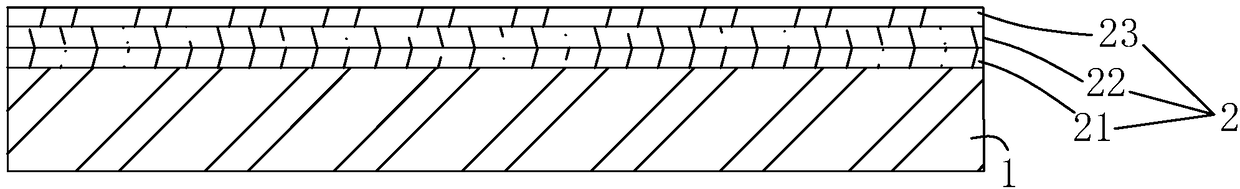

Processing technology of aluminum veneer for curtain wall

InactiveCN108993838AGood degreasingReduce the amount of fatWallsPretreated surfacesSurface grindingLacquer

The invention relates to a processing technology of an aluminum veneer for a curtain wall, and relates to the field of curtain wall materials. The processing technology solves the problems that the existing aluminum veneer and coatings are insufficient in binding force and the coatings are easy to fall off are solved. The processing technology specifically comprises the following steps of cutting-punching-bending-weld joint grinding-surface grinding-surface pretreatment-spray coating-drying; the surface pretreatment comprises degreasing, pickling and passivation; and the spray coating comprises priming, finishing coating and finish-coat painting. According to processing technology, in the degreasing process, a degreasing agent selected has an excellent degreasing effect, and grease can beadsorbed in the degreasing process, so that quantity of the grease with which the aluminum veneer is coated is reduced in a flushing process; the degreasing process is matched with pickling operation,the grease can be removed as much as possible, the aluminum veneer is good in degreasing effect, so that viscosity fastness of a primer can be increased when the priming is conducted; and the primer,the finish coat and finish-coat paint are connected tightly, and therefore paint layers of the finally generated aluminum veneer do not easily fall off.

Owner:安信铝业集团有限公司

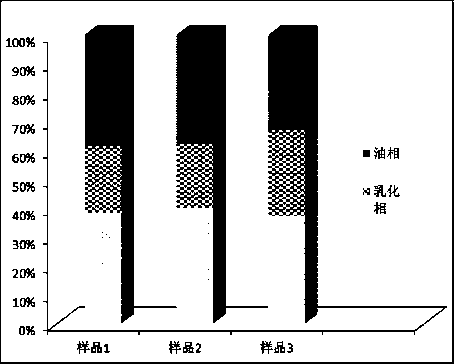

Method for preparing sodium alginate/ chitosan sustained-release microcapsule by external gelation

InactiveCN101239052AEasy to prepareGood spherical shapePharmaceutical delivery mechanismPharmaceutical non-active ingredientsCalcium EDTADispersed media

The invention discloses a method for emulsionizing outer gelation and preparing sodium alginate / chitosan slow release micro-capsule in one step. The current preparation method of calcium alginate gel by internal gelation has defects that small parts of the calcium salt granules cannot be richly reacted with glacial acetic acid and remained in the sodium alginate calcium beads, the encapsulization materials are easily lost and the wrapping rate is low due to the calcium salt is difficult to evenly disperse. The invention uses the sodium alginate liquor as the disperse phase, the edible plant oil as the disperse medium and the sorbitan monooleate as the surfactant to emulsionize small liquid drops wrapped with oil; calcium chloride chitosan liquor is used for initiating the gelation reaction of the sodium alginate so as to generate sodium alginate / chitosan slow release micro-capsule; the oil remained on the surface is eliminated by a oil removing device with precipitation self-drifting method. The invention elevates the micro-capsule medicine contents and the wrapping rate.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

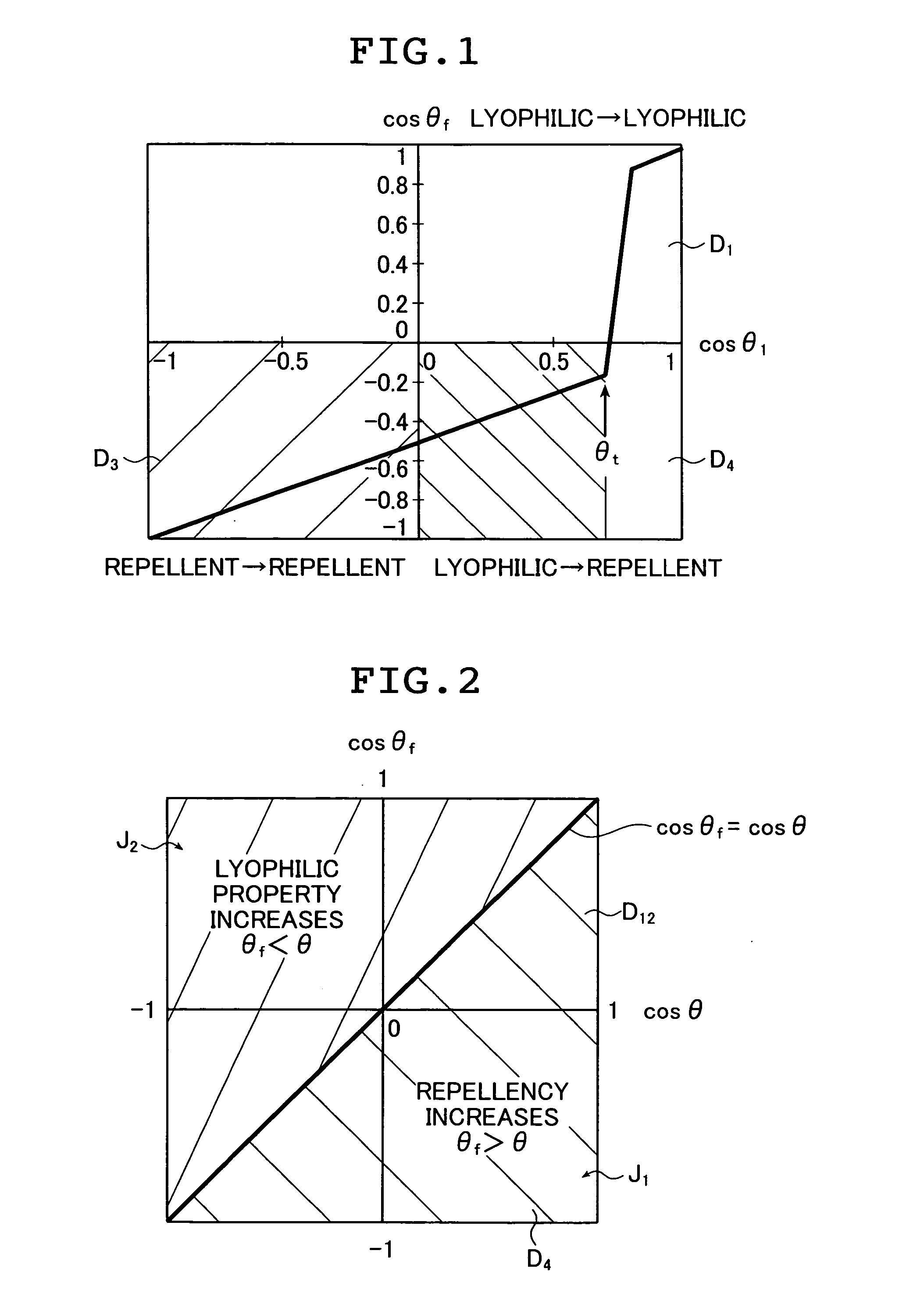

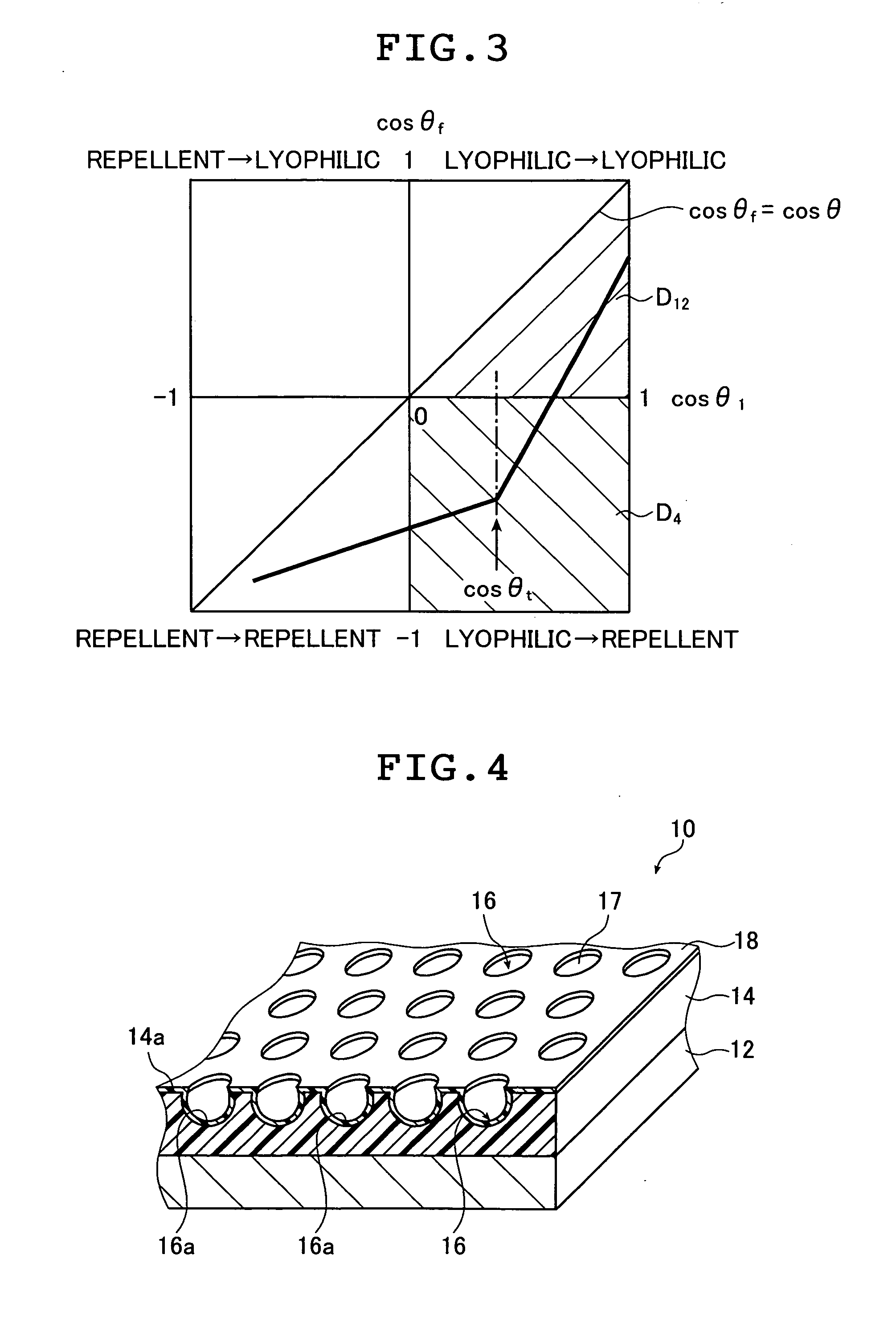

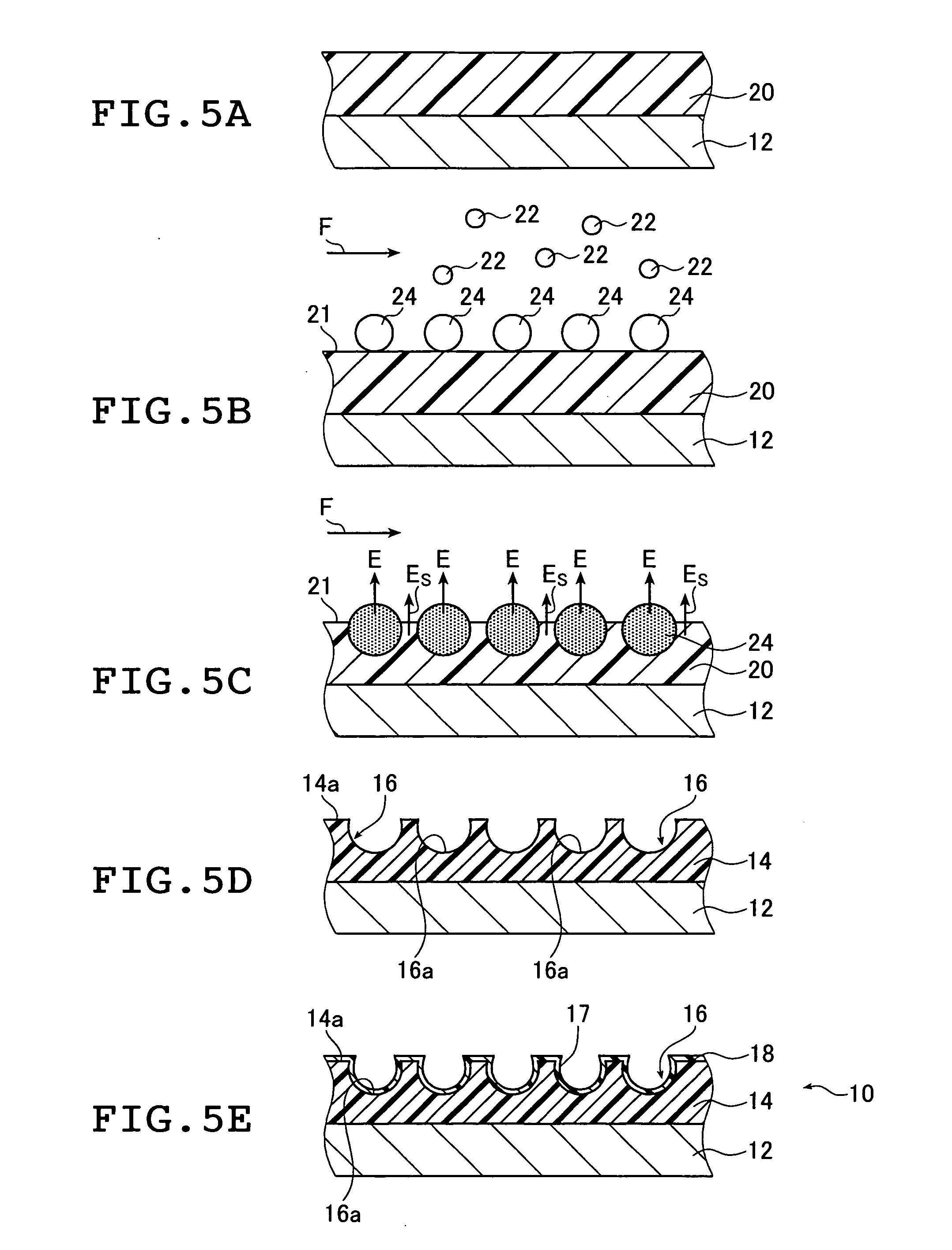

Liquid repellent structure, method of producing the same, liquid ejection head and protective film

InactiveUS20070160790A1Increase repulsionIncrease contact angleMovable spraying apparatusSynthetic resin layered productsTectorial membraneSimple Organic Compounds

The liquid repellent structure includes a support, and a honeycomb-patterned film and a coating film on the honeycomb-patterned film or a liquid repellent film. The method of producing the structure applies a solution of an organic compound in an organic solvent onto the support, places the support in an atmosphere containing water vapor to form water droplets on a surface of the solution film, evaporates the organic solvent and the droplets to form the honeycomb-patterned film, and forms the coating film made of a fluorine-containing material on a surface of the honeycomb-patterned film or etches the honeycomb-patterned film to form a second honeycomb-patterned film. The liquid ejection head includes an ejection substrate having the liquid repellent structure. The protective film includes a support base and the liquid repellent structure.

Owner:FUJIFILM CORP

Extraction method of morindea officinalis polysaccharide

The invention provides an extraction method of morindea officinalis polysaccharide, belonging to the technical field of traditional Chinese medicines and solving the problems that in the existing morindea officinalis polysaccharide extraction method, the extraction method has complicated process steps and a poor protein removal effect, and the yield and purity of the obtained morindea officinalispolysaccharide are low. The extraction method of morindea officinalis polysaccharide in the invention comprises the following steps of: drying morindea officinalis rhizome and then smashing to 40-80 meshes; adding a chloroform / methanol mixed solvent in morindea officinalis powder for carrying out reflux extraction; carrying out alcohol extraction on a filter cake obtained by filtration and then adding water for lixiviation; subsequently, filtering and concentrating a filtrate, carrying out alcohol precipitation on a concentrated liquid and then filtering so as to obtain the crude morindea officinalis polysaccharide; adding the crude morindea officinalis polysaccharide into a n-butanol / trichloroacetic acid mixed solvent for processing, and entering a chromatographic column for elution; andcarrying out concentration, alcohol precipitation, filtration and drying on an effluent liquid so as to obtain the morindea officinalis polysaccharide. The extraction method of the morindea officinalis polysaccharide in the invention has a simple process and a good protein removal effect, and the extracted morindea officinalis polysaccharide has less impurities and high yield and purity.

Owner:朱孟勇

Method for preparing washing surfactant by utilizing tanning waste chrome shavings

InactiveCN103525574ASolve the problem of environmental pollutionReduce manufacturing costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium acid carbonateActive agent

The invention relates to a method for preparing washing surfactant by utilizing tanning waste chrome shavings. The method comprises the following steps: performing protomorphic dechromization on the tanning waste chrome shavings to obtain a chrome shaving protomorphic dechromized product; hydrolyzing the obtained chrome shaving protomorphic dechromized product to obtain protein polypeptide hydrolysate; performing acylation condensation by utilizing fatty acyl chloride to obtain an initial product of the surfactant; and adding sodium carbonate, sodium dodecyl benzene sulfonate, absolute ethyl alcohol and sodium benzoate, and stirring to react to obtain the final product washing surfactant. If the surfactant prepared by utilizing waste leftovers in tanning can be popularized and applied, the problem of environmental pollution caused by tanning waste can be effectively solved, and the production cost for the surfactant product can be greatly reduced.

Owner:山东全杰皮革研究所有限公司

Degreasing agent used for workpieces, preparation method and workpiece surface spraying pretreatment method

ActiveCN108384645AGood degreasingImprove washing effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPretreatment method

The invention relates to a degreasing agent used for workpieces, a preparation method and a workpiece surface spraying pretreatment method. The degreasing agent includes 3-5% by mass of a component A,3-5% by mass of a component B and the balance of tap water or deionized water, wherein the component A includes deionized water, an inorganic base, a complexing agent and a compounded low-foam solubilizing surfactant, and a mass ratio of the deionized water to the inorganic base to the complexing agent to the compounded low-foam solubilizing surfactant is (65-70):(15-25):(1-2):(8-14); and the component B includes deionized water, a complexing dispersant, a corrosion inhibitor, a low-foam solubilizer, an end-capped / modified isomeric alcohol ether surfactant and a modified polyether, and a massratio of the deionized water to the complexing dispersant to the corrosion inhibitor to the low-foam solubilizer to the end-capped / modified isomeric alcohol ether surfactant to the modified polyetheris (50-70):(1-2):(0-5):(5-10):(8-15):(8-25). The degreasing agent provided by the invention can be used at room temperature during spraying, has an excellent degreasing effect, and does not generatea large amount of foam; and the method for preparing the degreasing agent and the workpiece surface spraying pretreatment method which uses the degreasing agent have simple operation, and are suitablefor mass production.

Owner:佛山科富科技有限公司

Extrusion forming agent and preparation and use thereof

The invention discloses an extrusion forming agent, and preparation and use thereof, in particular to a forming agent for a tungsten-based alloy or hard alloy or ceramic powder extrusion forming process, and preparation and use thereof. The forming agent comprises 60 to 80 percent of solid and liquid paraffin wax, 3 to 8 percent of carnauba wax, 10 to 20 percent of high density polyethylene and ethylene-vinylacetate copolymer, 1 to 8 percent of plasticizer, 1 to 5 percent of stearic acid and the balance of modifier. In the invention, the drawbacks of long degreasing time, low degreasing conformality and more degreasing defects of extrusion blanks, particularly large-size extrusion blanks, are overcome, the raw materials are cheap and easy to purchase, the component compatibility of the prepared forming agent is high, the forming agent is used in a powder extrusion forming process, the micro structure of the forming agent is uniform, the forming agent has strong interaction force with powder, the formability is high, the quick and flawless degreasing of blanks with a thickness of 40 millimeters can be realize, the production efficiency is improved, and the development of extrusion forming industry is promoted greatly.

Owner:CENT SOUTH UNIV

Non-denatured II type collagen of animal cartilage source and preparation method for non-denatured II type collagen

InactiveCN105331662AGood degreasingEasy to handlePeptide preparation methodsFermentationCartilage cellsFreeze-drying

The invention discloses a preparation method for non-denatured II type collagen of an animal cartilage source. The preparation method is characterized by comprising the following steps: taking fresh and traceable animal cartilages as raw materials; carrying out purification treatment on the animal cartilages by virtue of processes of repeated freeze-thawing, ultrasonic degreasing, hypertonic solution decellularizing, acid-base softening and the like; carrying out processes of guanidine hydrochloride sugar-removing, pickling, compound enzyme treatment, multi-time salting-out, multi-time centrifugal purification, membrane dialysis, freeze-drying and the like, thereby obtaining spongy non-denatured II type collagen. The high-purity high-yield II type collagen obtained by the preparation method keeps the original complete triple-helix structure of the collagen, is high in biological activity, stable in structure, easy to store and beneficial to adhesion, growth and multiplication of cartilage cells, and can be used for preparing medical biological materials.

Owner:SICHUAN UNIV

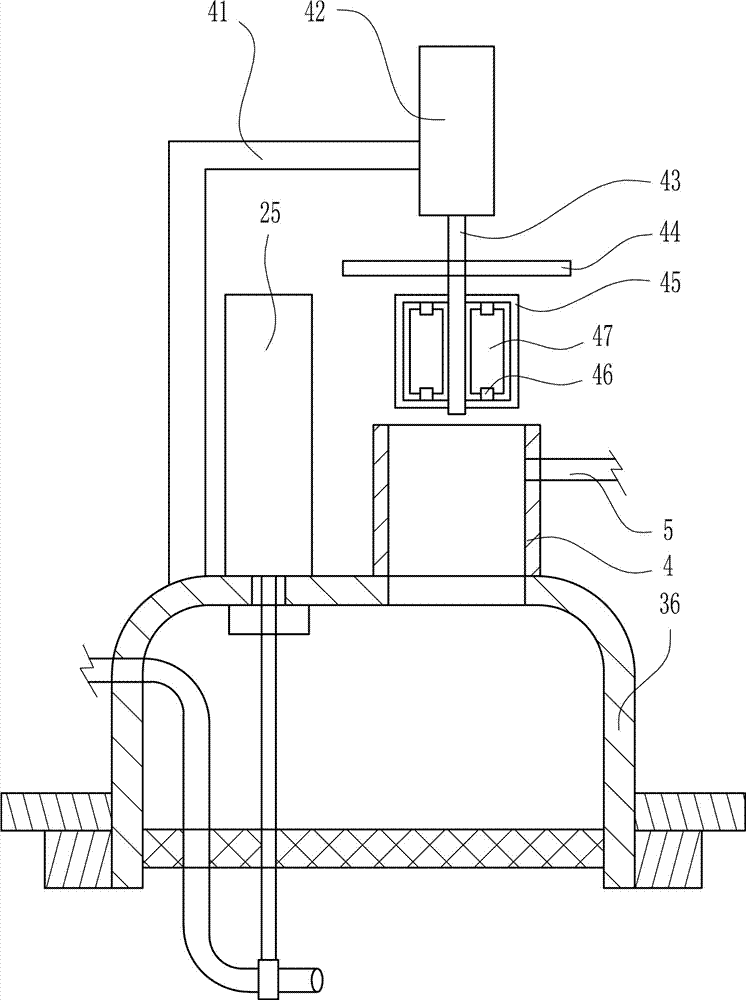

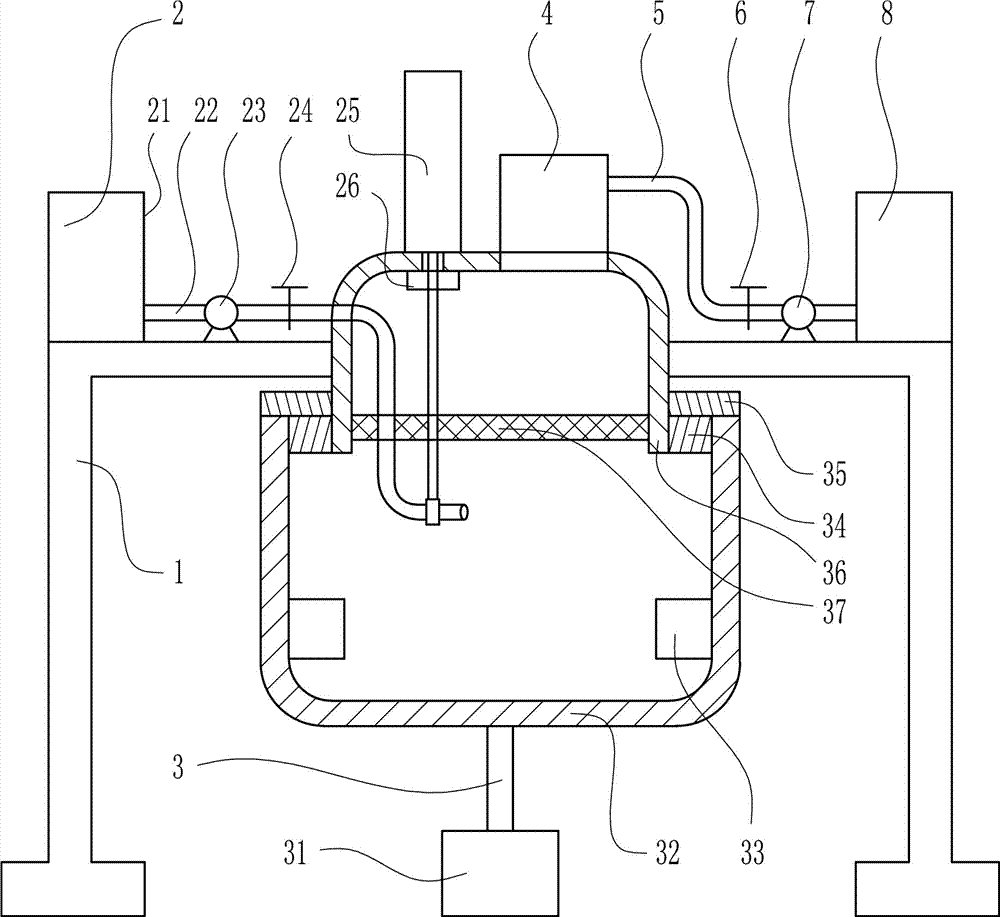

Process and apparatus for treating sewage

InactiveCN101264999APrevent subsidenceGrowth inhibitionFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesPeristaltic pumpDecomposition

The invention relates to a sewage treatment process and equipment thereof, belonging to the technology field of sewage treatment. The process comprises feeding oil field produced water into a flocculating and settling tank for flocculation and settlement; collecting supernatant in the flocculating and settling tank, and feeding into a hydrolysis and acidification tank with an electric stirrer; feeding the effluent from the hydrolysis and acidification tank into a settling tank, and allowing anaerobic hydrolysis; collecting supernatant in the upper part of the settling tank, and feeding into a dynamic bioreactor; removing small-diameter oil drops and macro molecules in the supernatant via aerobic microorganism decomposition and adsorptive filtration by biofilm component; and discharging reinjection water or discharge water coming up to the standards from the dynamic bioreactor. The equipment comprises a flocculating and settling tank, a hydrolysis and acidification tank, a settling tank, and a dynamic bioreactor, wherein a peristaltic pump is arranged between the flocculating and settling tank and the hydrolysis and acidification tank, sludge retune pipe is arranged between the settling tank and the hydrolysis and acidification tank, an electric stirrer is arranged inside the hydrolysis and acidification tank, and an aeration device and a biofilm component are arranged inside the dynamic bioreactor.

Owner:SHANDONG UNIV

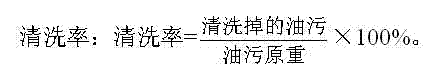

Preparation method of water-base efficient metal surface cleaning agent

The invention relates to a preparation method of a water-base efficient metal surface cleaning agent. At present, the commonly used metal cleaning agent is a solvent type or a phosphorus-containing water-base cleaning agent so that the generated pollution becomes the concerned problem and the environmentally-friendly water-base efficient metal surface cleaning agent which has good functions of decontamination, rust removal and rust prevention is urgently needed to be developed. The preparation method provided by the invention comprises the following steps of: carrying out an esterification reaction of polyoxyethylene polyoxypropylene amine ether and oleic acid to obtain polyoxyethylene polyoxypropylene amine ether oleate; and then compounding the polyoxyethylene polyoxypropylene amine ether oleate with 6053, penetrant JFC, dodecyl sulfonic acid, urea, sodium silicate, sodium citrate, flake caustic soda, isopropanol, polyether L61 and water to obtain the water-base efficient metal surface cleaning agent. The water-base efficient metal surface cleaning agent, provided by the invention, has the excellent functions of dust removal, surface oil contamination removal and rust prevention, and can be widely applied to treatments including surface cleaning, rust removal, contamination removal and the like of various metal materials and work pieces before and after the various metal materials and the work pieces are processed; and meanwhile, the water-base efficient metal surface cleaning agent also has the characteristics of small pollution, no phosphorus, low corrosion on equipments and the like.

Owner:SHAANXI UNIV OF SCI & TECH

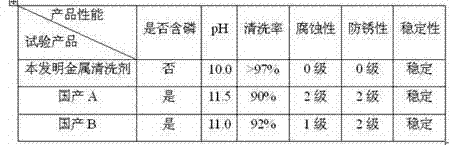

Sewage circulating treatment system

InactiveCN110255803ASave waterIncrease profitFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationPrecipitationSewage

The invention discloses a sewage circulating treatment system, which comprises a bracket, a filter box, a precipitation barrel, a base, an oil-water separation box and a purification box, the top of the bracket is provided with the precipitation barrel and the filter box; the two sides of the precipitation barrel are respectively fixedly provided with a fourth motor and a first slide rail; the output shaft of the fourth motor is fixedly provided with a second threaded rod; the second threaded rod is sleeved with a sleeve; and the sewage circulating treatment system carries out vibration filtration through a filter screen to remove large residues. The residues on the filter screen is extruded out of water by a hot pressing plate, grease is melted, and water utilization rate is improved; then the precipitation box carries out stirring and precipitating to remove a precipitate; the grease is absorbed by an oil absorption plate, oil and water separation is performed; finally, an absorption layer is used for absorption, peculiar smell is removed, a filter layer is used for filtering and decomposing; an ultraviolet lamp is used for sterilizing and disinfecting; and finally, the obtained liquid completely meets the use standard, and can be used again, and a large amount of water resources can be saved.

Owner:东莞市宇科机械科技有限公司

High entropy alloy feeding and preparation method and application thereof

InactiveCN107186208AImprove performanceHigh precision requirementsTransportation and packagingMetal-working apparatusHigh entropy alloysEconomic benefits

The invention relates to a high entropy alloy feeding and a preparation method and an application thereof. The high entropy alloy feeding comprises, by volume, 40%-70% of high entropy alloy powder, and 30%-60% of high molecular binder. The high entropy alloy feeding has the excellent properties of the high entropy alloy so that the high entropy alloy can be introduced in a metal injection molding technology, and application range of the high entropy alloy is expanded. According to the high entropy alloy feeding and the preparation method and the application thereof, the high entropy alloy feeding is applied to the metal injection molding technology, product stability during the injection molding process can be improved, the high entropy alloy product obtained has more than 97.5% of sintered density, production of high entropy alloy components and parts with complex production structures, excellent properties and high precision requirements is achieved beneficially. The high entropy alloy feeding has good economic benefit and application prospect.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

Scouring agent for cotton

The invention relates to a scouring agent for cotton. The scouring agent is prepared from 9-16 parts of high-molecular polymer, 8-18 parts of AEO-9, 8-14 parts of Sodium secondary alkyl sulfonate, 6-10 parts of ricinoleic acid butyl ester sodium sulfate, 12-19 parts of FMES, 3-6 parts of ethylene glycol monobutyl ether, 7-15 parts of isomeric alcohol ethoxylate and 350-420 parts of deionized water. During preparation, the deionized water is added into a stirrer, then AEO-9 and isomeric alcohol ethoxylate are added, the temperature is increased to 50 DEG C, and stirring and dissolving are conducted; then SAS60, ricinoleic acid butyl ester sodium sulfate, FMES, ethylene glycol monobutyl ether and high-molecular polymer are added and evenly stirred, and the scouring agent can be obtained. The scouring agent for cotton has good alkali resistance, permeability, cleaning performance, emulsification performance, dispersity, oil removing performance and the like, does not contain APEO, and is environmentally friendly.

Owner:绍兴市柯桥区科创高新技术开发中心

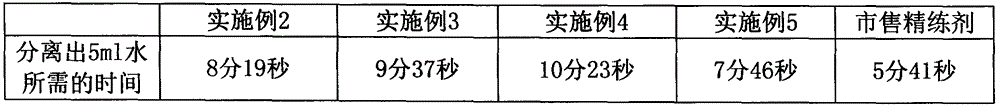

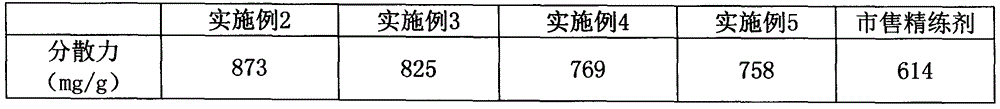

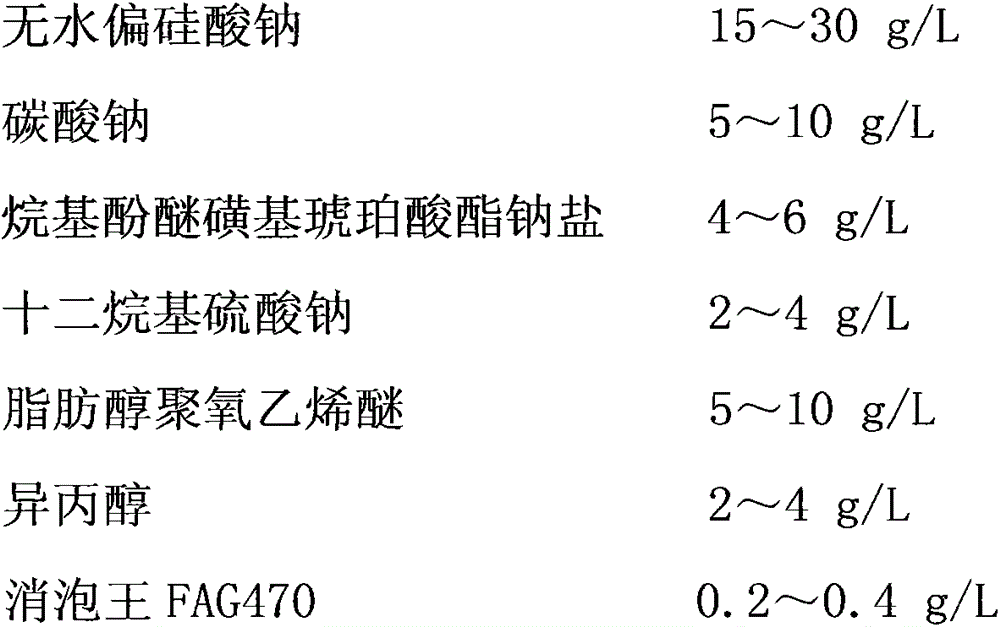

Phosphorus-free degreaser for surface spraying pretreatment of steel

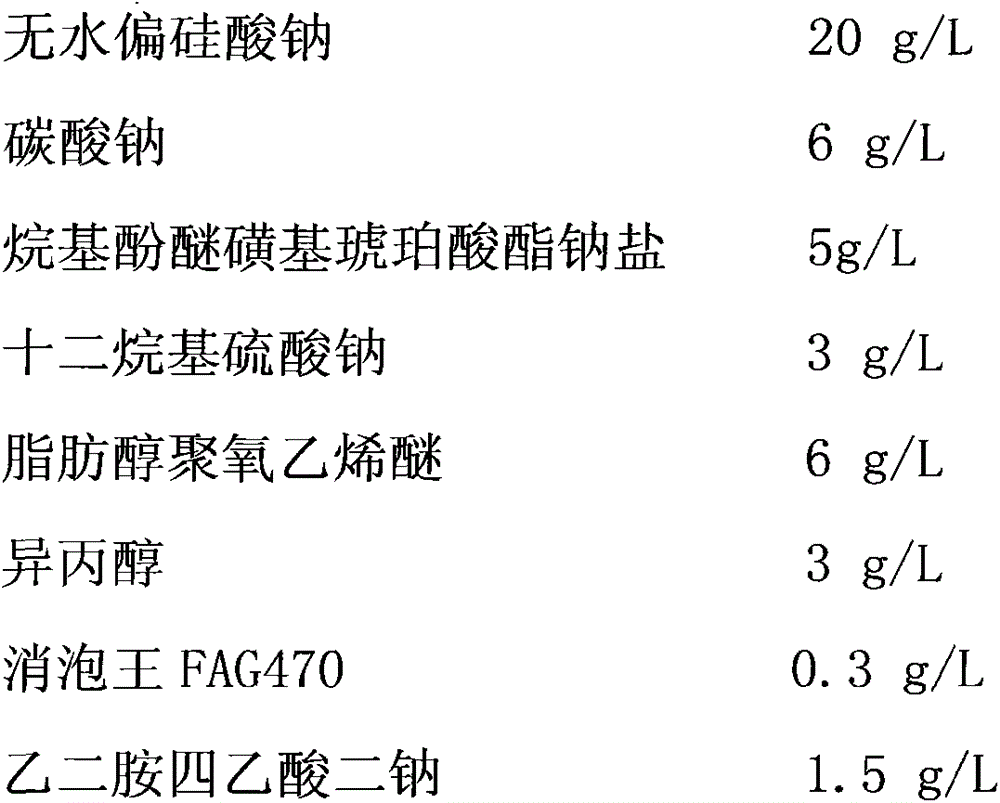

The invention relates to a steel surface spraying process, and particularly relates to a steel surface spraying pretreatment agent. The phosphorus-free degreaser for surface spraying pretreatment of steel is a mixed solution prepared from the following components in mass concentration: 15-30 g / L anhydrous sodium metasilicate, 5-10 g / L sodium carbonate, 4-6 g / L alkylphenol ether sulfosuccinate sodium salt, 2-4 g / L sodium lauryl sulfate, 5-10 g / L fatty alcohol-polyoxyethylene ether, 2-4 g / L isopropanol, 0.2-0.4 g / L defoaming agent FAG470, 0.5-2.5 g / L disodium edetate and the balance of water. The invention can realize thorough degreasing at normal temperature, and is easy to perform cleaning operation and low in foam.

Owner:湖南中皖骏环保科技有限公司

Acidic degreasing liquid for aluminum alloy

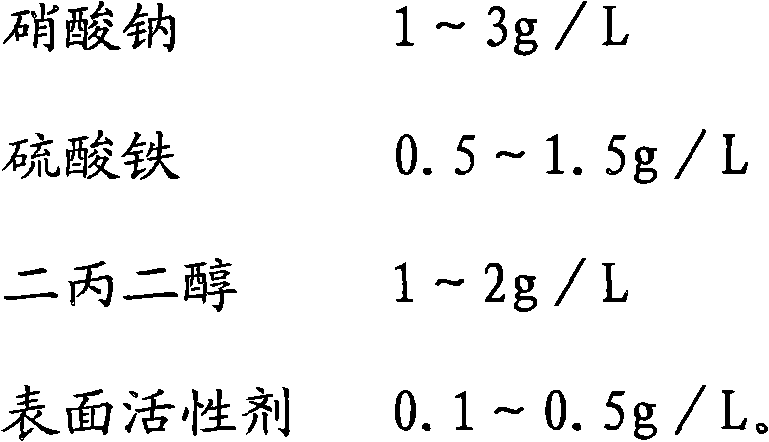

The invention discloses a degreasing treating agent for aluminum alloy and in particular relates to acidic degreasing liquid for aluminum alloy. The acidic degreasing liquid for the aluminum alloy is characterized in that: 1 liter of degreasing liquid consists of the following raw materials: 100 to 150 grams of sulfuric acid, 3 to 8 grams of ammonium bifluoride, 2 to 4 grams of nitric acid, 1 to 3 grams of sodium nitrate, 0.5 to 1.5 grams of ferric sulfate, 1 to 2 grams of dipropylene glycol and 0.1 to 0.5 gram of surfactant. The acidic degreasing liquid for aluminum alloy can achieve good degreasing effect at room temperature by using the sulfuric acid as base solution and other additives as auxiliary materials. The degreasing agent comprises components of an oxidizing agent, a surfactant, high-valence metal ions and the like, can be used for acid dipping of the aluminum metal, can be used for a long time, and is stable and reliable in degreasing property.

Owner:合肥华清高科表面技术股份有限公司

Comprehensive treatment agent and use method thereof

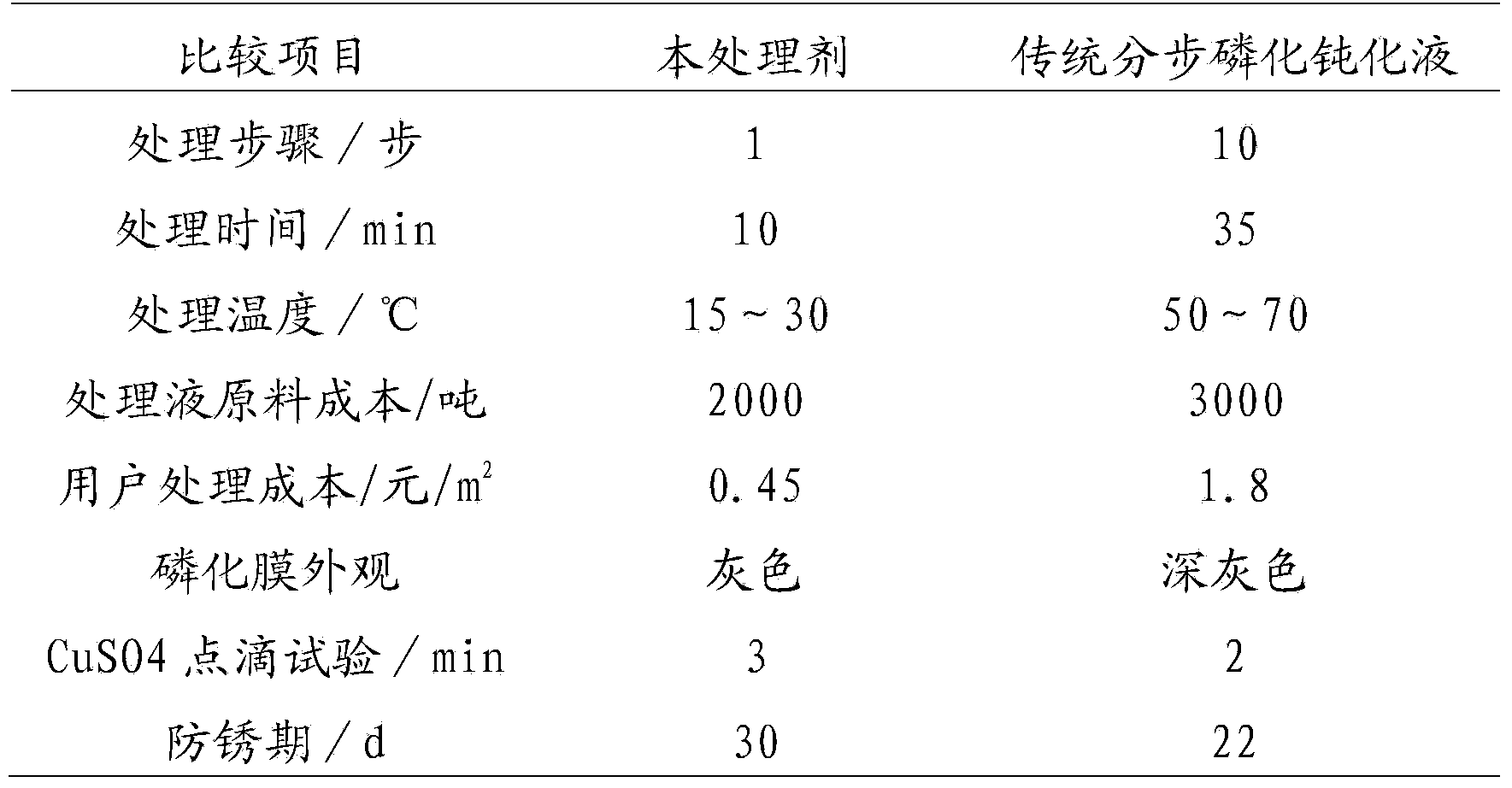

InactiveCN103436872AAvoid time costReduce processing costsMetallic material coating processesThioureaPhosphate

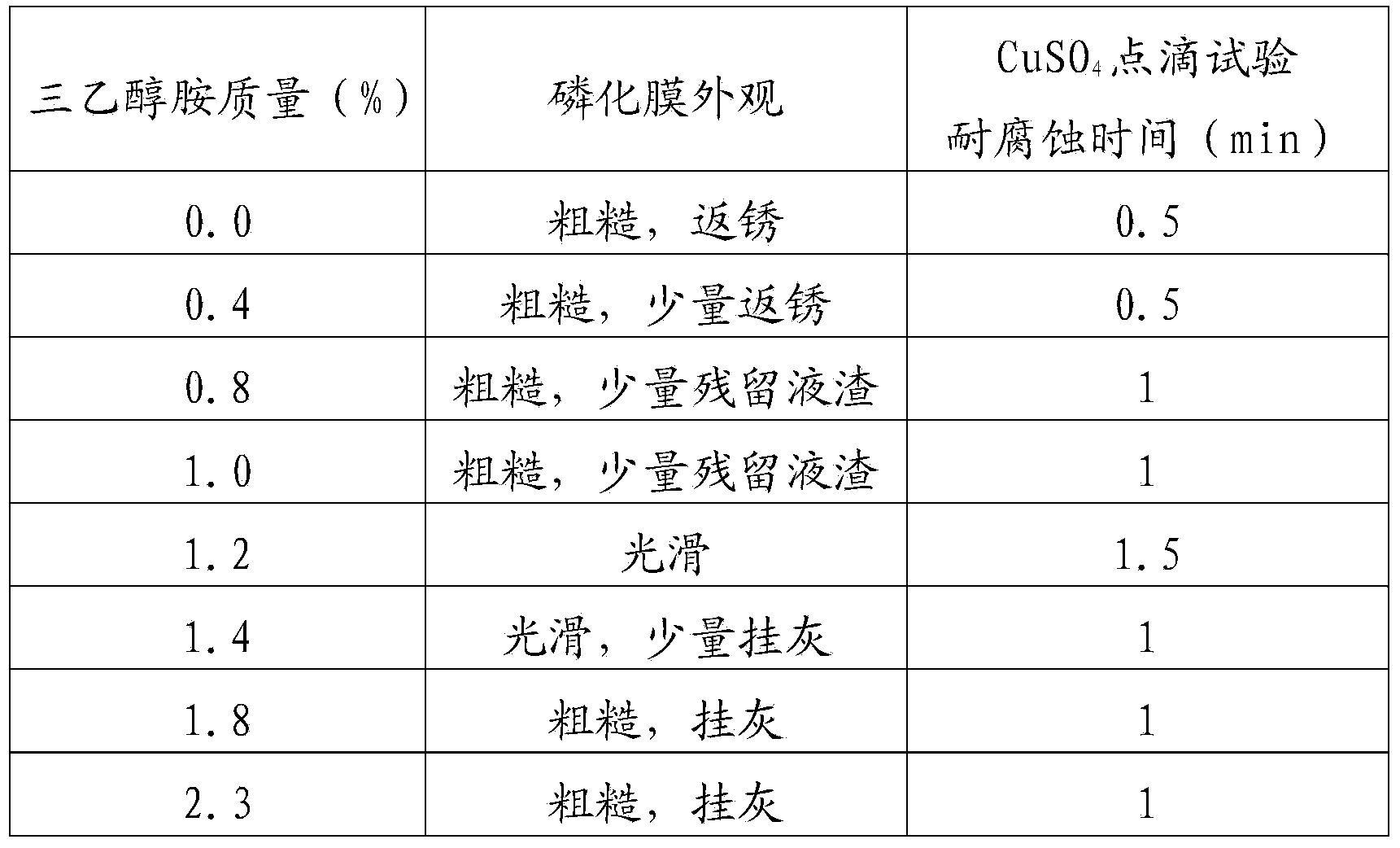

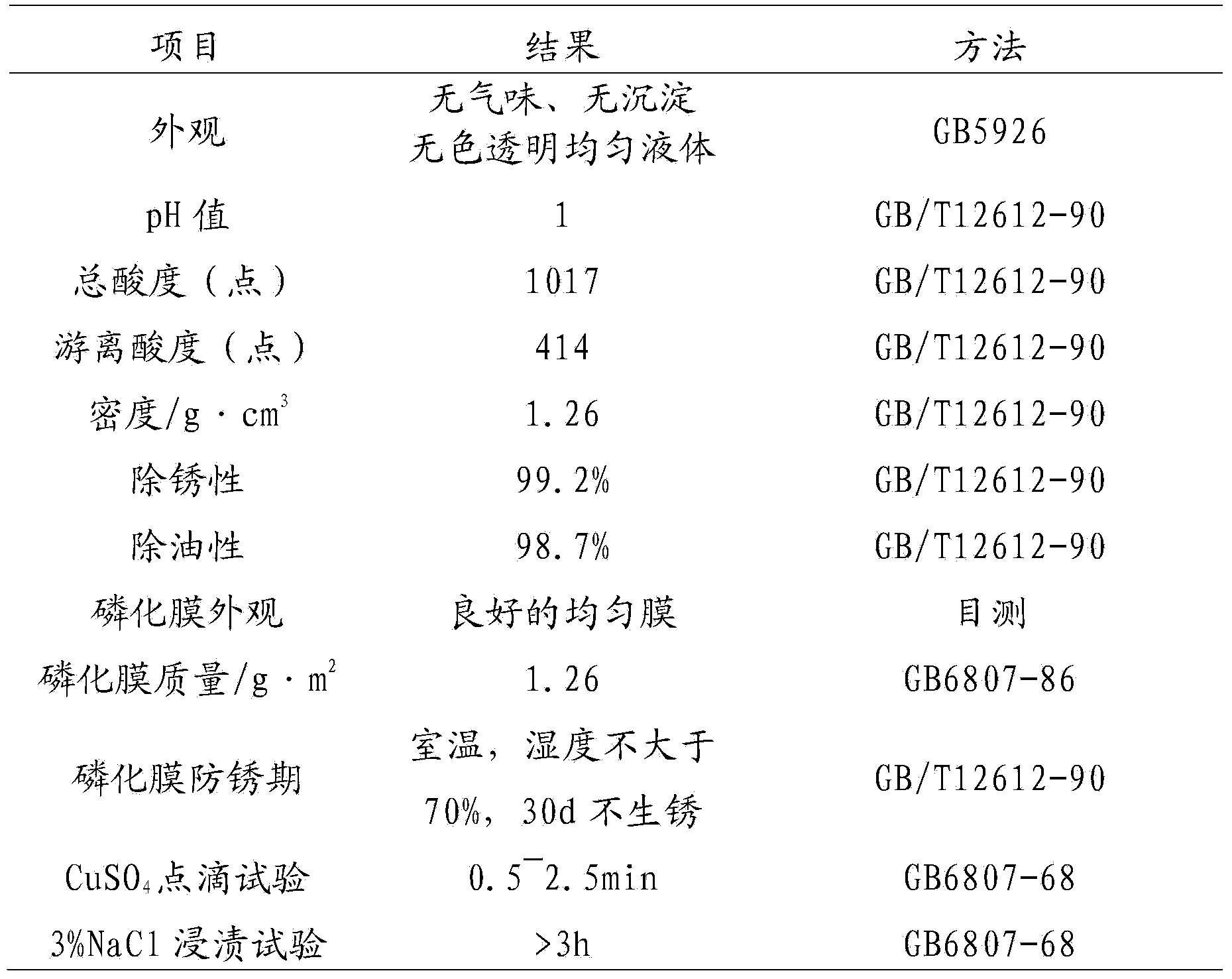

The present invention relates to a comprehensive treatment agent, which comprises, by mass, 25.0-30.0% of phosphoric acid, 1.0-3.0% of zinc oxide, 0.1-0.5% of sodium molybdate, 4.0-7.0% of zinc dihydrogen phosphate, 0.3-1.2% of potassium chlorate, 0.3-1.2% of a surfactant, 0.0-2.3% of triethanolamine, 0.8-2.3% of citric acid, 0.1-0.3% of thiourea, and 58.0-62.6% of water. According to the present invention, the treatment agent can be recycled, a treatment cost is low, and pollution on the environment can not be generated.

Owner:谢俊磊

Electrocatalysis oxidation pulping method for purified cotton and production system equipment

InactiveCN102392377AReduce processing costsReduce energy consumptionPulping with inorganic basesBlack liquorPulp and paper industry

An electrocatalysis oxidation pulping method for purified cotton and production system equipment belong to the technical field of purified cotton production. The method adopts the technology that bales of cotton linter are opened by an opener and then are made into a linter quilt through a combined cotton feeding device, the linter quilt enters into an impregnating machine through double clamp belts, an on-site hydroxyl free radical active oxygen and oxygen preparing method is adopted to continuously supply a pulping agent, the linter quilt and a pulping assistant are fully impregnated and then enter into an electrocatalysis oxidized still, pulp enters into a retention reactor that is filled with steam with a certain pressure, produced half stuff enters into a replacement and washing section and an extrusion and drying stage, and purified cotton cellulose products are obtained after the drying operation. Through the adoption of the method and the production system equipment, the effects of no black liquor, resource economy and energy consumption reduction can be achieved in the pulping process; and the pulping yield is high while clean and continuous pulping can be realized.

Owner:扬州市江都区明月机械有限公司

Method for improving quality of bottom layer of oriented silicon steel

ActiveCN105525087AReduce iron lossEnhanced inhibitory effectFurnace typesHeat treatment furnacesChemical compositionContinuous annealing

The invention discloses a method for improving quality of a bottom layer of oriented silicon steel. The method comprises the following steps: (1) regulating chemical components of steel billet; (2) grinding the surface of a steel plate by use of a metal brush roller after pickling the steel plate; (3) using ultrasonic waves to clean the steel plate before continuous annealing; and flushing the steel plate with clear water after cleaning; (4) regulating conditions for recovery annealing; (5) adding titanium dioxide and magnesium carbonate into an isolating coating which takes magnesium oxide as a main component; and (6) regulating conditions for high-temperature annealing of a steel coil. The method disclosed by the invention can solve the problem that the bottom layer of the current oriented silicon steel is poor in quality or is unstable in quality, and has a very good industrial application prospect.

Owner:GUANGDONG YINGQUAN HIGH TECH MATERIALS CO LTD

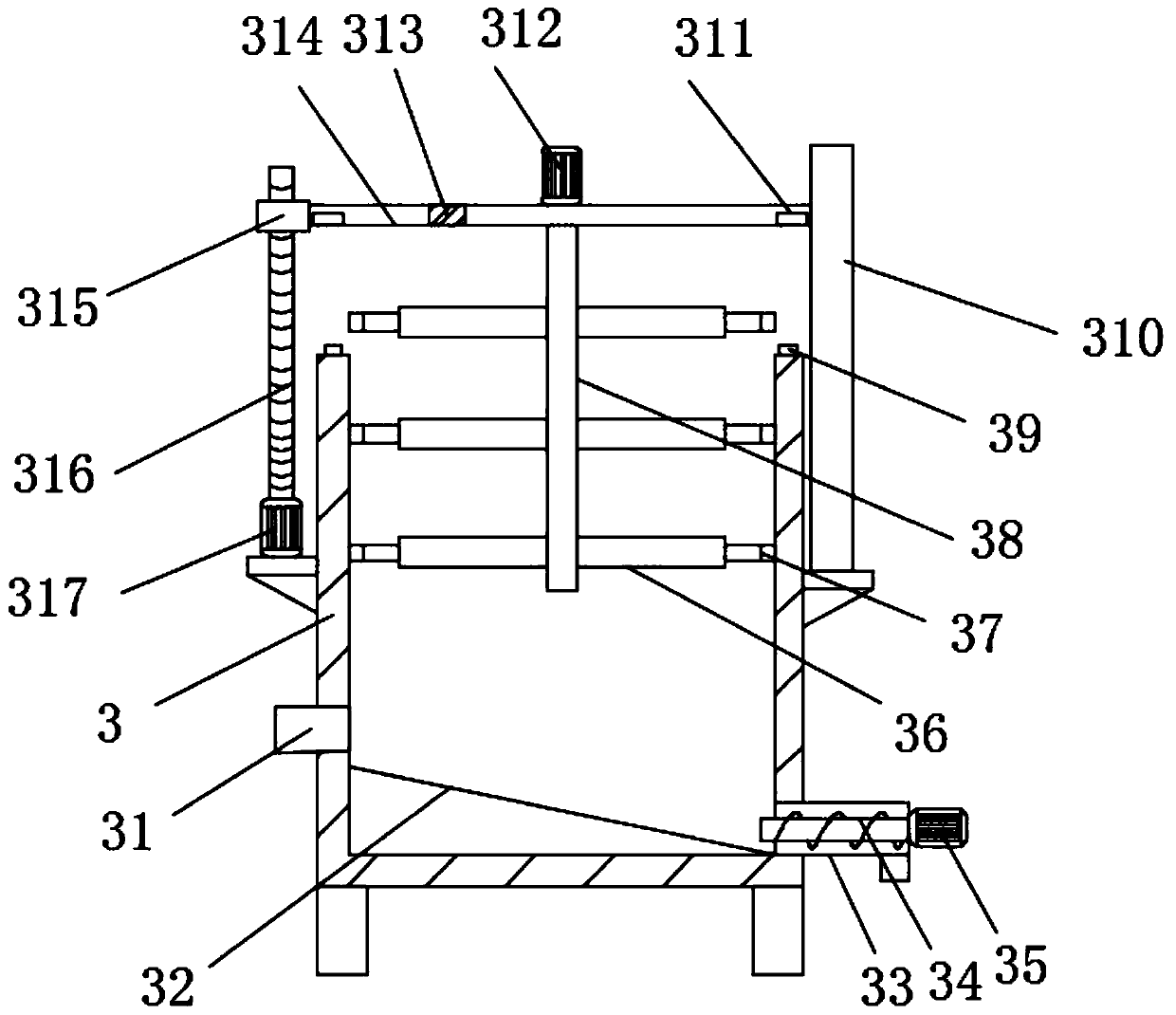

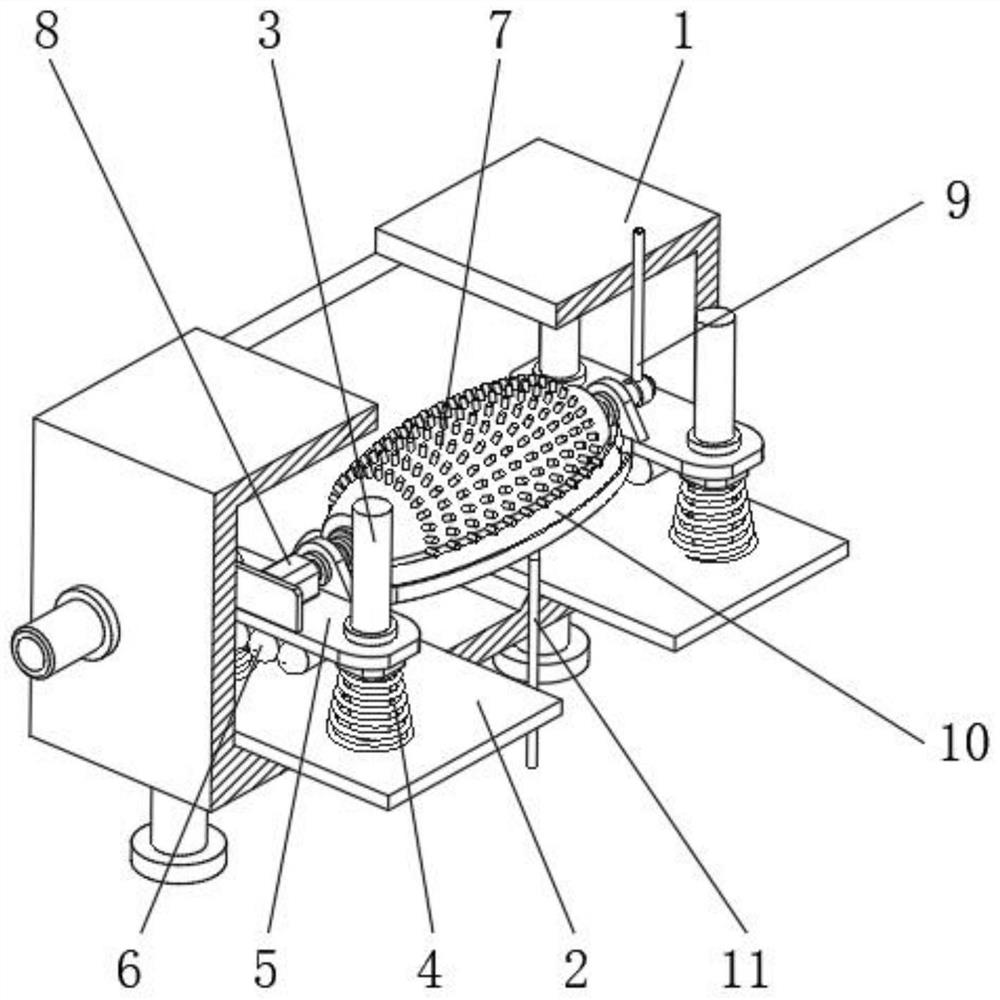

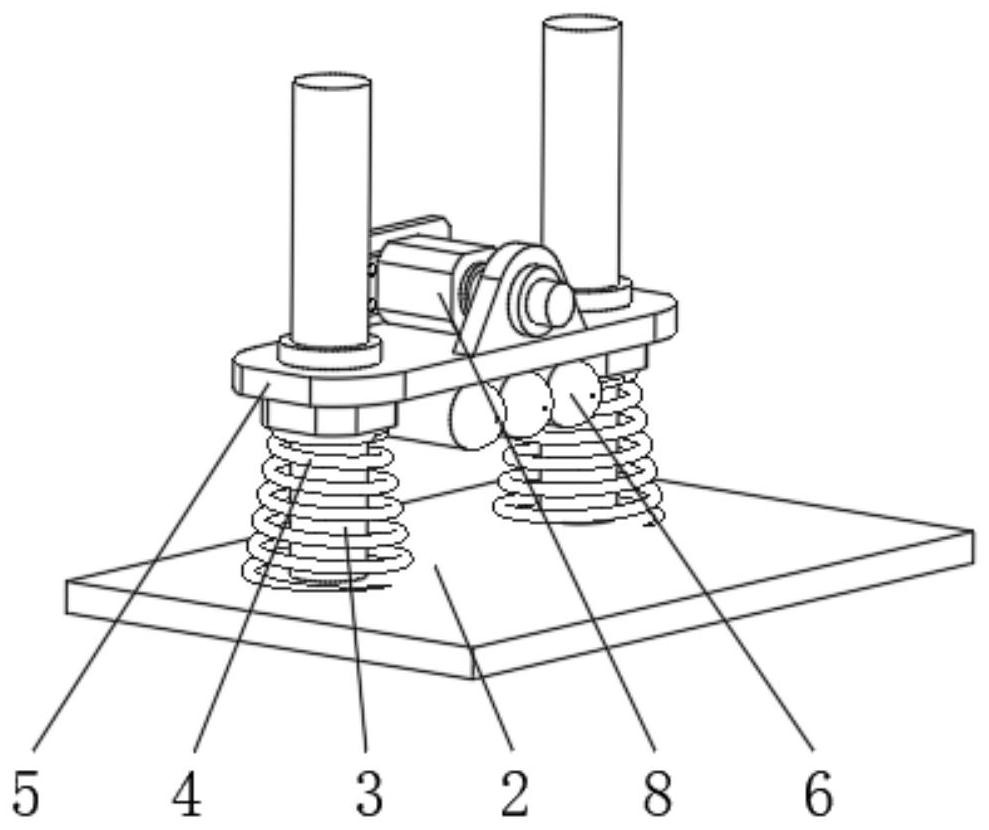

Efficient oil removal device for rare earth material liquid

ActiveCN107164645AGood degreasingHigh oil removal efficiencyProcess efficiency improvementRare earthBilateral symmetry

The invention relates to an oil removal device, in particular to an efficient oil removal device for rare earth material liquid. The efficient oil removal device for the rare earth material liquid comprises large L-shaped supports, a material liquid conveying device, a rotating device, a top pipe, a connecting pipe and the like, wherein the material liquid conveying device is arranged on one large L-shaped support, the rotating device is arranged between the large L-shaped supports in bilateral symmetry, the top pipe is arranged above the rotating device, the left end of the connecting pipe is connected with the right side wall of the top pipe in a welding mode, and the connecting pipe communicates with the top pipe. According to the efficient oil removal device for the rare earth material liquid, by combining the material liquid conveying device and the rotating device, high-efficiency oil removal can be carried out on the rare-earth material liquid, and the oil removal work efficiency is high.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Barrel plating method of trivalent color zinc

The invention relates to the field of electroplating, in particular to a barrel plating method of trivalent color zinc. The barrel plating method comprises the steps of step I, carrying out thermal degreasing; step II, carrying out pickling; step III, carrying out electroplating; step IV, carrying out bright dipping; step V, carrying out trivalent color zinc plating; step VI, cleaning with hot water; and step VII, placing a treated product in a tray. According to the barrel plating method, a new product is subjected to oil removing and derusing through clean water cleaning and pickling, the technological process is reduced, and the cost is reduced.

Owner:CHONGQING PENGLEI AUTO PARTS CO LTD

Preparation method of waterproof polytetrafluoroethylene thin film

The invention relates to the field of thin film, in particular to waterproof polytetrafluoroethylene thin film. A preparation method of the waterproof polytetrafluoroethylene thin film comprises the following steps of 1, mixing, wherein polytetrafluoroethylene resin powder, a liquid lubricant and a hydrophobic material are stirred and mixed; 2, blank pressing and calendering, wherein polytetrafluoroethylene materials are subjected to blank pressing and calendering to be prepared into a polytetrafluoroethylene base band; 3, longitudinal drawing and steam treatment, wherein polytetrafluoroethylene is subjected to longitudinal drawing and steaming through steam to obtain a degreased base band; 4, transverse drawing and heat setting, the degreased base band is subjected to transverse drawing on an expander, sintering heat setting is conducted, and the heat-setting thin film is obtained. The obtained polytetrafluoroethylene thin film has the advantages of being good in waterproof effect and uniform in thickness.

Owner:佛山市顺德区众明环保包装薄膜有限公司

Environment-friendly type cleaning agent

InactiveCN101838814ARoHS CompliantMeet the requirements of green environmental protectionNaphthaCleansing Agents

The invention discloses an environment-friendly type cleaning agent, which contains the following components in parts by weight: 10%-20% of 70# solvent naphtha, 10%-20% of 90# solvent naphtha, 30%-40% of 120# solvent naphtha, 20%-30% of 190# solvent naphtha, 5%-10% of industrial alcohol and 2%-5% normal butanol, and the sum of the percentage of the using amount of the raw material is 100%. The production method of the environment-friendly type cleaning agent has simple technique and low production cost; the technical indexes are in accordance with green and environment-friendly requirements; and the environment-friendly type cleaning agent is an environment-friendly type cleaning agent with excellent properties, and is widely used for the industries such as the electronic industry, the refrigeration industry, the automobile industry, the mold industry, the precision machining industry and the like.

Owner:陕西宏业电工电子新材料有限公司

High-purity rice protein powder and preparation method and applications thereof

InactiveCN109601693ARetain structural propertiesHigh puritySugar food ingredientsFood ingredient functionsCycloneCellulose

The invention discloses a high-purity rice protein powder. The preparation method of the rice protein powder comprises the following steps: (1) pulverizing rice, and performing size mixing; (2) performing enzymolysis and filtration; (3) subjecting rice slag to size mixing and pulverization; (4) adding a composite surfactant; 5), separating out a liquid phase and a heavy phase with a 12-stage cyclone washing device; (6) adding a complex enzyme agent to the heavy phase to obtain an enzymolysis liquid; and (7) subjecting the enzymolysis liquid to jet sterilization and plate-frame pressure filtration, collecting filter cakes, and performing pneumatic drying and superfine dry pulverization to obtain the high-purity rice protein powder. The method uses the rice as a raw material and the composite surfactant as a main means for removing grease and removing cellulose, and prepares the high-purity rice protein powder. The product has high purity, the treatment process is mild, the change of protein structure property is small, the taste is better, and the suspension stability is good.

Owner:WUXI JINNONG BIOTECH CO LTD

Super-micro-montmorillonite hand-washing liquid

InactiveCN101040826AEasy to cleanReduce pollutionCosmetic preparationsToilet preparationsBrickManufacturing technology

A ultra-fine montmorillonite hand cleanser belongs to washing product technique, which uses alta-mud to process ultra-fine treatment to prepare ultra-fine montmorillonite slurry, adds methylol cellulose, polymethyl sodium polyacrylate and surface activator to be mixed. The inventive hand cleanser is an emulsifier with hydrophilic, lipophilic, neutral, nontoxic, asepsis, non phosphorus-containing, de-oil, and beauty functions, while it can effectively reduce pollution, to be used to wash hand and clean dishware, in particular to be used by machine workers, clean brick, metal element and furs.

Owner:杨遇霄

Oil-containing sewage separation device

InactiveCN112125376AReduce internal space structureImprove work efficiencyFatty/oily/floating substances removal devicesLiquid separationSewageOil water

The invention relates to the technical field of sewage treatment equipment, and discloses an oil-containing sewage separation device, which comprises a separation box body, supporting base plates arefixedly mounted at the bottoms of the left side and the right side of an inner cavity of the separation box body, and fixed supporting columns are fixedly mounted on the front sides and the rear sidesof the tops of the supporting base plates. The top ends of the fixed supporting columns are fixedly connected with the top of the inner cavity of the separation box body. According to the oil-containing sewage separation device, through the arrangement of an oil absorption bag body and an oil stain scraping plate, a felt structure on the oil absorption bag body can be used for adsorbing oil stains in oil-containing sewage, and the oil stains on the oil absorption bag body are removed under the rotary extrusion of the oil stain scraping plate; compared with an existing oil-water separation device, oil-water separation operation can be carried out in the flowing state of oil-containing sewage, standing operation does not need to be carried out on the oil-containing sewage any more, then theinternal space structure of the separation device is effectively reduced, and meanwhile the working efficiency of oil-water separation in the oil-containing sewage is improved.

Owner:陶松娣

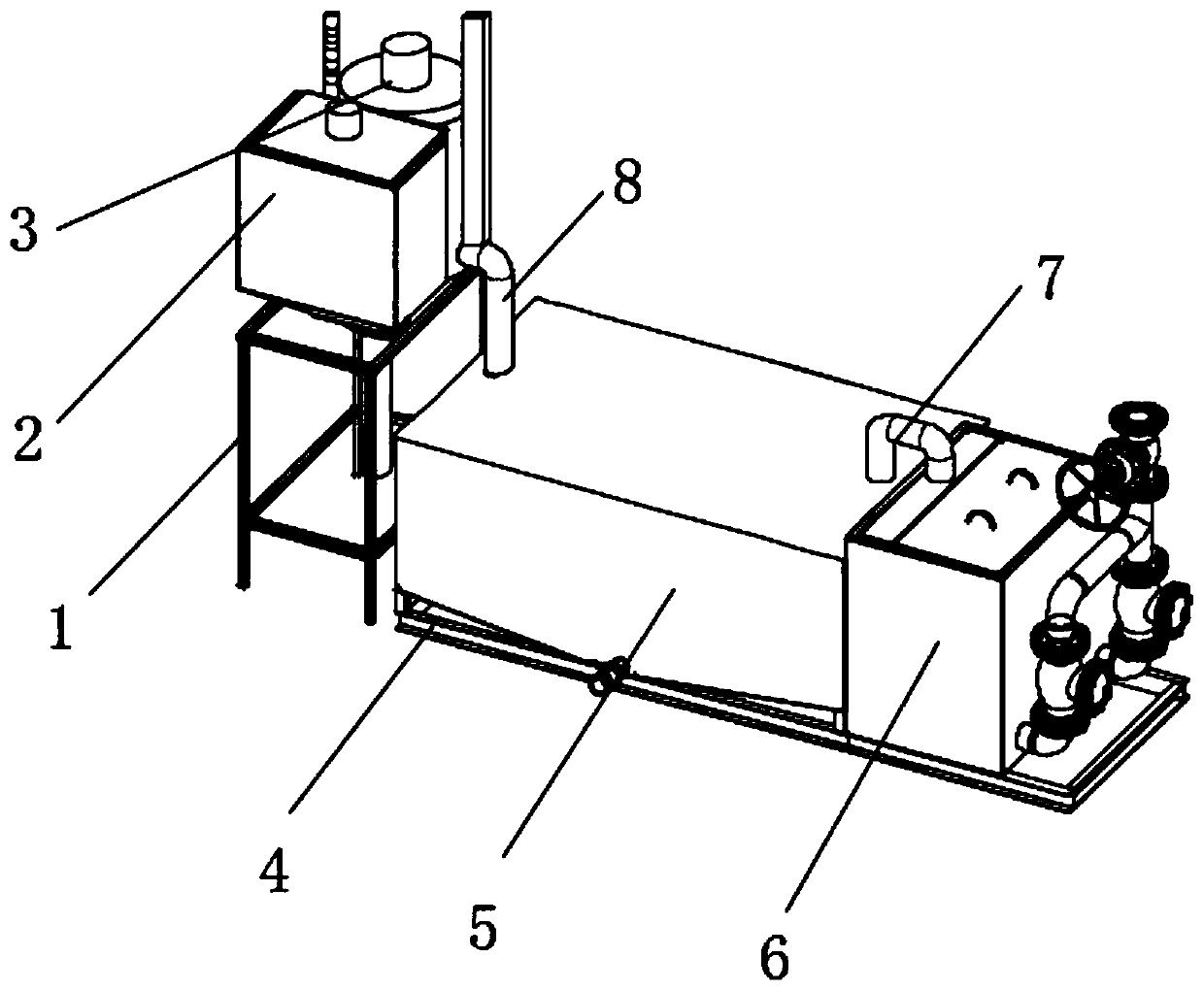

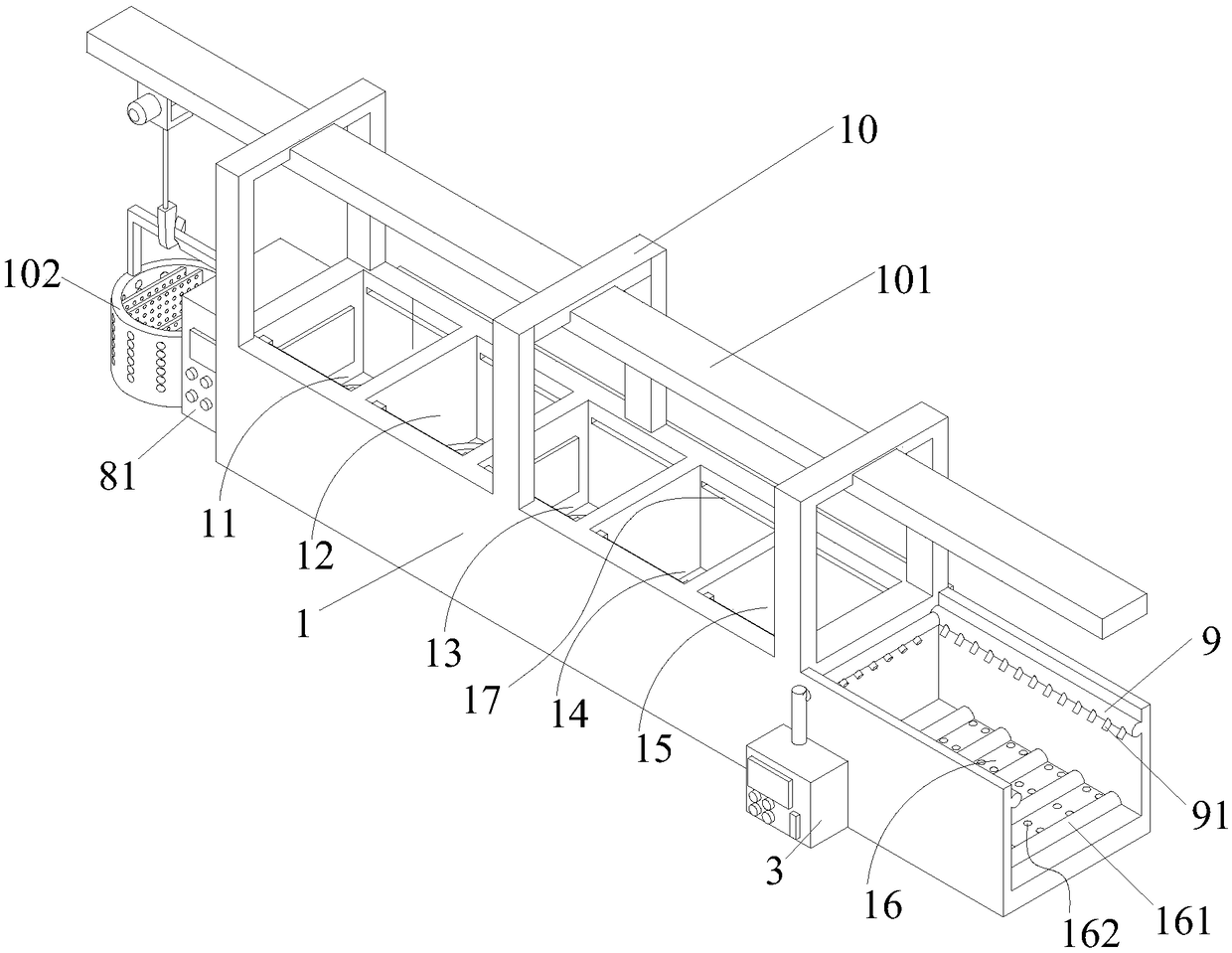

Device for deoiling surface of metal part

ActiveCN109201575ANo secondary pollutionSolve the poor effect of manual degreasing and degreasingCleaning using liquidsEngineeringSewage

The invention discloses a device for deoiling the surface of a metal part and a process of the device, and relates to the technical field of metal treatment devices. The device comprises a workbench.A first degreasing tank, a first pure water tank, a second degreasing tank, a second pure water tank, a third pure water tank and a water cutting box are sequentially arranged on the workbench, a sewage hopper and a draught fan are fixedly mounted on the side wall of the workbench, mounting frames are arranged on the workbench, a crane is fixedly mounted on the mounting frames, the crane is located over the workbench, and a storage basket is arranged on the crane. The multiple degreasing tanks and pure water tanks are arranged, the metal part is degreased and washed with ultrasound, a pre-degreasing agent, a main degreasing agent and pure water multiple times, the metal part is completely washed, generated oil dirt is discharged in time, it is guaranteed that the metal part is not secondarily contaminated, the deoiling quality and efficiency are improved, and the problems that the existing metal part manual deoiling and degreasing effect is poor, time and labor are wasted, and the production efficiency is low are solved.

Owner:安徽新合富力科技有限公司

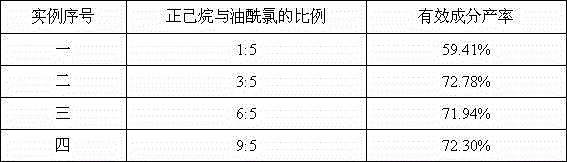

Method for preparing collagen polypeptide based surfactant

ActiveCN104923122AHigh yieldRealize resource utilizationConnective tissue peptidesTransportation and packagingProtein proteinSide product

The invention relates to a method for preparing a collagen polypeptide based surfactant. The method comprises the steps: hydrolyzing leather scraps with a strongly-alkaline solution of sodium hydroxide, then, filtrating a hydrolysis solution to remove chromium-containing filtrated residue, and carrying out reduced-pressure distillation on the filtrate so as to obtain a protein hydrolyzate; mixing oleoyl chloride and n-hexane according to a certain ratio, slowly dropwise adding the mixture into the concentrated protein hydrolyzate cooled by ice water, reacting for 20-30 minutes, and then, heating the reacted mixture to the temperature of 20-30 DEG C for aging reaction; after the reaction ends, heating the reaction solution to the temperature of 50-60 DEG C so as to remove part of n-hexane; and pouring out the reaction product, and carrying out centrifugal separation on the reaction product to remove a byproduct sodium oleate and superfluous n-hexane solvent, thereby obtaining the collagen polypeptide based surfactant. According to the method, the high-yield efficient protein based surfactant prepared from chromium-containing leather waste, which serves as a main raw material, can be applied to a leather making process again as a degreasing agent, so that not only is the resource utilization of the waste realized, but also the total cost of chemical raw materials for leather making enterprises is reduced.

Owner:烟台全杰技术产业有限公司

Environmentally-friendly alkali resistant scouring agent and preparation method thereof

The invention relates to an environmentally-friendly alkali resistant scouring agent and a preparation method thereof. Present common scouring agents cannot resist alkalis, and have an unsatisfactory permeability under alkaline conditions. Raw materials of the environmentally-friendly alkali resistant scouring agent comprise 2.0-2.5mol of isomeric alcohol ether, 1.0mol of a carboxylation agent and 1.05mol of an inorganic alkali. The preparation method of the environmentally-friendly alkali resistant scouring agent comprises the following steps: weighing the raw materials; adding the isomeric alcohol ether to a reaction container, stirring, heating to 30-50DEG C, and adding the carboxylation agent into the isomeric alcohol ether to obtain a mixed solution A; adding the inorganic alkali to the mixed solution A for reacting to obtain a mixed solution B; heating the mixed solution B to 60-75DEG C, and reacting for 2-4h to obtain a mixed solution C; sampling and analyzing the mixed solution C; and cooling the mixed solution C to 50DEG C to obtain the environmentally-friendly alkali resistant scouring agent. The environmentally-friendly alkali resistant scouring agent has the advantages of alkali resistance, environmental protection, good biodegradability, and no containment of APEO, P or heavy metals.

Owner:浙江亿普新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com