Phosphorus-free degreaser for surface spraying pretreatment of steel

A technology of steel surface and degreasing agent, which is used in the field of pre-treatment agent for spraying steel surface, can solve the problems of affecting degreasing effect, cleaning degree, strong foam stability, etc., and achieve good degreasing effect, less foam and strong degreasing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

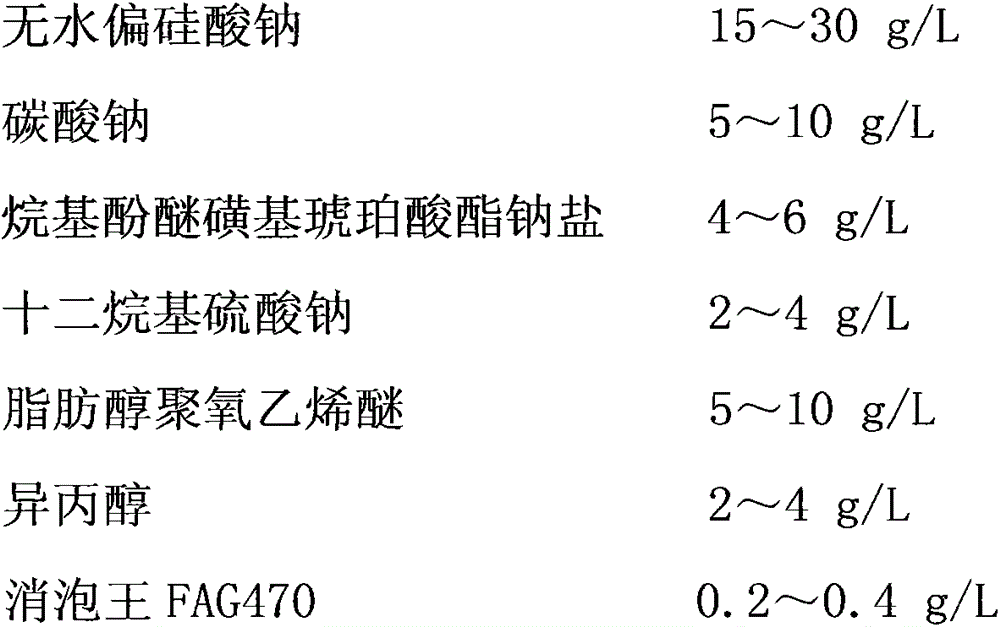

[0020] A phosphorus-free degreasing agent for steel surface spraying pretreatment, a mixed solution prepared from the following components, the mass concentration of each component in the mixed solution is:

[0021]

[0022] The remaining ingredients are water.

[0023] Preparation method: The preparation method is: dissolve the above-mentioned anhydrous sodium metasilicate, sodium carbonate, and disodium edetate in tap water, stir and dissolve, add defoaming king FAG470, and then add dodecane while stirring Sodium phenyl benzene sulfonate, after dissolving, add fatty alcohol polyoxyethylene ether and isopropanol mixed solution while stirring.

Embodiment 2

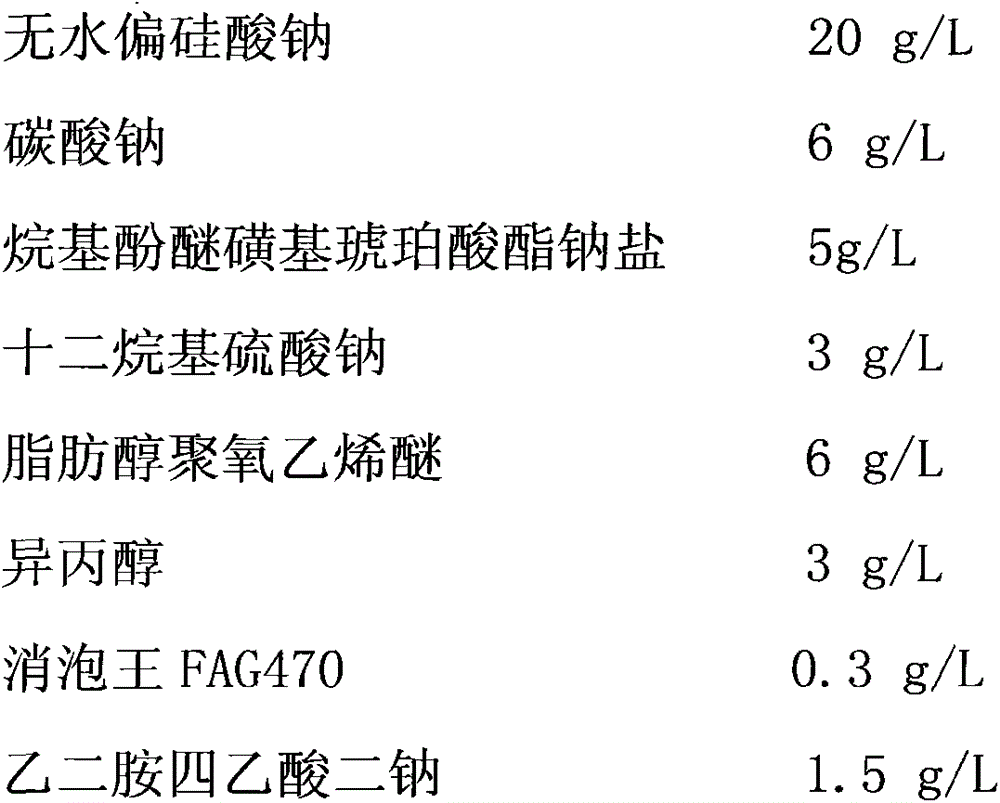

[0025] A phosphorus-free degreasing agent for steel surface spraying pretreatment, a mixed solution prepared from the following components, the mass concentration of each component in the mixed solution is:

[0026]

[0027] The preparation method is: dissolve the above-mentioned anhydrous sodium metasilicate, sodium carbonate, and disodium edetate in tap water, stir and dissolve, add defoaming king FAG470, and then add dodecylbenzenesulfonate while stirring After dissolving, add fatty alcohol polyoxyethylene ether and isopropanol mixed solution while stirring.

Embodiment 3

[0029] A phosphorus-free degreasing agent for steel surface spraying pretreatment, a mixed solution prepared from the following components, the mass concentration of each component in the mixed solution is:

[0030]

[0031]

[0032] Preparation method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com