Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "RoHS Compliant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature self-repairing conductive silver adhesive and preparation method thereof

ActiveCN103194164AGuaranteed long-term use effectEvenly dispersedEpoxy resin adhesivesMicroballoon preparationEpoxyAdhesive

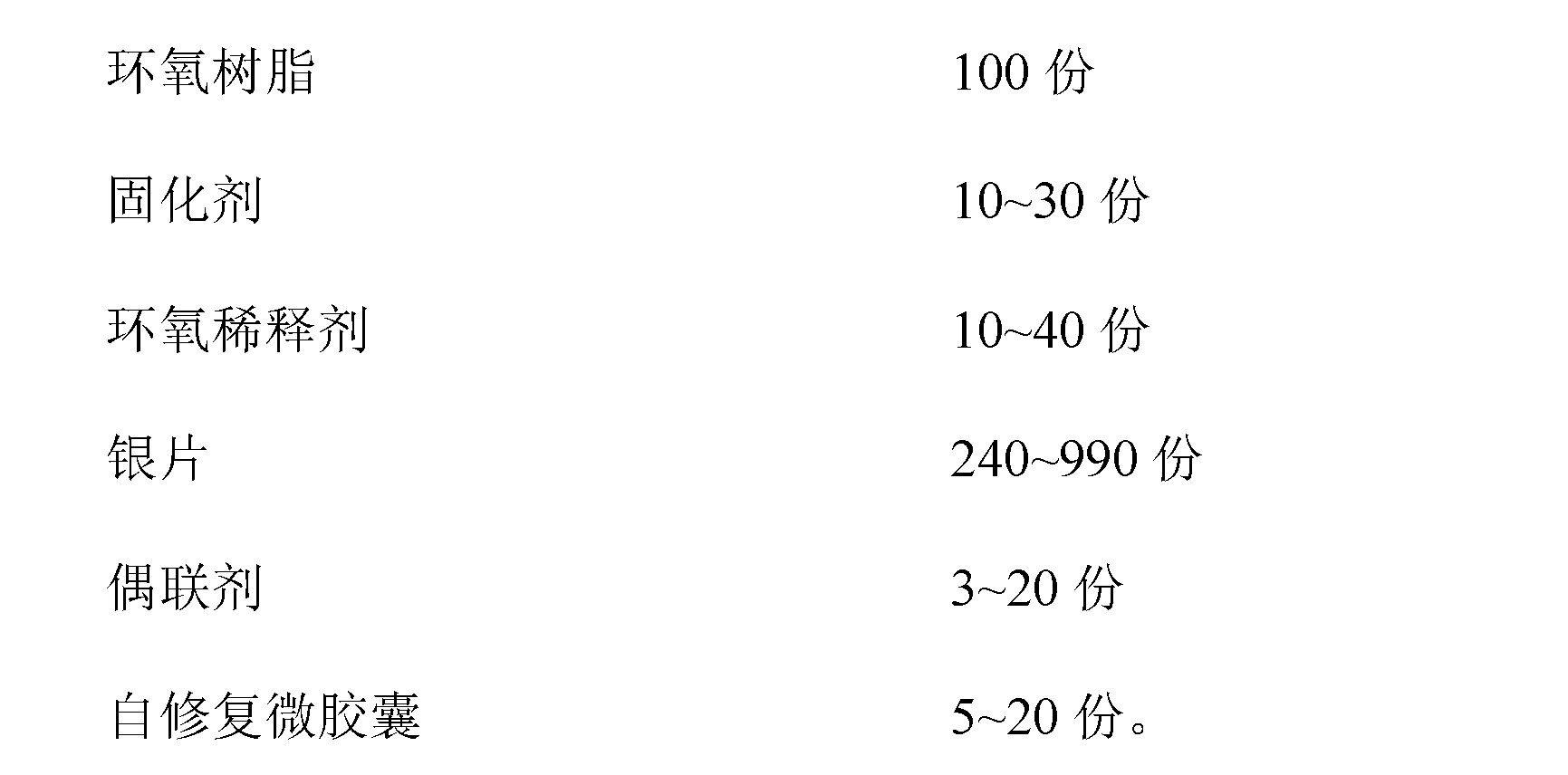

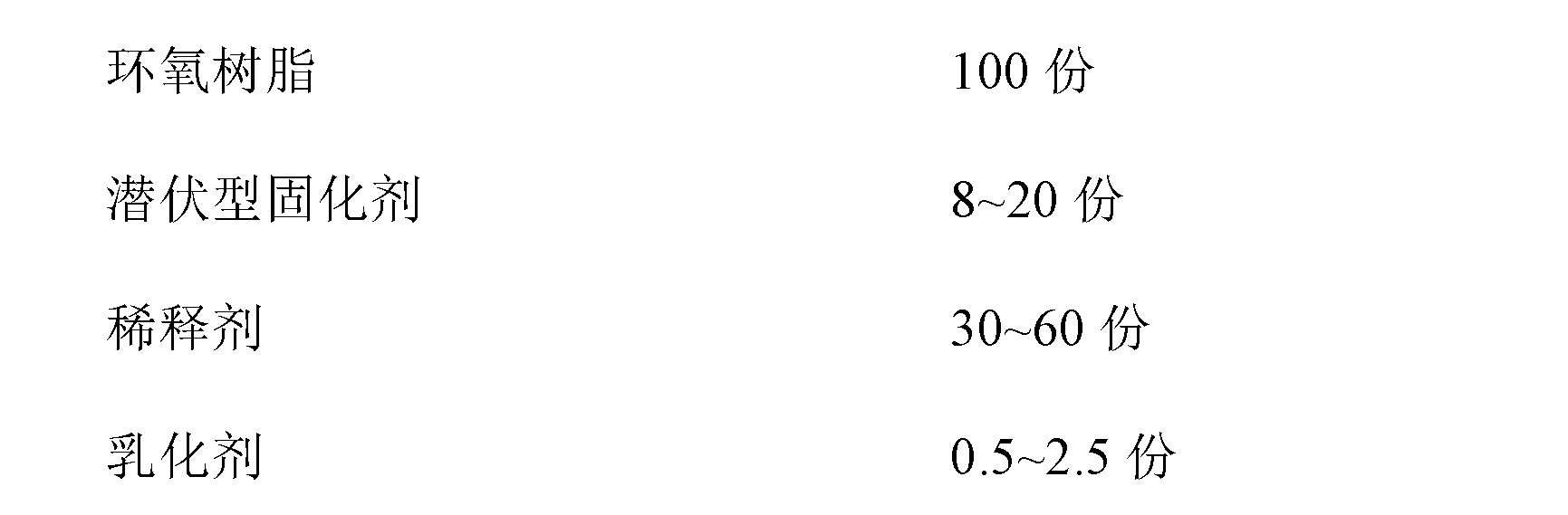

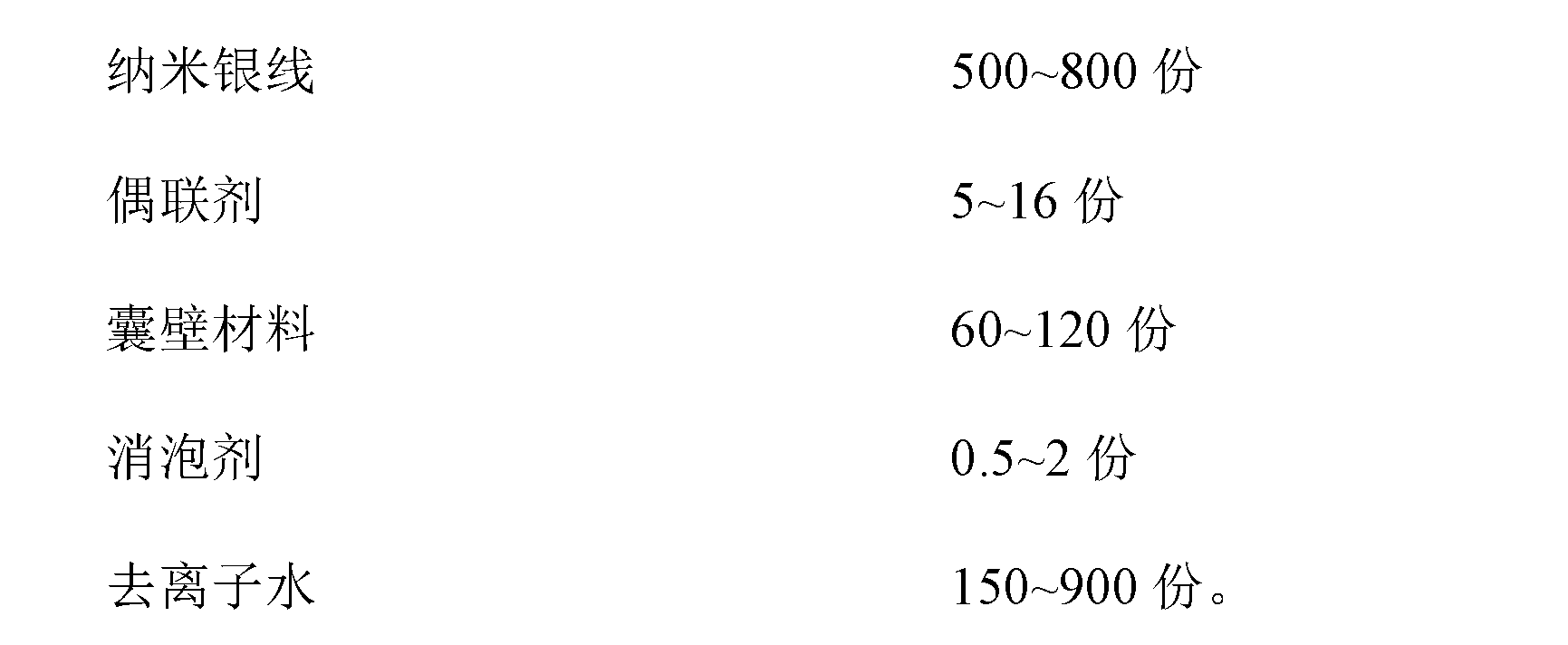

The invention provides a high temperature self-repairing conductive silver adhesive. The high temperature self-repairing conductive silver adhesive is prepared from the following raw constituents by parts: 100 parts of epoxy resin, 10-30 parts of curing agent, 10-40 parts of epoxy diluent, 240-990 parts of silver pieces, 3-20 parts of coupling agent and 5-20 parts of self-repairing microcapsule; wherein the self-repairing microcapsule is composed of the following raw constituents by parts: 100 parts of epoxy resin, 8-20 parts of latent curing agent, 30-60 parts of diluents, 0.5-2.5 parts of emulsifying agent, 500-800 parts of nano silver wires, 5-16 parts of coupling agent, 60-120 parts of capsule wall material, 0.5-2 parts of antifoaming agent and 150-900 parts of deionized water. The invention also provides a preparation method of the high temperature self-repairing conductive silver adhesive. The high temperature self-repairing conductive silver adhesive has the positive effects that the repairing efficiency is high, the repairing effect is expanded on the basis of the original conductive network, crack-conductive network double repairing is realized, and the long-term using effect of the conductive adhesive is guaranteed, the cost is saved, and the reliability and service life of the conductive adhesive in high temperature working environment are improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

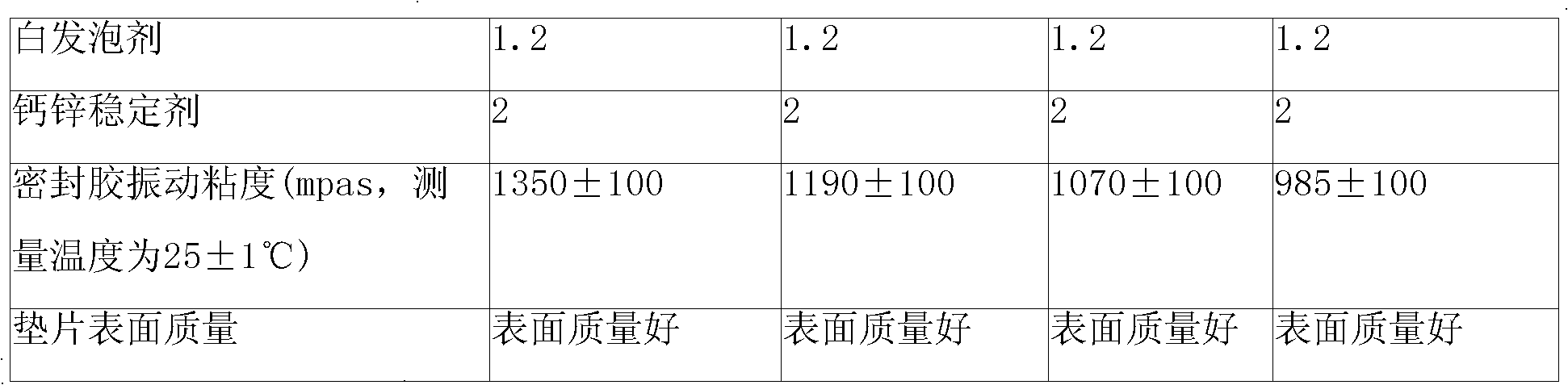

Asepsis environment-protecting polycinyl chloride bottle cap sealant and method for preparing same

InactiveCN101338171ALow priceImprove sealingOther chemical processesAdhesivesPolyvinyl chlorideRapeseed

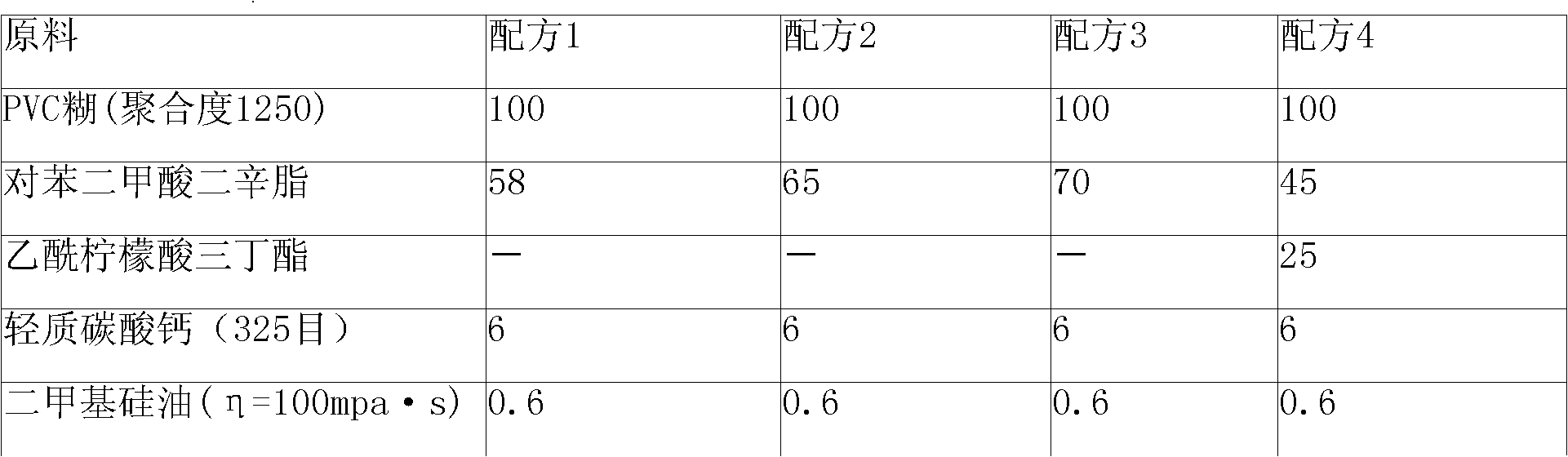

The invention discloses a nontoxic environment protection polyvinyl chloride sealing gel and a preparation method thereof. The gel is made of pvc paste resin, dioctyl phthalate, acetyl tri-n-butyl citrate, heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent, titanium dioxide, dimethicone and rapeseed oil. Phthalic ester plasticizer is not comprised. The gel meets the requirements of the food safety, and corresponds with the RoHS instruction. The gel is a foot and environmental friendly sealing gel. The using amount of fillings is added. The production cost is lowered. The nontoxic and environmental friendly sealing gel has the advantages of low price, high temperature resistance, good sealing effect and convenient engagement.

Owner:贵州省复合改性聚合物材料工程技术研究中心 +1

High-strength high-toughness flame-retardant polypropylene material, and preparation method and application thereof

The invention belongs to the technical fields of high molecular material modification and processing, and discloses a high-strength high-toughness flame-retardant polypropylene material, and a preparation method and application thereof. The polypropylene material disclosed by the invention comprises the following components in parts by weight: 20-50 parts of polypropylene, 0.1-10 parts of toughener, 1-10 parts of compatilizer, 16-22 parts of compound flame retardant, 0.2-0.4 parts of antioxidant, 0.1-0.4 parts of light stabilizer and 30-50 parts of glass fiber. The preparation method of the polypropylene material comprises the following steps: mixing 20-50 parts of polypropylene, 0.1-10 parts of toughener, 1-10 parts of compatilizer, 16-22 parts of compound flame retardant, 0.2-0.4 part of antioxidant, 0.1-0.4 part of light stabilizer and 30-50 parts of glass fiber in a high-speed mixer for 3-5 minutes, adding the mixture into an extruding machine, extruding and granulating to obtain the required high-strength high-toughness flame-retardant polypropylene material. The polypropylene material disclosed by the invention has the advantages of high tensile strength, high flexural modulus, high impact strength and favorable flame retardancy, and is an optimal material for engineering plastic building templets.

Owner:HEFEI GENIUS NEW MATERIALS

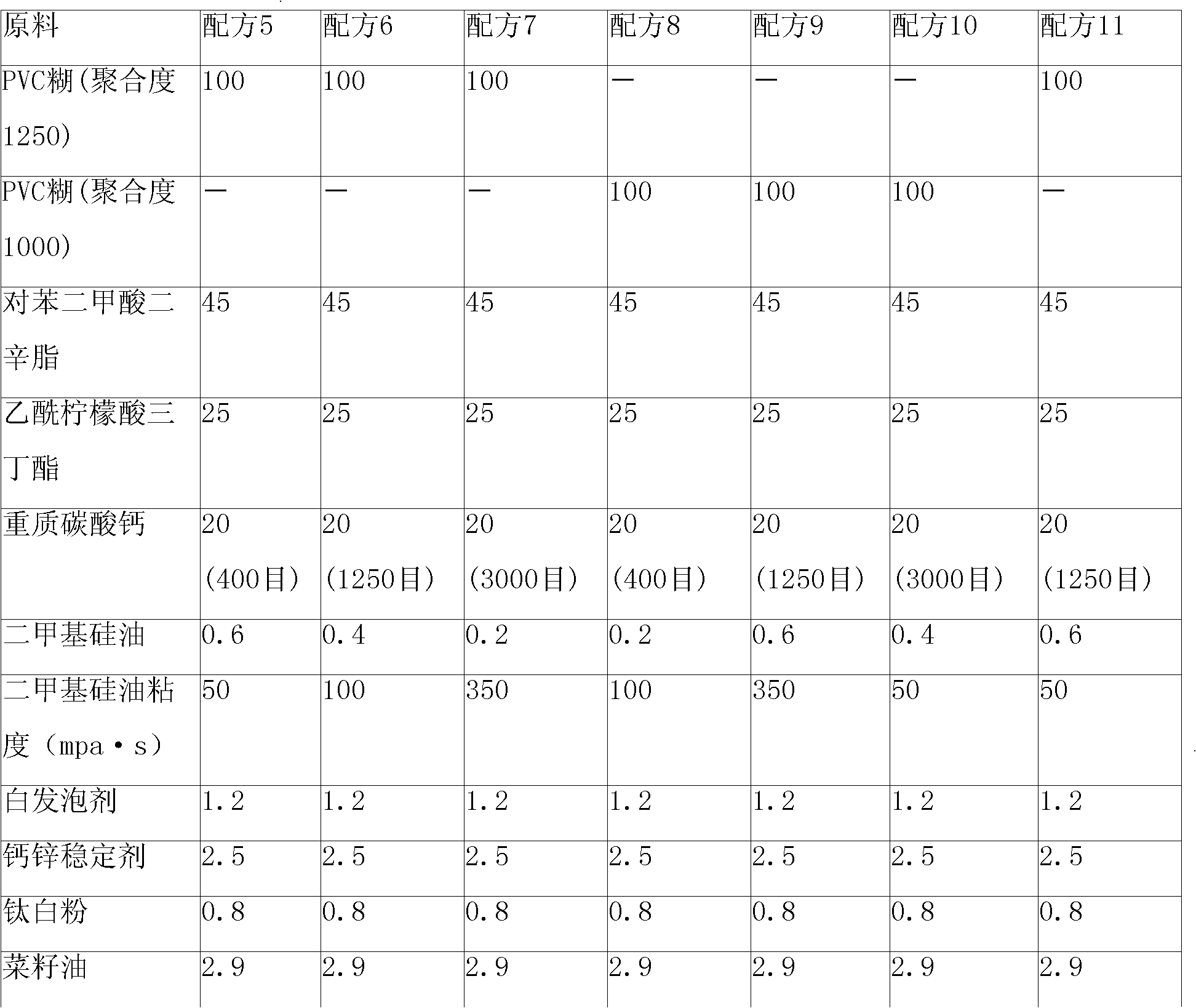

Preparation for aluminum or aluminum alloy trivalent chromium chemical conversion film

InactiveCN101275225ASolve the disadvantages of high toxicityMeet environmental protection requirementsMetallic material coating processesCleaning using liquidsPhosphoric acidReaction temperature

The invention discloses a method of preparing aluminum or aluminum alloy trivalent chromium chemical conversion film, comprising: aluminum or aluminum alloy work pieces are activated for 1 to 2 minutes in sodium hydroxide solution with a concentration of 50g / L to 100g / L and activation reaction temperature is 5 deg C to 30 deg C; using deionized water to wash the work pieces; putting the washed work pieces into mixed aqueous solution of soluble chromic salt and phosphoric acid to make a chromaking for 6 to 10 minutes, wherein, chromium ion has a concentration of 1g / L to 20g / L, and the phosphoric acid has a concentration of 1g / L to 25g / L; using dilute sodium hydroxide or dilute sulfuric acid to adjust reaction system PH value to 1.6 to 4.0 and the chromaking temperature to 10 deg C to 60 deg C. The invention solves a shortcoming that in existing technology hexavalent chromium has great toxicity. Technological process and products of the invention reach environmental requirements. The produced trivalent chromium chemical conversion film has the same quality with hexavalent chromium chemical conversion.

Owner:CENT SOUTH UNIV

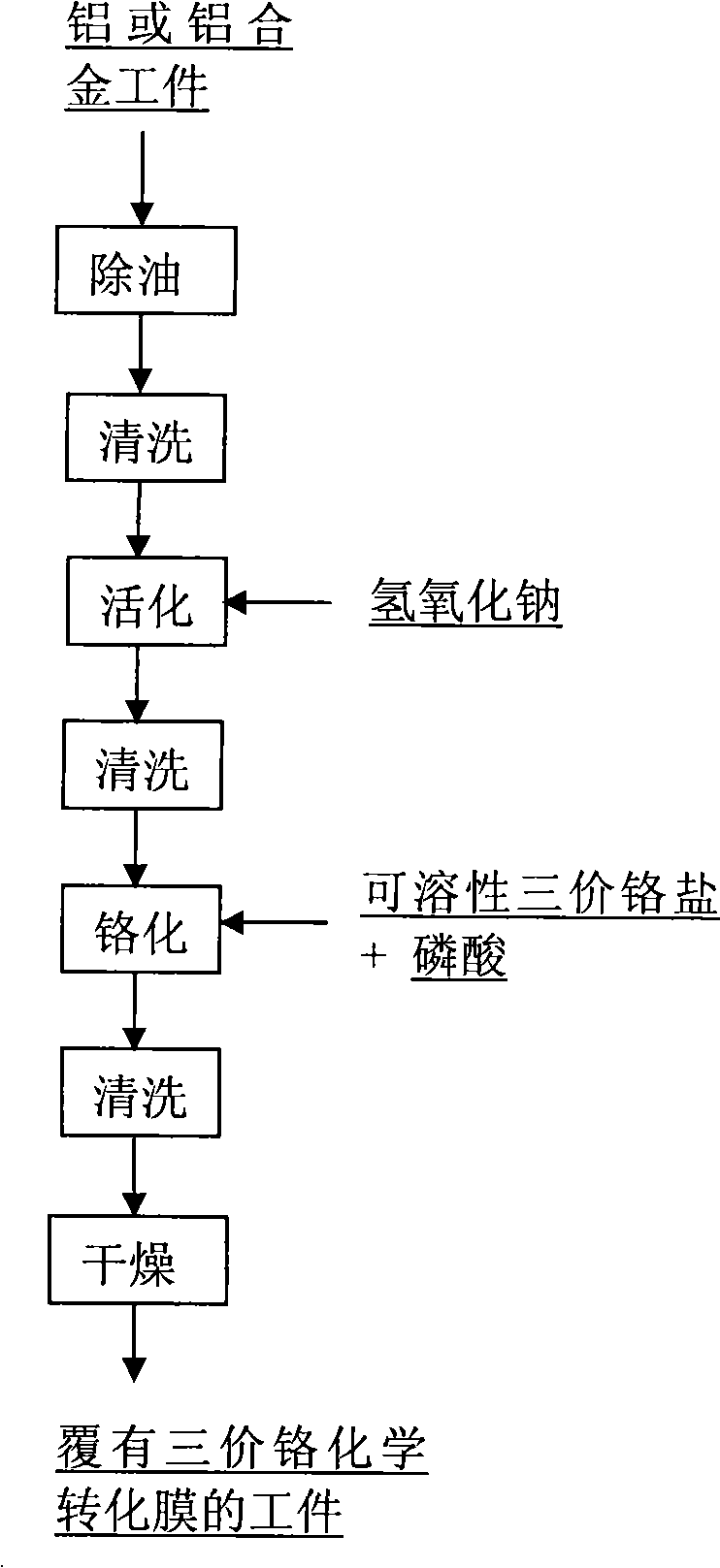

Computer hard disk aluminium base material parts chemical nickeling technology

InactiveCN101067205AMeet environmental protection requirementsRoHS CompliantLiquid/solution decomposition chemical coatingSuperimposed coating processWater qualityWastewater

The present invention relates to computer hard disc fitting production, and is especially chemical nickel plating and washing process for computer hard disc part of aluminum material. The chemical nickel plating and washing process includes: degreasing with solvent, degreasing with alkali solution, acid soaking, eliminating ash, immersion plating zinc, chemical nickel plating, deactivating, many times of water washing after each of the above steps, stoving and other steps. During the process, the used water is filtered for reuse so as to save water.

Owner:LIANGANG FASTENING SYST SHANGHAI

Conductive paste for thick film circuit, thick film circuit board employing same and manufacturing method thereof

InactiveCN102760934AImprove conductivityWide variety of sourcesAntenna supports/mountingsSolid-state devicesSilver pasteConductive paste

A conductive paste for a thick film circuit, a thick film circuit board employing the same and a manufacturing method thereof relate to the field of thick film circuits. One of the purposes of the invention is to provide a conductive paste for a thick film circuit, which can replace a silver paste and low cost and high security. The conductive paste comprises the following components by mass percent: 72-77 percent of copper powder, 8-10 percent of inorganic adhesive, 4-6 percent of organic adhesive, 5-12 percent of organic solvent and 1-5 percent of additive. Another purpose of the invention is to provide a thick film circuit board employing the paste and adopting toughened glass as a baseplate. The third purpose of the invention is to provide a manufacturing method of the thick film circuit board. The manufacturing method comprises the steps of preparation of the conductive paste, a encapsulating paste and the baseplate, as well as the printing, encapsulating, sintering, performance test and packaging of a circuit diagram. The thick film circuit board has favorable sintering characteristic and aesthetic appearance, and can be widely used in the manufacturing field of electronic components.

Owner:SHENZHEN SENLONT ELECTRONICS

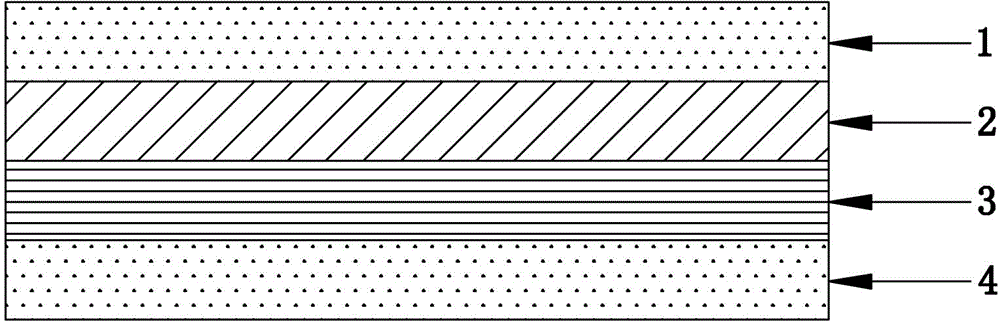

Special adhesive tape for energy storage and power lithium battery and production method of special adhesive tape

ActiveCN103333629APaste firmlyImprove puncture strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyPolyester

The invention relates to a special adhesive tape for an energy-storage or power lithium battery and a production method of the special adhesive tape. The adhesive tape comprises an adhesive layer, a hardened coating layer, a base layer and a release layer which are sequentially distributed. The base layer is a polyester thin film. The hardened coating layer is an epoxy resin layer and is coated on the front surface of the base layer. The release layer is a single-component non-silicon release agent coating layer and is arranged on the back surface of the base layer. The adhesive layer is arranged on the outer surface of the hardened coating layer. The adhesive tape is provided with a four-layer structure and each layer has a respective function, wherein the adhesive layer is in direct contact with the terminating part of the battery and has the characteristics that the adhesive layer is firm in bonding, is electrolyte-resistant and halogen-free and satisfies (RoHS) Restriction of Hazardous Substances requirements and the like; the hardened coating layer further improves the puncture strength of the base layer; the base layer can be prevented from being punctured by burrs on pole pieces; the release layer has an excellent adhering property and a quick drying performance similar to the base layer. The special adhesive tape for an energy-storage or power lithium battery has the advantages that the adhesive tape is environmentally-friendly, the RoHS requirements are satisfied, the electrolyte resistance is good and the like, and is mainly used for the insulation and the protection of the terminating part of the lithium battery.

Owner:佛山市顺德区永创翔亿电子材料有限公司

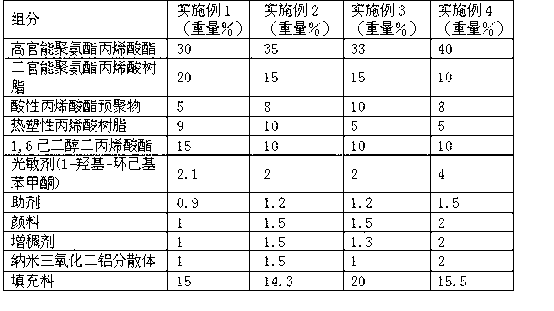

UV (ultraviolet) curing ink and application thereof

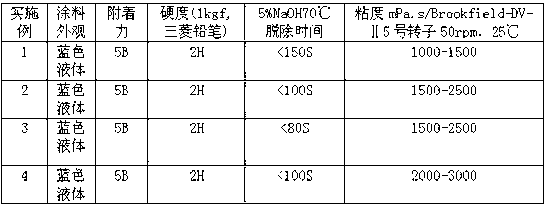

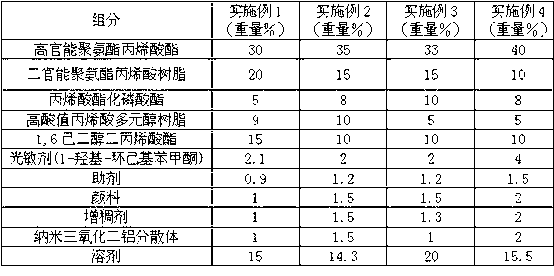

ActiveCN103232751ALow tolueneA low-concentration acid solution can quickly detoxifyInksPhotosensitizerUV curing

The invention discloses a UV (ultraviolet) curing ink and application thereof. The UV curing ink comprises the following components in percentage by weight: 30-40% of high-functionality polyurethane acrylate, 10-20% of dual-functionality polyurethane acrylic resin, 5-10% of amine-modified polyether acrylate prepolymer, 5-10% of thermoplastic acrylic resin, 10-15% of 1,6-hexanediol diacrylate, 2-4% of photosensitizer, 1-2% of nano aluminum oxide dispersion and 15-20% of filler. The UV photocuring ink is used for temporary protection in the glass surface working process; and after the UV photocuring ink is subjected to UV photocuring, a tough ink layer can be formed on the glass surface, thereby effectively ensuring the glass not to be scratched in the surface working process. After finishing the glass working, the glass can be soaked in 5% sulfuric acid solution, which is heated to 50 DEG C, to remove the UV curing ink on the glass surface without influencing the glass.

Owner:深圳市美丽华科技股份有限公司

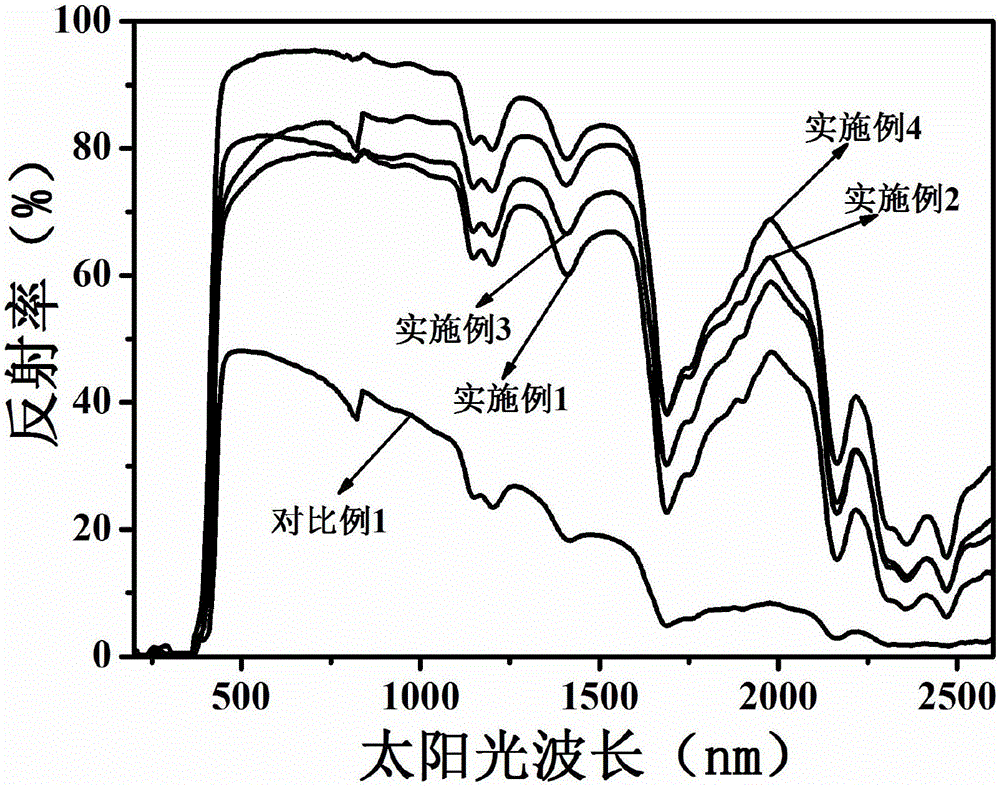

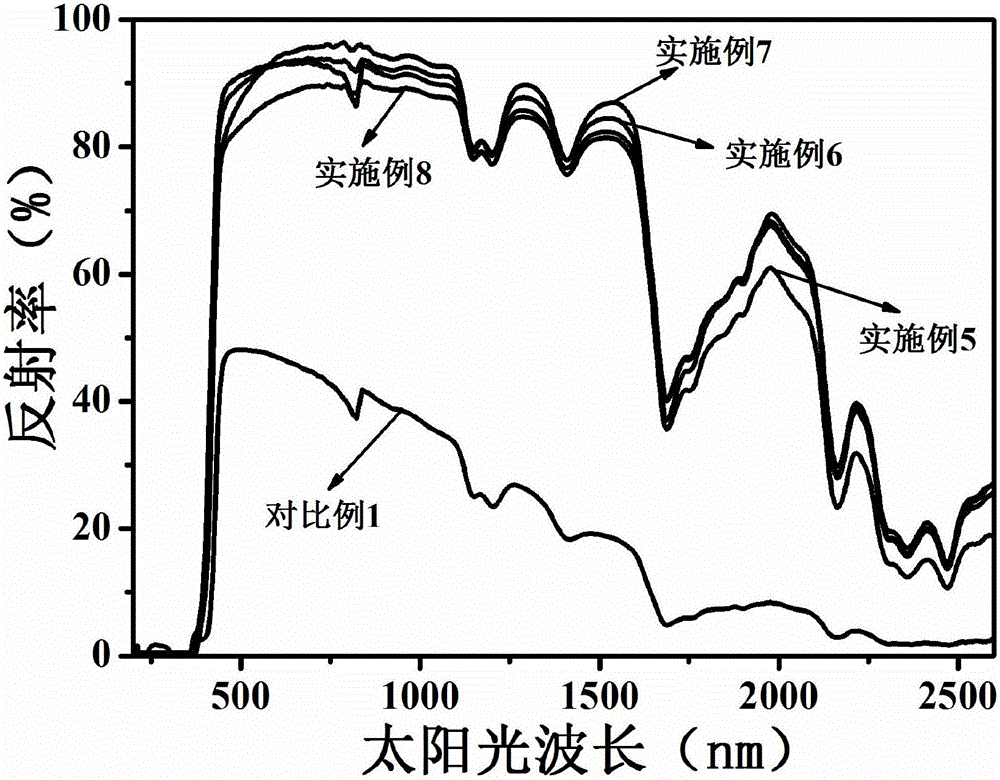

Functional modified ABS (acrylonitrile butadiene styrene) profiled base station antenna housing and production method thereof

The invention discloses a functional modified ABS (acrylonitrile butadiene styrene) profiled base station antenna housing and a production method thereof; the addition to easy access to materials and low price, the functional modified ABS profiled base station antenna housing has the functions such as environmental friendliness, excellent mechanical properties, high heat resistance, excellent dielectric property, and stable resistance to ultraviolet irradiation, especially excellent solar reflectivity. The functional modified ABS profiled base station antenna housing is produced from, by weight, 75-80 parts of ABS resin, 5-10 parts of AS resin, 5-10 parts of high-mobility AS (acrylonitrile-styrene) resin, 5-10 parts of AlphaMSAN (Alpha-methylstyrene-acrylonitrile) heat-resistant modified resin, 1-2 parts of lubricant EBS, 2.0-3.0 parts of photostabilizer UV326, 0.3-0.5 part of antioxidant GM, and 5-10 parts of a surface-modified inorganic nonmetal compound.

Owner:NANJING UNIV OF TECH +1

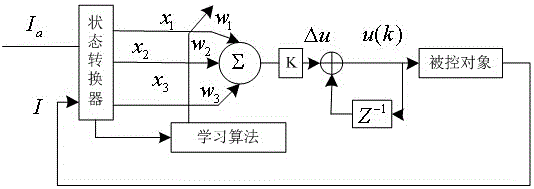

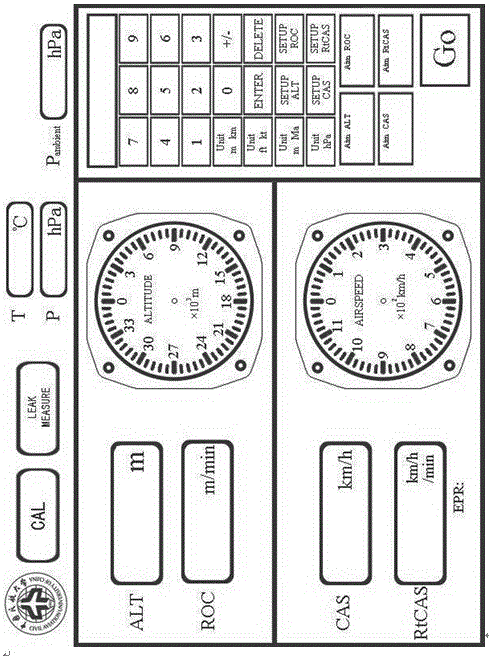

Airplane full static pressure test system based on adaptive PID method and method

ActiveCN105973544AHigh precisionFast dynamic responseMeasurement of fluid loss/gain rateControl engineeringAdaptive method

The invention relates to an airplane full static pressure test system based on an adaptive PID method and a method. According to the method, a power source starts power supply, self check is carried out; if correct, an analysis step of an instruction is carried out; if not correct, re-input of the instruction is carried out; a core module is controlled for converting and analyzing the instruction; the instruction is actuated; whether an emergency stop instruction is emitted is determined; if yes, the program is ended; if not, acquisition of pressure values of a sensor II and a sensor IV starts; values of the sensor II and the sensor IV are continuously acquired; the core module is controlled for checking whether a target value is reached; if yes, the progress is over; if not, the instruction is re-actuated. Through the method, a precise and reliable pressure source can be provided by the system for an airplane according to setting of an operator, real-time response can be carried out according to different demands of a test process, the airplane can be protected under emergent situations such as shedding of a pressure connector, and test tasks prescribed in an airplane manual can be accomplished according to demands of the airplane manual.

Owner:CIVIL AVIATION UNIV OF CHINA

Environment-friendly and flame retarded rubber material of inside liner of fire hose and preparation method thereof

InactiveCN101831117AGood weather resistanceWith flame retardant propertiesFlexible pipesRubber materialPolymer science

The invention discloses an environment-friendly and flame retarded rubber material of an inside liner of a fire hose and a preparation method thereof. The rubber material is prepared from the following raw materials in parts by weight: 100 parts of chlorinated polyethylene rubber, 10-15 parts of magnesium oxide, 0-8 parts of zinc oxide, 2-10 parts of thermal stabilizer, 15-20 parts of carbon black, 15-30 parts of white carbon black, 10-20 parts of citric acid plasticizer, 60-100 parts of aluminium hydroxide, 2-8 parts of adhesive, 2-5 parts of vulcanizing agent and 1.5-3 parts of co-vulcanizing agent. The method comprises the following steps of: placing the chlorinated polyethylene rubber, the thermal stabilizer, the magnesium oxide, the zinc oxide, the carbon black, the white carbon black, the aluminium hydroxide, the adhesive and the citric acid plasticizer into an internal mixer, mixing for 120-240 s, then adding the vulcanizing agent and the co-vulcanizing agent to continuously mix for 30-60 s, complementally mixing for 200-400 s on an open mill after discharging, and then pressing into sheet rubber suitable for processing on a tablet press.

Owner:WEIFANG YAXING GRP CO LTD

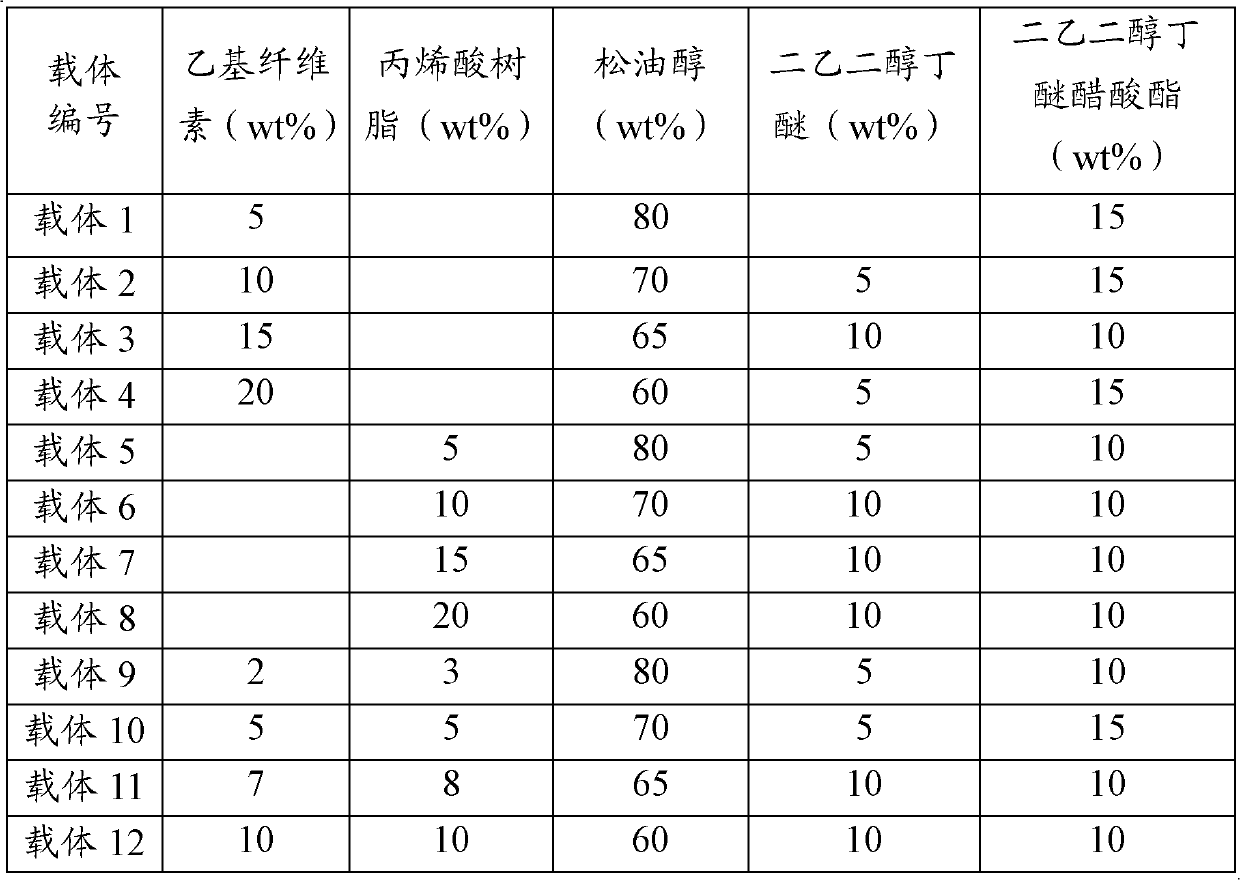

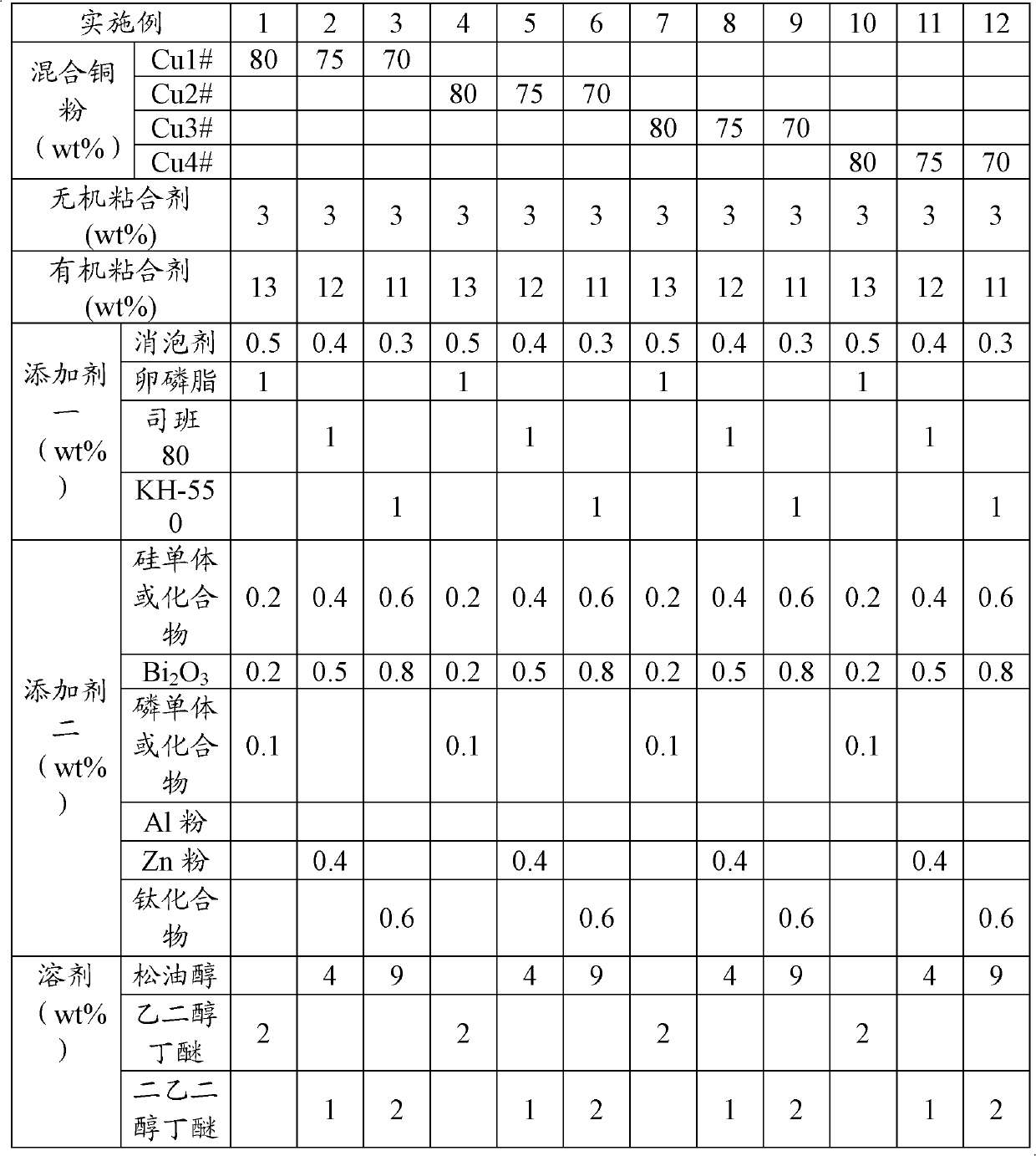

Lead-free copper slurry applied to silicon solar battery electrode and preparation method thereof

InactiveCN103310870AWide variety of sourcesLow priceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon solar cellSlurry

The present invention provides lead-free copper slurry applied to a silicon solar battery electrode and a preparation method thereof. The lead-free copper slurry is prepared from, by mass, 60% to 85% of mixed copper powder, 1% to 10% of inorganic binder, 10% to 30% of organic binder, 1% to 30% of mixed additive and 5% to 20% of organic solvent. The mixed copper powder comprises copper powder A whose particle diameter distribution is 0.5 to 2 microns, copper powder B whose particle size distribution is 1 to 3 microns and copper powder C whose particle diameter distribution is 4 to 7 microns, wherein the mass ratio of the three kinds of copper powder is 5 to 8:1 to 4:1. The mixed additive is composed of a first additive and a second additive. The first additive is the mixture of one or more than two of a defoaming agent, a silane coupling agent KH-550 and lecithin or span. The second additive is one or more of elements or compounds of transition family or III, IV and V family elements. Ratio restriction on the additive amount of the first additive and the second additive does not exist, and adding is carried out according to the actual situation. The lead-free copper slurry has the advantages of low cost and excellent conductivity, weldability and ohmic contact property, and can be used as universal electrode slurry of electrodes on front and back of a solar battery.

Owner:SHENZHEN SENLONT ELECTRONICS

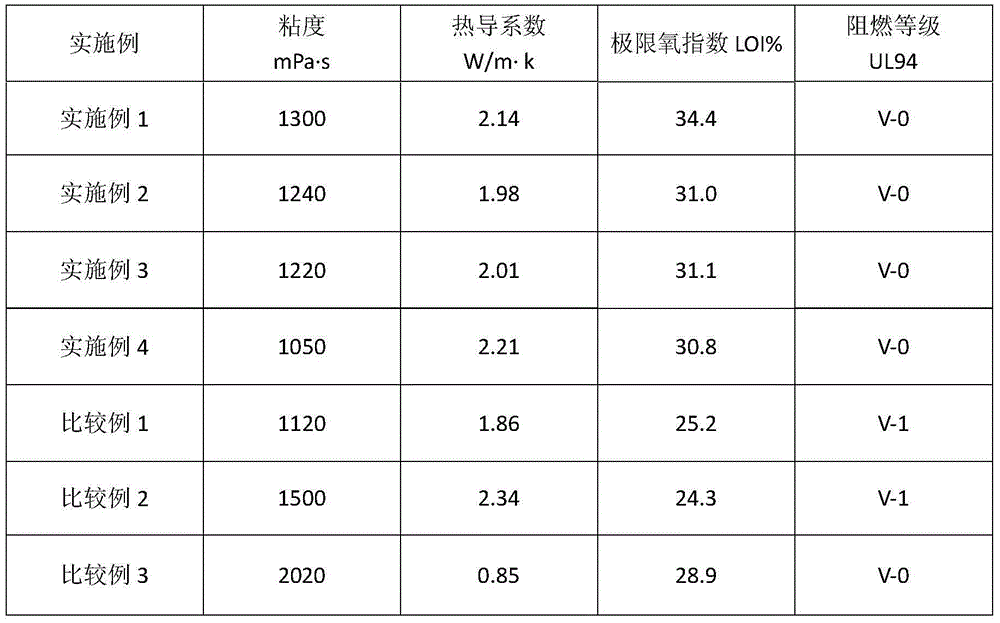

Environment-friendly flame-retardant heat-conducting glue and preparation method thereof

ActiveCN104559890AHigh softening pointImprove flame retardant performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyHeat conducting

The invention discloses environment-friendly flame-retardant heat-conducting glue and a preparation method thereof. The preparation method comprises the following steps: diluting a coupling agent by using absolute ethyl alcohol, regulating the pH value of the diluted solution, adding a heat-conducting filler, and mechanically stirring; centrifuging, washing, and drying, thereby obtaining a component A; uniformly mixing an epoxy resin, a curing agent and a curing accelerator by using a high-speed dispersion machine, thereby obtaining a low-viscosity component B; and uniformly grinding and mixing the component A, the component B, an organic phosphorus flame retardant and aluminum hydroxide, vacuumizing, heating the mixture at the temperature of 80-90 DEG C, and heating at the temperature of 130-150 DEG C, thereby obtaining the environment-friendly flame-retardant heat-conducting glue. The environment-friendly flame-retardant heat-conducting glue is low in viscosity, high in heat conductivity coefficient, good in mechanical property and high in acid-base resistance and corrosion resistance, the flame-retardant level reaches UL94V-0, the heat dissipation problem of a general electronic component can be solved; because the heat-conducting glue has good flame-retardant property, when the heat-conducting glue is applied to high-voltage and high-temperature electrical equipment, the on-fire potential safety hazard of the electronic component is effectively reduced.

Owner:中山沃硅化工科技有限公司

High-phosphorus chemical nickel-plating solution

InactiveCN106756904ALow costGood throwing abilityLiquid/solution decomposition chemical coatingSodium acetateSuccinic acid

The invention discloses a high-phosphorous chemical nickel-plating solution which comprises a cylinder opening solution and a supplement solution. The cylinder opening solution contains nickel sulfate, sodium hypophosphite, citric acid, lactic acid, sodium acetate, succinic acid, potassium iodate, potassium iodide, nitrilotriacetic acid, cerous sulfate, copper sulfate, benzotriazole, benzimidazole with the concentration being 2-10 mg / L, 5-25 mL / L of OP-10 with the concentration being 5-25 mL / L and the balance pure water. The nickel-plating solution has the advantages that cost is low, the excellent plating ability is achieved, the cylinder opening solution is stable, glossiness is achieved, the magnetism level requirement is met, and the service life reaches 11.0 MTO; during the service life, the average sedimentation rate is 12-14 [mu]m / h, the phosphorus content of a plating layer is 10%-14%, the time for neutral salt spraying is longer than or equal to 96 h (the thickness of the plating layer is 18-25 [mu]m), and the time for a purification resistant nitric-acid test is longer than or equal to 8 min (the thickness of the plating layer is 18-25 [mu]m); the magnetism level is lower than or equals to 200 gamma (specifically, 1 gamma is equal to 1 nT, and in general, remanence in the aerospace field takes gamma as a unit), the western country standard is met, and the magnetism is required to meet the NMB magnetism level; and the plating solution is free of lead and cadmium, conforms to the RoHS command and is an environment-friendly high-phosphorous chemical nickel-plating solution.

Owner:贵阳华科电镀有限公司

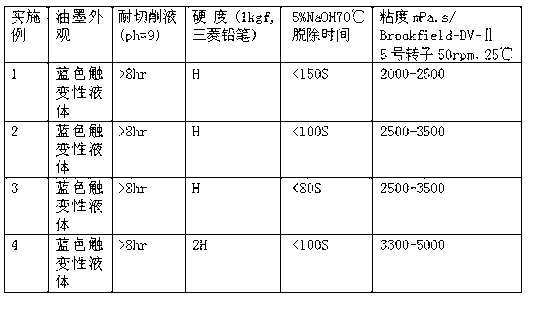

UV (ultraviolet) curing ink and application thereof

The invention discloses a UV (ultraviolet) curing ink and application thereof. The UV curing ink comprises the following components in percentage by weight:30-40% of high-functionality polyurethane acrylate, 10-20% of dual-functionality polyurethane acrylic resin, 5-10% acidic acrylate prepolymer, 5-10% of thermoplastic acrylic resin, 10-15% of 1,6-hexanediol diacrylate and 2-4% of photosensitizer. When being printed on a glass workpiece, the UV photocuring ink is used for temporary protection in the glass surface working process. After the UV photocuring ink is subjected to UV photocuring, a tough ink layer, which has the advantages of favorable adhesion to glass, high surface hardness, favorable scratch resistance and favorable cutting fluid resistance, can be formed on the glass surface, and can effectively ensure the glass not to be scratched in the surface working process. After finishing the glass working, alkaline water can quickly remove the UV photocuring ink layer, so that the glass can not be influenced.

Owner:深圳市美丽华科技股份有限公司

Thermoplastic low-smoke halogen-free flame-resistant polyolefin oxygen barrier filling material

InactiveCN101157774AImprove flame retardant performanceExcellent self-extinguishing performanceThermoplasticPolymer science

The invention relates to an oxygen separation layer filler of thermoplastic property, low smoke, no halogen and flame retardant polyolefin. The filler comprises the following components (by weight): 100 of polyolefin resin, 100 to 300 of flame retardant agent, 0 to 100 of flame retardant synergist, 0.5 to 5.0 of antioxidant, 1 to 10 of surface treatment agent, 0 to 20 of lubricant and 0 to 20 of other promoters. Compared with the prior art, the invention has the advantages of having optimal flame retardant performance, off-fire self-extinguish performance and no trickling after burning, being completely stuck on cable, forming a layer of hard carbon shell to isolate oxygen and heat, preventing burning and protecting the cable completely, etc.

Owner:SURREY HI TECH INC

Packaging adhesive tape

ActiveCN104946154AAvoid harmMeet blow molding requirementsFilm/foil adhesivesStearic acidAnti oxidant

The invention discloses a packaging adhesive tape which is prepared by taking a polyurethane modified chlorinated polypropylene composite as a base material, wherein the polyurethane modified chlorinated polypropylene composite comprises the following raw materials in parts by weight: 100 parts of chlorinated polypropylene, 60-85 parts of a chlorinated polypropylene graft polymer, 12-24 parts of a toughened master batch, 5-20 parts of a halogen-free flame retardant, 0.5-4 parts of a coupling agent, 1-3 parts of an anti-oxidant, 2-4 parts of stearic acid, 1-3 parts of dioctyl phthalate, 0.5-2 parts of ethylene bis stearamide and 0.2-4 parts of polyethylene wax; the composite is formed by conducting graft modification on chlorinated polypropylene through polyurethane and maleic anhydride, and is used for preparing a high-performance high-molecular composite, and the finally obtained composite has relatively high abrasion resistance, weather resistance, impact resistance, corrosion resistance and high-low temperature resistance.

Owner:芜湖通发机械科技有限公司

Environment-friendly type cleaning agent

InactiveCN101838814ARoHS CompliantMeet the requirements of green environmental protectionNaphthaCleansing Agents

The invention discloses an environment-friendly type cleaning agent, which contains the following components in parts by weight: 10%-20% of 70# solvent naphtha, 10%-20% of 90# solvent naphtha, 30%-40% of 120# solvent naphtha, 20%-30% of 190# solvent naphtha, 5%-10% of industrial alcohol and 2%-5% normal butanol, and the sum of the percentage of the using amount of the raw material is 100%. The production method of the environment-friendly type cleaning agent has simple technique and low production cost; the technical indexes are in accordance with green and environment-friendly requirements; and the environment-friendly type cleaning agent is an environment-friendly type cleaning agent with excellent properties, and is widely used for the industries such as the electronic industry, the refrigeration industry, the automobile industry, the mold industry, the precision machining industry and the like.

Owner:陕西宏业电工电子新材料有限公司

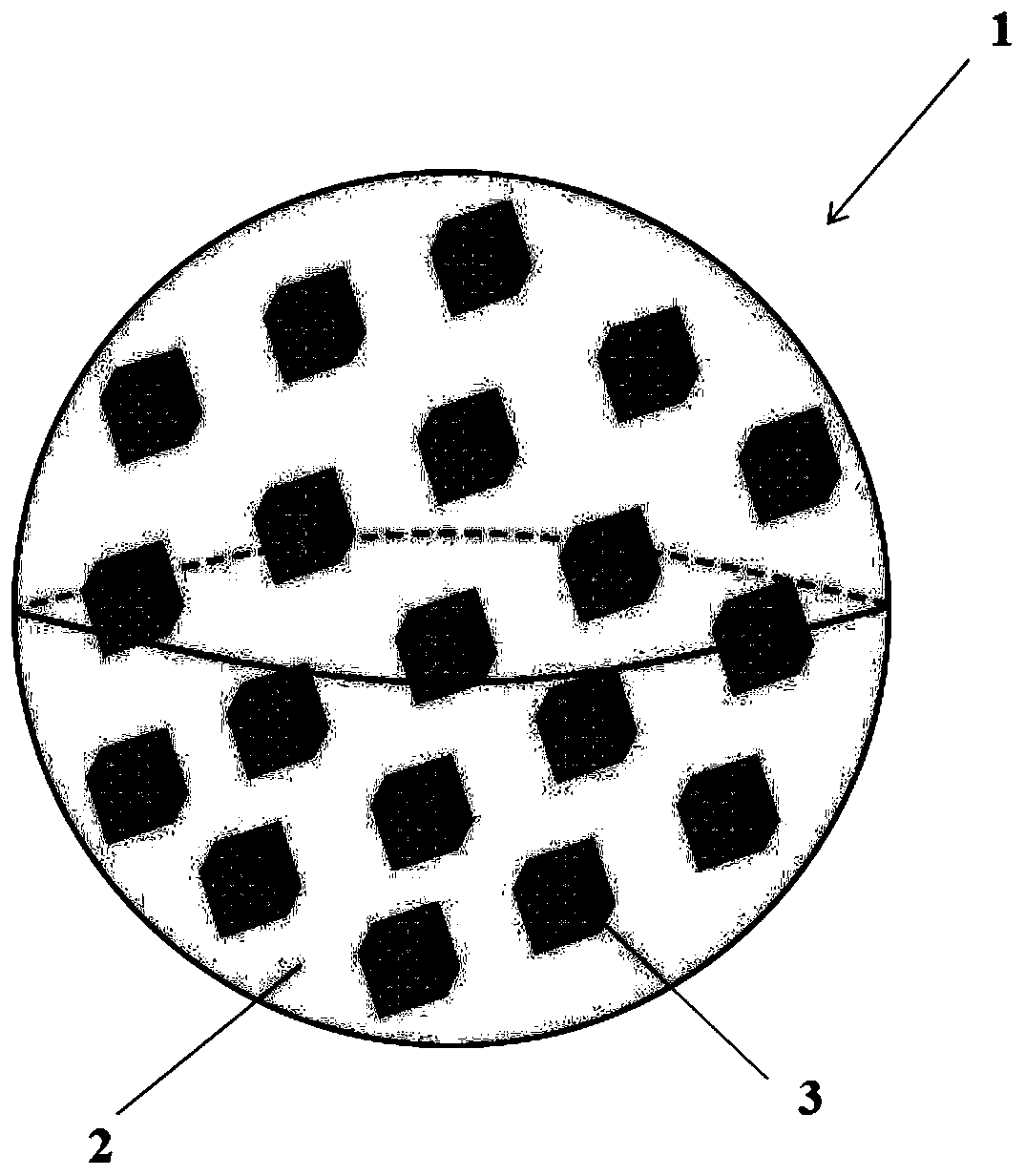

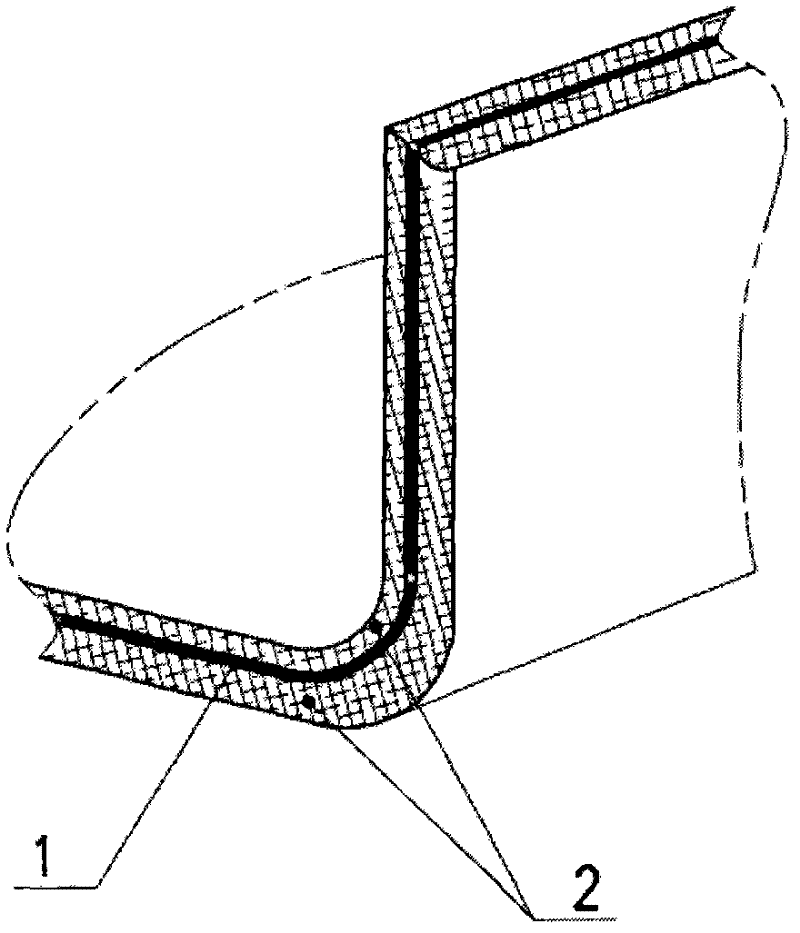

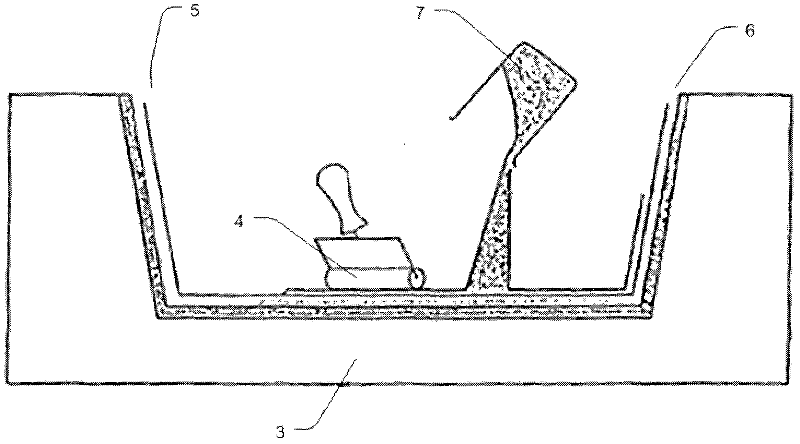

Color conversion layer and display apparatus having the same

The present invention relates to a color conversion layer (4) comprising at least one light emitting material (7) comprising at least one composite particle (1) surrounded partially or totally by at least one surrounding medium (71); wherein said light emitting material (7) is configured to emit light in response to an excitation and the at least one composite particle (1) comprises a plurality ofnanoparticles encapsulated in an inorganic material; and wherein said inorganic material (2) has a difference of refractive index compared to the at least one surrounding medium (71) superior or equal to 0.02 at 450 nm. The present invention also relates to display apparatus.

Owner:NEXDOT

Environment-friendly high and low temperature resistant and oil resistant flame-retardant nano-composite thermoplastic elastomer and preparation process thereof

The invention provides an environment-friendly high and low temperature resistant and oil resistant flame-retardant nano-composite thermoplastic elastomer and a preparation process thereof. The nano-composite thermoplastic elastomer is prepared from the following components in parts by weight: 60 to 75 parts of NBR (Nitrile-Butadiene Rubber) nano-composite particles, 25 to 40 parts of PVC (polyvinyl chloride) premolding powder, 10 to 15 parts of modifier ABS (Acrylonitrile Butadiene Styrene), 10 to 15 parts of first flame retardant, 5.0 to 10 parts of second flame retardant, 0.8 to 1.2 parts of activating agent, 0.2 to 0.4 part of vulcanizing agent, 0.8 to 1.2 parts of anti-aging agent, 0.5 to 1.0 part of accelerator, 0.3 to 0.5 part of ultraviolet light absorber and 1.0 to 2.0 parts of processing aid. The thermoplastic elastomer provided by the invention is green and environment-friendly, resistant to ozone and excellent in mechanical property, high and low temperature resistance, oil immersion resistance and flame retardance and can be used for sheaths and shoes of flame-resistant, oil-resistant and heat-resistant flexible wires, elastomer cables, oil-resistant heavy flexible wires, movable cables and the like, as well as oil pipes and the like.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Environment-friendly inflaming-retarding acrylonitrile-butadiene-styrene (ABS) material

An environment-friendly inflaming-retarding acrylonitrile-butadiene-styrene (ABS) material belongs to the technical field of high polymer materials, which comprises the following components, by weight: 50-90 parts of ABS, 10-50 parts of flame retardants, 5-20 parts of flame retardant association effect agents, 0-2 parts of antioxidants and 0-2 parts of processing agents. The ABS material is friendly to the environment and has high inflaming-retarding performance and an excellent mechanics effect.

Owner:杭州金州高分子科技有限公司

Matte PVC sheathing material for cable applied to electric vehicle charging pile and preparation method thereof

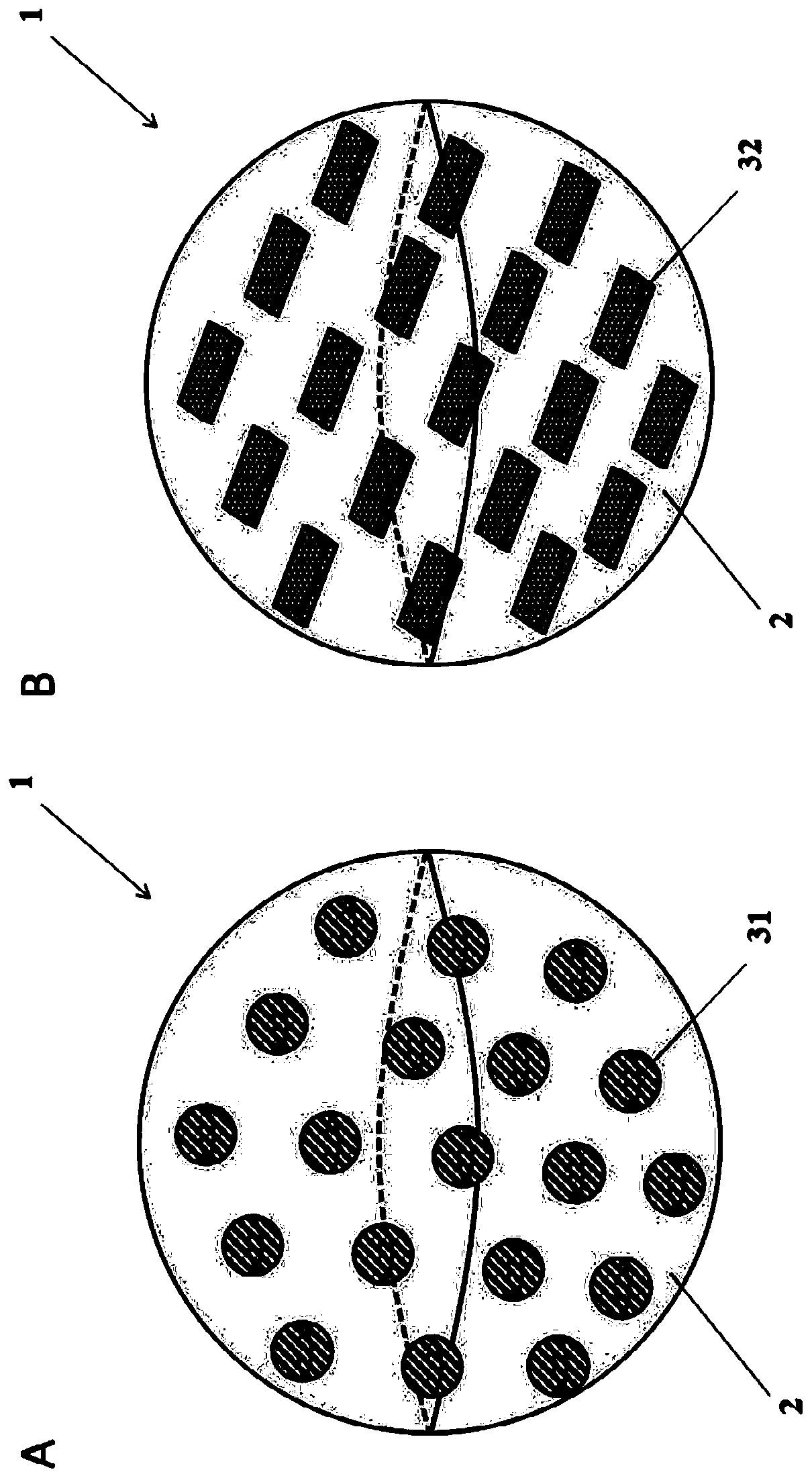

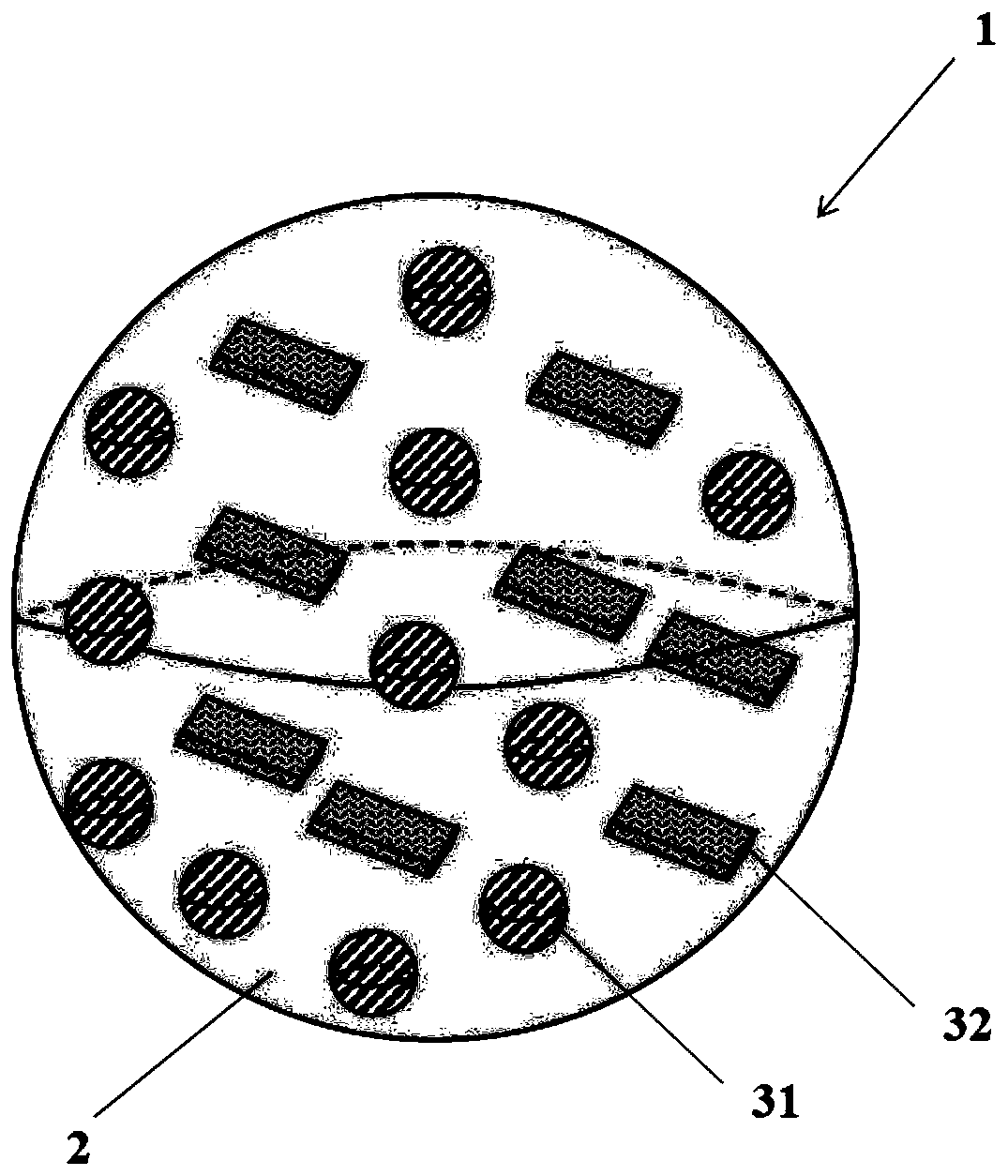

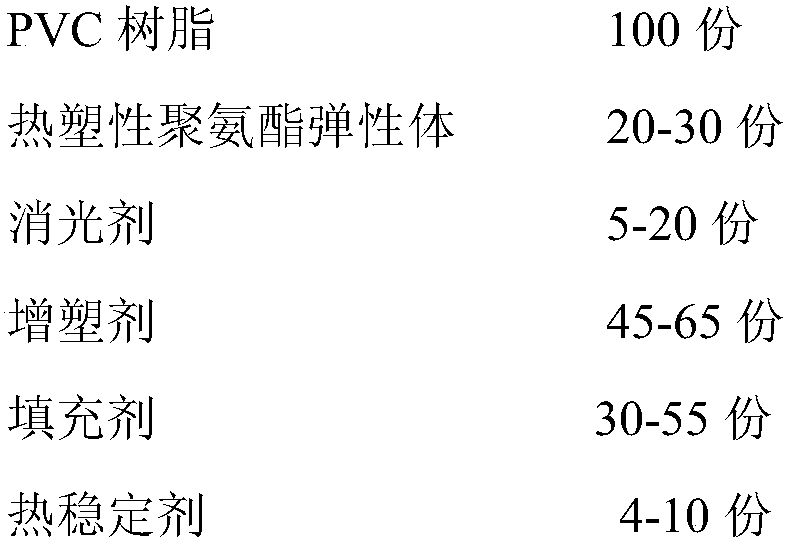

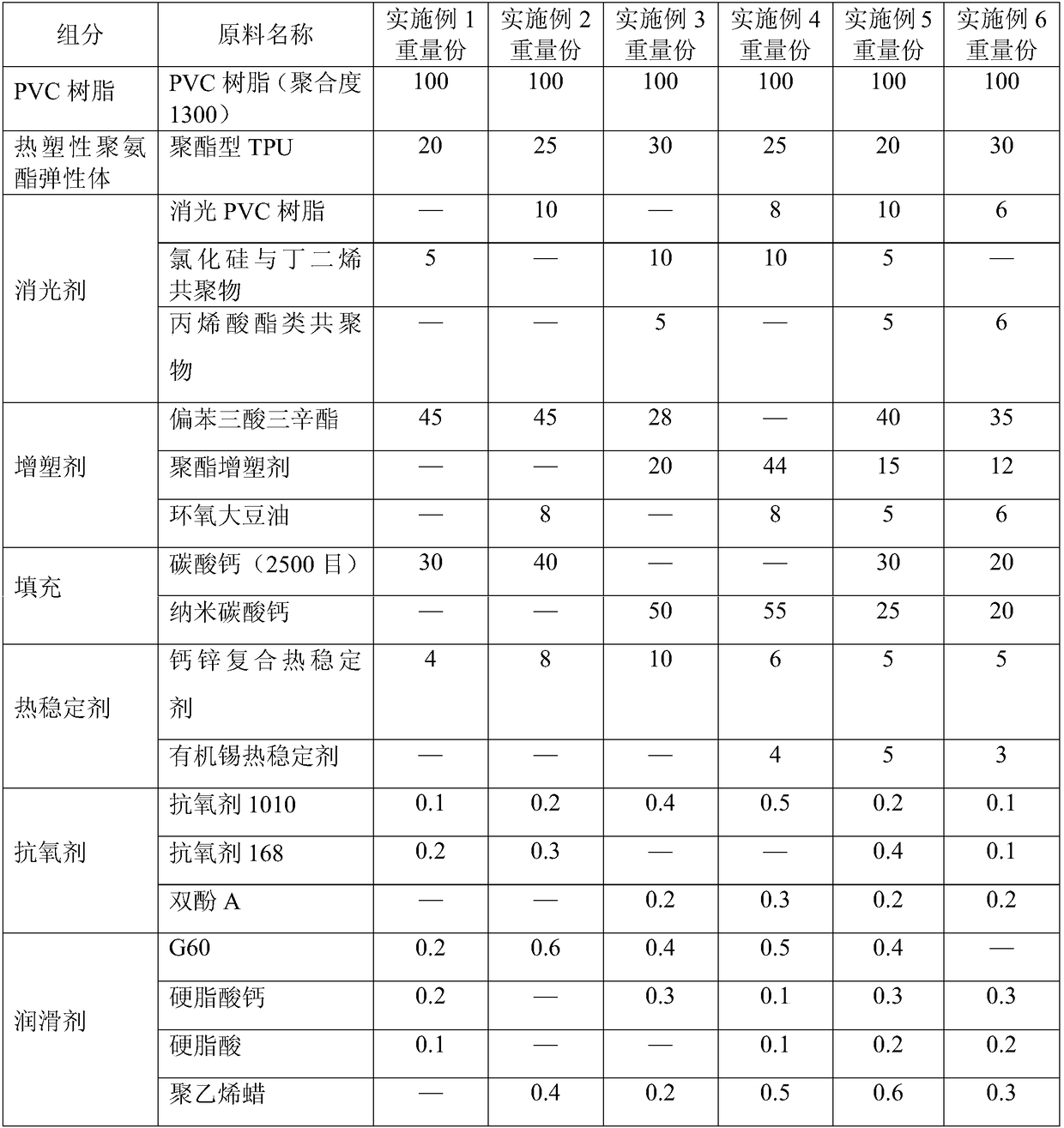

InactiveCN108164862AEasy to processGives a matte finishPlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention discloses a matte PVC sheathing material for a cable applied to an electric vehicle charging pile, belonging to the field of cable materials and preparation methods thereof. The matte PVC sheathing material comprises the following raw material by weight: 100 parts of PVC resin, 20-30 parts of thermoplastic polyurethane elastomer, 5-20 parts of a matting agent, 45-65 parts of a plasticizer, 30-55 parts of a filler, 4-10 parts of a heat stabilizer, 0.3-0.8 part of an antioxidant and 0.5-1.5 parts of a lubricant. The matt PVC sheathing material for the cable applied to the electricvehicle charging pile has all the properties prescribed in the Standard GB / T 8815-2008 for polyvinyl chloride sheathing materials HII-90 at 90 DEG C, and presents excellent processing performance; thesurface of the finished sheathing material presents matte effect; and the prepared cable meets the requirements of EV-VV and EV-VVPV specified in the Standard CQC1103-2014, accords with the StandardRoHS and is environmentally friendly and harmless.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Method for preparing La0.5Li0.5TiO3 fiber reinforced Ag based electric contact material

ActiveCN106784804ARoHS CompliantConforms to WEEE DirectiveCell electrodesElectrospinningFiber structure

The invention discloses a method for preparing a La0.5Li0.5TiO3 fiber reinforced Ag based electrical contact material. The method includes preparation of La0.5Li0.5TiO3 conductive ceramic fiber by electrospinning, implantation of silver mirror reaction in the process of electrospinning for surface silver plating modification of the La0.5Li0.5TiO3 conductive ceramic fiber, and collection of specificall oriented silver plating La0.5Li0.5TiO3 fiber between bridge-type electrodes; immersion orientation of the silver plating La0.5Li0.5TiO3 fiber in molten Ag to form a precursor, replenishment of Ag powder for ingredient proportion, and isostatic pressing billet preparation, sintering, re-pressing, after-combustion, hot extrusion drawing molding and other successive processes to obtain the electrical contact material. A La0.5Li0.5TiO3 reinforcement phase is inlayed in an Ag matrix in the manner that fiber orientation is perpendicular to a working face, the processing stress, working current, thermal conductivity and the like of the electrical contact material all can be conducted by pure silver pathways among the La0.5Li0.5TiO3 fiber structures, and the problems of high resistivity, low elongation percentage, short electric life and the like of a Cd-free environmentally-friendly electrical contact material can be improved.

Owner:QUZHOU UNIV

Circuit forming method of outer layer of circuit board

ActiveCN105338752AHigh hardnessImprove scratch resistanceInksConductive material chemical/electrolytical removalAcid etchingIrradiation

The invention relates to a circuit forming method of an outer layer of a circuit board. The method comprises: a circuit board with an outer layer circuit needing to be processed is provided; pouring and coating of deep-curing UV ink are carried out on a hole needing protection and / or a predetermined region needing protection at a circuit board surface on the circuit board; exposure is carried out on the condition of 100-300mJ / cm<2>; and development, etching, and membrane removing are carried out on the exposed circuit board to form an outer layer circuit of the circuit board. According to the invention, the deep-curing UV ink is used for manufacturing the circuit board and the inside of the hole and the region with the surface needing protection are coated with the ink; and deep curing can be realized after UV light source irradiation. Therefore, chemical impacts on a weak base developing solution with the pH being approximately equal to 10 and an acid etching solution with the pH being 2 to 3 and thus the anti-etching effect is realized.

Owner:深圳市乐建感光材料科技有限公司

UV (ultraviolet) curing paint and application thereof

The invention discloses UV (ultraviolet) curing paint and application thereof. The UV curing paint comprises the following components in percentage by weight: 30-40% of high-functionality polyurethane acrylate, 10-20% of bifunctional polyurethane acrylic resin, 5-10% of acrylic ester phosphate, 5-10% of high-acid-value acrylic polyalcohol resin, 10-15% of 1,6-hexanediol diacrylate, 2-4% of photosensitizer, 1-2% of nano aluminum oxide dispersion and 15-20% of solvent. The UV photocuring paint is used for temporary protection in metal surface processing. After being subjected to UV photocuring, the UV photocuring paint can form a tough paint layer on the surface of metal; and the paint layer has favorable metal adhesive force, high surface hardness and favorable scratch resistance, and can effectively ensure that the metal can not be scratched in the surface processing course. Besides, after the metal is processed, the UV photocuring paint layer can be quickly removed with alkaline water, and no influence can be caused on the metal itself.

Owner:深圳市美丽华科技股份有限公司

Anti-radiation material and CT (computed tomography) chassis

InactiveCN102479563AProtection from Excessive RadiationImprove shielding performanceSynthetic resin layered productsComputerised tomographsComposite materialTungsten

The invention provides a novel anti-radiation material and a CT (computed tomography) chassis made with the novel anti-radiation material. The anti-radiation material comprises a resin material, a fiber material and a tungsten-molybdenum material. Due to combination of the resin material and the fiber material, high strength of the material can be ensured. Moreover, since the tungsten-molybdenum material of a high atomic number is used, the function of absorbing radiation can be achieved, and the impact on the human body and the environment is very low.

Owner:SIEMENS SHANGHAI MEDICAL EQUIP LTD

Halogen-free flame-retardant heat-resistant weather-resistant polypropylene nano composite insulating material for automobile wire and preparation method thereof

ActiveCN105219006AHigh strengthImprove wear resistancePlastic/resin/waxes insulatorsInsulated cablesPolypropyleneExtrusion Granulation

The invention relates to a halogen-free heat-resistant weather-resistant polypropylene nano composite insulating material for an automobile wire and a preparation method thereof. The composite insulating material is prepared from 50-60 parts of polypropylene nano compounds and 50-60 parts of halogen-free flame-retardant master batches. The polypropylene nano compounds are prepared from, by weight, 100 parts of polypropylene, 10-15 parts of polypropylene polar monomer grafts, 4.0-8.0 parts of nano inorganic compounds and the like. The halogen-free flame-retardant master batches are prepared from, by weight, 100 parts of organic hydroxide, 20-30 parts of carrier resin and the like. By the adoption of the binary technology, the polypropylene nano compounds and the halogen-free flame-retardant master batches high in flame-retardant agent content are prepared, the polypropylene nano compounds and the halogen-free flame-retardant master batches are mixed, extruded and granulated through a double-screw extruding machine, and the nano composite insulating material is obtained. The material is low in cost and environmentally friendly, integrates excellent physical and mechanical performance and electric performance and good extruding processability, is suitable for insulating processing of the automobile original wire, and can be used for insulating wrapping of communication cables, logging cables and oil-submerged pump cables.

Owner:TONGJI UNIV

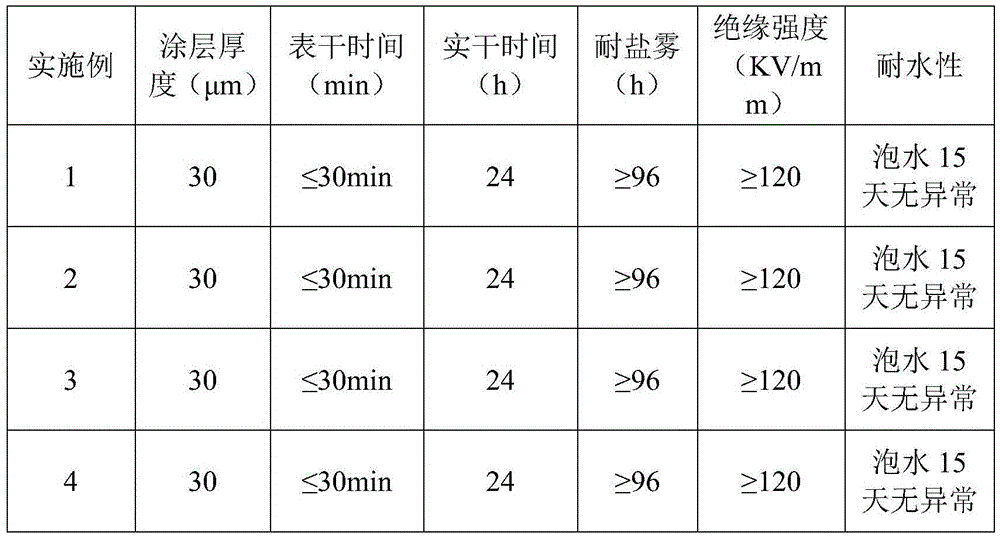

Three-prevention paint for printed circuit board with high salt fog resistance

The invention discloses three-prevention paint for a printed circuit board with high salt fog resistance. The three-prevention paint is prepared by mixing modified resin with drier accounting for 0.5-2.0% of modified resin at a high speed for 30-120 minutes. Modified resin is prepared from raw materials such as unsaturated resin, p-methylstyrene, fluorinated acrylate, dearomatization solvent oil and initiator, and unsaturated resin is prepared from raw materials such as pentaerythritol and / or trihydric alcohol and unsaturated fatty acid. The hydrophobicity performance and salt fog resistance of the prepared three-prevention paint resin are remarkably improved, the prepared three-prevention paint can be used for protecting the circuit board and relevant devices against corrosion of the environment, and the service life of a product is prolonged; the obtained three-prevention paint product does not contain aromatic solvent such as benzene, methylbenzene and xylene, the damage of aromatic solvent to the environment and human bodies is reduced, the use safety of the product is improved, production cost is reduced, the environment protection requirement is met, and the paint conforms to the European Union RoHS standard.

Owner:SHENZHEN NEWOLL NEW MATERIAL CO LTD

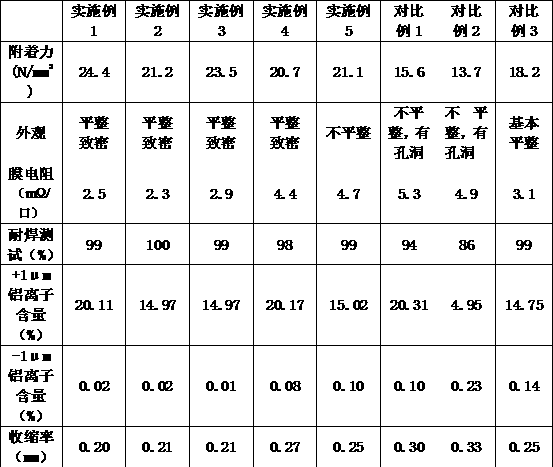

Conductive silver paste for LTCC ceramic substrate and preparation method thereof

ActiveCN108962422AGood matchSilver levelingNon-conductive material with dispersed conductive materialCable/conductor manufactureCo-fired ceramicSolvent

The present invention provides a conductive silver paste for LTCC (Low Temperature Co-fired Ceramic) ceramic substrate. According to the mass percent, the conductive silver paste is formed by 82%-86%of silver powder, 3%-4% of polymer resin, 0.2%-1.1% of glass powder and 10%-15% of solvent. The polymer resin is formed by ethyecellulose, carboxymethylcellulose and polyaspartic acid. The conductivesilver paste obtained by employing the preparation method provided by the invention is good in conductivity, high in adhesive force, and smooth and dense in appearance. The bonding force of the sliverlayer and the ceramic interface is high, and the internal portion of the device cannot generate cracking and delamination.

Owner:华昇电子材料(无锡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com