Method for preparing La0.5Li0.5TiO3 fiber reinforced Ag based electric contact material

An electrical contact material, fiber-reinforced technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as health hazards, achieve the effect of saving silver, improving high resistivity, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

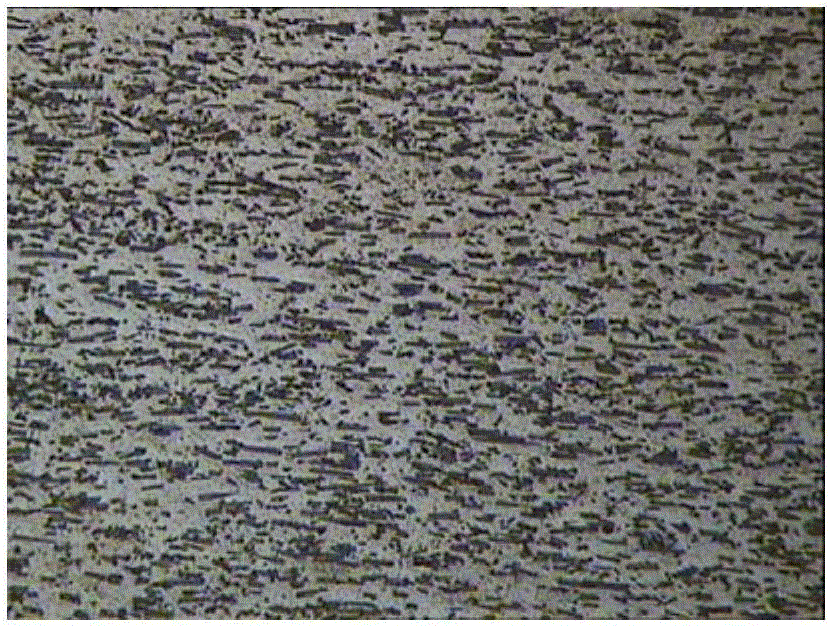

Image

Examples

preparation example Construction

[0028] La 0.5 Li 0.5 TiO 3 A method for preparing a fiber-reinforced Ag-based electrical contact material, specifically comprising the steps of:

[0029] (1) Preparation of La by electrospinning 0.5 Li 0.5 TiO 3 conductive ceramic fibers, and implanted silver mirror reactions during electrospinning, the La 0.5 Li 0.5 TiO 3The surface of the fiber was modified by silver plating. The specific method of surface silver plating modification is as follows:

[0030] First, accurately weigh La(NO 3 ) 3 , Li 3 C 6 h 5 o 7 4H 2 O and Ti(C 4 h 9 O) 4 , under the assistance of ultrasonic waves, dissolve in deionized water to form a metal alkoxide solution; accurately weigh citric acid and ethylene glycol according to a certain molar ratio, dissolve in deionized water, adjust the pH with ammonia water, and configure it as a complex complexing agent Slowly add the composite complexing agent into the metal alkoxide solution, control the constant temperature with a water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com