Conductive silver paste for LTCC ceramic substrate and preparation method thereof

A technology of conductive silver paste and ceramic substrate, which is used in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. Equal issues, to achieve the effect of eliminating the risk of electrical breakdown, good matching, good solder resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

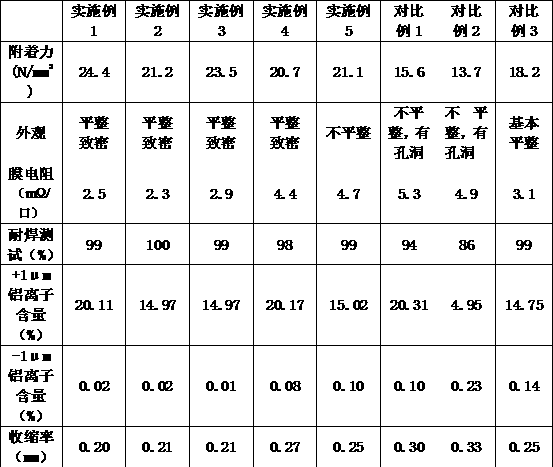

Examples

preparation example Construction

[0031] The present invention also discloses the preparation method of the above-mentioned conductive silver paste for LTCC ceramic substrate, including:

[0032] (1) The polymer resin and the solvent are mixed according to a certain ratio and fully dissolved to obtain an organic vehicle. According to the formula, a certain proportion of polymer resin and solvent is dissolved at a certain temperature of 80°C-85°C for 1-2 hours to form a uniform and transparent fluid with a certain viscosity, which is an organic carrier.

[0033] In the present invention, the preparation of the organic carrier can be prepared by conventional methods in the field, for example, the following steps can be included: drying the polymer resin: placing the polymer resin in an oven at a constant temperature of 60°C-65°C for 8 -9 hours, so that the polymer resin is fully dried; the polymer resin and the solvent are mixed according to the proportion and fully dissolved to obtain the mixture: put the conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com