Universal back electrode silver paste for PERC single-sided and double-sided batteriesand preparation method thereof

A double-sided battery, back electrode technology, used in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of poor aging resistance of PERC back silver technology, affecting the reliability and use of components Life, the silver-aluminum lap joints pull off the powder and other problems, to achieve the effect of improving reliability and service life, high aging tensile force, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

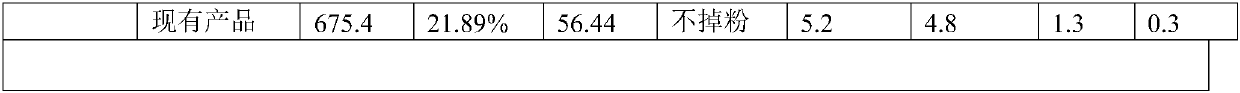

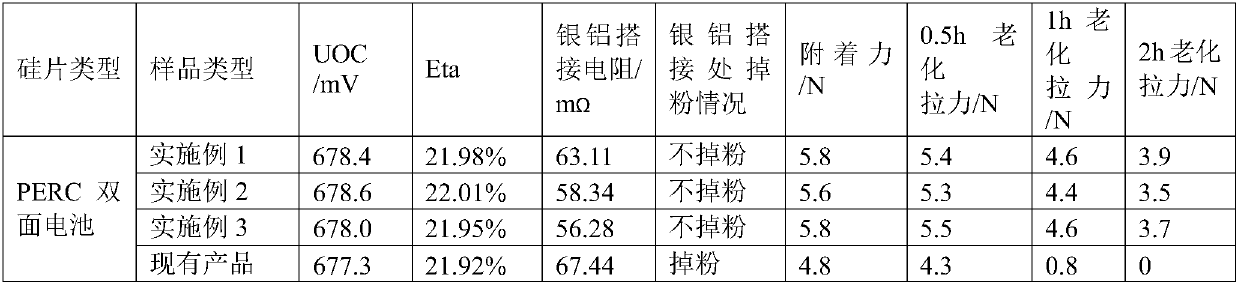

Examples

Embodiment 1

[0032] The universal back electrode silver paste for PERC single-sided and double-sided batteries provided in this embodiment comprises the following components in parts by weight: 10 parts of nano silver powder, 20 parts of spherical silver powder, 25 parts of microcrystalline silver powder, 2 parts of glass powder, and 42 parts of organic vehicle 1 part, 1 part of organic additives.

[0033] The organic vehicle includes the following components in parts by weight: 10 parts of Dow ethyl cellulose STD-100, 75 parts of Dow ethyl cellulose STD-75 parts, 45 parts of terpineol, 25 parts of butyl carbitol acetate, alcohol Ester twelve 15 parts.

[0034] The glass powder comprises the following components in parts by weight: Bi 2 o 3 44 copies, B 2 o 3 4 parts, SiO 2 20 copies, Al 2 o 3 2 parts, CuO 15 parts, MnO 2 6 parts, ZrO 2 2 copies, W 2 o 3 1 part, Na 2 CO 3 0.5 parts, ROx 5.5 parts.

[0035] The preparation method of the universal back electrode silver pa...

Embodiment 2

[0045] The universal back electrode silver paste for PERC single-sided and double-sided batteries provided in this embodiment comprises the following components in parts by weight: 6 parts of nano silver powder, 33 parts of spherical silver powder, 16 parts of microcrystalline silver powder, 2.5 parts of glass powder, and 40.5 parts of organic vehicle Parts, 2 parts of organic additives.

[0046] The organic vehicle includes the following components in parts by weight: Dow ethyl cellulose STD-2003 parts, STD-1008 parts, Dow ethyl cellulose STD-74 parts, terpineol 40 parts, butyl carbitol 10 parts Parts, 20 parts of butyl carbitol acetate, 15 parts of alcohol ester twelve.

[0047] The glass powder comprises the following components in parts by weight: Bi 2 o 3 35 copies, B 2 o 3 6 parts, SiO 2 23 parts, Al 2 o 3 2 parts, CuO 20 parts, MnO 2 3 parts, ZrO 2 0.5 parts, W 2 o 3 1 part, Na 2 CO 3 0.5 parts, ROx 9 parts.

[0048] The method for preparing the un...

Embodiment 3

[0055] The universal back electrode silver paste for PERC single-sided and double-sided batteries provided in this embodiment comprises the following components in parts by weight: 15 parts of nano silver powder, 10 parts of spherical silver powder, 30 parts of microcrystalline silver powder, 1 part of glass powder, and 43.5 parts of organic vehicle parts, 0.5 parts of organic additives.

[0056] The organic vehicle includes the following components in parts by weight: 12 parts of Dow ethyl cellulose STD-100, 72 parts of Dow ethyl cellulose STD-72, 40 parts of terpineol, 28 parts of butyl carbitol acetate, alcohol Ester twelve 18 parts.

[0057] The glass powder comprises the following components in parts by weight: Bi 2 o 3 46 copies, B 2 o 3 5 parts, SiO 2 15 copies, Al 2 o 3 2 parts, CuO 8 parts, MnO 2 8 parts, ZrO 2 2 copies, W 2 o 3 1.5 parts, Na 2 CO 3 0.5 parts, ROx 12 parts.

[0058] The preparation method of the PERC single-sided double-sided cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com