Three-prevention paint for printed circuit board with high salt fog resistance

A printed circuit board, high salt spray resistance technology, applied in coatings and other directions, can solve the problems of poor salt spray resistance, short protection period, toxic and harmful, and improve hydrophobicity and salt spray resistance. , The effect of improving the safety of use and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

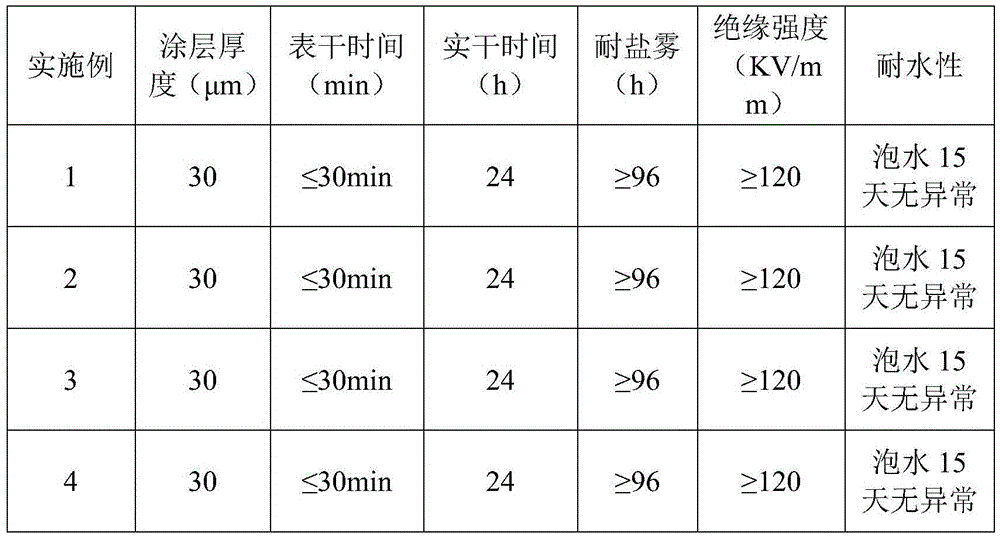

Examples

Embodiment 1

[0026] Add 300 parts of linseed oil fatty acid, 120 parts of dehydrated castor oil fatty acid, and 75 parts of pentaerythritol into the reaction kettle, start stirring, heat up to 180°C-250°C for high-temperature dehydration treatment until the acid value is 8mgKOH / g, stop the reaction, and cool down to 60 °C, an unsaturated resin was obtained.

[0027] Take 80 parts of the above-mentioned unsaturated resin and 45 parts of p-methylstyrene, put them into the reaction kettle, raise the temperature to 125°C, react at a constant temperature, add 1.8 parts of tert-butylperoxytrimethylcyclohexane dropwise at a constant rate, drop After adding time for 3 hours, take 4 parts of hexafluorobutyl methacrylate and 1.8 parts of tert-butyl peroxytrimethylcyclohexane, mix evenly, add dropwise to the reaction kettle at a constant speed, drop for 3 hours, and then react at constant temperature , to obtain a resin sample; take the resin sample and dilute it with a low-boiling dearomatized hydro...

Embodiment 2

[0029] Add 230 parts of linseed oil fatty acid, 180 parts of soybean oil fatty acid, 160 parts of dehydrated castor oil fatty acid, 25 parts of pentaerythritol, and 80 parts of trimethylolpropane into the reaction kettle, start stirring, and heat up to 180°C to 250°C for high-temperature dehydration treatment to The acid value was 20 mgKOH / g, the reaction was stopped, and the temperature was lowered to 60° C. to obtain an unsaturated resin.

[0030] Take 150 parts of unsaturated resin and 138 parts of p-methylstyrene, add them to the reaction kettle, raise the temperature to 125°C, and react at a constant temperature, add 4.5 parts of tert-butyl peroxybenzoate dropwise at a constant rate for 3 hours, and then Take 12 parts of trifluoroethyl methacrylate and 4.5 parts of tert-butyl peroxybenzoate, mix evenly, add dropwise to the reaction kettle at a constant speed, and the dropwise addition time is 3 hours, and then react at a constant temperature to obtain a resin sample; take ...

Embodiment 3

[0032] Add 450 parts of linseed oil fatty acid, 220 parts of soybean oil fatty acid, 300 parts of dehydrated castor oil fatty acid, 140 parts of pentaerythritol into the reaction kettle, start stirring, heat up to 180 ℃ ~ 250 ℃ high temperature dehydration treatment until the acid value is 30mgKOH / g, stop React and lower the temperature to 60°C to obtain an unsaturated resin.

[0033] Take 200 parts of unsaturated resin and 250 parts of p-methylstyrene, put them into the reaction kettle, raise the temperature to 125°C, react at constant temperature, add 3.75 parts of tert-butyl peroxybenzoate dropwise at a constant speed for 3 hours, and then Take 8 parts of dodecafluoroheptyl methacrylate and 3.75 parts of tert-butyl peroxybenzoate, mix evenly, add dropwise to the reaction kettle at a constant speed, dropwise for 3 hours, and then react at a constant temperature to obtain a resin sample; The above resin sample is diluted with low boiling point dearomatized hydrocarbon solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com