Solvent type thixotropic anti-rust oil and preparation method thereof

An anti-rust oil, solvent-based technology, used in the petroleum industry, lubricating compositions, etc., can solve problems such as unfavorable oil film stability, and achieve excellent resistance to salt spray, good thixotropy, and increase the effect of salt spray time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

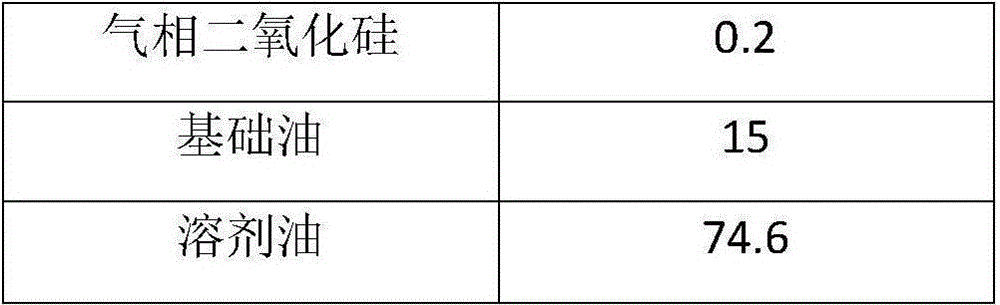

[0037] A solvent type thixotropic antirust oil is prepared from the following table 2 weight percent components:

[0038] The formula of the solvent type thixotropic antirust oil of table 2 embodiment 2

[0039]

[0040]

[0041] Add base oil with a viscosity of 25-30cSt at 40°C into the reaction kettle, and raise the temperature to 80°C. Start stirring at a stirring rate of 100 rpm, add calcium dinonylsulfonate, oxidized paraffin calcium soap, lanolin, and dodecenylsuccinic acid, stir for 20 minutes, and the oil in the reactor is clarified. Then add oil-soluble polyaniline and dioctyl sebacate, stir for 20 minutes, and the oil in the reaction kettle is clarified. Add hydrogenated castor oil and fumed silica, and stir for 10 minutes. Turn off the heating, lower the temperature to 40°C, and add dearomatized solvent oil.

Embodiment 3

[0043] A solvent type thixotropic antirust oil is formulated from the following table 3 weight percent components:

[0044] The formula of solvent-type thixotropic antirust oil of table 3 embodiment 3

[0045] raw material name

[0046] Add base oil with a viscosity of 30-35cSt at 40°C into the reaction kettle and raise the temperature to 80°C. Start stirring at a stirring rate of 100 rpm, add barium dinonylsulfonate, barium paraffin oxide soap, sulfonated lanolin calcium soap, and dodecenylsuccinic acid, stir for 20 minutes, and the oil in the reactor is clarified. Then add oil-soluble polyaniline and dioctyl sebacate, stir for 20 minutes, and the oil in the reaction kettle is clarified. Add modified hydrogenated castor oil and fumed silica, and stir for 10 minutes. Turn off the heating, lower the temperature to 40°C, and add dearomatized solvent oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com