Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Excellent resistance to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

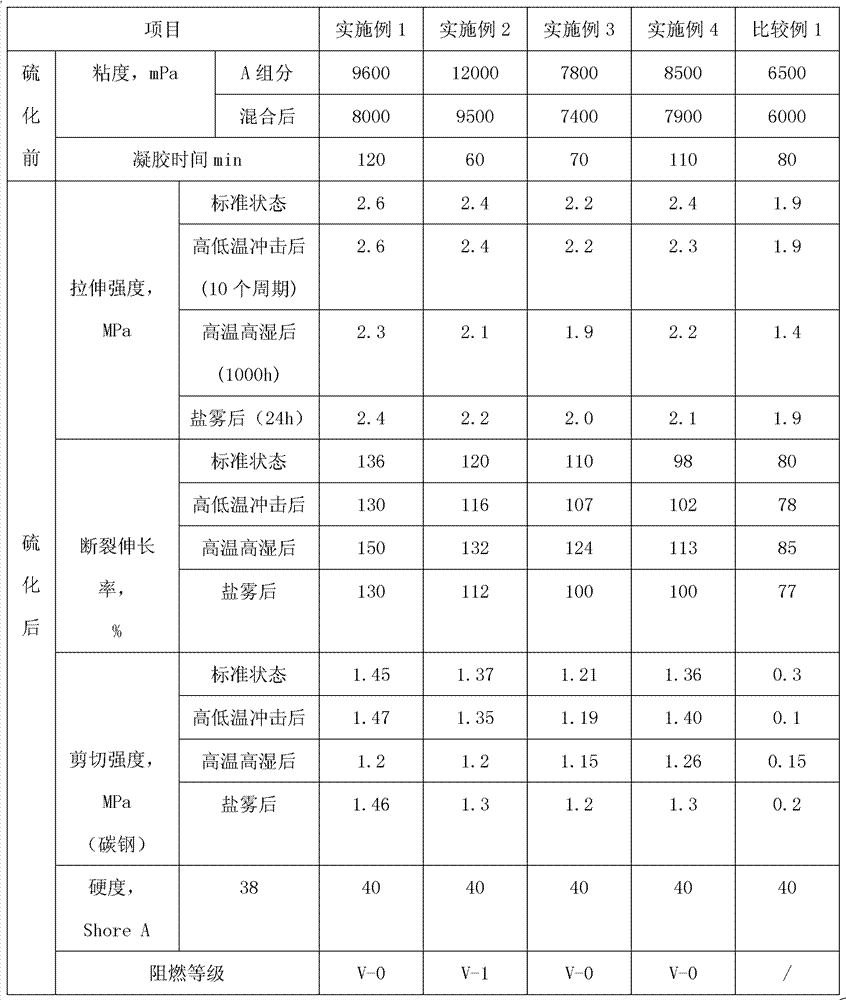

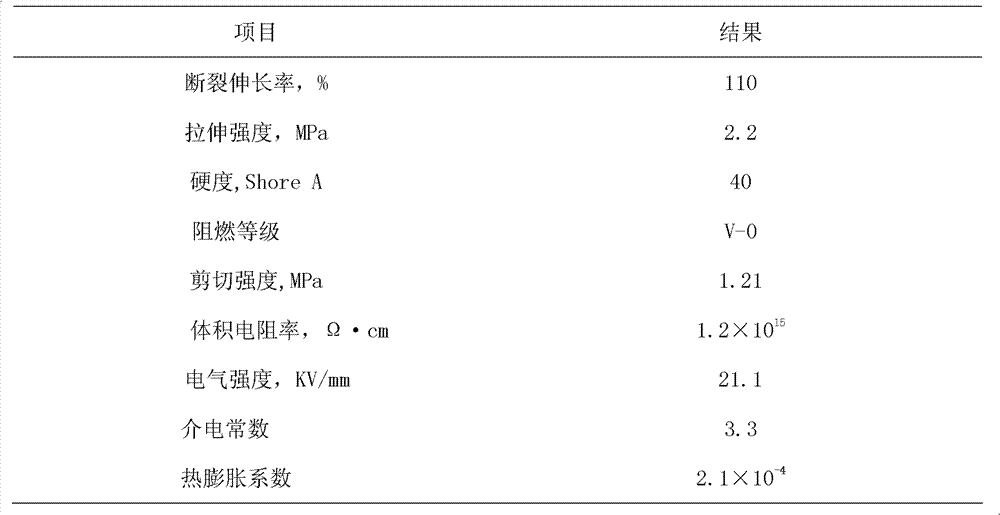

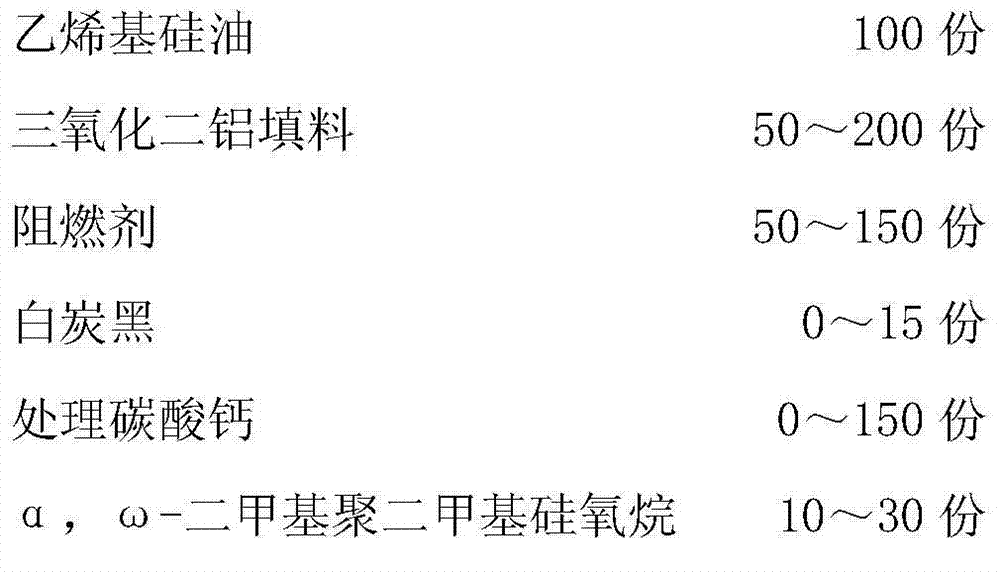

Additive pouring sealant used for wind driven generator and preparation method thereof

ActiveCN102093839AHigh thermal conductivityDissipate quicklyNon-macromolecular adhesive additivesOther chemical processesWind drivenMass ratio

The invention discloses an additive pouring sealant used for a wind driven generator and a preparation method thereof. The preparation method is characterized by comprising the following steps of: dewatering and blending 100 parts by weight of vinyl silicone oil, 50-200 parts by weight of aluminium oxide filler, 50-150 parts by weight of fire retardant, 0-15 parts by weight of white carbon black, 0-150 parts by weight of processed calcium carbonate, 10-30 parts by weight of alpha and omega-dimethyl polydimethylsiloxane for 30-200 minutes at the temperature of 120-170DEG C and the vacuum degree of 0.06-0.99mpa to obtain base stock; at the constant temperature, taking 100 parts by weight of base stock, adding 1-4 parts by weight of hydrogen-containing silicone oil and 0-0.06 part by weight of inhibitor, stirring in a stirrer for 20-30 minutes to obtain sealant A; taking 100 parts by weight of base stock, 1-6 parts by weight of platinum catalyst and 0.6-2 parts by weight of tackifier, and stirring in the stirrer to obtain sealant B; evenly mixing the sealant A and the sealant B at the mass ratio of 5:1; and solidifying the mixture is solidified at the room temperature to obtain the additive pouring sealant used for a wind driven generator, wherein the additive pouring sealant used for a wind driven generator has the advantages of high thermal conductivity coefficient, excellent electrical property, high and low temperature impact resistance, salt mist resistance, good adhesive property at high temperature and high moisture, and the fire resistance of V-1 level.

Owner:CHENGDU GUIBAO SCI & TECH

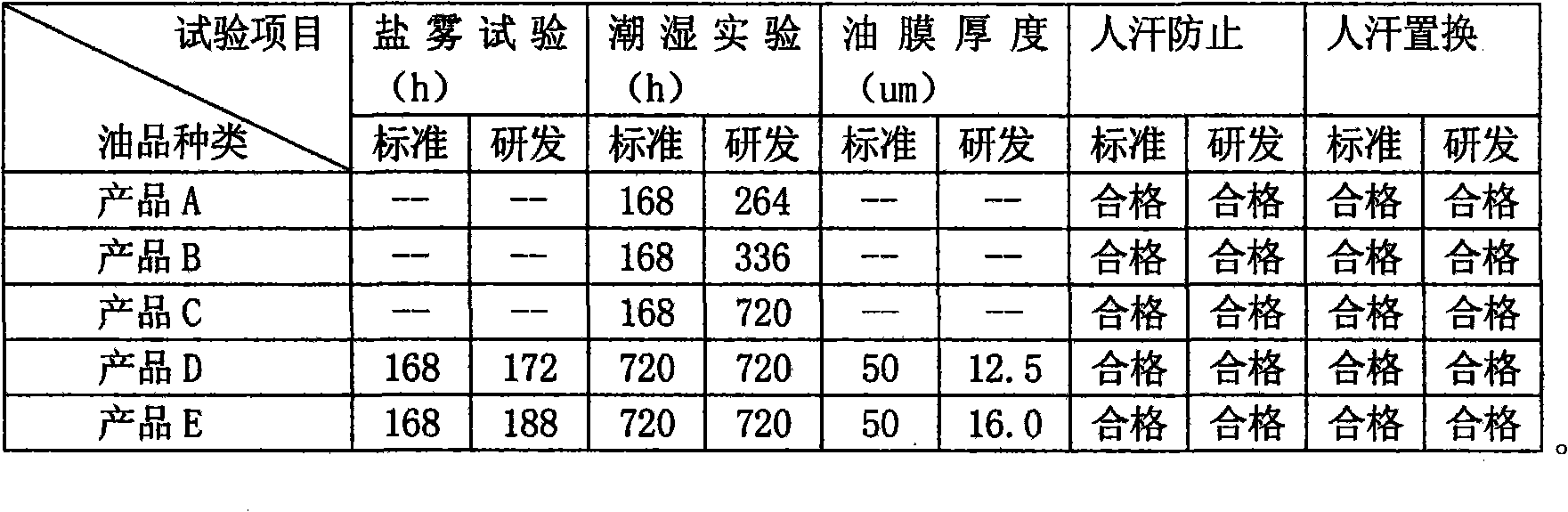

Antirust oil composition used for metal processing and preparation method thereof

ActiveCN101602976AExcellent resistance to salt sprayExcellent rust and corrosion inhibition propertiesAdditivesChemistryPetroleum

The invention relates to an antirust oil composition used for metal processing and a preparation method thereof, solving the problems of poor antirust effect, over thick oil film, difficult removal and the like of the existing antirust oil. The antirust oil composition adopts 15-20% of base oil, 37.5-52% of petroleum sulfonate, 26-35% of high molecular carboxylic acid and soap, 4.5-7% of ester and 0.2-0.5% of benzotriazole and derivative as raw materials and is prepared by heating and stirring. The invention adopts the compounding of various corrosion inhibitors, exerts a complementary and accessorial ultra-effect composite action in the antirust performance, and generates major breakthrough in use performance and the effect, the antirust performance of the invention is far superior to the performance of antirust oil prepared from single agent and completely passes through the test and assessment of an optimizing antirust platform rack, and the invention has excellent moisture resistance and antirust functions, has excellent salt water erosion resistance, water replacement property, acid neutralizing performance and sweat control capability and reaches the quality requirement of a thin multi-effect environment-friendly antirust oil complex additive.

Owner:锦州康泰润滑油添加剂有限公司

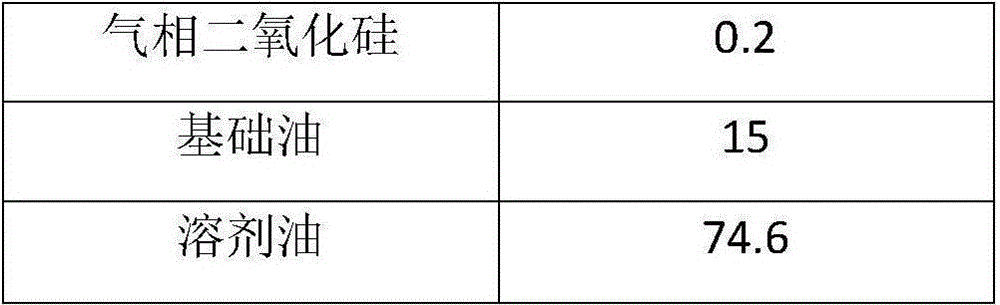

Solvent type thixotropic anti-rust oil and preparation method thereof

InactiveCN106221880ALess overall consumptionImprove thixotropyLubricant compositionFilm-forming agentSolvent

The invention relates to anti-rust oil for steel corrosion protection and a preparation method of anti-rust oil, in particular to solvent type thixotropic anti-rust oil and a preparation method thereof and belongs to the field of metal protection. The solvent type thixotropic anti-rust oil is prepared from components including, by weight, 5-30% of an anti-rust agent, 0.1-5% of a thixotropic agent, 0.1-5% of a film-forming agent, 0.1-3% of a coalescing agent, 5-20% of the base oil and the balance of dearomatization solvent oil. The thixotropic agent is combined with oil-soluble polyaniline, so that good salt fog resistance of the anti-rust oil is achieved, and time for salt fog can reach more than 400 hours.

Owner:NANJING KERUN NEW MATERIAL TECH

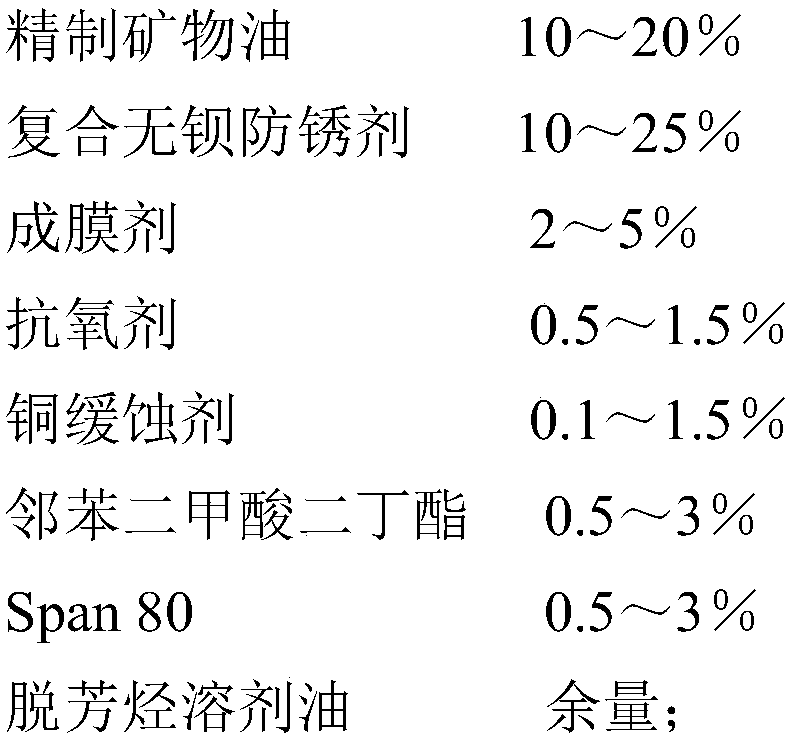

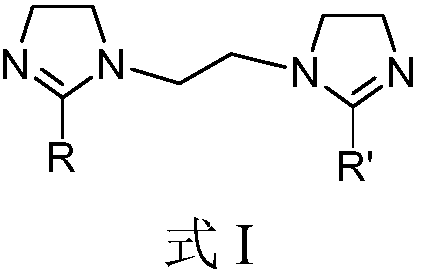

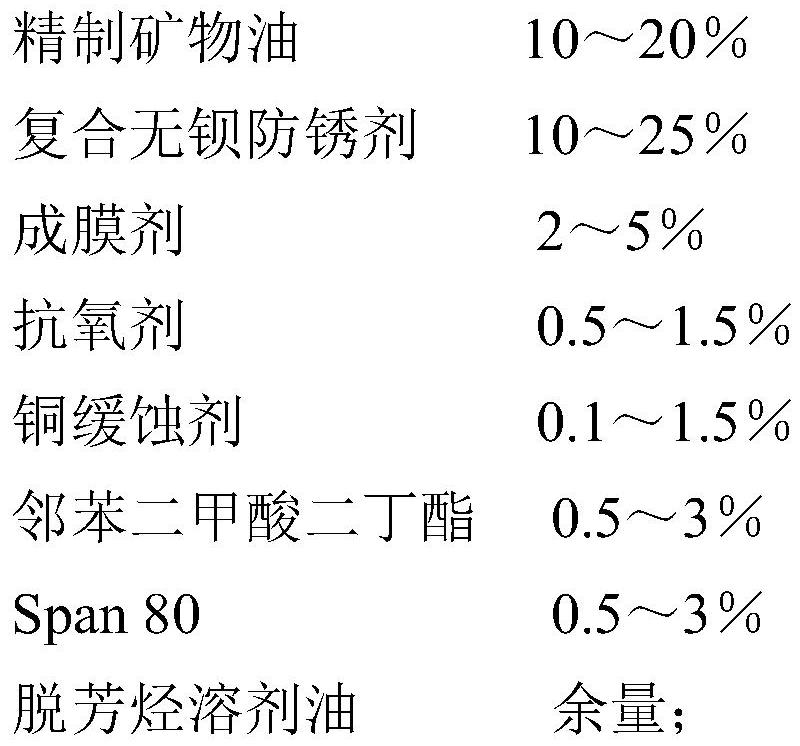

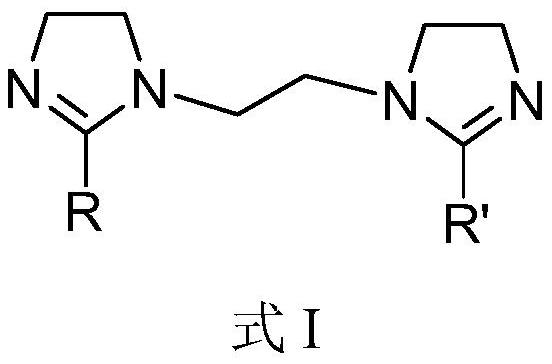

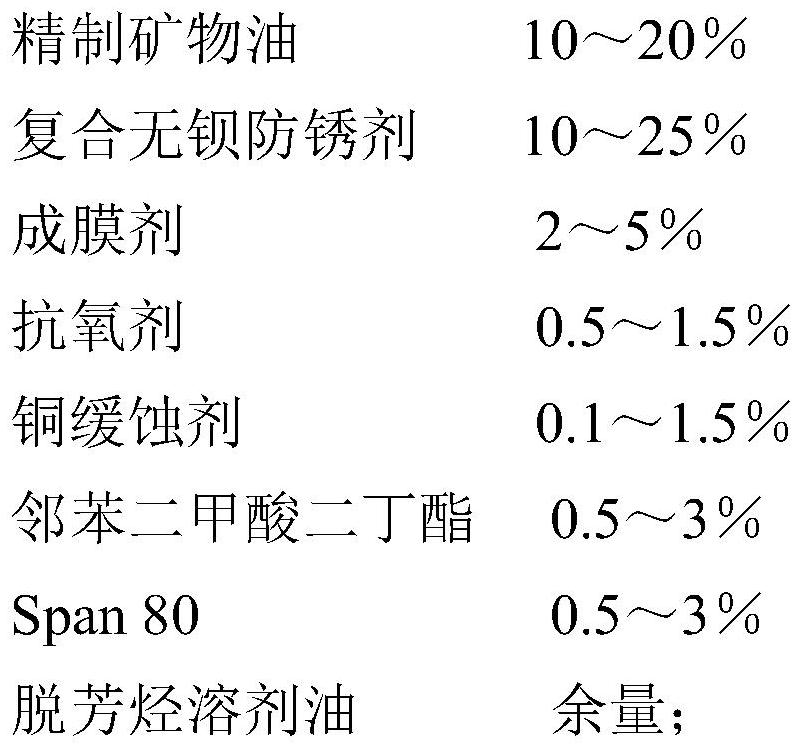

Barium-free soft film antirust oil

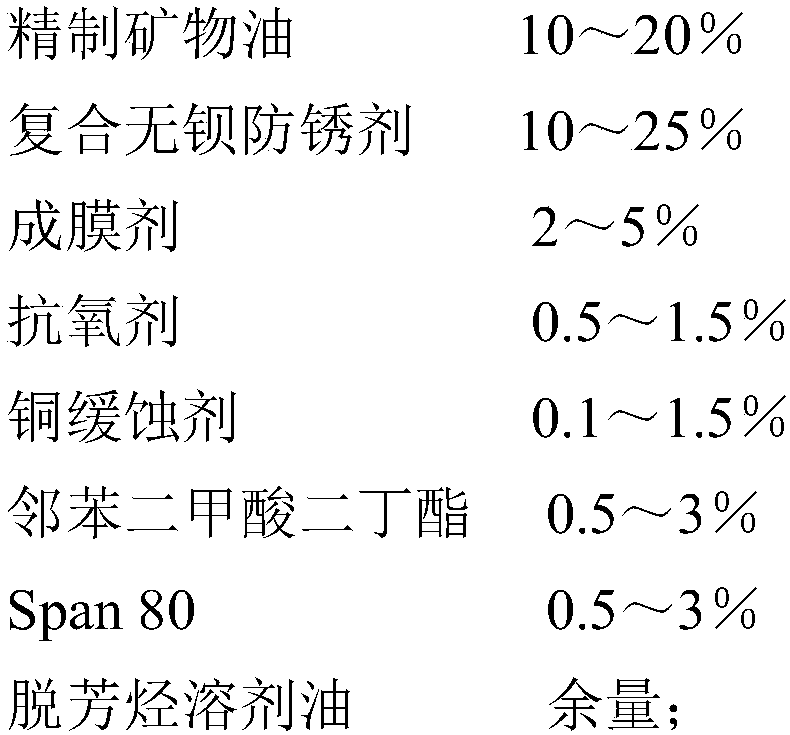

ActiveCN109897718ASatisfy the environmental protection requirement that barium should not be containedLow aromatic contentLubricant compositionAntioxidantSolvent

The invention relates to a barium-free soft film antirust oil. In terms of 100% of the total weight of the barium-free soft film antirust oil, the barium-free soft film antirust oil comprises the following components: 10-20% of refined mineral oil, 10-25% of a compound barium-free antirust agent, 2-5% of a film-forming agent, 0.5-1.5% of an antioxidant, 0.1-1.5% of a copper corrosion inhibitor, 0.5-3% of dibutyl phthalate, 0.5-3% of Span 80, and the balance dearomatization solvent oil. Specifically, the compound barium-free antirust agent comprises petroleum calcium sulfonate, calcium dinonylnaphthalene sulfonate and a gemini imidazoline corrosion inhibitor. The soft film antirust oil provided by the invention has low solvent oil aromatic hydrocarbon content, does not contain barium or other heavy metals, while meeting the environmental protection requirements of foreign environmental protection laws and regulations for exported metal product antirust materials, greatly improves the rust-proof performance of products, is applicable to medium and long-term storage and package rust prevention of ferrous metal products and copper-containing metal workpieces, also has excellent storage stability, is free of precipitate after long-term placement, and the oil film is thin and easy to clean, and can achieve assembly with oil.

Owner:PETROCHINA CO LTD

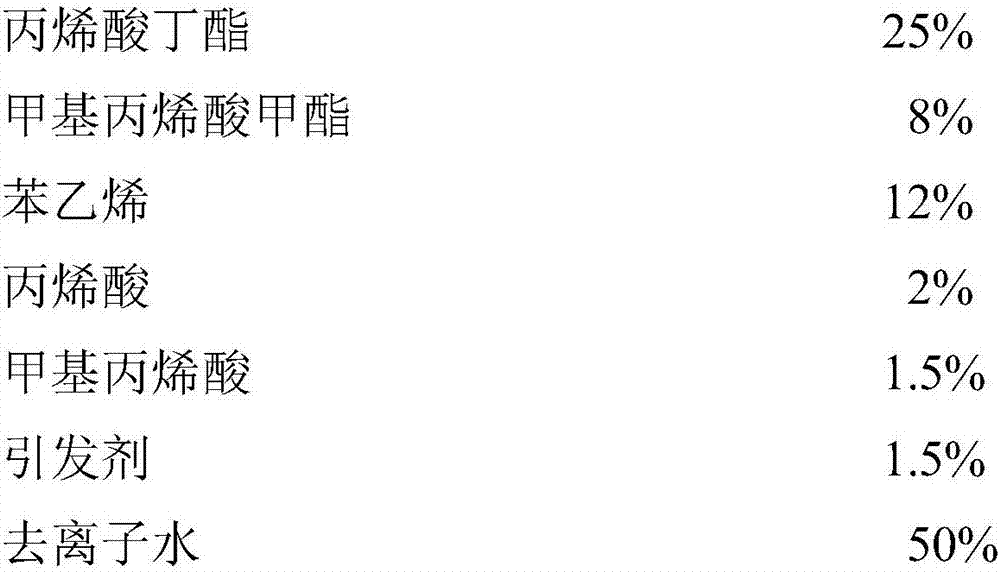

Epoxy organosilicon phosphoester compound modified acrylic resin

InactiveCN101412791AImprove corrosion resistanceIncrease crosslink densityAnti-corrosive paintsMetallic material coating processesEpoxyAcrylic resin

The invention relates to epoxy silicon phosphate ester composite modified acrylic resin, which is characterized in that epoxy groups, phosphate ester groups and siloxane groups are introduced into acrylic resin; and the weight percentage of resin solid is between 40 and 60 percent, and the balance being a solvent. The acrylic resin comprises the following compositions with the percentage content: as calculated by the total weight of the resin solid, acrylate monomers account for 60 to 96 percent; epoxy resin accounts for 2 to 20 percent; silicon monomers account for 1 to 10 percent; phosphate monomers account for 1 to 10 percent; and an initiator is 0.5 to 1.5 percent of the amount of the acrylate monomers. After the resin is prepared into single-component anticorrosive coating, the anticorrosive property of a film coating is superior to that of the prior single-component anticorrosive coating, and the salt water resistance and the salt fog resistance of the film coating are even superior to those of the prior double-component anticorrosive coating. The epoxy silicon phosphate ester composite modified acrylic resin overcomes the defects of trivial use of the prior double-component coating and poor anticorrosive effect of the single-component coating.

Owner:CHINA NAT OFFSHORE OIL CORP +2

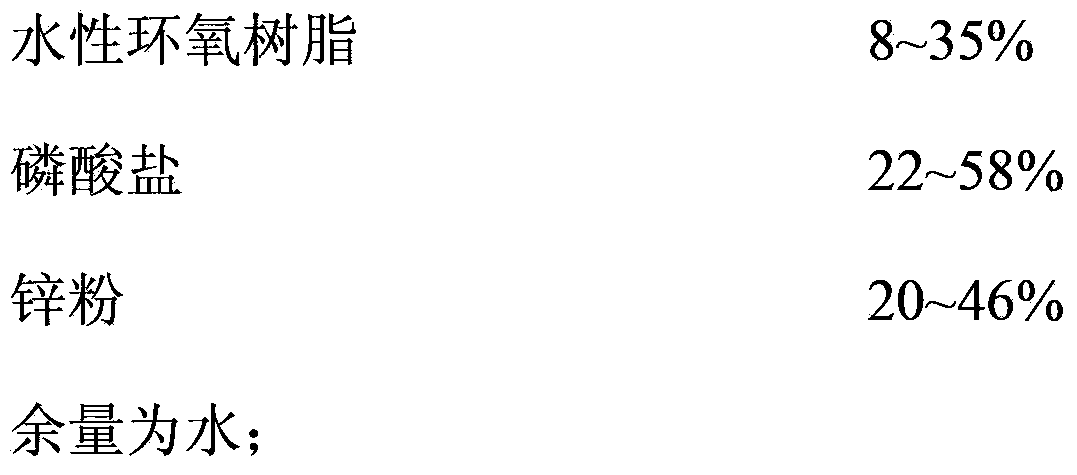

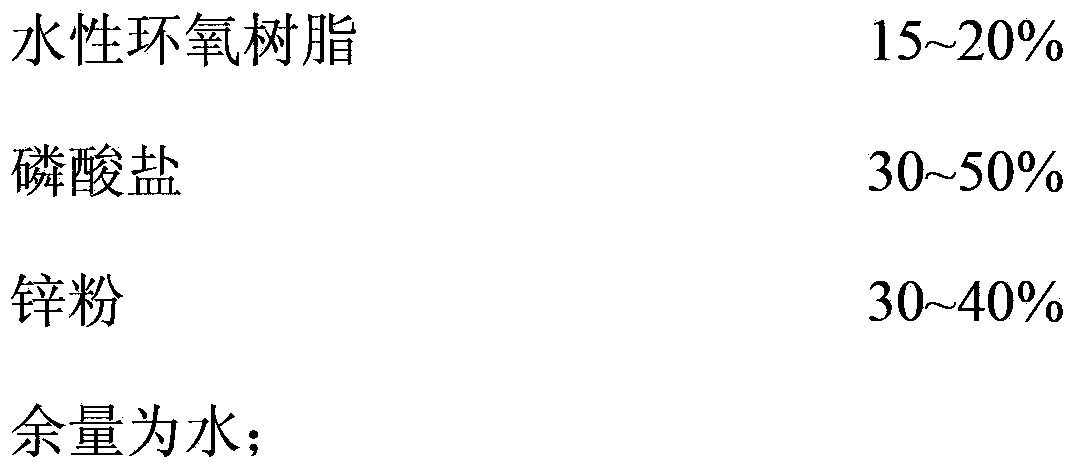

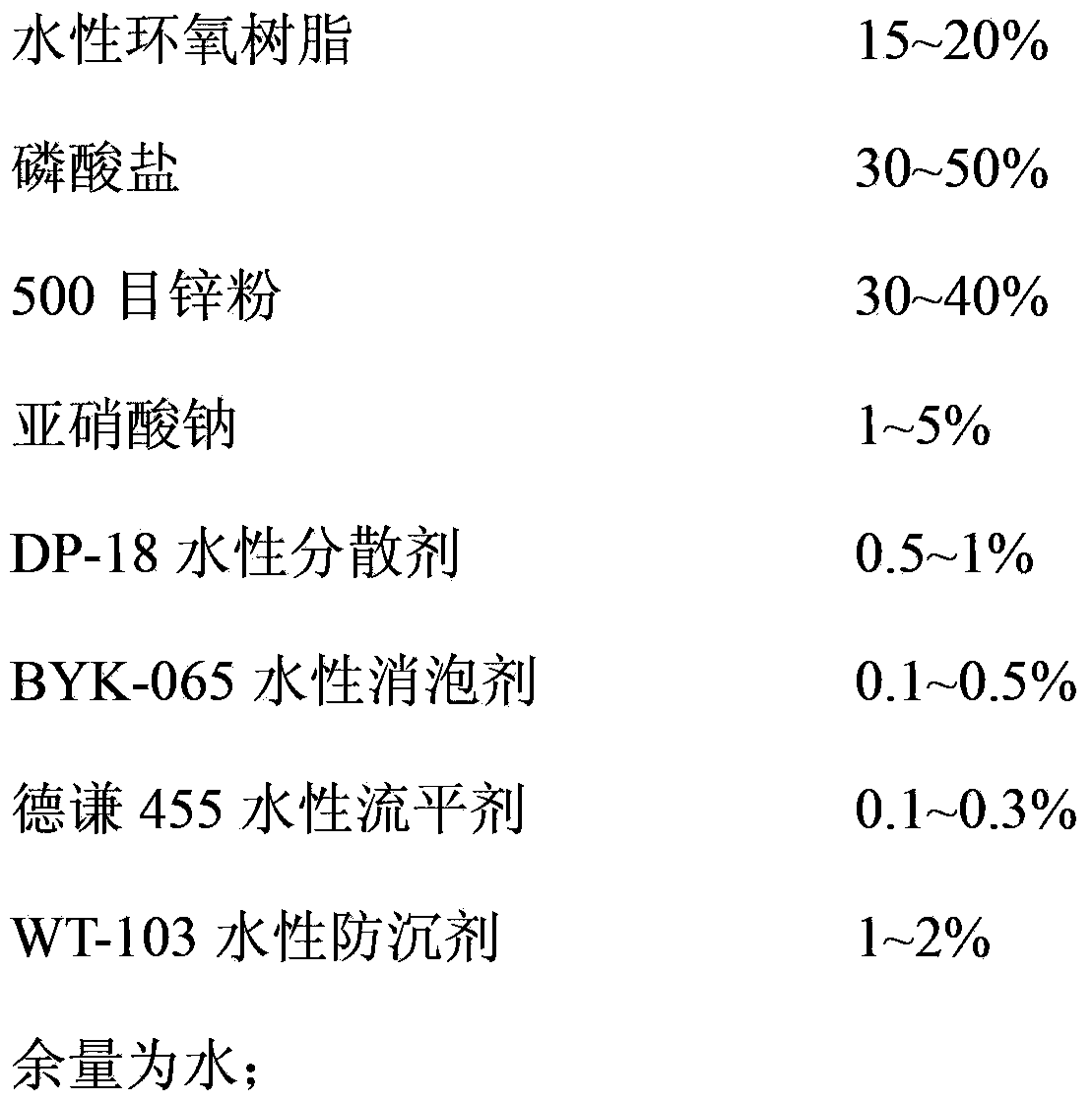

Waterborne epoxy phosphatic zinc dust antirust paint and its preparation method

InactiveCN103360903ALow toxicityImprove permeabilityAnti-corrosive paintsEpoxy resin coatingsChemistryFineness

The invention relates to a waterborne epoxy phosphatic zinc dust antirust paint and its preparation method. The antirust paint is mainly composed of a component A and a component B: 1) the component A comprises the following ingredients: by weight, 8-35% of waterborne epoxy resin, 22-58% of phosphate, 20-46% of zinc dust and the balance water; and 2) the component B is a curing agent. The preparation method comprises the following steps: firstly mixing waterborne epoxy resin, phosphate, zinc dust, sodium nitrite, a dispersant and water according to the formula ratio, dispersing, and carrying out sand milling until the fineness is below 70 microns; adding other auxiliary agents into the obtained mixture and uniformly stirring, adjusting viscosity to 3-5 Pa, filtering and packaging to obtain the component B; and packaging the obtained component A and the component B according to the mass ratio.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

General aseptic base coat and production method thereof

ActiveCN101624495AExcellent resistance to salt sprayExcellent physical and mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsTitanium dioxide

The invention discloses a general aseptic base coat and a production method thereof and aims at providing an aseptic base coat which has strong popularity, can be widely used for a plurality of base materials, such as aluminum, steel, titanium, stainless steel, other alloy materials, and the like, is convenient to use and ensures that a solidified coat film formed by the general aseptic base coat has favorable mechanical performance and excellent protection performance. The aseptic base coat is formed by the combination of an A component and a B component according to the weight parts of 100:(20-25), wherein the B component comprises a polyamide resin curing agent and a polyamide resin thinning agent, and the solid content of the B component is 40 percent; and the A component comprises the following components based on parts by weight: 40-50 epoxy resin, 20-30 aseptic pigment, 15-20 titanium dioxide, 0.1-0.3 carbon block pigment, 0.3-1 dispersing agent, 0.2-0.5 flatting agent, 0.2-0.5 defoaming agent and 35-40 thinning agent. The aseptic base coat can be used on different materials, is convenient to use and easy to manage.

Owner:天津灯塔涂料工业发展有限公司

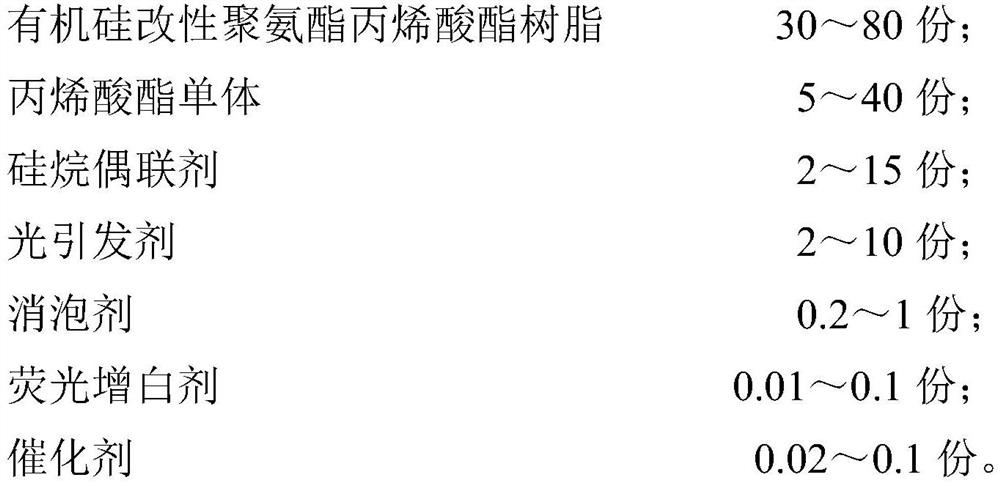

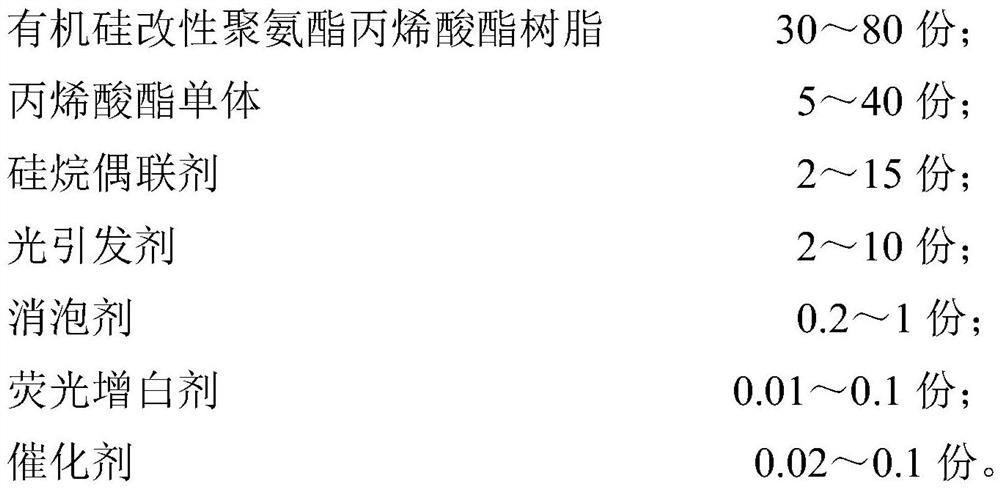

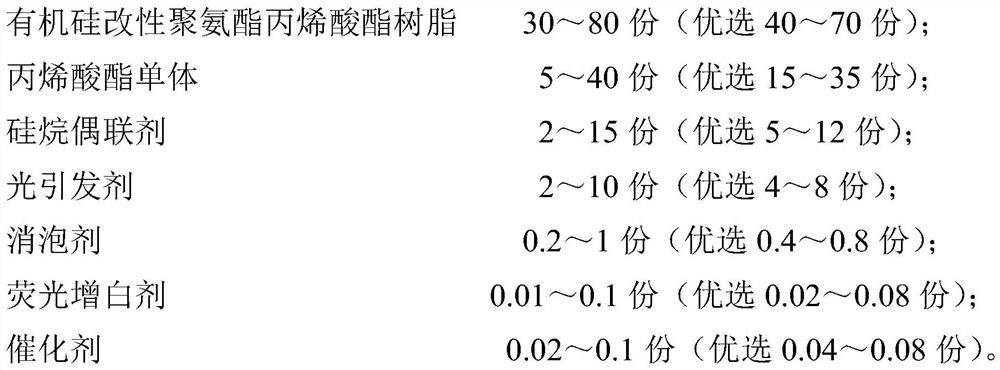

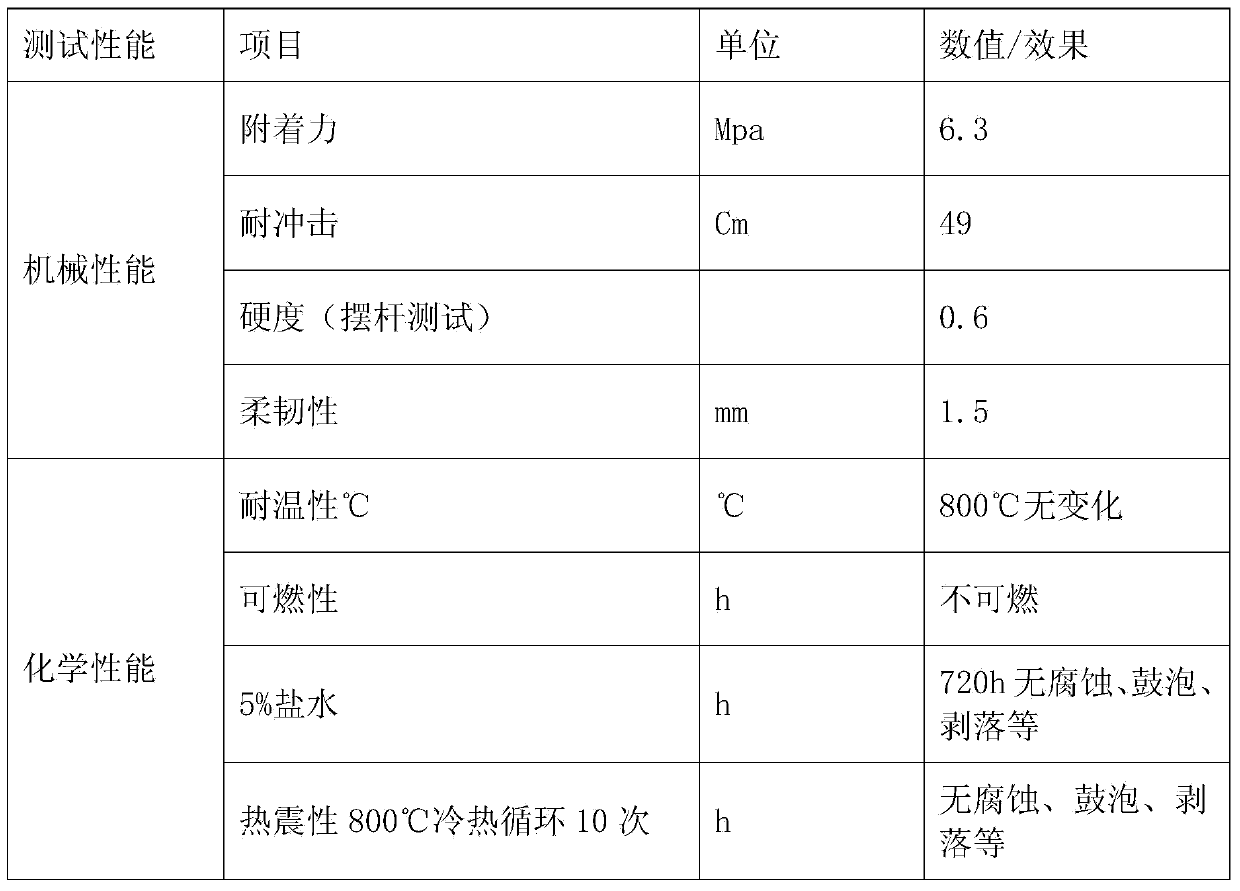

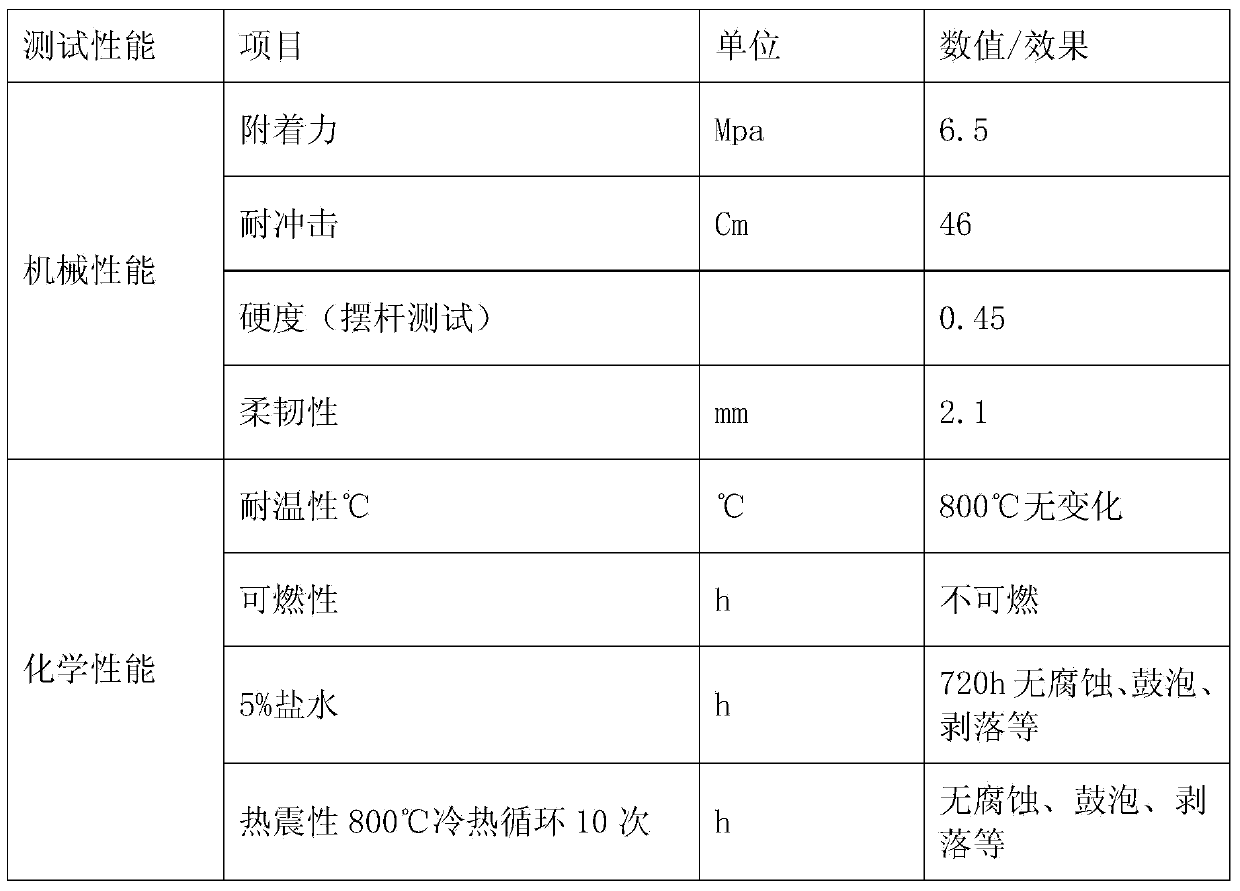

Organic silicon modified polyurethane acrylate ultraviolet light and moisture dual-curing conformal coating and preparation method thereof

PendingCN114231162AMeet environmental protection requirementsFast curingFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an organic silicon modified polyurethane acrylate ultraviolet light and moisture dual-curing conformal coating and a preparation method thereof, and belongs to the field of conformal coatings. The conformal coating is prepared from the following components in parts by mass: 30 to 80 parts of organic silicon modified polyurethane acrylate resin, 10 to 40 parts of acrylate monomer, 2 to 15 parts of silane coupling agent, 2 to 10 parts of photoinitiator, 0.2 to 1 part of defoaming agent, 0.01 to 0.1 part of fluorescent whitening agent and 0.02 to 0.1 part of catalyst. The materials are physically stirred to prepare the ultraviolet light and moisture dual-curing conformal coating, and the ultraviolet light and moisture dual-curing conformal coating can be rapidly photocured to reach a surface dry state under the ultraviolet light irradiation of a middle-high pressure mercury lamp, so that the production efficiency is improved; and a paint film has the characteristics of high and low temperature impact resistance, good flame retardance and excellent electrical insulating property of organic silicon and high mechanical strength, excellent protection performance and the like of polyurethane.

Owner:广东腐蚀科学与技术创新研究院

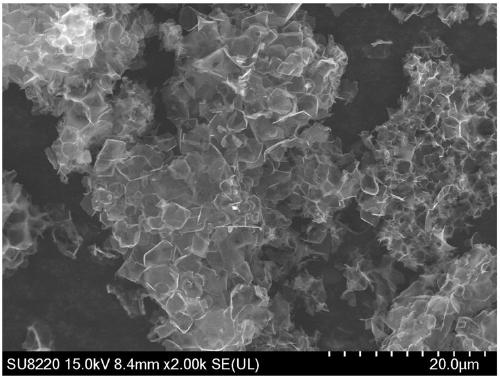

Anticorrosion coating of stereoscopic-structure graphene-reinforced epoxy resin

InactiveCN109486342ASimple processGood physical and mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsEpoxyIron oxide

The invention discloses a preparation method of an anticorrosion coating of stereoscopic-structure graphene-reinforced epoxy resin. The preparation method comprises the steps of (1) weighing the components of epoxy resin, diluent I and graphene powder by mass percent, mixing, and dispersing to obtain graphene epoxy resin liquid; (2) adding a filler, aids and diluent I to obtain graphene epoxy resin color paste; (3) adding mica iron oxide, and mixing to obtain graphene-reinforced epoxy resin anticorrosion coating component A; (4) mixing a curing agent and diluent II, and dispersing to obtain graphene-reinforced epoxy resin anticorrosion coating component B; (5) mixing the graphene-reinforced epoxy resin anticorrosion coating components A and B to obtain the anticorrosion coating of stereoscopic-structure graphene-reinforced epoxy resin. The process of the anticorrosion coating is simple; large-scale production of graphene-based coatings can be achieved; the prepared coating with stereoscopic-structure graphene has good physical properties and evident salt spray resistance.

Owner:GUANGXI UNIV

Environmental-friendly long-acting sealing anti-rust oil composition and preparation method thereof

ActiveCN104450013AExcellent resistance to salt sprayExcellent water separation performanceLubricant compositionSolventChemistry

The invention discloses an environmental-friendly long-acting sealing anti-rust oil composition. The environmental-friendly long-acting sealing anti-rust oil composition is characterized in that the environmental-friendly long-acting sealing anti-rust oil composition is prepared from the following components in percentage by weight: 2-8 percent of petroleum calcium sulfonate, 0-8 percent of oxidized paraffin calcium soap, 1-2 percent of a film-forming agent, 3-10 percent of an anti-rust complexing agent, 15-30 percent of machinery oil and 58-77 percent of solvent oil. According to the anti-rust oil disclosed by the invention, the salt mist resistance, the moist resistance and the water separation property are excellent; metal barium and other heavy metals are not contained, so that the anti-rust oil is safe to use; the penetrating performance and the wettability are good; as the anti-pollution capacity is strong, and an oil film is formed by coating the anti-rust oil on the surface of a workpiece is thin, the anti-rust oil is small in oil consumption in the using process of a metal workpiece, the oil film is good in thixotropy and coating property, easy in film removal and wide in adaptation range of steel materials, and the anti-rust oil is suitable for long-time sealing and rust prevention of metal products made of steels in multiple textures and the like.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Elastic anticorrosive paint and preparation method thereof

InactiveCN104212343AAnti-agingRadiation resistantAnti-corrosive paintsEpoxy resin coatingsAging resistanceDiluent

The invention discloses elastic anticorrosive paint which is prepared from the following components in percentage by weight: 6-12% of a flexibilizer, 30-45% of polysiloxane, 25-55% of packing, 5-8% of a crosslinking agent, 10-18% of a diluent, 5-10% of an auxiliary, 1-5% of sodium pyrophosphate, 1-3% of sodium tripolyphosphate and 2-4% of polyacrylate resin. The invention further discloses a preparation method of the elastic anticorrosive paint. A product disclosed by the invention is strong in adhesive force and the binding force of a coating and a matrix is strong; and the paint is efficient and convenient and simple to construct, and the inorganic paint is self-cured at normal temperature, so that the high-efficiency construction can be ensured and the paint has excellent salt mist resistance and aging resistance. The coating is self-repaired and local scratch caused by external forces still can be protected. The coating is free from cutting and welding damages and the welding quality is not affected with the coating.

Owner:JIANGSU MARINE VICTORY COATING

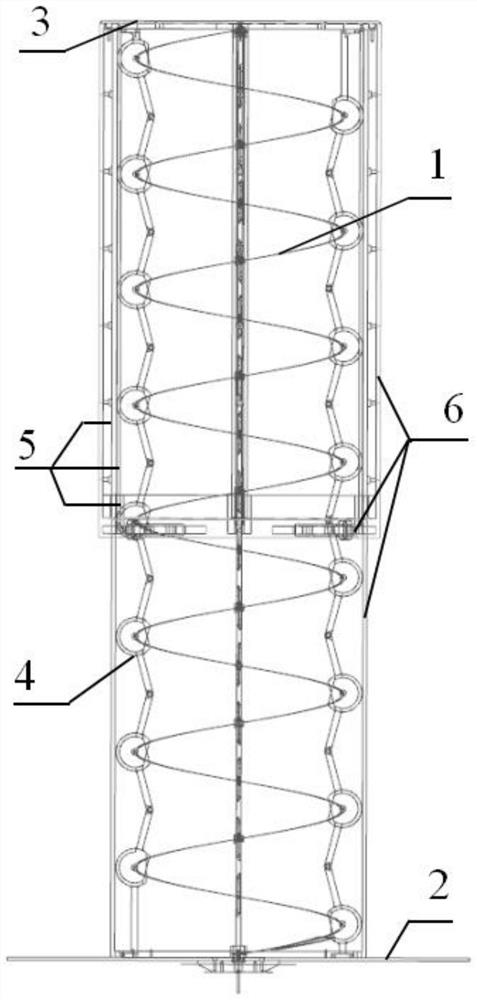

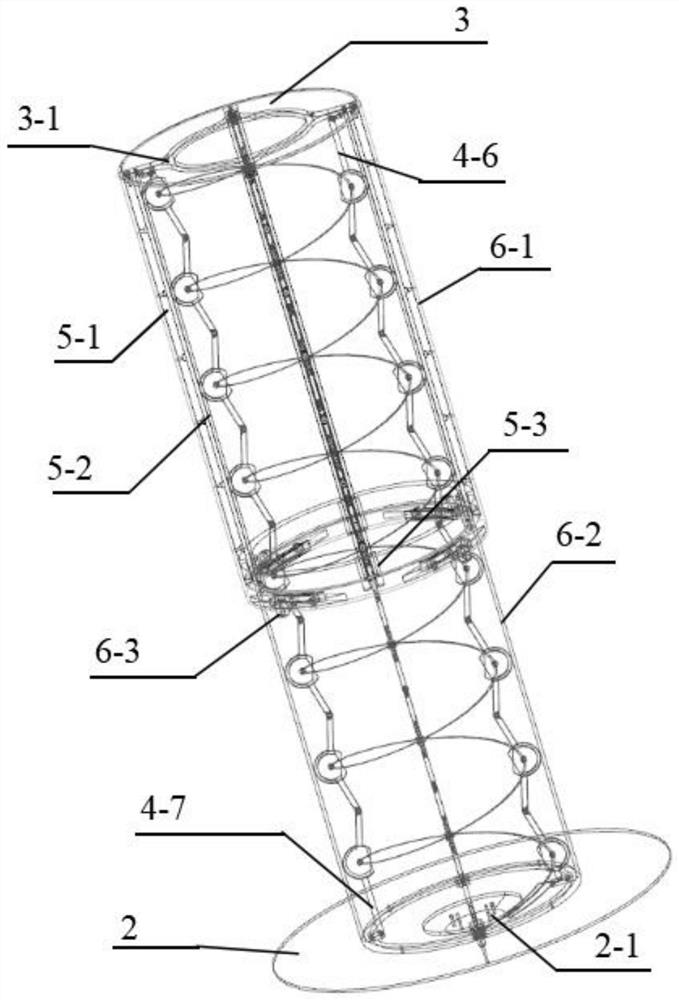

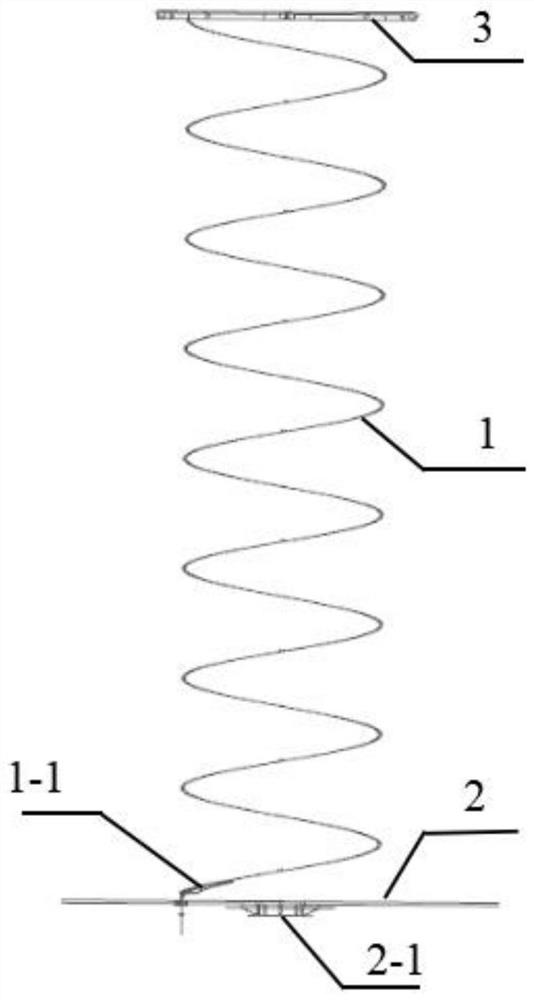

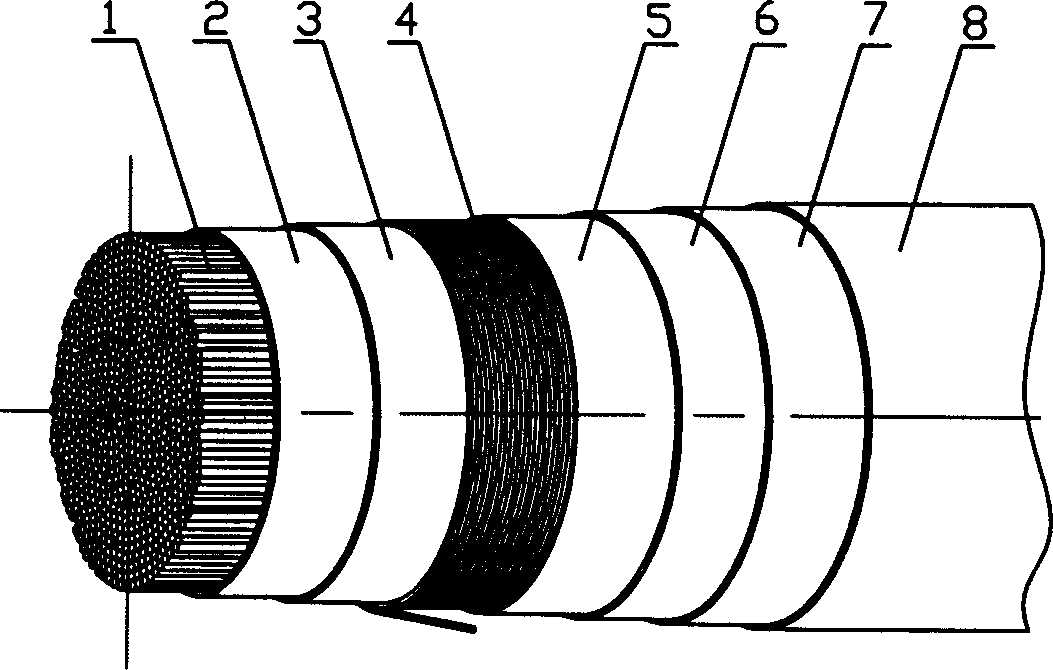

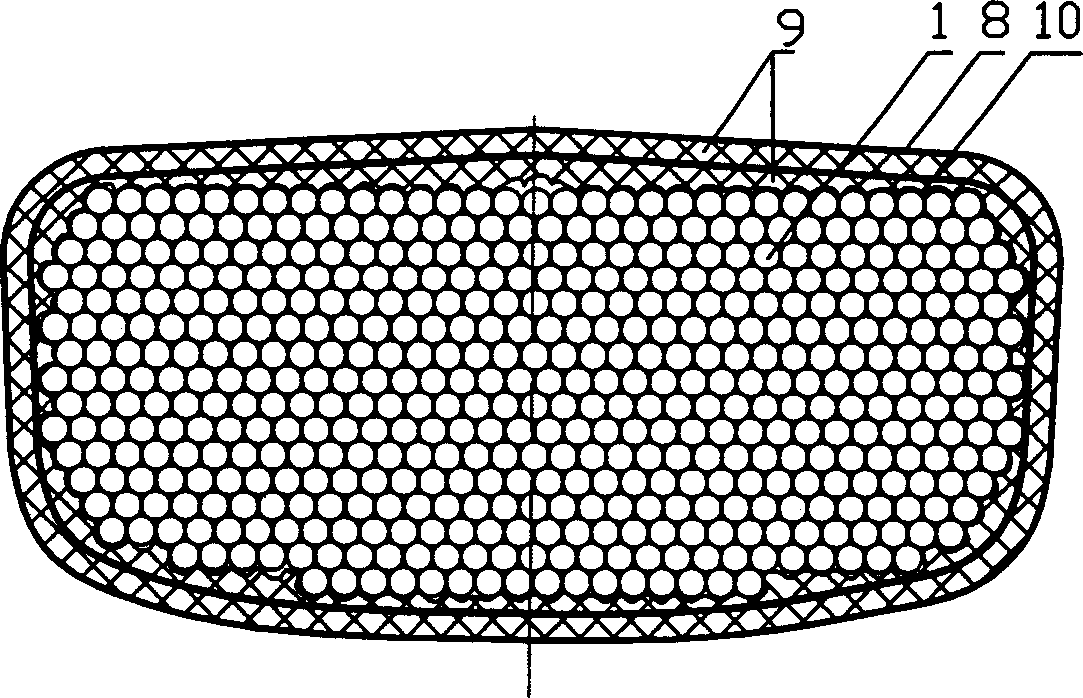

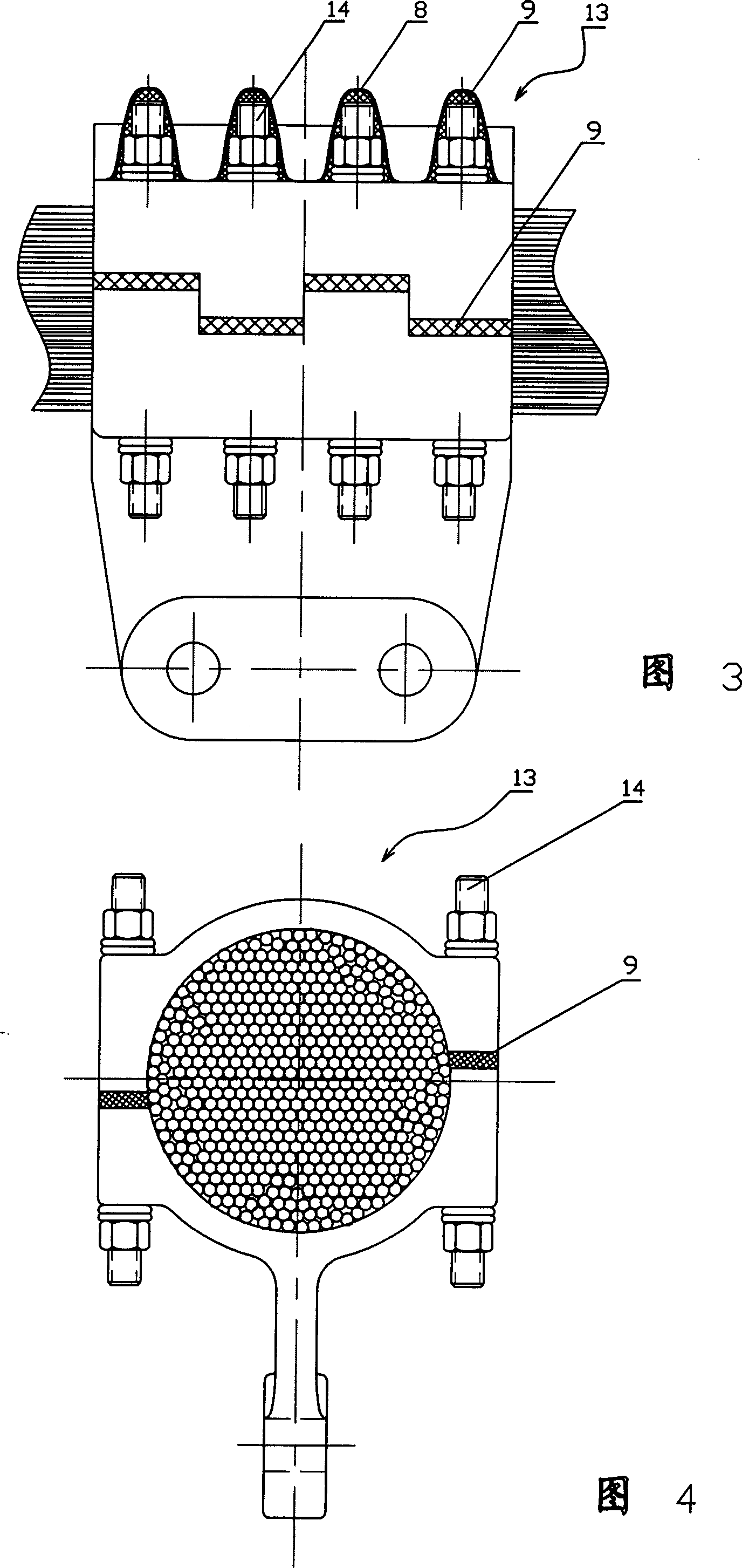

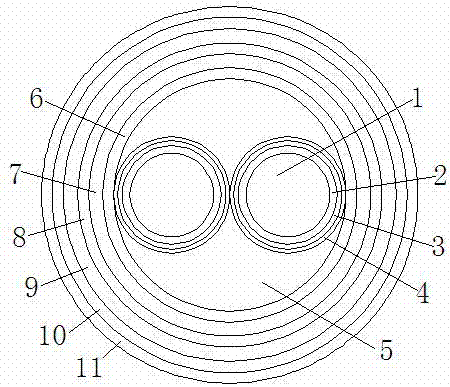

Deployable helical antenna, communication system, radar and electronic countermeasure system

ActiveCN112018487AGuaranteed StrengthGuaranteed stabilityWave based measurement systemsAntenna supports/mountingsCommunications systemStructural engineering

The invention belongs to the technical field of antennas, and discloses a deployable helical antenna, a communication system, a radar and an electronic countermeasure system. The antenna comprises a helical line radiator, a bottom plate, a top cover, a plurality of deployable support devices, a plurality of deployable slide rail devices and an antenna housing. The unfolding supporting devices aredistributed between spiral line radiation arms in the axial direction and slide in a telescopic mode in the axial direction of a sliding rail device to achieve unfolding and folding of the spiral lineradiation arms, and it is synchronously guaranteed that the spiral diameter of the antenna is stable in the unfolding process. An upper radome and a lower radome are unfolded and folded through the synergistic effect of supporting rods, positioning blocks and the sliding rail. According to the invention, unfolding and folding of the large-size three-dimensional helical antenna are realized, so that the large-size three-dimensional helical antenna is convenient to carry and high in assembly repeatability; and the strength and stability of the helical antenna are guaranteed, the leakproofness is good, the helical antenna can be applied to a severe environment, when the helical antenna is in an unfolded state, the high-gain and narrow-beam requirements are met, and when the helical antenna is in a folded state, the low-gain and wide-beam requirements are met.

Owner:XIDIAN UNIV

A kind of salt spray resistant metal antirust paint and preparation method thereof

ActiveCN106009958BGood resistance to salt sprayExcellent resistance to salt sprayAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinSilanes

The invention discloses a salt-spray-resistant anti-rust metal coating and a preparation method thereof. The coating is prepared from raw materials in parts by weight as follows: 20-30 parts of sodium silicate, 5-15 parts of potassium silicate, 10-20 parts of nano silica powder, 6-8 parts of chlorinated paraffin, 15-25 parts of waterborne styrene acrylic resin, 5-15 parts of waterborne polyurethane resin, 15-25 parts of a silane coupling agent, namely, methyl-tri-butanone-oxime silane, 8-12 parts of ethylene glycol, 4-6 parts of isopropyl myristate, 1-3 parts of citric acid, 60-70 parts of water and 7-9 parts of isothiazolone and benzyl glycidyl ether in total, wherein the weight part ratio of isothiazolone to benzyl glycidyl ether is (6-8):1. The anti-rust metal coating has the excellent salt-spray resistance which is related to the weight part ratio of isothiazolone to benzyl glycidyl ether in the raw materials, and the salt-spray resistance is most outstanding when the weight part ratio of isothiazolone to benzyl glycidyl ether is (6-8):1.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

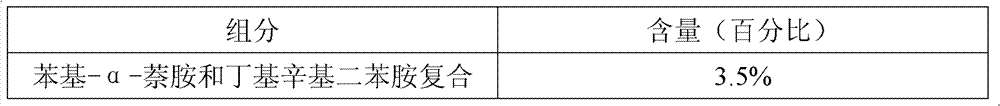

Lubricating-oil composition of speed reducing machine in gas turbine for ship

The invention discloses a lubricating-oil composition of a speed reducing machine in a gas turbine for ship. The lubricating-oil composition comprises the following components in percent by mass: 2-4% of antioxidant, 5-6% of antiwear agent, 0.1-0.4% of antirusting agent, 0.06-0.08% of metal passivating agent, 0.05-0.3% of demulsifying agent, 0.005-0.01% of anti-foaming agent, 1-2% of oiliness agent and the balance of base oil. The lubricating-oil composition has the obvious advantages that the comprehensive performance is good, and all performance indexes meet the use requirements; not only are the antioxygen, anticorrosion and antiwear performances good, but also the antirusting, anti-salt-fog and antifoaming performances are quite excellent; the lubricating-oil composition also meet the use requirements of the gas turbine for ship in the aspects of acid control capability, clean dispersity and rubber adaptability; and the base oil is compounded and synthesized by selecting diester and polyol ester which have excellent performance, so that the base oil assuredly has good heat stability, good viscosity-temperature characteristic, excellent low-temperature mobility, low volatility and good lubricity simultaneously.

Owner:GUANGXI UNIV

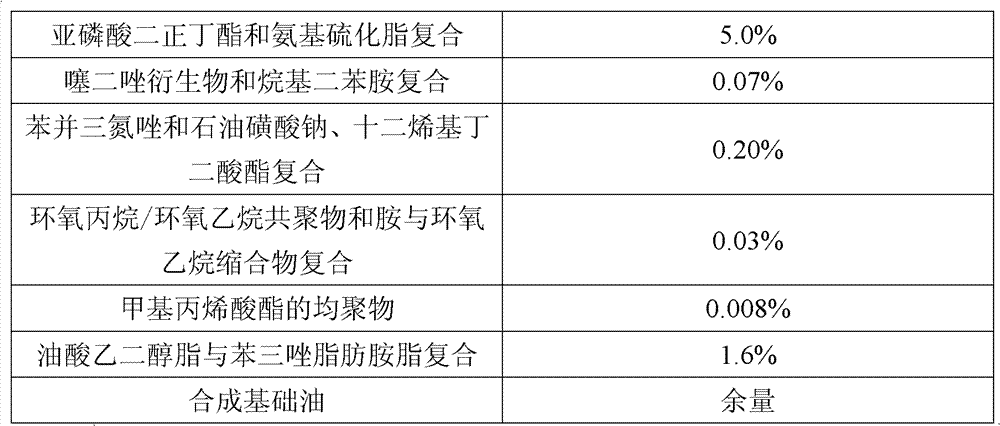

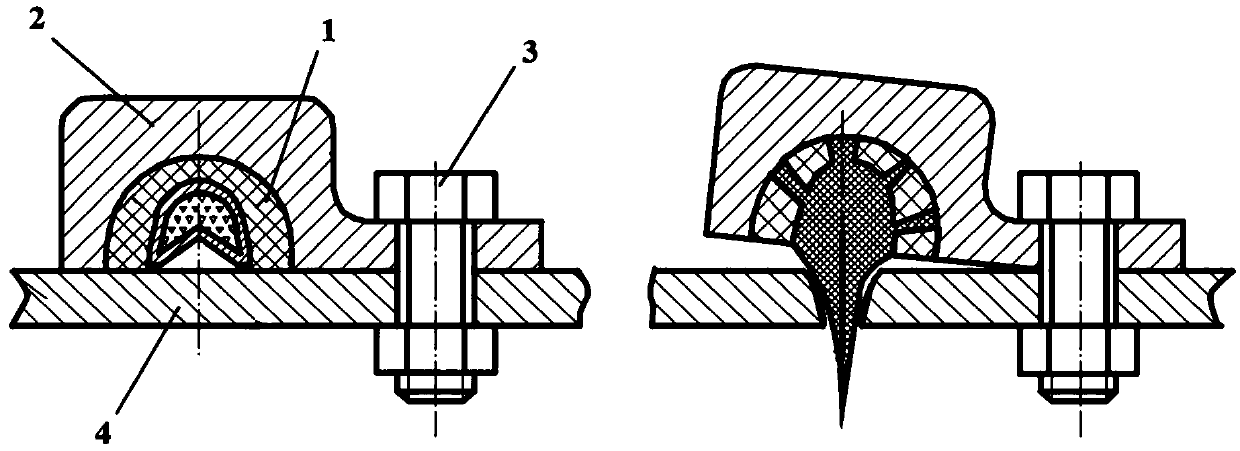

Method for protecting thin-wall energy gathering cutting ropes by using Parylene micro-nano films

InactiveCN110965045ALow deposition temperatureFilm composition is easy to controlChemical vapor deposition coatingMicro nanoDetonator

The invention discloses a method for protecting thin-wall energy gathering cutting ropes by using Parylene micro-nano films. A chemical vapor deposition method is adopted to coat Parylene films with micro-nano-scale thicknesses on the outer surfaces of the thin-wall energy gathering cutting ropes for damp prevention, salt mist prevention and mould prevention of the thin-wall energy gathering cutting ropes to enable the protecting performance to meet environmental test requirements stated by the GJB344-87 general design specification for insensitive electric detonators. After experimental tests, the thin-wall lead pipe energy gathering cutting ropes still achieve high reliability, and can be applied to interstage separation of multistage propulsion rockets, window casting and slitting of mother-son bullet shells.

Owner:NANJING UNIV OF SCI & TECH

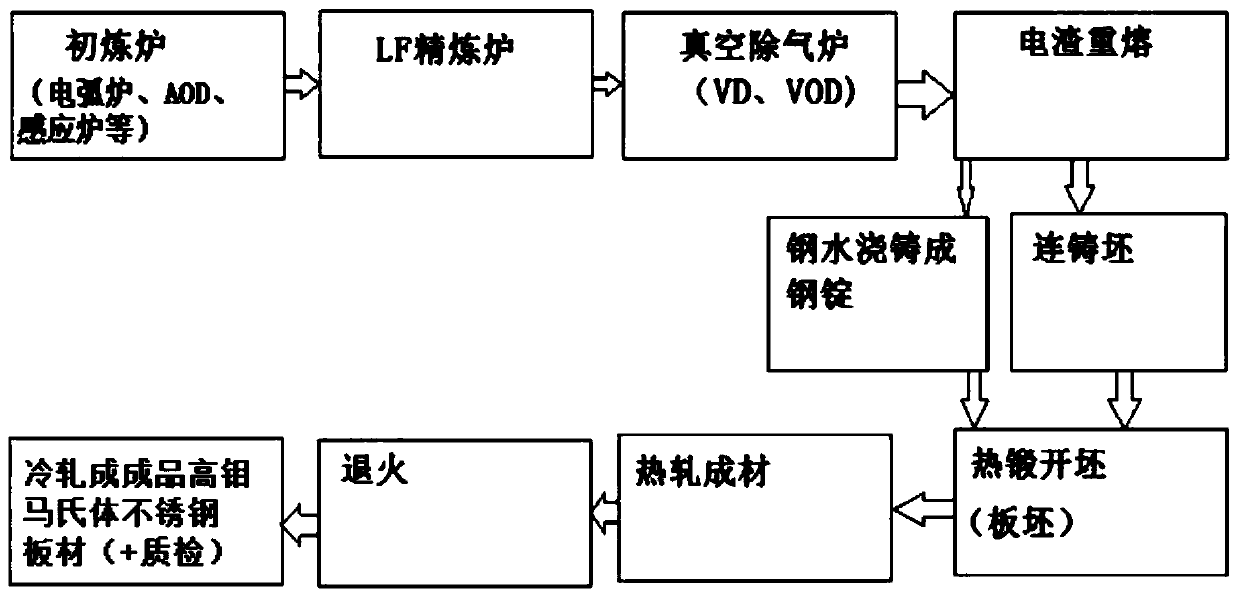

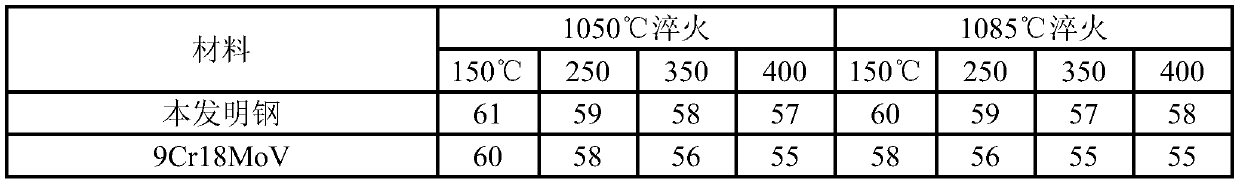

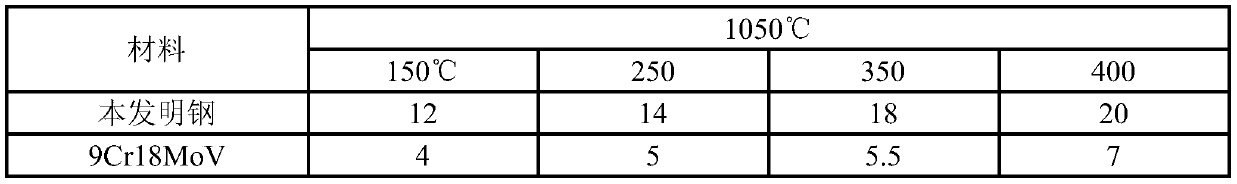

Tool high molybdenum martensitic stainless steel with toughness and corrosion resistance superior to toughness and corrosion resistance of 9Cr18MoV and method

The invention discloses a tool high molybdenum martensitic stainless steel with the toughness and corrosion resistance superior to toughness and corrosion resistance of 9Cr18MoV and a method. The highmolybdenum means that the molybdenum content of the steel is increased by at least 90% compared with that of 9Cr18MoV tool steel. According to the steel and the method, the toughness of the steel isimproved by at least 70% compared with that of the 9Cr18MoV tool steel, the corrosion resistance of the steel is improved by at least 14 times compared with that of the 9Cr18MoV tool steel, and the steel is high-end cutter steel, and is suitable for high-end kitchen knives, outdoor knives and the like.

Owner:上大新材料(泰州)研究院有限公司

Water-based paint for various substrates and preparation method thereof

InactiveCN112457760AFast film formationImprove performanceFireproof paintsAntifouling/underwater paintsPolymer scienceAcrylic resin

The invention relates to a water-based paint for multiple substrates and a preparation method thereof. The water-based paint comprises the following components in parts by mass: 30-50 parts of water-based organic silicon modified polyurethane resin, 10-20 parts of acrylic resin, 15-20 parts of titanium dioxide, 1-3 parts of a titanate coupling agent, 1-3 parts of graphene, 3-5 parts of a cosolvent, 0.1-0.5 part of a wetting agent, 0.5-1 part of a dispersing agent, 0.8-1.5 parts of a rheological agent, 0.5-1 part of a waterborne crosslinker and 20-60 parts of water. The water-based paint is suitable for various base materials, can also be used for rust-proof coating of rusty base materials, and can avoid the rusting problem caused by incomplete substrate treatment.

Owner:鲁嘉涂料(福建)有限公司

Method and structure for protecting primary cable system of suspension bridge

InactiveCN1110606CEffective protectionGood sealing and anti-corrosion performanceBridge structural detailsSuperimposed coating processStrip steelHigh intensity

A protecting structure for the main cable of suspension bridge is composed of main cable made up of multistrand high-strength zinc-plated steel wire bundles, multiple cable clampers fixed to the main cable and multiple suspension cables fixed to the cable clampers. After the external surface of main cable is anticorrosively treated, a layer of steel wire or strip steel is wound arount it and the external surface of wound layer is treated for protection. Said anticorrosion treatment of main cable is to coat unsulfurized non-drying sealing rubber paste on it. Said protective layer of main cable has same service life as the primary cable.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

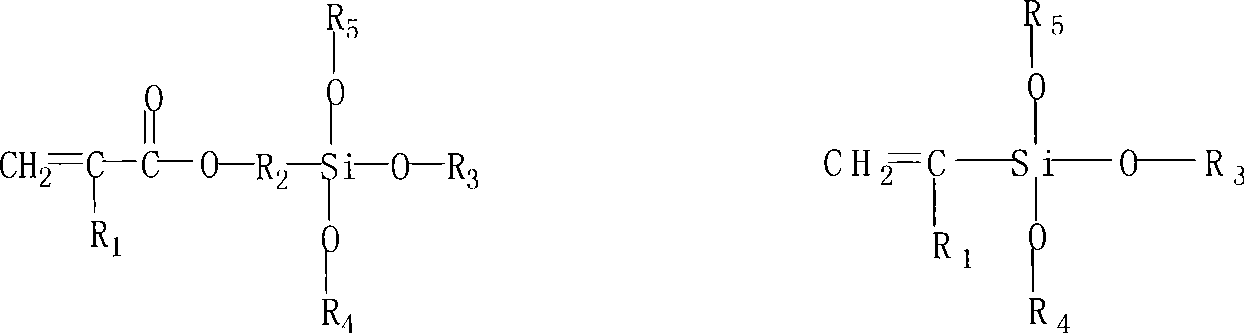

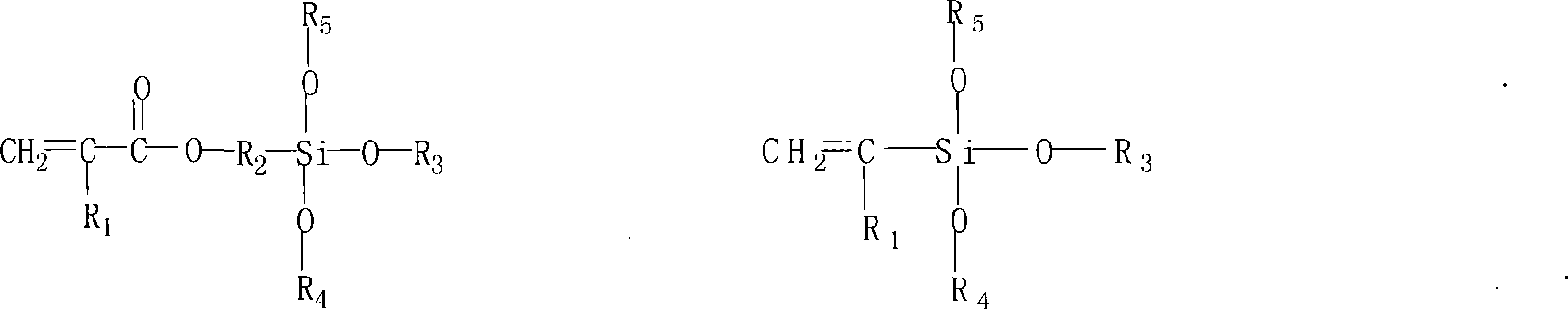

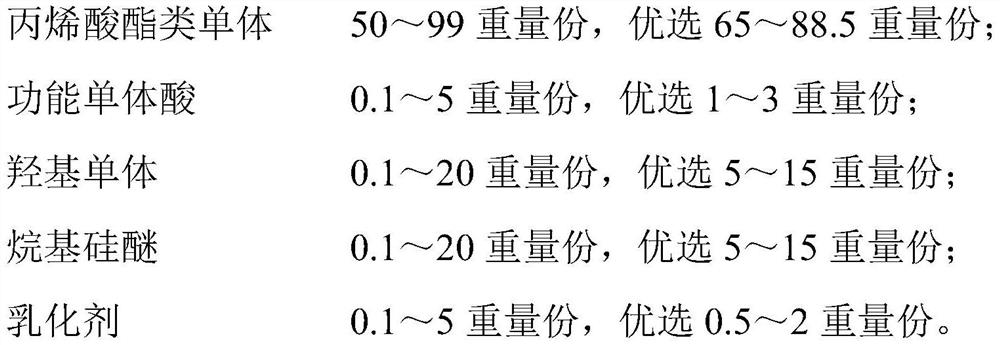

Alkyl silyl ether modified hydroxyl acrylic emulsion and preparation method thereof and application thereof

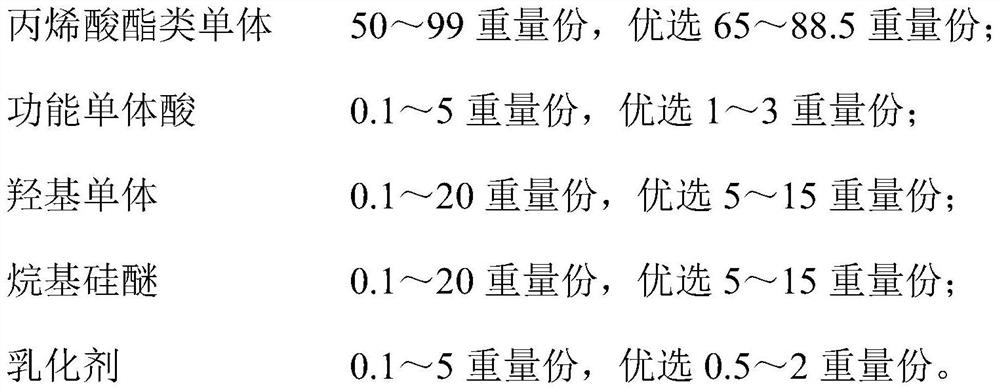

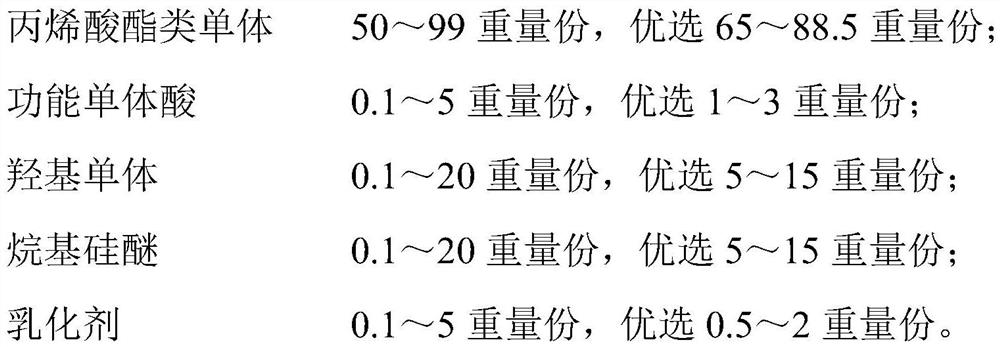

ActiveCN111909318AAchieve protectionLong activation periodAnti-corrosive paintsPolymer scienceFunctional monomer

The invention provides an alkyl silyl ether modified hydroxy acrylic emulsion and a preparation method thereof and application thereof. The hydroxyl acrylic emulsion is prepared from the following components in parts by weight: 50-99 parts of acrylate monomers; 0.1 to 5 parts of a functional monomer acid; 0.1 to 20 parts of a hydroxyl monomer; 0.1 to 20 parts of alkyl silyl ether; 0.1-5 parts of emulsifier. The hydroxyl acrylic emulsion is obtained by adding alkyl silyl ether into the acrylic emulsion neutralized to alkalescence and reacting at room temperature. According to the invention, byutilizing the change of the pH value of the prepared alkyl silyl ether modified hydroxyl acrylic emulsion before and after film formation, the conversion of protection and deprotection of alkyl silylether on hydroxyl is ingeniously realized, so that the water-based two-component acrylic industrial coating has an ultra-long activation period, does not influence the normal use of the coating, and has excellent paint film performance.

Owner:WANHUA CHEM GRP CO LTD

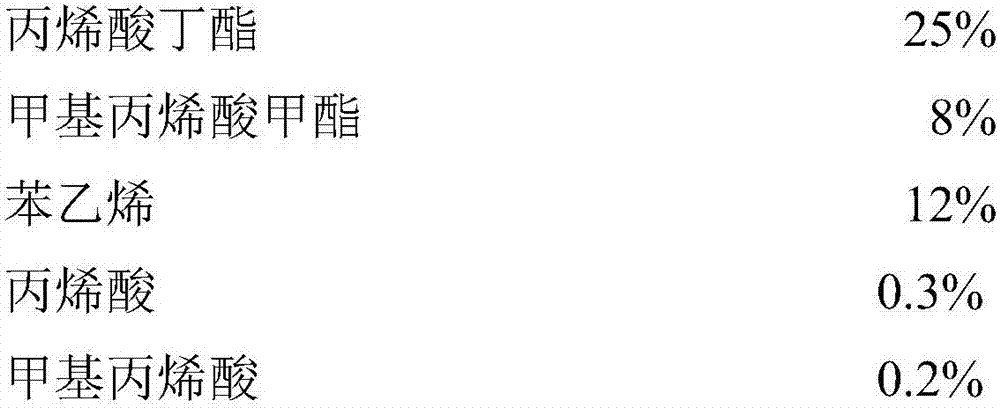

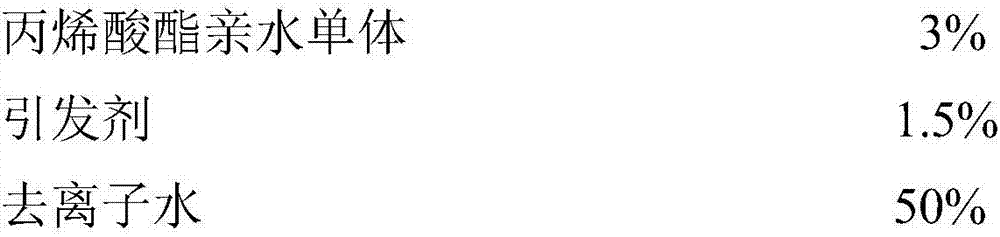

Acrylate hydrophilic monomer synthesized by using monoisocyanate polyoxyethylene monomethyl ether

InactiveCN107189038AGood quality and stabilityNot easy to hydrolyzeCoatingsHydrophilic monomerEmulsion

The invention discloses an acrylate hydrophilic monomer synthesized by using monoisocyanate polyoxyethylene monomethyl ether, and relates to the technical field of waterborne acrylic resins. The acrylate hydrophilic monomer is prepared from the following raw materials in percentage by mass: 10 to 20% of hydroxyethl acrylate and 80 to 90% of monoisocyanate polyoxyethylene monomethyl ether. The acrylate monomer with hydrophilic groups is synthesized by reacting the isocyanate in the monoisocyanate polyoxyethylene monomethyl ether structure and the hydroxy in the hydroxyethyl acrylate structure; the waterborne acrylic emulsion prepared by the acrylate hydrophilic monomer has good quality stability, is not easy to hydrolyze in the storage process and low in acid value, and the water resistance and the salt spray resistance are better than that of conventional acrylic emulsion.

Owner:安徽艾珀希德化工科技有限公司

Barium-free soft film antirust oil

ActiveCN109897718BSatisfy the environmental protection requirement that barium should not be containedLow aromatic contentLubricant compositionEngineeringMaterials science

The invention relates to a barium-free soft film anti-rust oil. The barium-free soft film anti-rust oil comprises the following components based on the total weight of the barium-free soft film anti-rust oil: 10-20% of refined mineral oil, compound Barium-free rust inhibitor 10-25%, film-forming agent 2-5%, antioxidant 0.5-1.5%, copper corrosion inhibitor 0.1-1.5%, dibutyl phthalate 0.5-3%, Span 80 0.5 ~3%, the balance of dearomatized solvent oil; wherein, the composite barium-free rust inhibitor includes calcium petroleum sulfonate, calcium dinonylnaphthalene sulfonate and gemini imidazoline corrosion inhibitor. The soft film antirust oil of the present invention has low content of solvent oil aromatics and does not contain heavy metals such as barium. While meeting the environmental protection requirements of foreign environmental protection regulations on antirust materials for export metal products, it greatly improves the antirust performance of the product. It is suitable for medium and long-term storage and packaging of ferrous metal products and copper-containing metal workpieces. It has excellent storage stability and does not produce precipitation for a long time. The oil film is thin and easy to clean. It can be assembled with oil.

Owner:PETROCHINA CO LTD

Weather-resistant and high-ductility finish paint

InactiveCN111040595ANo pollution problemAvoid security issuesAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidWeather resistance

The invention relates to a weather-resistant and high-ductility finish paint. The weather-resistant and high-ductility finish paint is composed of a white paste, a black paste, an organosilicon leveling agent, an acrylic acid leveling agent, an ultraviolet light absorber, a light stabilizer and an adhesion promoter, wherein the white paste comprises titanium dioxide, a dispersant and polyasparticacid ester resin; and the black paste comprises carbon black, a dispersant and polyaspartic acid ester resin. The weather-resistant and high-ductility finish paint provided by the invention has the advantages of weather resistance, water resistance, salt spray resistance, wear resistance, high hardness, favorable fullness, favorable leveling property, favorable adhesive force and high tensile strength, and has the characteristics of high solid content, low viscosity, no solvent, greenness and environmental friendliness during spraying construction.

Owner:江阴市荣新塑化有限公司

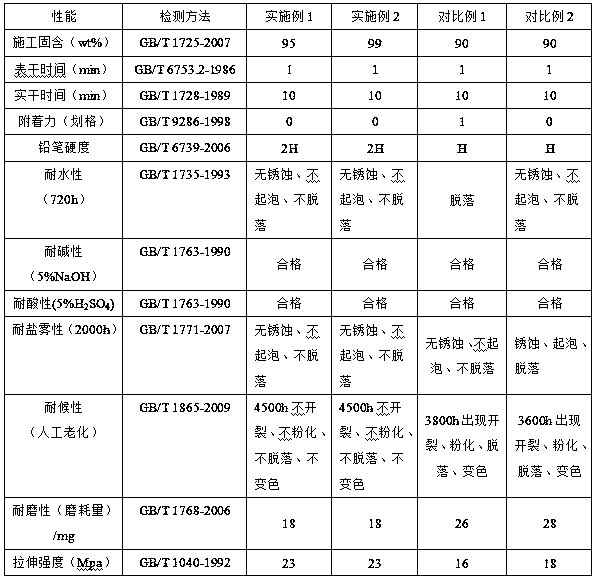

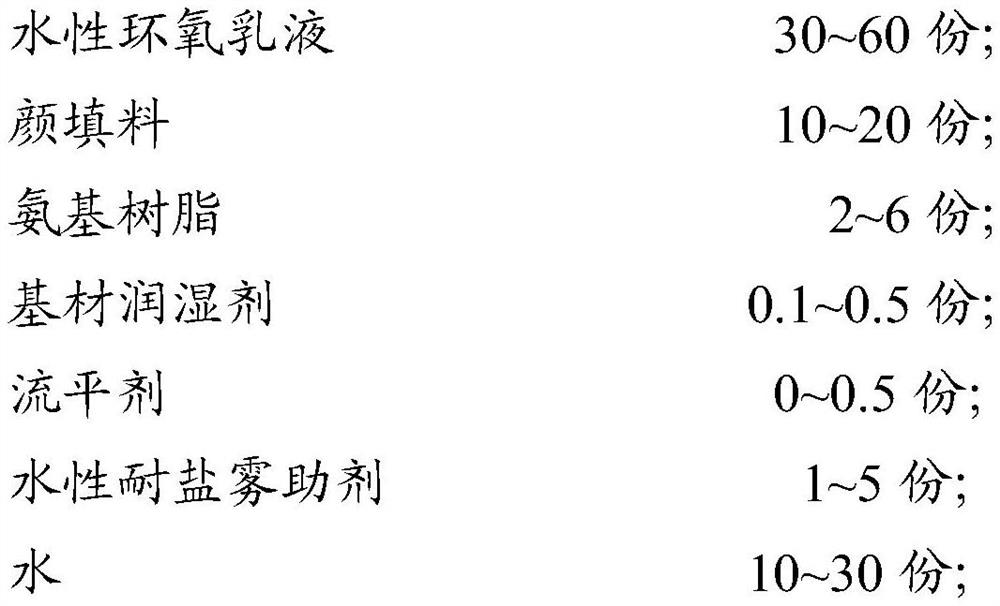

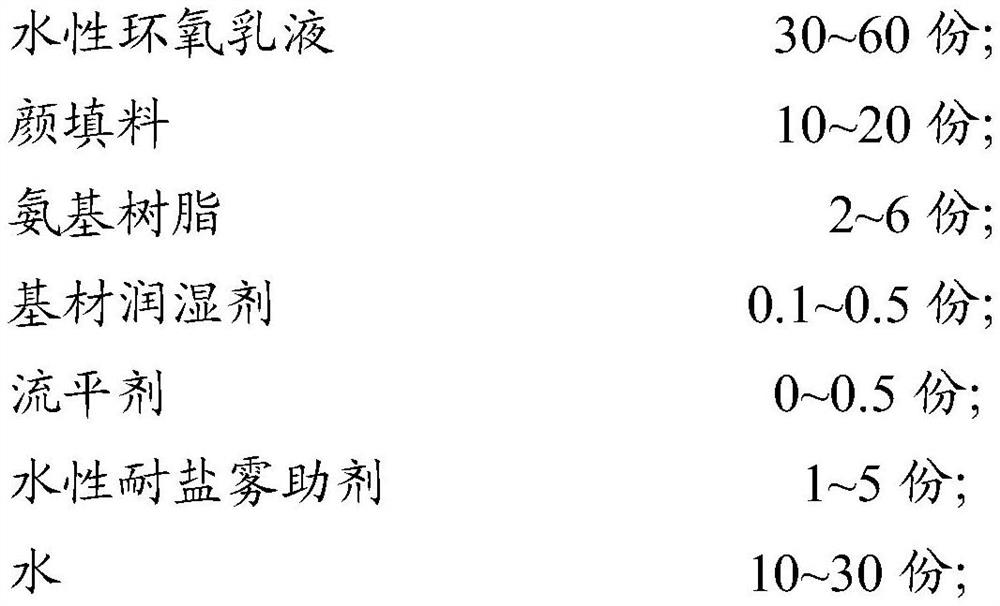

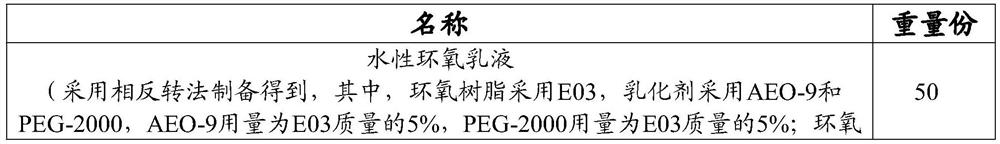

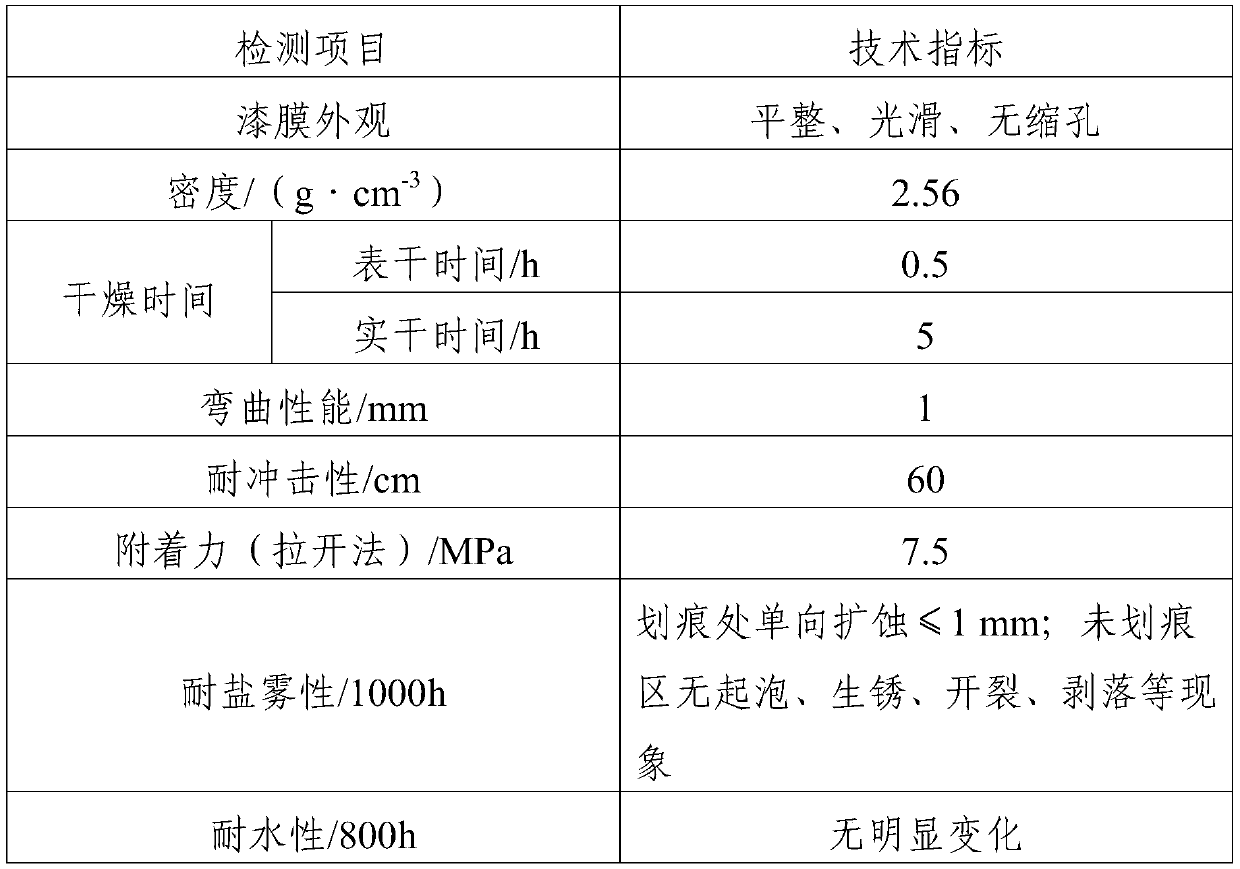

A kind of water-based epoxy primer for pre-coated coils and preparation method thereof

ActiveCN109385183BHigh hardnessImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention belongs to the field of paint materials, and in particular relates to a water-based epoxy primer for pre-coated coils and a preparation method thereof. The epoxy primer comprises, in parts by weight: 30-60 parts of water-based epoxy emulsion; pigments and fillers 10-20 parts; 2-6 parts of amino resin; 0.1-0.5 parts of substrate wetting agent; 0-0.5 parts of leveling agent; 1-5 parts of water-based salt spray resistance additive; 10-30 parts of water; amino resin includes Full and / or partially methylated amino resins; substrate wetting agents include one or more of silicone, nonionic, and anionic substrate wetting agents; leveling agents include acrylic leveling agents and / or fluorine modified acrylic leveling agent. In the present invention, by designing a suitable amino group ratio, pigment-base ratio, and selecting suitable additives, the provided epoxy primer can be rapidly cured at a temperature of 200-250°C on a galvanized sheet or a galvanized aluminum sheet, and the formed paint film It has the properties of high hardness, good adhesion, good flexibility, and excellent salt spray resistance time.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

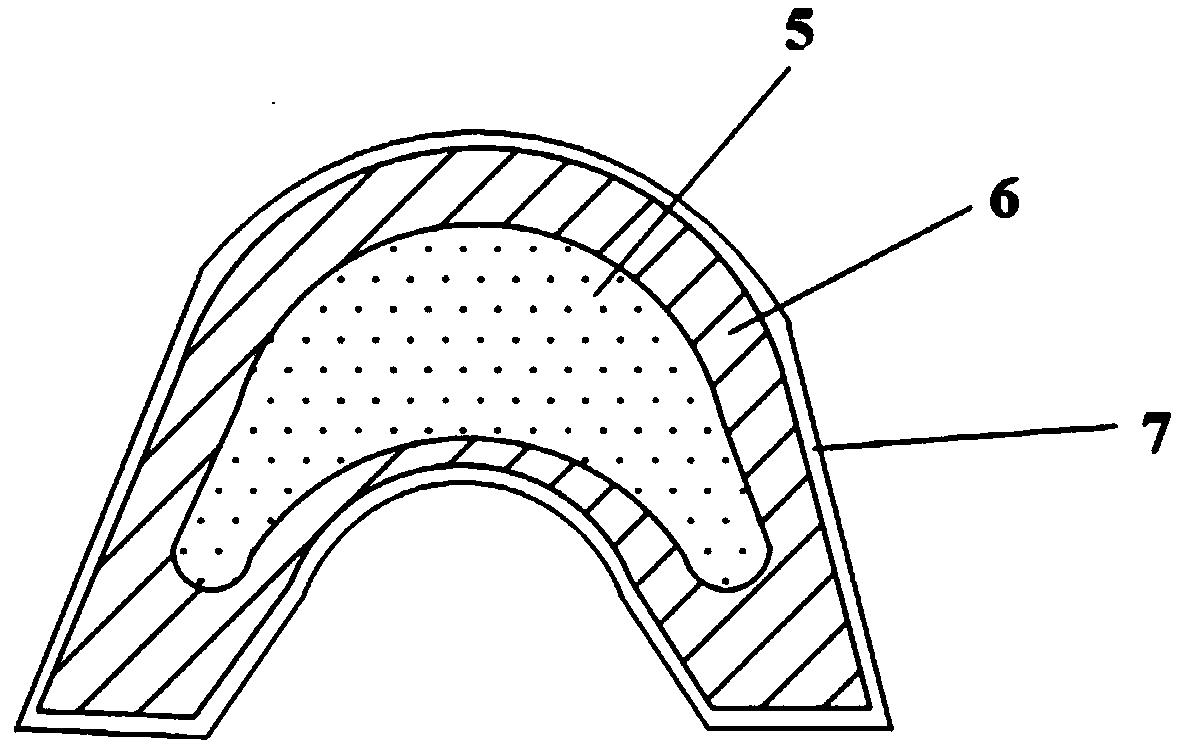

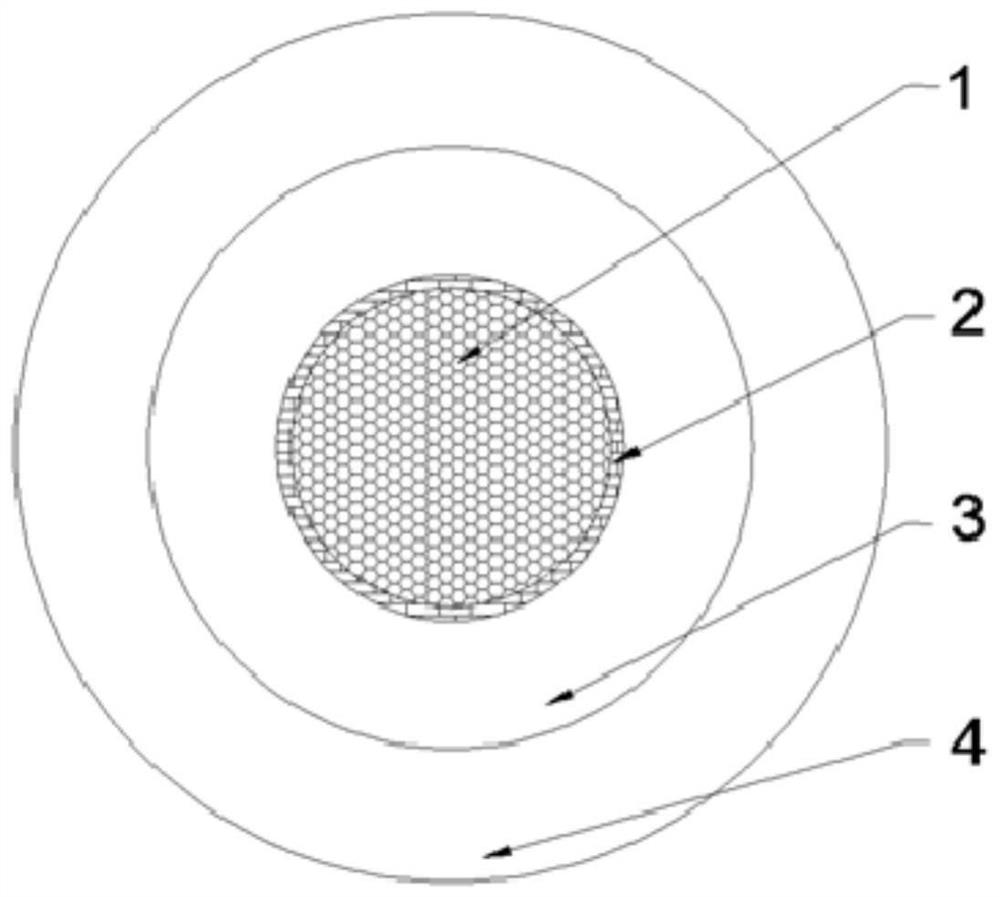

Salt fog-prevention and waterproof ship cable

PendingCN107305798AImprove corrosion resistanceExcellent resistance to salt sprayFloating cablesInsulated conductorsEpoxyElectrical resistance and conductance

The invention relates to a salt fog-prevention and waterproof ship cable. The salt fog-prevention and waterproof ship cable comprises conductors, wherein an insulation layer is arranged outside each conductor, a shielding layer is arranged outside the insulation layer, a buffer layer is arranged outside the shielding layer to form a conductive unit, the insulation layer and the shielding layer are formed by co-extrusion, at least two conductive units are arranged and are arranged in an externally tangent way, a filling layer is arranged outside the conductive units, a semiconduction water blocking belt layer is arranged outside the filling layer, a floating layer is arranged outside the semiconduction water blocking belt layer, an epoxy resin layer is arranged outside the floating layer, a waterproof lining layer is arranged outside the epoxy resin layer, a salt fog prevention layer is arranged outside the waterproof lining layer, and an external sheath layer is arranged outside the salt fog prevention layer. The salt fog-prevention and waterproof ship cable has good integral waterproof performance and good salt fog prevention performance and is safe and reliable to run.

Owner:WUXI SUNAN CABLE

An addition type potting glue for wind turbines and its manufacturing method

ActiveCN102093839BHigh thermal conductivityDissipate quicklyNon-macromolecular adhesive additivesOther chemical processesWind drivenMass ratio

The invention discloses an additive pouring sealant used for a wind driven generator and a preparation method thereof. The preparation method is characterized by comprising the following steps of: dewatering and blending 100 parts by weight of vinyl silicone oil, 50-200 parts by weight of aluminium oxide filler, 50-150 parts by weight of fire retardant, 0-15 parts by weight of white carbon black, 0-150 parts by weight of processed calcium carbonate, 10-30 parts by weight of alpha and omega-dimethyl polydimethylsiloxane for 30-200 minutes at the temperature of 120-170DEG C and the vacuum degree of 0.06-0.99mpa to obtain base stock; at the constant temperature, taking 100 parts by weight of base stock, adding 1-4 parts by weight of hydrogen-containing silicone oil and 0-0.06 part by weight of inhibitor, stirring in a stirrer for 20-30 minutes to obtain sealant A; taking 100 parts by weight of base stock, 1-6 parts by weight of platinum catalyst and 0.6-2 parts by weight of tackifier, and stirring in the stirrer to obtain sealant B; evenly mixing the sealant A and the sealant B at the mass ratio of 5:1; and solidifying the mixture is solidified at the room temperature to obtain the additive pouring sealant used for a wind driven generator, wherein the additive pouring sealant used for a wind driven generator has the advantages of high thermal conductivity coefficient, excellent electrical property, high and low temperature impact resistance, salt mist resistance, good adhesive property at high temperature and high moisture, and the fire resistance of V-1 level.

Owner:CHENGDU GUIBAO SCI & TECH

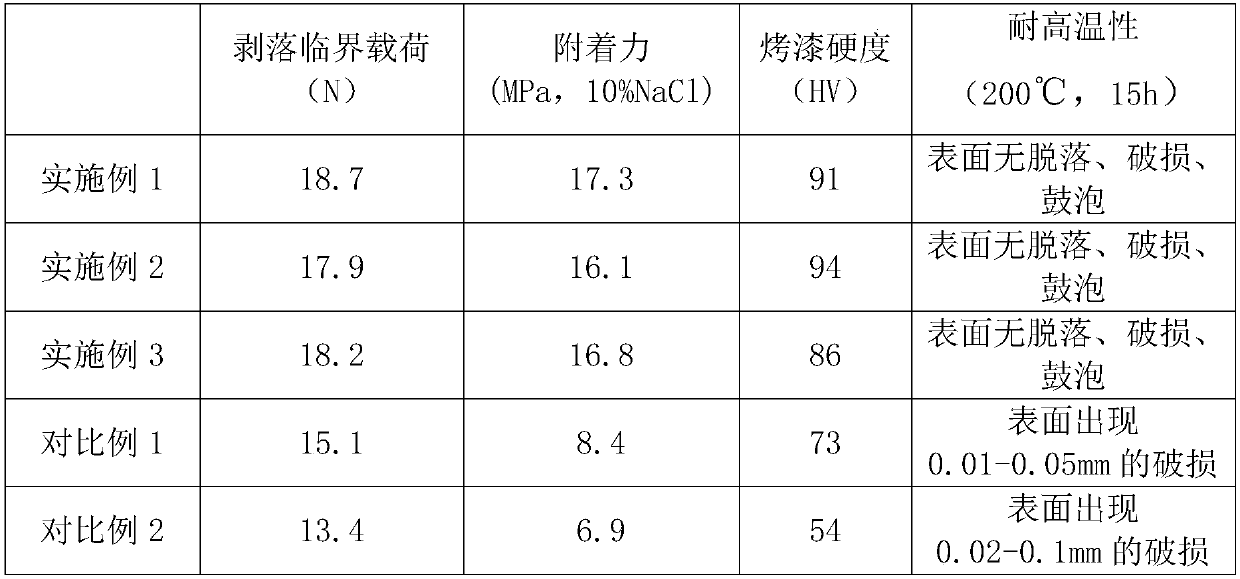

A kind of surface treatment method of aluminum alloy vehicle frame

ActiveCN107868945BPlay an emulsifying roleSkim wellPretreated surfacesChemical vapor deposition coatingAlloyCorrosion

The invention relates to a surface treatment method for an aluminum alloy frame. The surface treatment method comprises the three steps of pretreatment, surface coating and primer and finishing coat spraying. The plasma enhanced chemical vapor deposition coating technology is matched with NaOH-sodium silicate ungrease treatment liquid, barium petroleum sulfonate-hydrochloric acid antirust treatment liquid to conduct surface treatment on the aluminum alloy frame, and the mechanical strength, the corrosion resisting performance and the high-temperature resisting performance of a frame surface coating are improved; and meanwhile, the thickness of the coating is uniform, proceeding of the later paint baking technology is guaranteed, the frame paint baking hardness is increased, and the integral quality of the bicycle frame is improved.

Owner:上海凤凰自行车江苏有限公司

A kind of moisture curing epoxy asphalt anticorrosion coating and preparation method thereof

ActiveCN104073127BLong-term anti-corrosion lifeImprove bindingAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to a moisture-curing epoxy asphalt anticorrosion coating and a preparation method thereof. The moisture-curing epoxy asphalt anticorrosion coating is composed of component A and component B in a weight percentage of 2-5:3-1; component A The raw material composition and weight percentage are respectively: solvent 9%~12%, thickener 1%~2.5%, dispersant 0.8%~1.2%, toughening agent 5%~7%, epoxy resin 33%~ 37%, coal tar pitch 19% to 30%, antirust pigment 9% to 16%, talcum powder 9% to 12%. The invention also includes methods of making such coatings. Its beneficial effect is that when the ambient humidity is higher than 85%, normal construction can still be carried out, and the link of using a dehumidifier to reduce the ambient humidity in the construction process is omitted, which greatly saves energy, reduces construction costs, and improves work efficiency.

Owner:天津市津海特种涂料装饰有限公司

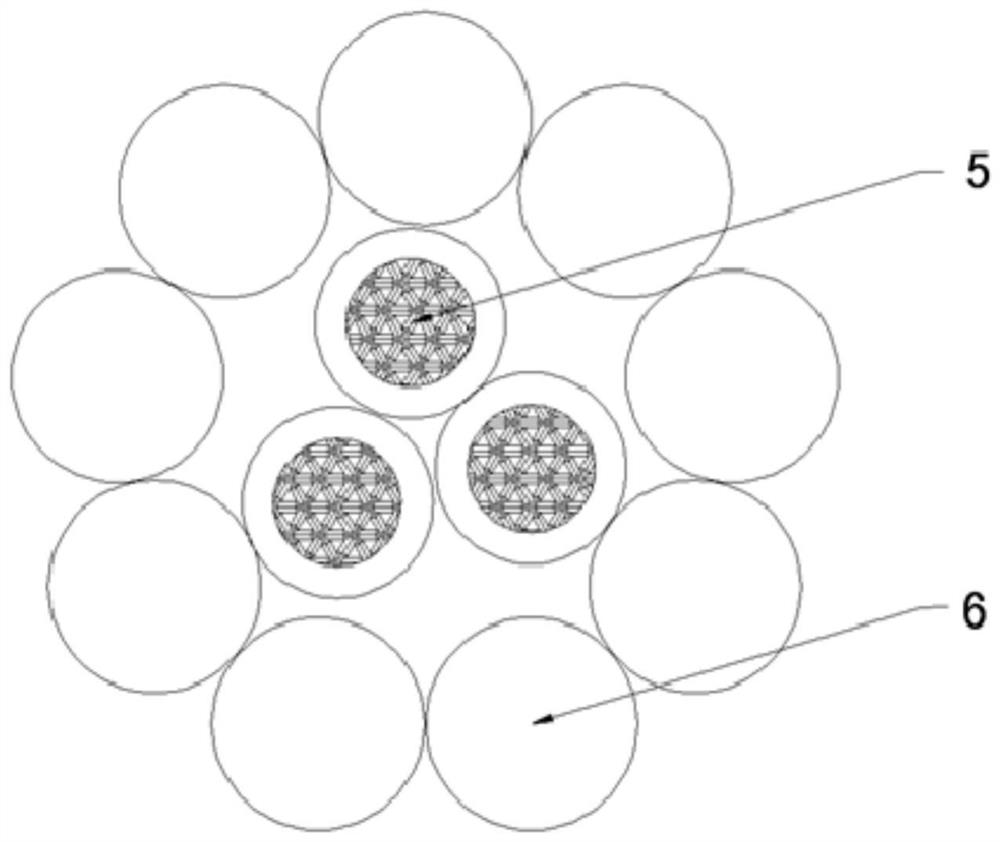

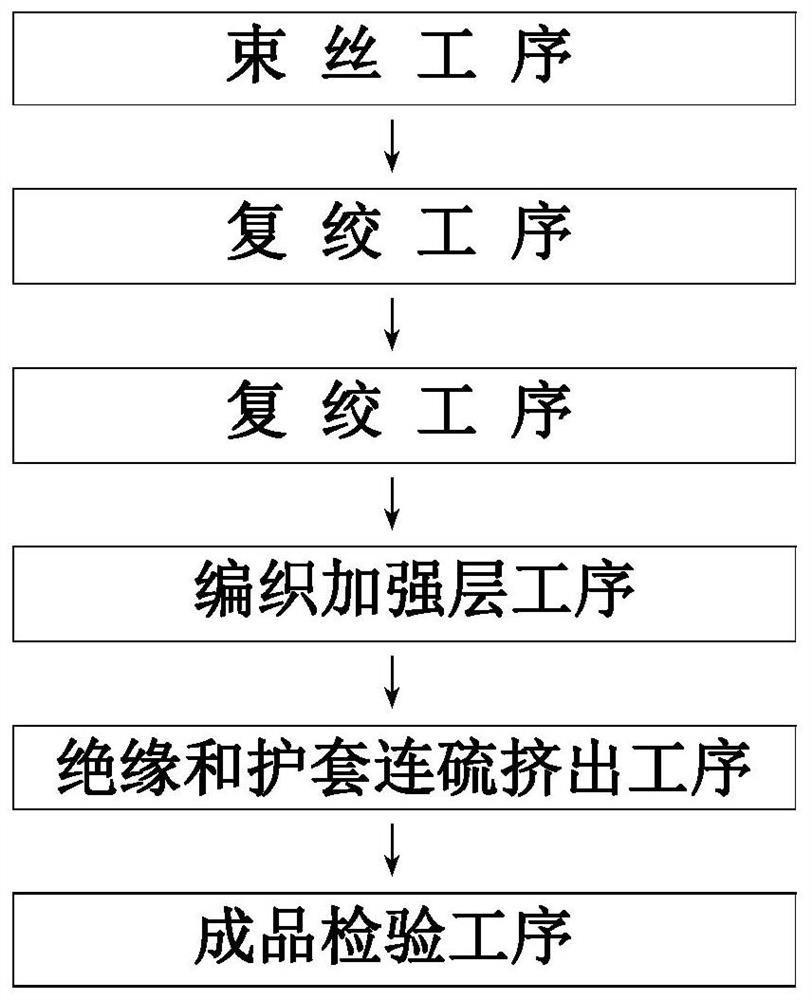

Flexible cable for 10MW offshore wind generating set and preparation method of flexible cable

PendingCN114068061AImprove tensile propertiesIncrease tightnessRubber insulatorsStrip/foil conductorsElectrical conductorCopper wire

The invention belongs to the technical field of wires and cables, and particularly relates to a flexible cable for a 10MW offshore wind generating set and a preparation method of the flexible cable. The flexible cable for the 10MW offshore wind generating set comprises a conductor, a reinforcing layer, an insulating layer and a sheath layer; the reinforcing layer is arranged in the outer side of the conductor, the insulating layer is arranged in the outer side of the reinforcing layer, and the sheath layer is extruded outside the insulating layer; the conductor comprises a single copper wire and a copper foil wire, the copper foil wire comprises a Kevlar bulletproof wire fiber wire and a copper foil metal belt, the copper foil wire is supported by the Kevlar bulletproof wire fiber wire and is formed by wrapping the copper foil metal belt, and the reinforcing layer is formed by weaving Kevlar bulletproof wires. According to the flexible cable for the 10MW offshore wind generating set and the preparation method of the flexible cable, the torsion resistance and the tensile property of the cable can be remarkably improved, and meanwhile, the cable also has excellent high and low temperature resistance, ageing resistance, salt mist resistance and flame retardance.

Owner:天津金山电线电缆股份有限公司

High-performance epoxy zinc-rich antirust primer and preparation method thereof

InactiveCN110885611AImprove heat resistanceGood time stabilityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSilanes

The invention provides high-performance epoxy zinc-rich antirust primer and a preparation method thereof, and relates to the technical field of coating. The primer comprises a component A and a component B. The component A includes: 10-15 parts of water-based epoxy resin, 3-7 parts of organic bentonite, 1-2 parts of polyamide wax slurry, 50-55 parts of zinc powder, 5-10 parts of rare earth praseodymium powder, 2-4 parts of polymerized iron phosphate powder, 10-12 parts of fumed silica, 0.2-1 part of a TEGO-KL245 high-efficiency substrate wetting agent, 1-1.5 parts of an R-760F water-based flash rust inhibitor, 0.5-2 parts of a dispersant, 0.3-0.7 part of an anti-settling agent, 1-3 parts of a cellulose derivative, 4-8 parts of n-butanol, and 100-120 parts of water. The component B includes: 40-60 parts of a cashew nut shell oil modified polyamide curing agent, 4-8 parts of a CMP-410 epoxy resin active toughening agent, 2-4 parts of methyldiethanolamine, 1-2 parts of propylene glycol monomethyl ether, 1-2 parts of a silane coupling agent, 0.1-1 part of a defoamer, 0-0.3 part of a corrosion inhibitor and 30-50 parts of ethanol. The primer has various excellent properties, has excellent salt mist resistance and water resistance and high mechanical strength and meets application requirements.

Owner:安徽鹿客通讯科技有限公司

Special heavy-duty anticorrosive coating and preparation method thereof

PendingCN110698941ALong corrosion lifeGood weather resistanceFireproof paintsAntifouling/underwater paintsPolymer sciencePolymer chemistry

The invention discloses a special heavy-duty anticorrosive coating and a preparation method thereof, belonging to the field of special anticorrosive coatings. The coating is mainly prepared from 5-10parts by weight of methyl acrylate, 15 to 30 parts of butyl acrylate, 0.5 to 5 parts of acrylic acid, 5 to 30 parts of a silane coupling agent, 0.05 to 2.5 parts of a bacteriostatic agent, 0.1 to 1.5parts of an initiator, 5 to 10 parts of toluene, 0.05 to 0.5 part of an antifoaming agent, 0.05 to 0.5 part of a leveling agent and 5 to 30 parts of a diluent. The prepared special heavy-duty anticorrosive coating is long in anti-corrosion service life, the combination of the methyl acrylate, butyl acrylate and acrylic acid is adopted as a basic system, the weather resistance of the special heavy-duty anticorrosive coating is greatly improved, the high temperature resistance is higher than 200 DEG C, and the low temperature resistance is lower than-40 DEG C.

Owner:HARBIN JINSHIJIA TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com