Functional modified ABS (acrylonitrile butadiene styrene) profiled base station antenna housing and production method thereof

A technology for base station antennas and profiled materials, which is applied in the field of profiled material covers and its preparation, can solve problems affecting the service life and effect of base station antennas, and achieve the effects of low cost, low price, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

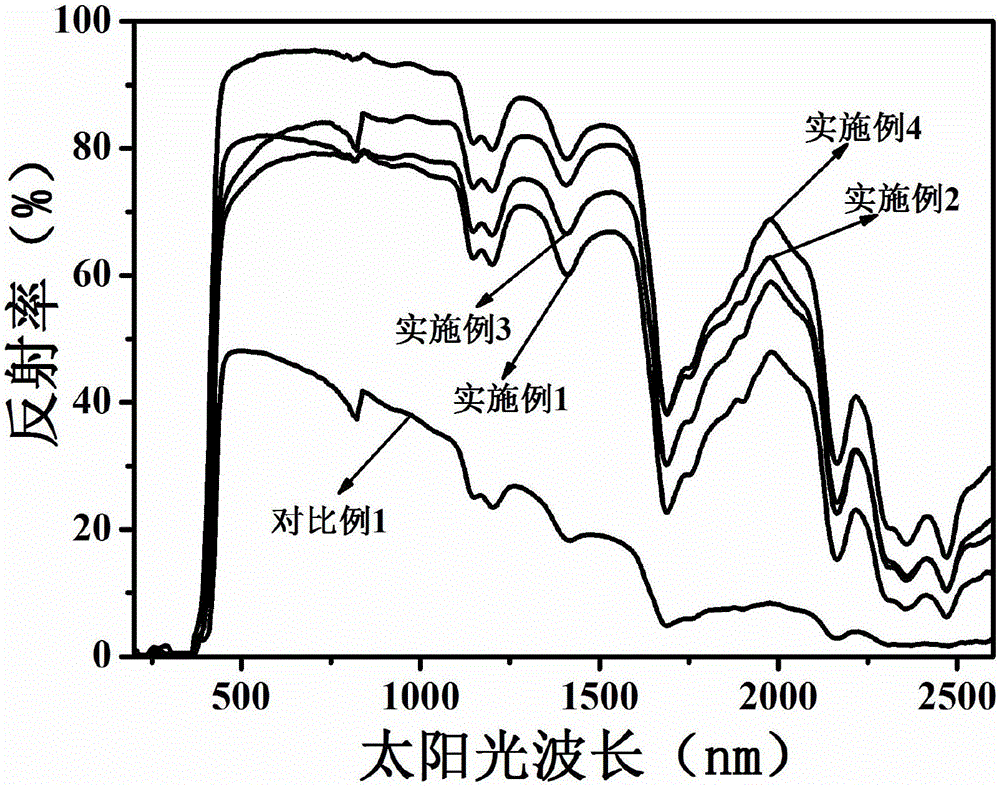

Embodiment 1

[0041] Raw material formula (mass ratio, part): ABS resin (200 ℃ * 5kg MFR = 1.0g / 10min) 80, AS resin (AN = 25wt%, 200 ℃ * 5kg MFR = 0.5g / 10min) 10, high fluidity AS resin (AN=33wt%, 200°C×5kg melt mass flow rate=15g / 10min) 5, αMSAN heat-resistant modified resin (AN=20wt%, 200°C×5kg melt mass Flow rate=0.5g / 10mi) 5, lubricant EBS 1.0, ultraviolet absorber UV326 2.0, antioxidant GM 0.3, surface modified antimony trioxide 6 (the most probable distribution of particle size 0.55 μm, 1.1 μm and 2.0 for each of the three particles of 2 μm).

[0042] Preparation process: ① Surface chemical grafting modification of inorganic non-metallic compounds: 6 grams of Sb 2 o 3 Place in toluene (mass ratio 1:10), ultrasonically disperse for 30 minutes, and then transfer to a constant temperature magnetic stirring device. After stirring for 30 minutes, add 3% mass fraction of silane coupling agent KH-570 and 1mL triethylamine to the inorganic non-metallic compound -in benzene dispersion, rea...

Embodiment 2

[0048] Raw material formula (mass ratio, part): ABS resin (200 ℃ × 5kg MFR = 0.5g / 10min) 80, AS resin (AN = 33wt%, 200 ℃ × 5kg MFR = 3.0g / 10min) 5. High fluidity AS resin (AN=25wt%, 200°C×5kg melt mass flow rate=20g / 10min) 5, αMSAN heat-resistant modified resin (AN=30wt%, 200°C×5kg melt mass Flow rate = 0.1g / 10mi) 10, lubricant EBS 1.5, ultraviolet light absorber UV326 2.5, antioxidant GM 0.5, surface modified rutile titanium dioxide 6 (particle size most probable distribution 0.55 μm particles 1.0 parts, 1.1 μm 2.0 parts for particles and 3.0 parts for 2 μm particles).

[0049] Preparation process: ① Inorganic non-metallic compound surface chemical grafting modification: 6 grams of TiO 2 Place in toluene (mass ratio 1:10), ultrasonically disperse for 30 minutes and then transfer to a constant temperature magnetic stirring device. After stirring for 30 minutes, add 1% mass fraction of silane coupling agent KH-570 and 1mL triethylamine to the inorganic non-metallic compound ...

Embodiment 3

[0055] Raw material formula (mass ratio, part): ABS resin (200 ℃ * 5kg melt mass flow rate = 0.8g / 10min) 70, AS resin (AN = 30wt%, 200 ℃ * 5kg melt mass flow rate = 2.0g / 10min) 10, high fluidity AS resin (AN=25wt%, 200°C×5kg melt mass flow rate=18g / 10min) 10, αMSAN heat-resistant modified resin (AN=25wt%, 200°C×5kg melt mass Flow rate = 0.3g / 10mi) 10, lubricant EBS 2.0, ultraviolet light absorber UV326 3.0, antioxidant GM 0.4, surface modified barium titanate 5 (particle size most probable distribution 0.55 μm particles 1.0 parts, 1.1 μm 2.0 parts for particles and 2.0 parts for 2 μm particles).

[0056] Preparation process: ① Inorganic non-metallic compound surface chemical grafting modification: 5 grams of BaTiO 3 Place in toluene (mass ratio 1:10), ultrasonically disperse for 30 minutes, transfer to a constant temperature magnetic stirring device, and after stirring for 30 minutes, add silane coupling agent KH-570 with a mass fraction of 5% and 1 mL of triethylamine to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com