Comprehensive treatment agent and use method thereof

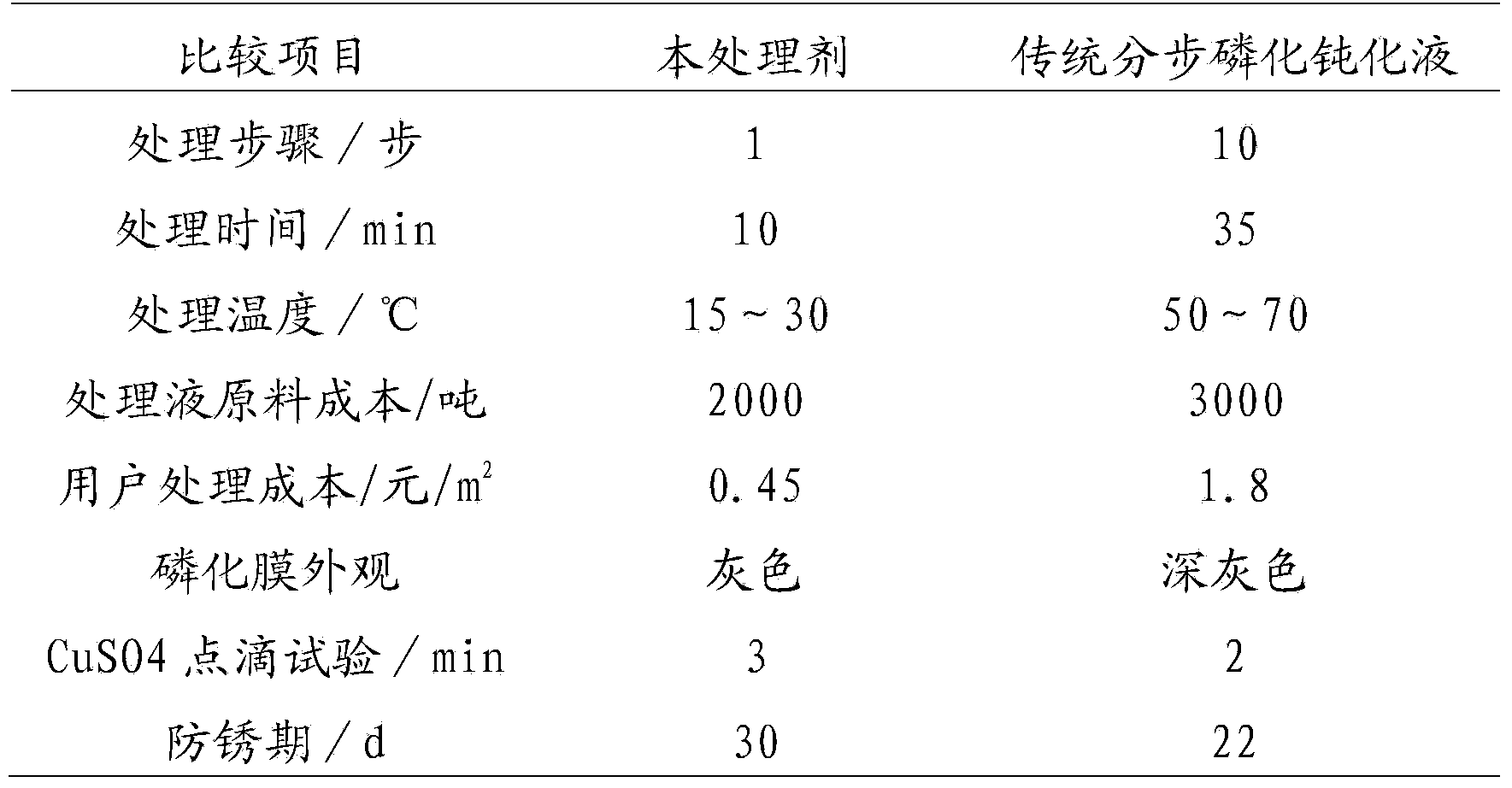

A comprehensive treatment agent and treatment agent technology, applied in the direction of metal material coating process, etc., can solve the problems of high maintenance cost, large equipment investment, large environmental pollution, etc., and achieve low treatment cost, good treatment effect and high corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

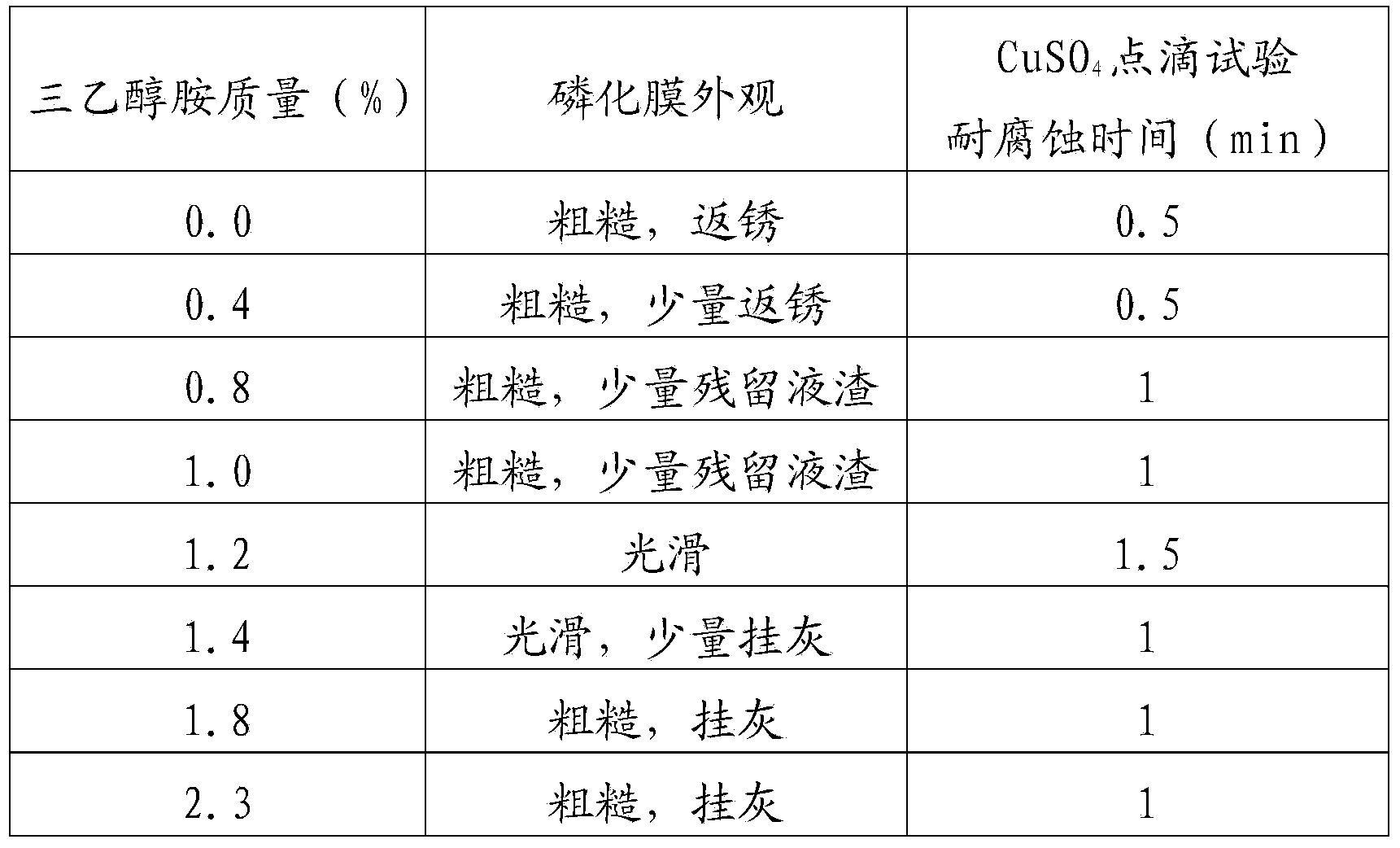

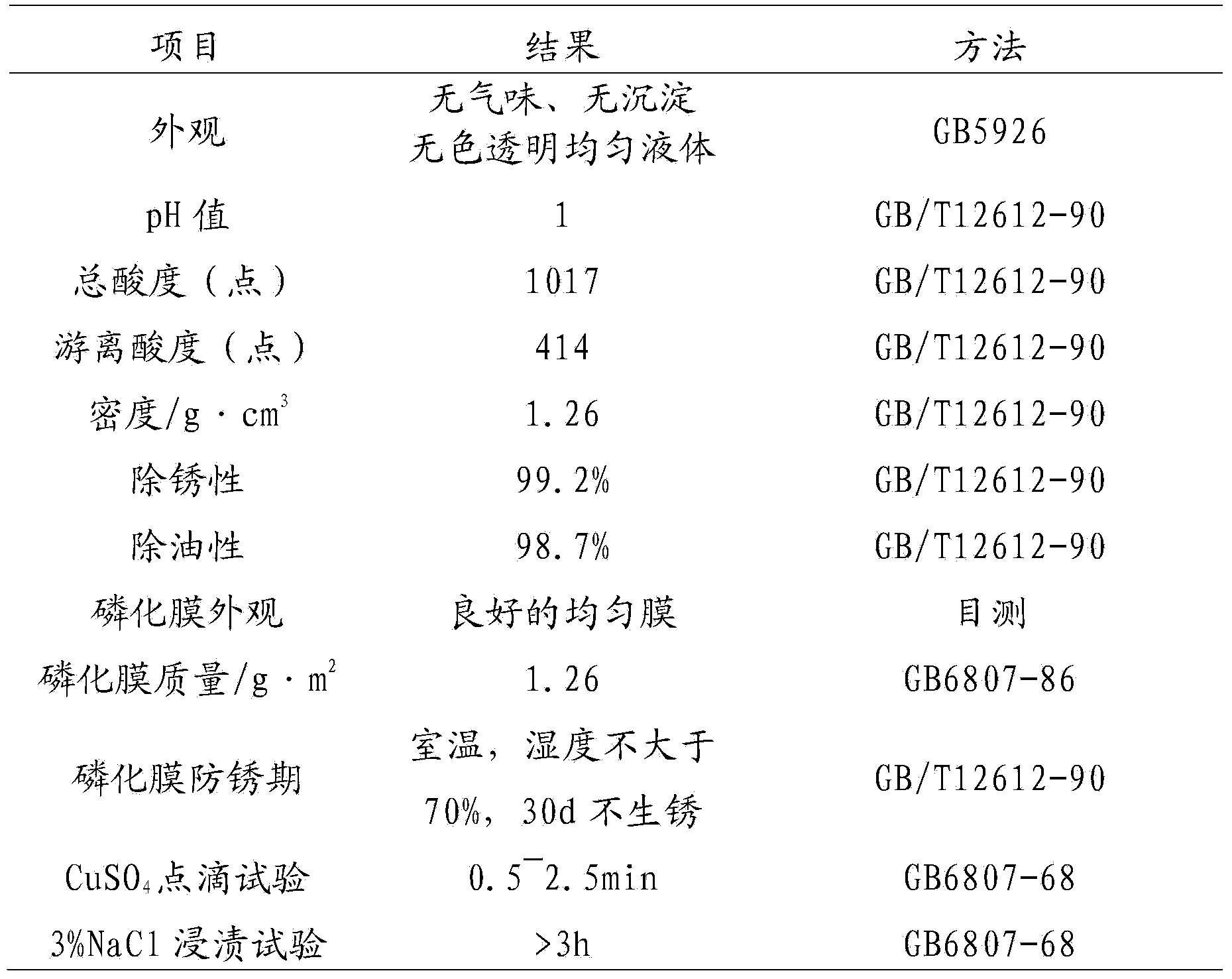

[0072] Weigh the quantitative reagent according to the following formula ratio, phosphoric acid (27.5%), zinc oxide (2.0%), sodium molybdate (0.3%), zinc dihydrogen phosphate (5.5%), potassium chlorate (0.7%), OP-10 (0.2 %), TX-10 (0.2%), SDBS (0.4%), triethanolamine (1.3%), citric acid (1.2%), thiourea (0.15%), deionized water (60.55%). The treatment agent is prepared according to the preparation method of the multifunctional shell surface treatment agent. The shell cleaning operation is carried out by spraying method. The operating conditions are as follows: spraying pressure 0.12MPa, solution temperature 35°C, spraying time 2.5min, ambient temperature 20°C. The test results show that under the above operating conditions, the formula has a rust removal rate of 99.4%, an oil removal rate of 99.0%, and the quality of the phosphating film formed is 1.42g / m2. The phosphating film is uniform and dense, and has good corrosion resistance. The test time is 1.6min. The soaking oper...

Embodiment 3

[0074] Weigh the quantitative reagent according to the following formula ratio, phosphoric acid (30.0%), zinc oxide (2.0%), sodium molybdate (0.5%), zinc dihydrogen phosphate (4.0%), potassium chlorate (0.7%), OP-10 (0.3 %), TX-10 (0.2%), SDBS (0.4%), triethanolamine (1.3%), citric acid (1.2%), thiourea (0.15%), deionized water (59.25%). The treatment agent is prepared according to the preparation method of the multifunctional shell surface treatment agent. Use the spray method to clean the shells. The operating conditions are as follows: spray pressure 0.15MPa, solution temperature 40°C, spray time 3min, ambient temperature 20°C. Under the above operating conditions, the formula has a rust removal rate of 99.6% and an oil removal rate of 98.5%. The quality of the phosphating film formed is 1.37g / m2. The phosphating film is relatively uniform, has slight pores, and has good corrosion resistance. , CuSO4 drop test time is 1.4min. The soaking operation conditions are as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com