Method and device for preparing high-concentration dilute nitric acid

A dilute nitric acid, high-concentration technology, applied in nitric acid, nitrogen oxides/oxyacids, etc., can solve the problem of low concentration of dilute nitric acid, and achieve the effect of promoting oxidation reaction, increasing acid concentration, and improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

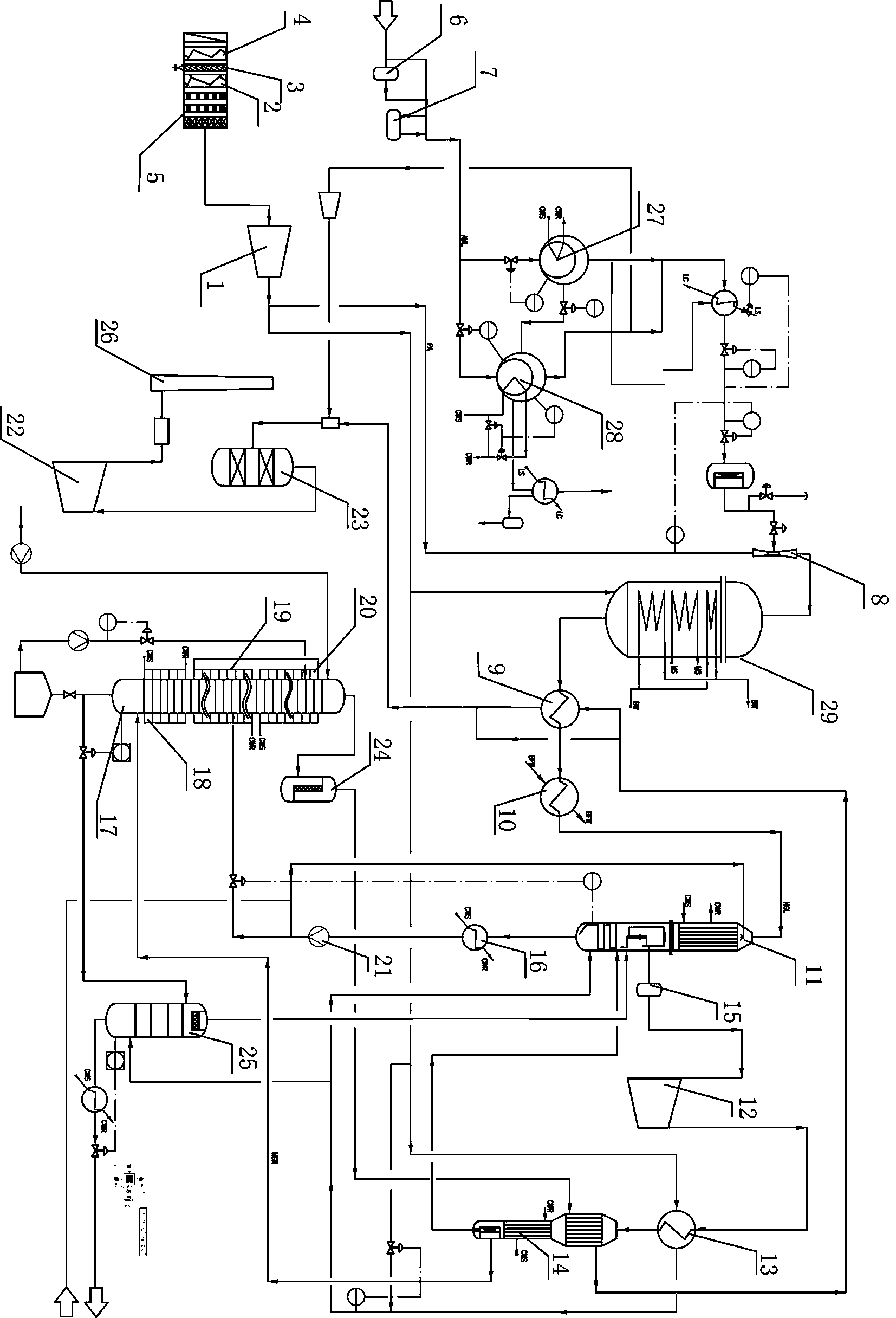

[0041] In order to further understand the technical content, characteristics and effects of the present invention. Take a company's nitric acid production plant with an annual output of 270,000 tons as an example, and describe it in detail with the accompanying drawings.

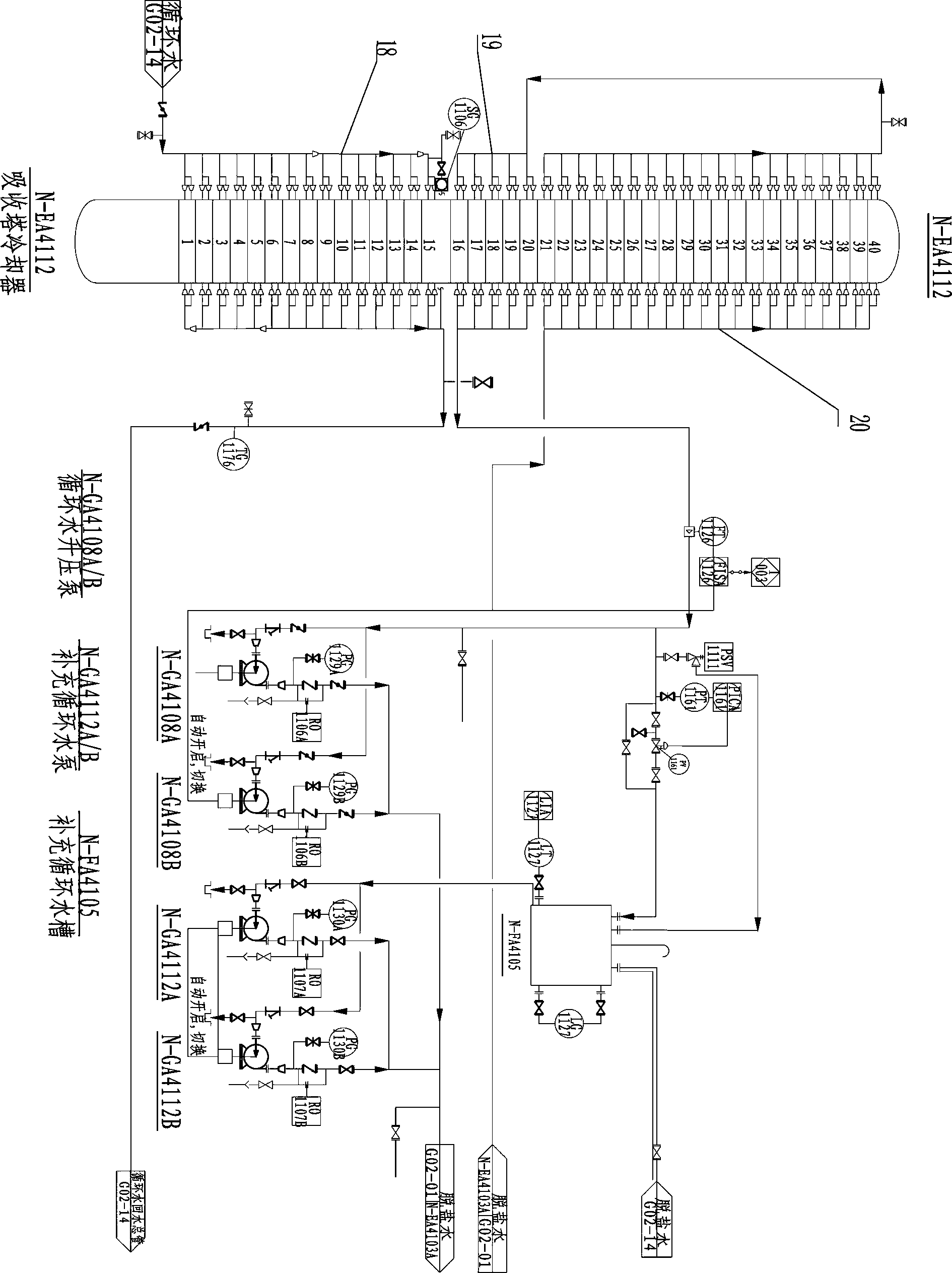

[0042] like figure 1 As shown, the first-stage air filter of the four-stage air filter device 5 communicates with the ammonia-air condenser 4, the droplet separator 3, and the air preheater 2 successively, and the air preheater 2 communicates with the four-stage air filter device 5 again. The second, third, and fourth-stage air filters are connected, and the air outlet of the fourth-stage air filter device 5 is connected with the air compressor 1, which is used to make the air pass through the first-stage air filter to remove impurities, cool down and condense through the ammonia-air condenser 4, The condensed water is removed by the droplet separator 3, the dust is removed by the second, third and fourth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com