Preparation method of water-base efficient metal surface cleaning agent

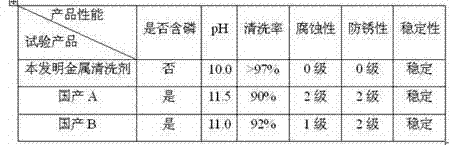

A technology for metal surface and cleaning agent, applied in the field of preparation of water-based high-efficiency metal surface cleaning agent, can solve the problems of rust spots, strong corrosion, poor microbial degradation, etc., and achieve the effect of less pollution, low equipment corrosion, and excellent degreasing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: (1) Mix 30 parts of oleic acid, 230 parts of polyoxyethylene polyoxypropylene amine ether, and 2.3 parts of p-toluenesulfonic acid in a dry, anhydrous reactor, stir and heat to 100°C, keep it warm for 3.5 hours, and cool down to room temperature An oleic acid polyoxyethylene polyoxypropylene amine ether ester surfactant is obtained. (2) Mix 6 parts of oleic acid polyoxyethylene polyoxypropylene amine ether ester with 2 parts of 6053, 1 part of JFC, 4 parts of dodecylsulfonic acid, 1 part of urea, 1 part of sodium silicate, and 1 part of sodium citrate , 1 part of isopropanol, 0.1 part of polyether L61 and 82.9 parts of water are mixed and stirred evenly, and then the pH of the mixed solution is adjusted to 10 with caustic soda.

Embodiment 2

[0030] Example 2: (1) Mix 30 parts of oleic acid, 240 parts of polyoxyethylene polyoxypropylene amine ether, and 2.4 parts of p-toluenesulfonic acid in a dry, anhydrous reactor, stir and heat to 110°C, keep it warm for 4 hours, and cool down to room temperature An oleic acid polyoxyethylene polyoxypropylene amine ether ester surfactant is obtained. (2) Mix 6 parts of oleic acid polyoxyethylene polyoxypropylene amine ether ester with 4 parts of 6053, 1 part of JFC, 6 parts of dodecylsulfonic acid, 1 part of urea, 1 part of sodium silicate, and 1 part of sodium citrate , 0.5 parts of isopropanol, 0.1 parts of polyether L61 and 79.4 parts of water are mixed and stirred evenly, and then the pH of the mixed solution is adjusted to 10 with caustic soda.

Embodiment 3

[0031] Example 3: (1) Mix 32 parts of oleic acid, 240 parts of polyoxyethylene polyoxypropylene amine ether, and 2.4 parts of p-toluenesulfonic acid in a dry, anhydrous reactor, stir and heat to 110°C, keep it warm for 3.5 hours, and cool down to room temperature An oleic acid polyoxyethylene polyoxypropylene amine ether ester surfactant is obtained. (2) Mix 5 parts of oleic acid polyoxyethylene polyoxypropylene amine ether ester with 5 parts of 6053, 2 parts of JFC, 4 parts of dodecylsulfonic acid, 2 parts of urea, 1.5 parts of sodium silicate, and 1 part of sodium citrate , 1.5 parts of isopropanol, 0.1 part of polyether L61 and 77.9 parts of water are mixed and stirred evenly, and then the pH of the mixed solution is adjusted to 10 with caustic soda.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com