Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Anti-oxidation temperature is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

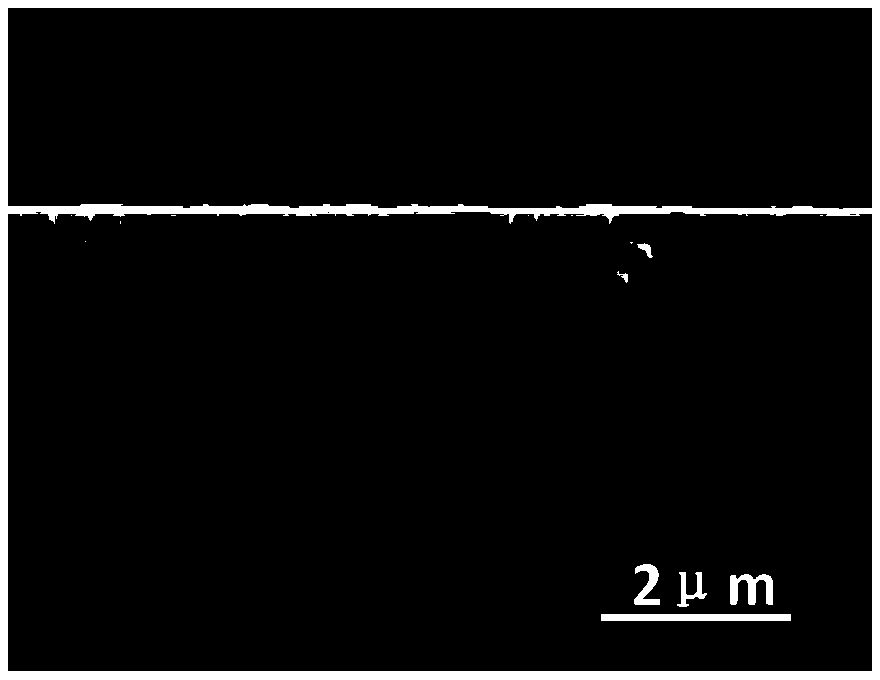

Wolframium (W) doped diamond-like coating and preparation method thereof

InactiveCN103451608AHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingChemical stabilityMaterials science

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Miniature PVD coat miller cutter for PCB, and making method thereof

InactiveCN103737092AReduce coefficient of frictionAnti-oxidation temperature is highMilling cuttersVacuum evaporation coatingMilling cutterWear resistant

The invention discloses a miniature PVD coat miller cutter for PCB, and a making method thereof. The miniature PVD coat miller cutter for PCB comprises a substrate and one or more layers of a hard and wear-resistant coat deposited on the substrate through a physical vapor deposition process; the hard and wear-resistant coat is an MeCxNyOz coat, Me is one or more of Al, Cr, Ti, Zr, Si, Hf, Nb, Ni, W, Ta, B, V, Y and Cu, and x+y+z is 1; and the total thickness of the one or more layers of the coat on the substrate is 0.1-10mum. The substrate is made by using a cemented carbide material, a ceramet material, a ceramic material, a cubic boron nitride based material or a high-speed steel material. By improving the structure of the PVD coat in the invention, a processing problem that printed circuit boards are difficult to process is overcome, and a problem that the service life of a common miniature milling cutter is short is prolonged.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Method for preparing zirconium diboride coating

ActiveCN103757603AReduce concentrationPrevent oxidationChemical vapor deposition coatingTemperature controlCeramic coating

The invention discloses a method for preparing a zirconium diboride coating and relates to a method for preparing a ceramic coating. The invention aims to solve the problems that a gas circuit needs to be subjected to thermal insulation treatment and the requirement of a gas flowmeter is high by adopting a method for heating ZrCl4 to be higher than a sublimation temperature and introducing the ZrCl4 into a reaction chamber through the flowmeter in the process of preparing ZrB2 through a conventional chemical vapor deposition method. The preparation method comprises the following steps: by using a double-temperature-area heating mode, by taking ZrCl4, BCl3 and H2 as source gases, by taking Ar gas or N2 as carrier gas and protective gas, preparing the zirconium diboride coating by adopting the chemical vapor deposition method. According to the method in the invention, the gas circuit needs no special thermal insulation treatment, and the flow of the ZrCl4 can be controlled through a temperature control method. The method can be used for preparing zirconium diboride coating.

Owner:HARBIN INST OF TECH

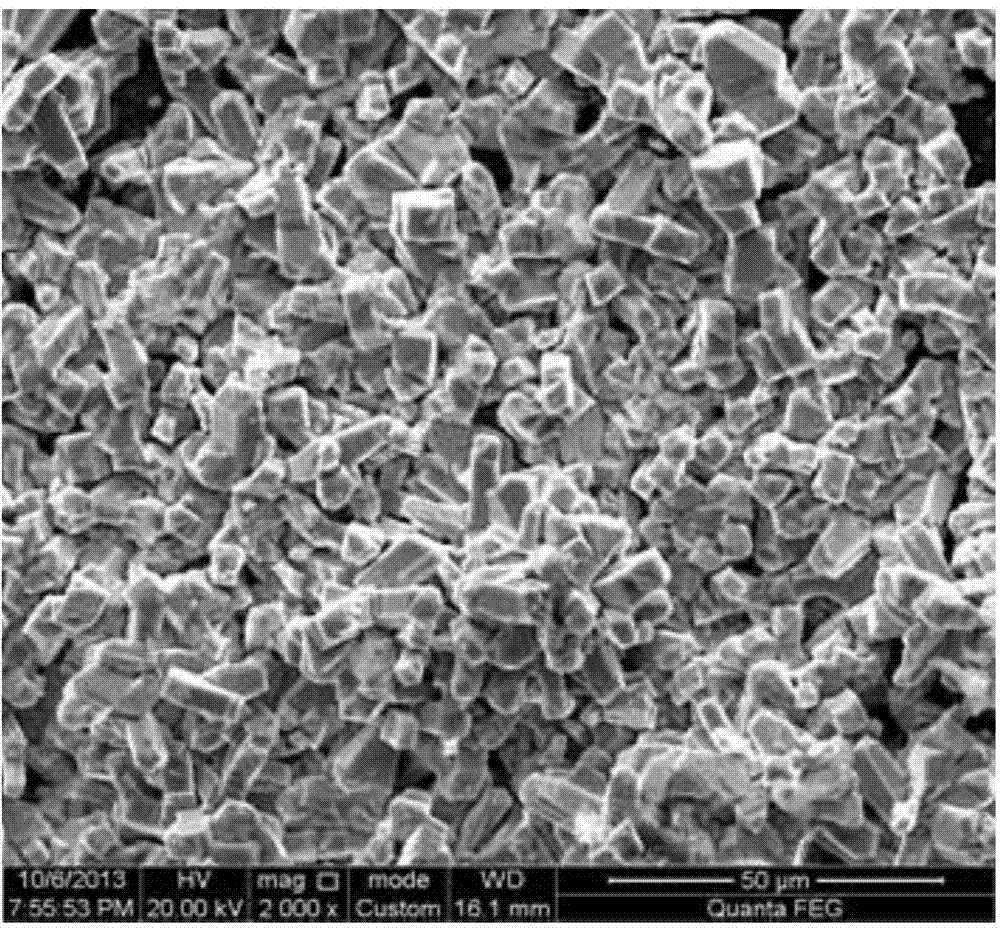

Low-cobalt hard alloy resistant to high temperature, abrasion and corrosion and preparation method thereof

The invention belongs to the technical field of powder metallurgy, and relates to a low-cobalt hard alloy resistant to high temperature, abrasion and corrosion and a preparation method thereof. The low-cobalt hard alloy resistant to high temperature, abrasion and corrosion comprises the following ingredients in parts by mass: 0.1-1.0 part of Co, 0.4-0.6 part of Cr3C2, 6.0-8.0 parts of TaC, 0.6-1.0 part of NbC, 2.0-4.0 parts of TiC and 75-90 parts of WC. The low-cobalt hard alloy provided by the invention is relatively small in WC grain size and is uniform in distribution, and has an average grain size being 0.30-0.35 [mu]m; meanwhile, the low-cobalt alloy has hardness of HRA94.6-96.5, bending strength of 2300-2700N / mm<2>, has good high temperature resistance, good abrasion resistance and good corrosion resistance, can effectively prolong the service life of a tool, and can improve cutting efficiency of the tool.

Owner:HEYUAN ZHENGXIN HARDMETAL CARBIDE

Molybdenum base nitride composite ganoine thin film and preparation thereof

InactiveCN101244644AReduce the temperatureNo holesLayered productsVacuum evaporation coatingMo elementArea ratio

The invention discloses a Mo-based nitride composite hard film and a preparation method, wherein the substrate is coated with nanometer composite hard film that is made of Mo-based metal nitride or nonmetal nitride, the crystallized size of the film is 5-40nm, the thickness of the film is 1-5Mum, the molar percentage between the Mo element and the substitution element in the film is 50 to 94% : 6 to 50%; the preparation method is that: (a) the target material (made of Mo and the substitution) and the substrate are respectively arranged on the cathode and sample table in vacuum room of magnetic control sputtering equipment, the area ratio of the Mo and the substitution in the target material is 1 to 8 : 8 to 1, the distance between the target material and the substrate is 40-80mm; (b) after the vacuum degree in the vacuum room is less than or equal to 8 x 10-4pa and substrate temperature reaches 300 to 500 DEG C, the vacuum room is made to be in the atmosphere of argon and nitrogen mixed gas and 30-130 minutes sputtering is made so as to prepare the Mo-based nitride composite hard film. The invention can widely be used for material protection and can improve abradability and durability of material obviously.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Brake block friction material taking Mn+1XAn lamellar compound as antifriction phase and preparation method

InactiveCN103184385AModerate enhancementImprove stabilityFriction liningRoom temperatureSilicon oxide

The invention discloses a brake block friction material taking a Mn+1XAn lamellar compound as an antifriction phase and a preparation method. The friction material comprises components in percentage by mass as follows: 20%-60% of copper, 0-20% of nickel, 5%-15% of ferrum, 3%-10% of silicon oxide, 0-10% of chromium, 0-4% of molybdenum sulfide and 15%-35% of Mn+1XAn, and the components are technical pure. The preparation method for the friction material comprises the steps as follows: (1) mixing the raw materials; (2), assembling; and (3) hot pressed sintering. The hardness of the copper based friction composite material sintering body obtained by the invention is HRB56-65, and the relative density is 92%-94%. Moreover, the friction coefficient ranges from 0.38 to 0.53, is still maintained within the range at the room temperature of subzero 600 DEG C, and is stabilized in a range from about 0.40 to 0.43 after initial seconds, excellent high-temperature stability is shown, and use requirements of brake blocks of high speed trains can be met completely.

Owner:YANSHAN UNIV

Surface strengthening method of extrusion die

ActiveCN104195553AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingComposite filmThin membrane

The invention proposes a surface strengthening method of an extrusion die. The method comprises the following steps: introducing a superhard coating life-extending technology, removing oil stains on the surface and close to the surface and participating solid particles by a reasonable surface pretreatment mode, and then carrying out die surface strengthening in an environment at 150-200 DEG C by adopting a multi-layer composite deposition film. Particularly, a multi-layer composite film structure, which takes a TiN film as a priming coat and is combined with a TiAlN film and a CrN film, is formed on the surface of the extrusion die; the friction coefficient of the die surface is reduced by over 60% on the premise that the mechanical property and the geometric accuracy of a die base material are not affected, the Vickers hardness of the die surface is improved by over 2.5 times, the service life of the die is prolonged by over three times, the exchange frequency of the extrusion die and the workload of operating personnel in the production process are greatly reduced, the usability and the production efficiency of the extrusion die are improved, and the equipment cost is reduced.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Polyvinyl PTC thermo-sensitive conductive composite material and manufacturing method thereof

InactiveCN101870783AImprove conductivityImprove thermal conductivityNon-conductive material with dispersed conductive materialRoom temperatureStearic acid

The invention relates to a polyvinyl PTC thermo-sensitive conductive composite material, which comprises a base material and an additive, wherein the base material comprises 10-25% of LDPE, 20-40% of TiB2, 0-8% of CB and the balance of HDPE, and the additive comprises 0.1-0.3% of antioxidant1010, 1-3% of stearic acid, 1-2% vinyl trimethoxysilane, 3-5% of Sb2O3 and 8-12% of decabromodiphenyl ethane; and the adding amount of the additive is measured by the mass of organic matter components in the base material. The material has room temperature resistivity of 23.5omega . cm, long-term current capacity flow of greater than 100A and PTC intensity of 7.8, and resistance keeps stable after 100 thermal cycles.

Owner:合肥上雅电子科技有限公司

Polyethylene/titanium diboride PTC (Positive Temperature Coefficient) composite material and preparation method thereof

InactiveCN102702603AImprove conductivityImprove thermal conductivityNon-conductive material with dispersed conductive materialLow-density polyethyleneVolumetric Mass Density

The invention discloses a polyethylene / titanium diboride PTC (Positive Temperature Coefficient) composite material and a preparation method thereof. The polyethylene / titanium diboride PTC composite material is prepared from the raw materials consisting of main materials and processing auxiliary agents, wherein the main materials comprise the following components in percentage by mass: 10-25 percent of low density polyethylene, 40.1-50 percent of TiB2, 0-6 percent of CB and the balance of high density polyethylene; and the processing auxiliary materials comprise antioxidant 1010, stearic acid, a coupling agent of vinyl trimethoxy silane, antimony trioxide and a fire retardant of decabromodiphenylethane. The polyethylene / titanium diboride PTC composite material has low room temperature resistivity, high voltage resistance, heavy current resistance, long-term flow stability performance, high PTC strength and high PTC stability.

Owner:HEFEI UNIV OF TECH

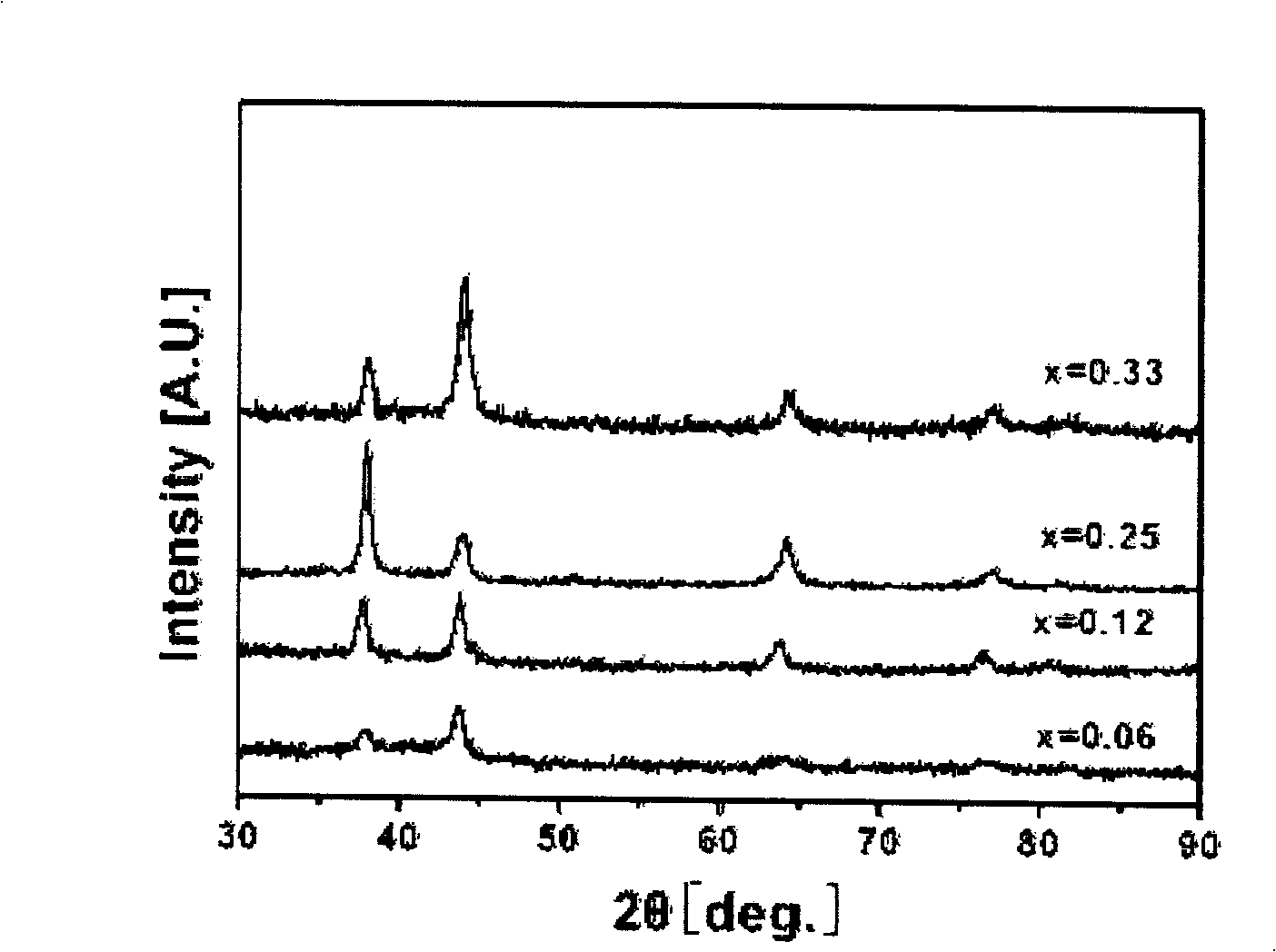

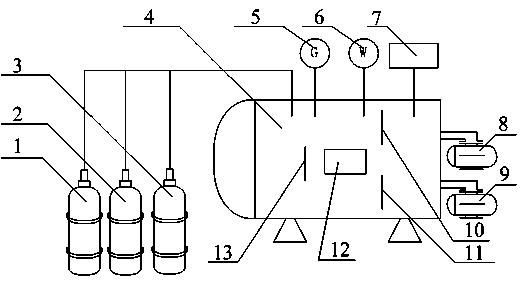

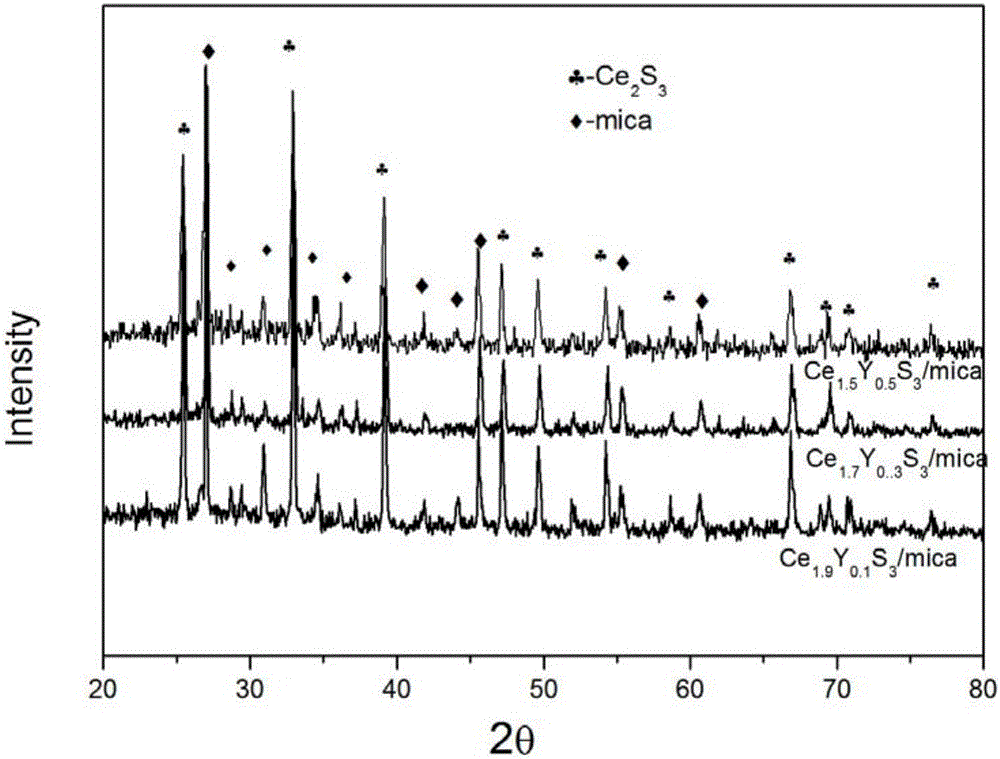

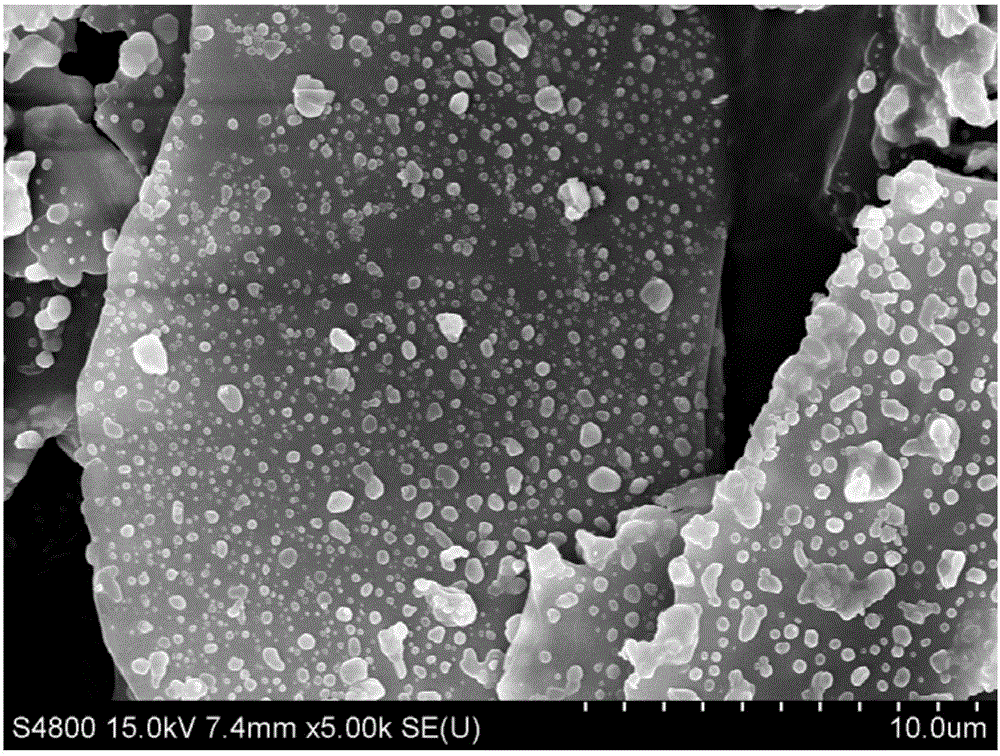

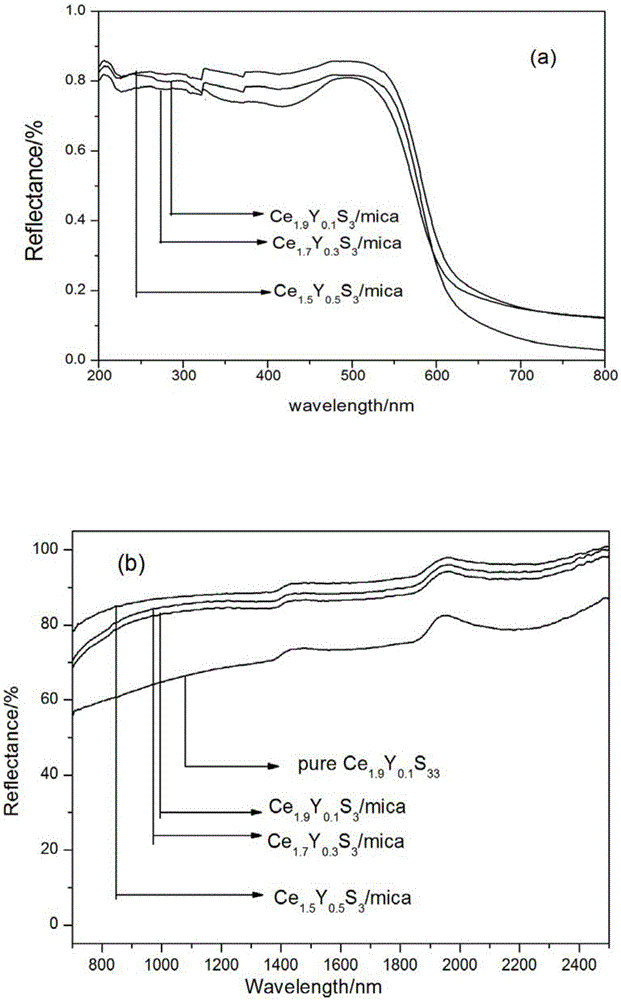

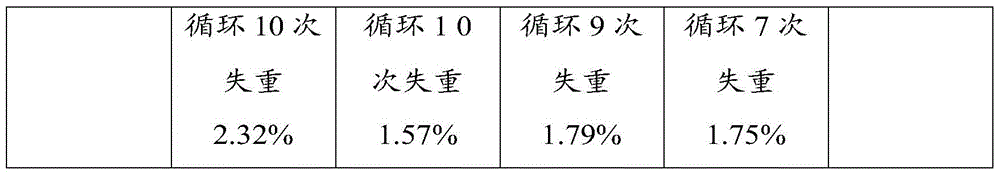

Doped high-infrared reflection rare-earth sesquisulfide gamma-Ce2S3 coated mica pearlescent pigment and preparation method thereof

InactiveCN106009786AUniform particle sizeGood dispersionInorganic pigment treatmentThermal insulationRare earth

The invention discloses a doped high-infrared reflection rare-earth sesquisulfide gamma-Ce2S3 coated mica pearlescent pigment and a preparation method thereof. The preparation method comprises the following steps: preparing a mixed oxide coated mica pearlescent pigment with soft pearly luster by a sol-gel process; uniformly mixing the mixed oxide / mica pearlescent pigment with appropriate additive; and performing high-temperature sulfurizing reduction to obtain a doped rare-earth sesquisulfide Ce(2-x)MxS3 (M=Y<3+> or Nd<3+>) coated mica pearlescent pigment. The hue and tinting strength of the doped rare-earth sulfide pearlescent pigment prepared by the method change along with the type, dosage and coating rate of the doping metal M. Moreover, the sintering degree of the composite pigment is low, and the properties such as brightness and oxidation resistance of the product are remarkably improved over pure rare-earth sulfide pigment; and meanwhile, the synthesized Ce(2-x)MxS3 (M=Y<3+> or Nd<3+>) coated mica pearlescent pigment has a high ultraviolet absorption property in an ultraviolet region and a high infrared reflection property in a near infrared region and has broad application prospects in the field of anti-ultraviolet and solar heat-reflection thermal insulation coatings.

Owner:NANJING UNIV OF SCI & TECH

Carbon nano onion lubricating phase Ti (C,N) base self-lubricating composite material and preparing method thereof

ActiveCN110760729AStable structureExcellent intrinsic propertiesFracture toughnessMaterial technology

The invention provides a carbon nano onion lubricating phase Ti (C,N) base self-lubricating composite material and a preparing method thereof, and belongs to the technical field of composite materials. The composite material comprises, by weight percent, 10%-20% of OLC and 80%-90% of TiNx, wherein X in TiCx is larger than or equal to 0.4 and smaller than or equal to 0.9 or is equal to 1.1-1.3. According to the self-lubricating composite material, TiNx and OLC powder which are prepared through a mechanical alloying method and are in a non-stoichiometric ratio are mixed, hot pressing sintering is adopted for preparing the OLC lubricating phase Ti (C,N) base self-lubricating composite material, by utilization of the vacancy in TiNx, the sintering temperature can be reduced, and sintering is promoted. On the basis, the OLC lubricating phase Ti (C,N) base self-lubricating composite material is formed through composite sintering with OLC, the defect of lubricating failures of a traditional lubricating material in the extreme condition is overcome, and meanwhile hardness and fracture toughness of the OLC lubricating phase Ti (C,N) base self-lubricating composite material are improved.

Owner:YANSHAN UNIV

Aluminium tungsten carbide hard alloy sintered body

The invention relates to a tungsten-cemented aluminium carbide sintered body, and the expression is(W1-xAlx)C-Co, in which x=0.1-0.86, which is alloy block-shaped material with good crystalline shape and fine texture. Proved by X-ray powder diffraction analysis and scanning electron microscope analysis, the tungsten-cemented aluminium carbide sintered body is of stable structure, improved crystallinity and higher degree of compactness. The tungsten-cemented aluminium carbide sintered body of this invention not only has glass hard and high-wearing feature of tungsten carbide, but also has lightweight, oxidation resistance and fine ductility of aluminium, which makes the alloy have high hardness, high bending strength and lower density and develop into new carbide alloy with high hardness, high strength, good workability and high oxidation-resistance temperature. The said material is hoped to be used in mechanical tool, glass-cutting, bolt die, broaching die, bowl, well drill, mine drill, cutting drill and electrical contact material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Ce-Y-containing A1-Ti-N multicomponent composite coating and preparation thereof

InactiveCN101353776AReduce oxidation rateReduce in quantityVacuum evaporation coatingSputtering coatingSuperhard materialOxidation resistant

The invention pertains to the technical field of ultrahard materials and provides a Al-Ti-N multielement compound coating layers containing Ce-Y and a preparation method thereof, aiming at lowering the number and size of 'bulky grain' in a coating layer, promoting the anti-strip performance and anti-oxidation temperature of the coating layer and increasing film forming speed simultaneously. The compound coating of the invention adopts that the Ce-Y is deposited at least one of coating layers of Ti-N and Al-Ti-N. Simultaneously, the preparation method of the invention adopts the technical proposal that Ti target containing 0.5 percent to 3 percent of the Ce-Y by weight percentage and Ti-Al target with atomic ratio of 1: 2 or 1: 3 are vaporized and ionized, and gas of N2 is conveyed to a vacuum chamber for carrying out sedimentation of the TiN coating layers and the Al-Ti-N coating layers both containing Ce-Y. The method of the invention greatly enhances the stiffness, the abrasive resistance and the high-temperature oxidation resistance of workpieces and obviously prolongs the service life and leads the Al-Ti-N multielement compound coating layers to be applicable to the processing fields, such as cutting, dry machining and the like, with high accuracy and high speed.

Owner:CHONGYI ZHANGYUAN TUNGSTEN +1

Aluminium tungsten carbide hard alloy sintered body

The invention relates to a tungsten-cemented aluminium carbide sintered body, and the expression is(W1-xAlx)C-Co, in which x=0.1-0.86, which is alloy block-shaped material with good crystalline shape and fine texture. Proved by X-ray powder diffraction analysis and scanning electron microscope analysis, the tungsten-cemented aluminium carbide sintered body is of stable structure, improved crystallinity and higher degree of compactness. The tungsten-cemented aluminium carbide sintered body of this invention not only has glass hard and high-wearing feature of tungsten carbide, but also has lightweight, oxidation resistance and fine ductility of aluminium, which makes the alloy have high hardness, high bending strength and lower density and develop into new carbide alloy with high hardness, high strength, good workability and high oxidation-resistance temperature. The said material is hoped to be used in mechanical tool, glass-cutting, bolt die, broaching die, bowl, well drill, mine drill, cutting drill and electrical contact material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Oxidation-resistant SiC foam and preparation method thereof

The invention provides oxidation-resistant SiC foam and a preparation method thereof. Organic foam is impregnated in mixed slurry, a Si-Zr alloy is introduced into the organic foam, the Si-Zr alloy homogeneously distributed in the foam reacts with C through a cracking reaction and a melting reaction, and SiC and ZrC are generated in situ. Starting from the foam body, refractory metal Zr is introduced into the body during introduction of a C precursor, ZrC-SiC compound foam is formed, a ZrO2-SiO2 composite protective film is formed on the surface of the compound foam in a high-temperature aerobic environment, and the oxidation resistance of the whole SiC foam is improved under the synergistic effect of the two oxides; the preferable proportion range of Si and Zr in Si-Zr alloy powder is determined, the synergistic effect of the two oxides is exerted sufficiently, and the oxidation resistance and the heat resistance of the SiC foam material are improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for improving high-temperature-oxidation resistance of TC4 titanium alloy

InactiveCN106637081AAnti-oxidation temperature is highImprove high temperature oxidation resistanceAnodisationVacuum evaporation coatingPlasma electrolytic oxidationMicro arc oxidation

Provided is a method for improving high-temperature-oxidation resistance of TC4 titanium alloy. The method includes the steps that an aluminum coating with the thickness being 2-3 micrometers is deposited on the surface of the TC4 alloy through an arc ion plating technology and an aluminum target with the purity of more than 99.9wt%, and then the TC4 alloy with the aluminum coating on the surface is used as an anode at the room temperature and placed in a 100g / L sodium silicate solution so as to be subjected to micro-arc oxidation treatment for 20 minutes through a square-wave pulse power supply with the frequency of 1200 Hz and the duty ratio of 60%, wherein the square-wave pulse current density is 15 A / dm2, and during micro-arc oxidation, 304 stainless steel with the surface area 2-3 times that of the TC4 alloy is used as the cathode. An oxidized film mainly containing aluminum oxide and silicon oxide is produced on the surface of the TC4 titanium alloy, the oxidized film is high in bonding performance with the base body, namely the TC4 titanium alloy, and thus the oxidation temperature to which the TC4 titanium alloy can resist in air is increased to 800 DEG C from 500 DEGC. By means of the method, the high-temperature-oxidation resistance of the TC4 titanium alloy is remarkably improved, and the method is simple and can be widely applied.

Owner:NANCHANG HANGKONG UNIVERSITY

Modified copper powder, modification method thereof and conductive paste

PendingCN114453578AIncreased initial antioxidant temperatureAnti-oxidation temperature is highTransportation and packagingMetal-working apparatusConductive pasteThiazole

The embodiment of the invention discloses modified copper powder, a modification method of the modified copper powder and conductive paste. The modification method of the copper powder comprises the steps that deoxidation treatment is conducted on the copper powder; the copper powder subjected to deoxidation treatment is in contact with an antioxidant, so that a first coating film is formed on the surface of the copper powder, and the antioxidant comprises methylbenzotriazole and / or 2-mercaptobenzothiazole sodium salt. According to the modification method, a hydrophobic and compact coating layer is formed on the surface of the copper powder through the coordination effect of methylbenzotriazole and / or 2-mercaptobenzothiazole sodium salt and the copper powder, oxidation resistance and corrosion resistance protection is provided for the copper powder, the initial oxidation resistance temperature of the copper powder under the high-humidity condition is increased to 170-250 DEG C, and the oxidation resistance of the copper powder is improved. And the stability in the environment is enhanced.

Owner:LONGI SOLAR TECH (XIAN) CO LTD

Method for preparing Y2Si2O7 whisker-toughened mullite composite coating

ActiveCN102924108BImprove the effect of anti-erosion shear stressImprove antioxidant capacityLoss rateActive agent

The invention relates to a method for preparing a Y2Si2O7 whisker-toughened mullite composite coating. The method comprises the following steps: preparing a SiC porous internal coating on the matrix surface of a C / C composite material through an embedding method, preparing Y2Si2O7 whiskers, and then performing surface modification to the Y2Si2O7 whiskers with a composite surface active agent to obtain a mixed liquor; and performing ultrasonic electrophoretic selective assembly deposition to the C / C composite material prepared with the SiC porous internal coating and the mixed liquor to obtain a Y2Si2O7 whisker pinning layer, and finally preparing the Y2Si2O7 whisker-toughened mullite composite coating through a hydrothermal electrophoretic deposition method. Compared with other coatings, the prepared Y2Si2O7 whisker-toughened mullite composite coating can effectively increase the oxidation-resistance temperature, can realize the anti-oxidation protection of 400 hours for the C / C composite material under the condition of dynamic brush of high temperature (1700 DEG C) gas, and the oxidation loss rate is lower than 0.77 percent.

Owner:杨洁如

Preparation method of Y4Si3O12 whisker toughened mullite composite coating

ActiveCN102951920AImprove the effect of anti-erosion shear stressImprove antioxidant capacityElectrophoresisMullite

The invention discloses a preparation method of an Y4Si3O12 whisker toughened mullite composite coating. The preparation method comprises the following steps of: preparing a SiC porous internal coating on the surface of a C / C composite material substrate by using an embedding method; preparing Y4Si3O12 whisker and performing surface modification on the Y4Si3O12 whisker by using composite surfactant to obtain mixed solution; performing ultrasonic electrophoresis selective assembly and deposition by using the C / C composite material prepared with the SiC porous internal coating on the surface and the mixed solution to obtain a Y4Si3O12 whisker pinning layer; and finally preparing the Y4Si3O12 whisker toughened mullite composite coating by using a hydrothermal electrophoretic deposition method. Compared with other coatings, the Y4Si3O12 whisker toughened mullite composite coating has the advantages that the anti-oxidation temperature can be effectively improved, anti-oxidation protection of 450 hours for the C / C composite material can be achieved under the high-temperature gas dynamic erosion condition of 1,500 DEG C, and the oxidation weight loss ratio is less than 0.62 percent.

Owner:吴文婕

Copper-nickel alloy powder for ultralow-resistance chip resistor

InactiveCN106435259ALower sintering temperatureLow melting pointConductive materialMetal/alloy conductorsGas phaseMicrometer

The invention provides copper-nickel alloy powder for an ultralow-resistance chip resistor. The copper-nickel alloy powder is characterized by being prepared from following components of 35-45 wt% of Ni, smaller than 1 wt% of Mn, smaller than 1 wt% of Fe and the balance Cu. The grain diameter of the copper-nickel alloy powder is uniform, and the average grain diameter ranges from 0.3 micrometer to 3 micrometers; and through further screening and high-precision gas phase classification, granularity distribution of the powder can be adjusted and controlled, upgrading of the printing process of a thick film of a low chip resistor can be promoted, the thickness is close to that achieved through a thin film evaporation process, and therefore the electrical performance of the ultralow-resistance chip resistor is improved.

Owner:JIANGSU BOQIAN NEW MATERIALS

Anti-oxidation HfC/SiC foam and preparation method thereof

The invention provides anti-oxidation HfC / SiC foam and a preparation method thereof. Organic foam is impregnated with mixed slurry, a silicon-hafnium alloy is introduced into the organic foam, cracking and melting reactions are performed, so that the silicon-hafnium alloy homogenously distributed in the foam reacts with carbon, and SiC and HfC are produced in situ. Starting from a foam body, refractory metal Hf is introduced into the body while a carbon precursor is introduced, HfC / SiC composite foam is formed, an HfO2 and SiO2 composite protective membrane is formed on the surface in a high-temperature aerobic environment, and the oxidation resistance of the foam is improved under the synergistic effect of two oxides.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method of Y4Si3O12 whisker toughened mullite composite coating

ActiveCN102951920BImprove the effect of anti-erosion shear stressImprove antioxidant capacityElectrophoresisMullite

The invention discloses a preparation method of an Y4Si3O12 whisker toughened mullite composite coating. The preparation method comprises the following steps of: preparing a SiC porous internal coating on the surface of a C / C composite material substrate by using an embedding method; preparing Y4Si3O12 whisker and performing surface modification on the Y4Si3O12 whisker by using composite surfactant to obtain mixed solution; performing ultrasonic electrophoresis selective assembly and deposition by using the C / C composite material prepared with the SiC porous internal coating on the surface and the mixed solution to obtain a Y4Si3O12 whisker pinning layer; and finally preparing the Y4Si3O12 whisker toughened mullite composite coating by using a hydrothermal electrophoretic deposition method. Compared with other coatings, the Y4Si3O12 whisker toughened mullite composite coating has the advantages that the anti-oxidation temperature can be effectively improved, anti-oxidation protection of 450 hours for the C / C composite material can be achieved under the high-temperature gas dynamic erosion condition of 1,500 DEG C, and the oxidation weight loss ratio is less than 0.62 percent.

Owner:吴文婕

A kind of preparation method of c/c composite material and its surface anti-oxidation composite coating

Owner:HEBEI VOCATIONAL & TECHN COLLEGE OF BUILDING MATERIALS

A kind of low cobalt cemented carbide with high temperature resistance, wear resistance and corrosion resistance and preparation method thereof

The invention belongs to the technical field of powder metallurgy, and relates to a low-cobalt hard alloy resistant to high temperature, abrasion and corrosion and a preparation method thereof. The low-cobalt hard alloy resistant to high temperature, abrasion and corrosion comprises the following ingredients in parts by mass: 0.1-1.0 part of Co, 0.4-0.6 part of Cr3C2, 6.0-8.0 parts of TaC, 0.6-1.0 part of NbC, 2.0-4.0 parts of TiC and 75-90 parts of WC. The low-cobalt hard alloy provided by the invention is relatively small in WC grain size and is uniform in distribution, and has an average grain size being 0.30-0.35 [mu]m; meanwhile, the low-cobalt alloy has hardness of HRA94.6-96.5, bending strength of 2300-2700N / mm<2>, has good high temperature resistance, good abrasion resistance and good corrosion resistance, can effectively prolong the service life of a tool, and can improve cutting efficiency of the tool.

Owner:HEYUAN ZHENGXIN HARDMETAL CARBIDE

Preparation and use method of graphite antioxidant

The invention discloses a preparation method and a use method of a graphite antioxidant, belonging to the technical field of graphite antioxidants. The preparation method of the graphite antioxidant comprises the following step: S1, adding 30-100 parts of alkoxy silane into a reaction kettle, and then adding an aqueous solution of acetic acid, hydrochloric acid and the like, wherein the aqueous solution of acetic acid, hydrochloric acid and the like is prepared by dissolving 10-50 parts of acetic acid, hydrochloric acid and the like in 100 parts of water and then conducting uniform stirring. The boron / silicon-based antioxidant can be completely dissolved in water, a common organic solvent is not adopted, and no VOCs are discharged when the antioxidant is used; the antioxidant is faintly acid or neutral, so corrosion to a reaction container or other steel and the like is basically avoided; and after a graphite material is soaked or brushed with the antioxidant, a network structure such as Si-O-B-O-C can be formed through heat treatment, so pores or active sites of the graphite material can be better protected, and the anti-oxidation temperature of the graphite material is increased to 1000-1100 DEG C.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

Recyclable unmanned aerial vehicle booster shell and manufacturing method

PendingCN110104198ASuper hard and wear-resistantWith high and low temperature resistanceLaunching/towing gearTransition metal carbidesPolyvinyl alcohol

The invention discloses a recyclable unmanned aerial vehicle booster shell. The recyclable unmanned aerial vehicle booster shell mainly comprises a flange plate and a cylinder, a circle of groove is formed by centering the center of the upper part of a front end positioning flange plate, a groove hole in a circular truncated cone shape is formed by centering the center of the groove, the bottom end surface of the groove hole is integrally connected with the bottom end of a slope surface shell in a circular truncated cone shape in a flush mode, and the slope surface shell in a circular truncated cone shape is closely connected with the groove hole in a circular truncated cone shape; the top end of the slope surface shell in a circular truncated cone shape is integrally connected with one end of the cylinder; and a circle of step part is processed on the lower part of the front end positioning flange plate. In raw materials, a silicon nitride ceramic material is used for replacing the original high temperature-resistance metal; the silicon nitride ceramic material is prepared from components in parts by mass: 95-99 parts of silicon nitride ceramic powder, 1-2 parts of metal oxide, 5-8 parts of rare earth oxide mixtures, 0-1 part of transition metal carbide, 1 part of polyvinyl alcohol, 0-2 parts of alumina and deionized water in the amount of three times the amount of the siliconnitride powder. The recyclable unmanned aerial vehicle booster shell has the advantages of high hardness, wear resistance, high and low temperature resistance and recyclability.

Owner:NEW DELONG SPECIAL TYPE CERAMIC DALIAN

A kind of doping type high infrared reflection rare earth sesquisulfide gamma-ce2s3 coated mica pearlescent pigment and preparation method thereof

InactiveCN106009786BUniform particle sizeGood dispersionInorganic pigment treatmentThermal insulationRare earth

The invention discloses a doped high-infrared reflection rare-earth sesquisulfide gamma-Ce2S3 coated mica pearlescent pigment and a preparation method thereof. The preparation method comprises the following steps: preparing a mixed oxide coated mica pearlescent pigment with soft pearly luster by a sol-gel process; uniformly mixing the mixed oxide / mica pearlescent pigment with appropriate additive; and performing high-temperature sulfurizing reduction to obtain a doped rare-earth sesquisulfide Ce(2-x)MxS3 (M=Y<3+> or Nd<3+>) coated mica pearlescent pigment. The hue and tinting strength of the doped rare-earth sulfide pearlescent pigment prepared by the method change along with the type, dosage and coating rate of the doping metal M. Moreover, the sintering degree of the composite pigment is low, and the properties such as brightness and oxidation resistance of the product are remarkably improved over pure rare-earth sulfide pigment; and meanwhile, the synthesized Ce(2-x)MxS3 (M=Y<3+> or Nd<3+>) coated mica pearlescent pigment has a high ultraviolet absorption property in an ultraviolet region and a high infrared reflection property in a near infrared region and has broad application prospects in the field of anti-ultraviolet and solar heat-reflection thermal insulation coatings.

Owner:NANJING UNIV OF SCI & TECH

A nickel-based alloy ultra-high temperature enamel coating and its preparation method

The invention discloses a nickel-based alloy ultra-high temperature enamel coating and a preparation method thereof. The enamel coating comprises the following chemical components in parts by mass: 60-65 parts of glass material, 35-40 parts of aluminum oxide and titanium oxide composite ceramic material, 4-6 parts of kaolin and 65-70 parts of water, wherein the glass material comprises the following chemical components in percentage by mass: 40-42% of SiO2, 40-42% of BaO, 4-6% of CaO, 3-5% of TiO2, 3-4% of ZnO, 2-4% of CeO2, 1-2% of CoO and 2-3% of K2O. The preparation method comprises the following steps: sintering aluminum oxide and titanium oxide in a mole ratio of 1 to 1 to prepare composite ceramic, crushing and grinding, mixing the glass material, the aluminum oxide and titanium oxide composite ceramic material, the kaolin and the water, performing high-energy ball-milling so as to obtain enamel pulp, spraying the enamel pulp onto the surface of a nickel-based alloy, drying, and sintering for 5 minutes at 1190 DEG C, thereby obtaining the ultra-high temperature enamel coating. The nickel-based alloy ultra-high temperature enamel coating disclosed by the invention has the anti-oxidation capability of 100 hours at 1130 DEG C, and has the thermal shock resistance capability when being heated at 1000 DEG C and subsequently cooled in water of 20 DEG C for 15 times.

Owner:AIR FORCE UNIV PLA

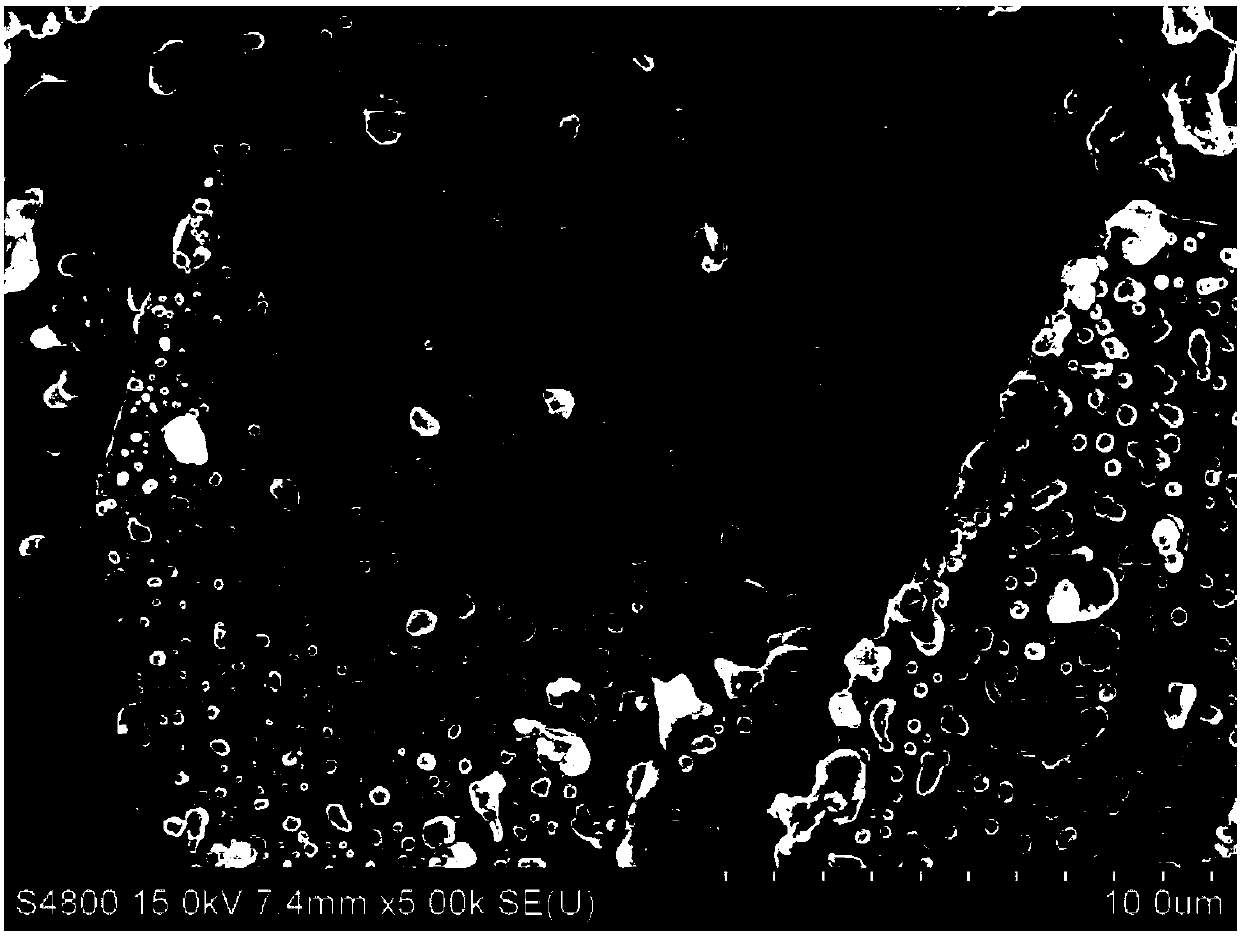

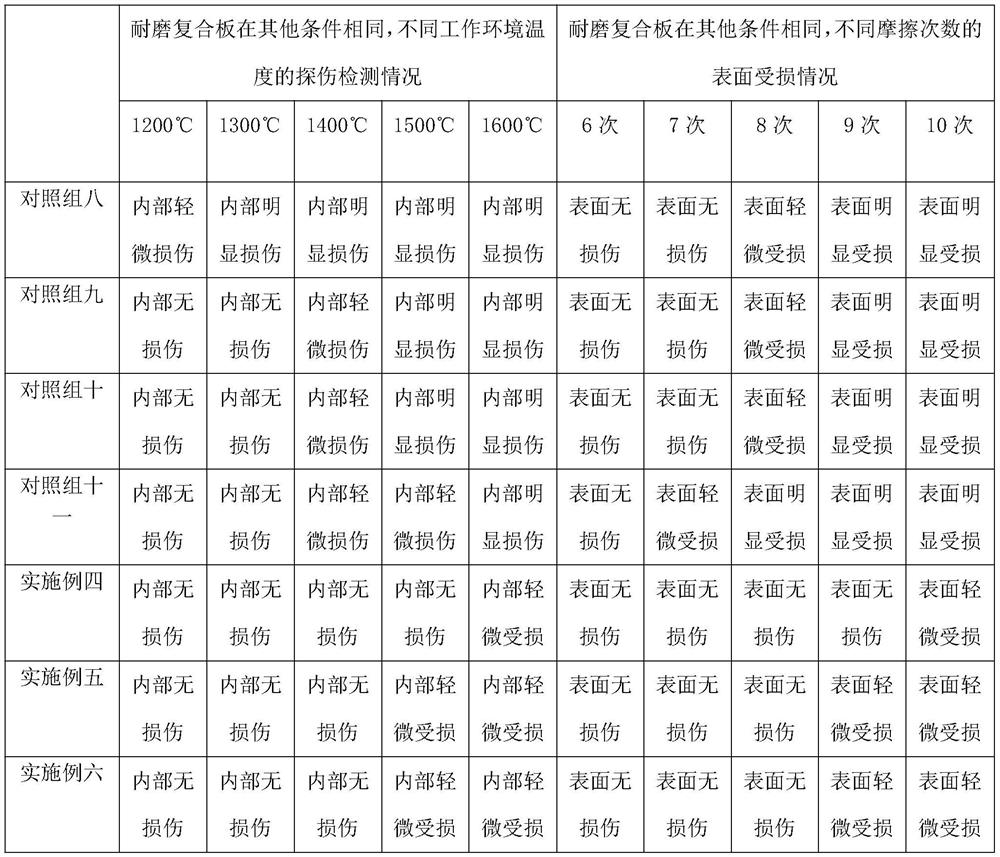

A heat-resistant and wear-resistant composite board and its preparation method

ActiveCN113292924BImprove heat resistanceImprove wear resistanceClimate change adaptationLaminationModified carbonBoron nitride

Owner:江苏沃盾耐磨新材料有限公司

A kind of tungsten-doped diamond-like coating and preparation method thereof

InactiveCN103451608BHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingDlc coatingOxidation resistant

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com