Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce dry friction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

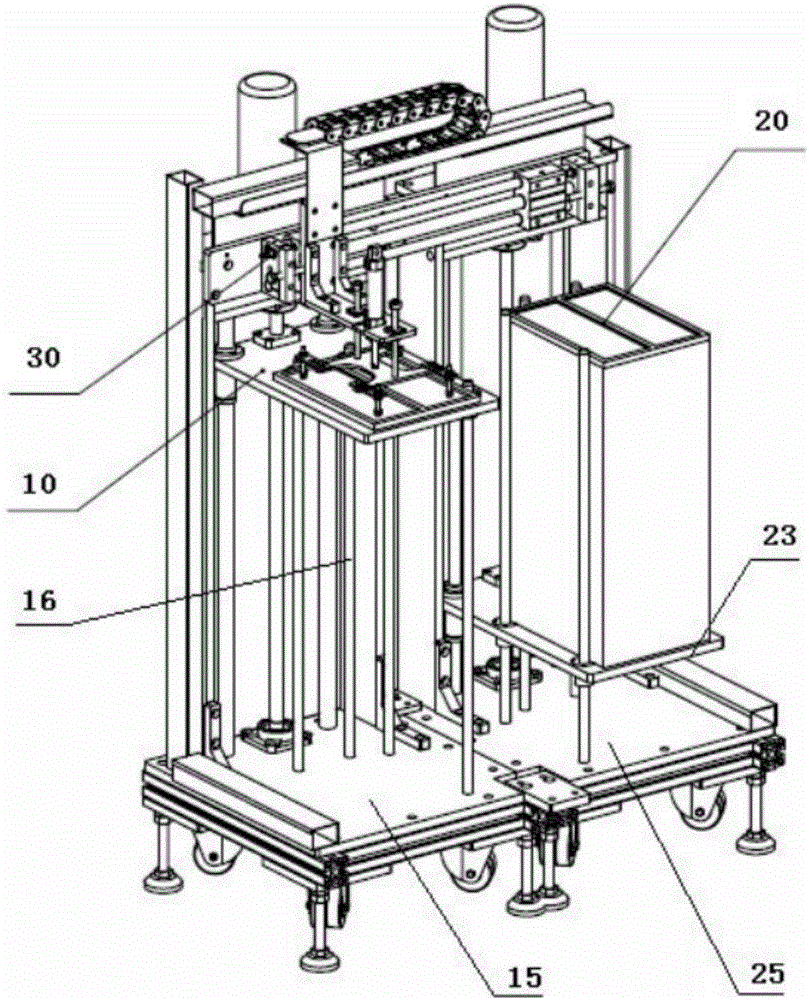

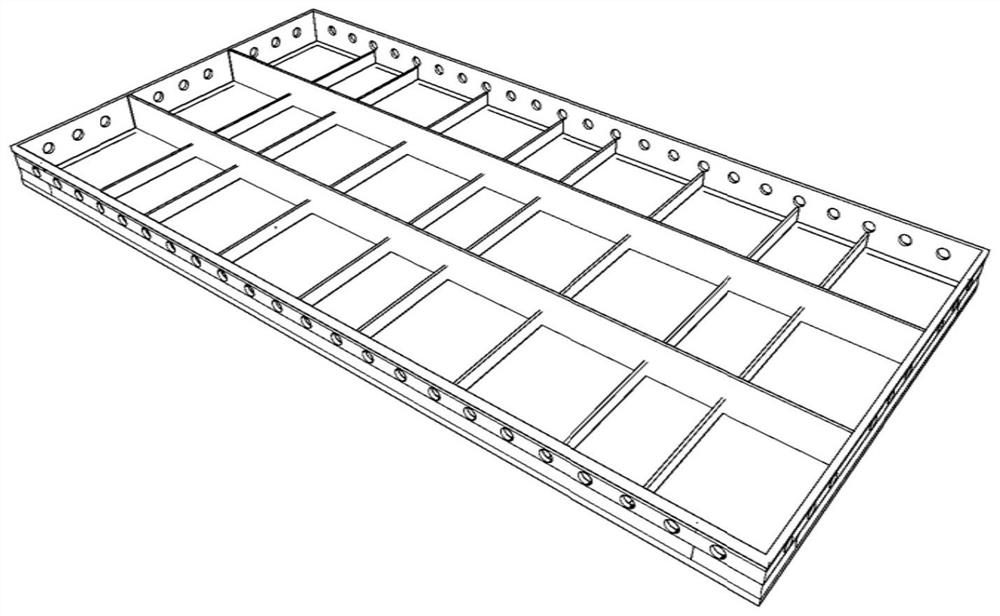

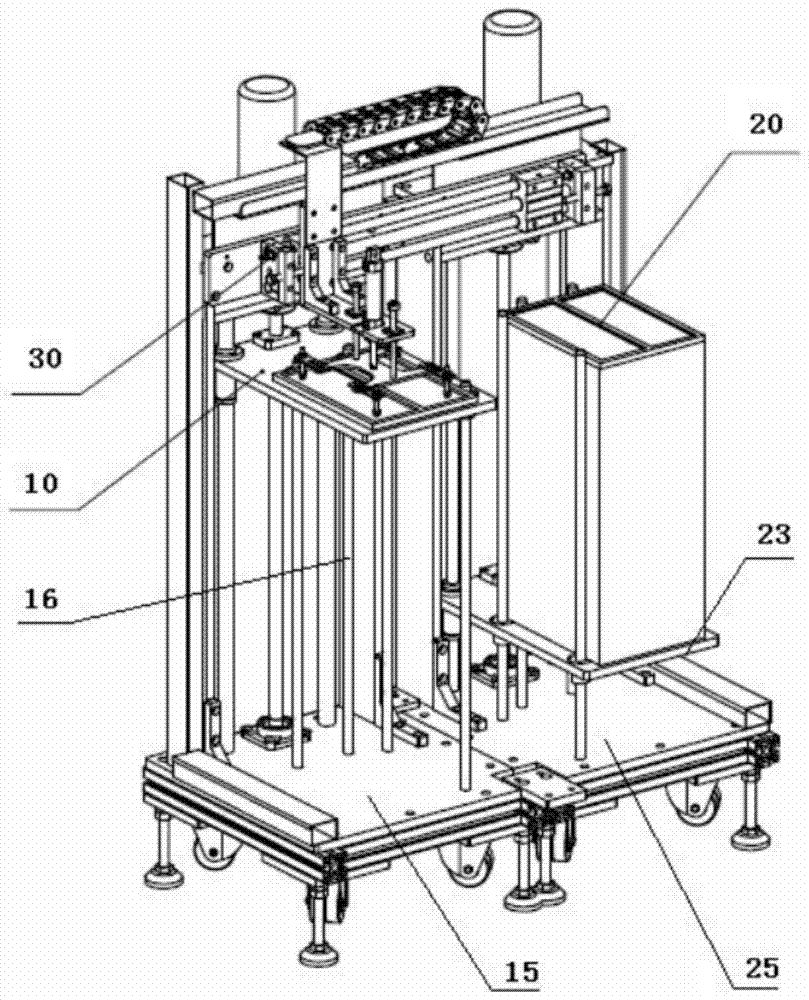

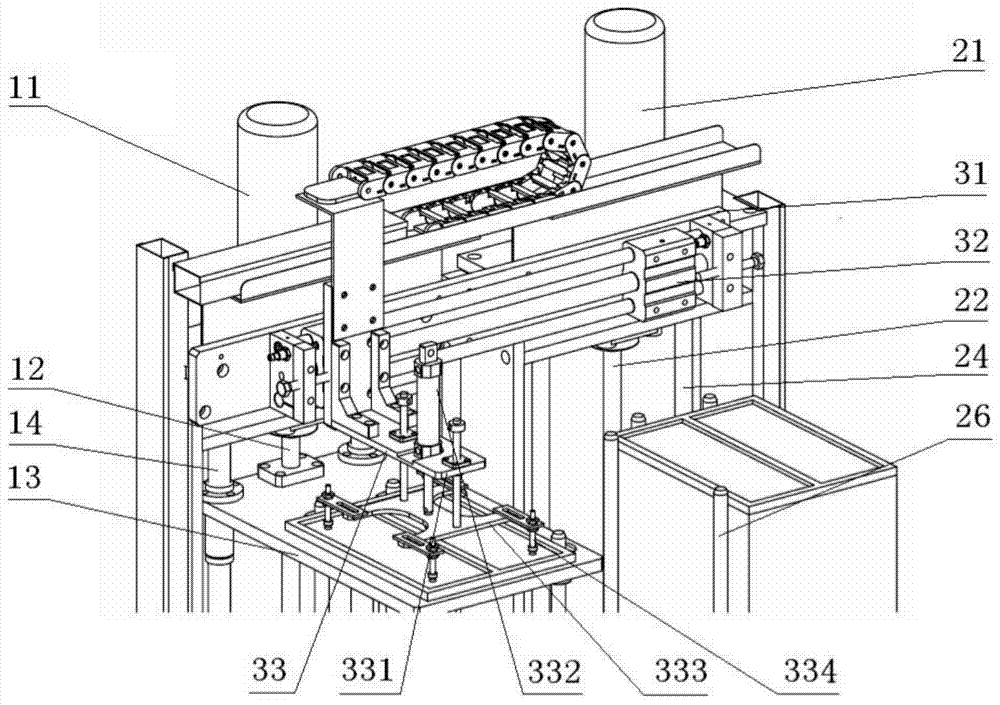

Lifting type charging tray feeding and discharging equipment

ActiveCN105293081ASave spaceGood streamlineStacking articlesDe-stacking articlesMechanical engineeringPiston

The invention discloses lifting type charging tray feeding and discharging equipment. The lifting type charging tray feeding and discharging equipment comprises an empty charging tray lifting mechanism, a discharge lifting mechanism and a moving mechanism. The empty charging tray lifting mechanism and the discharge lifting mechanism each comprise a lifting motor, a lead screw, a supporting plate and a guiding device, wherein the lead screw is connected with the lifting motor and vertically arranged; the supporting plate is in threaded connection with the lead screw and horizontally arranged; the guiding device is used for guiding ascending and descending of the supporting plate; a charging tray is borne by the supporting plate. The moving mechanism comprises a cross beam, a moving cylinder mounted on the cross beam and an unloading mechanism mounted on a piston of the moving cylinder. The moving cylinder drives the unloading mechanism to horizontally move between the empty charging tray lifting mechanism and the discharge lifting mechanism. According to the technical scheme, the lifting type charging tray feeding and discharging equipment has the beneficial effects that multiple empty charging trays can be placed at a time, and labor and time are saved; the charging trays can be taken at a time when all fully loaded with materials in the material taking process, and labor and time are saved.

Owner:SUZHOU HEROIC AUTOMATION TECH

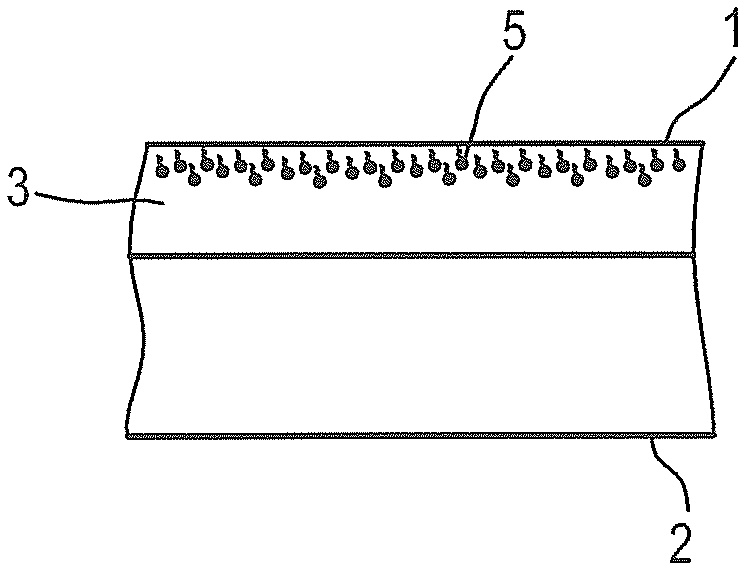

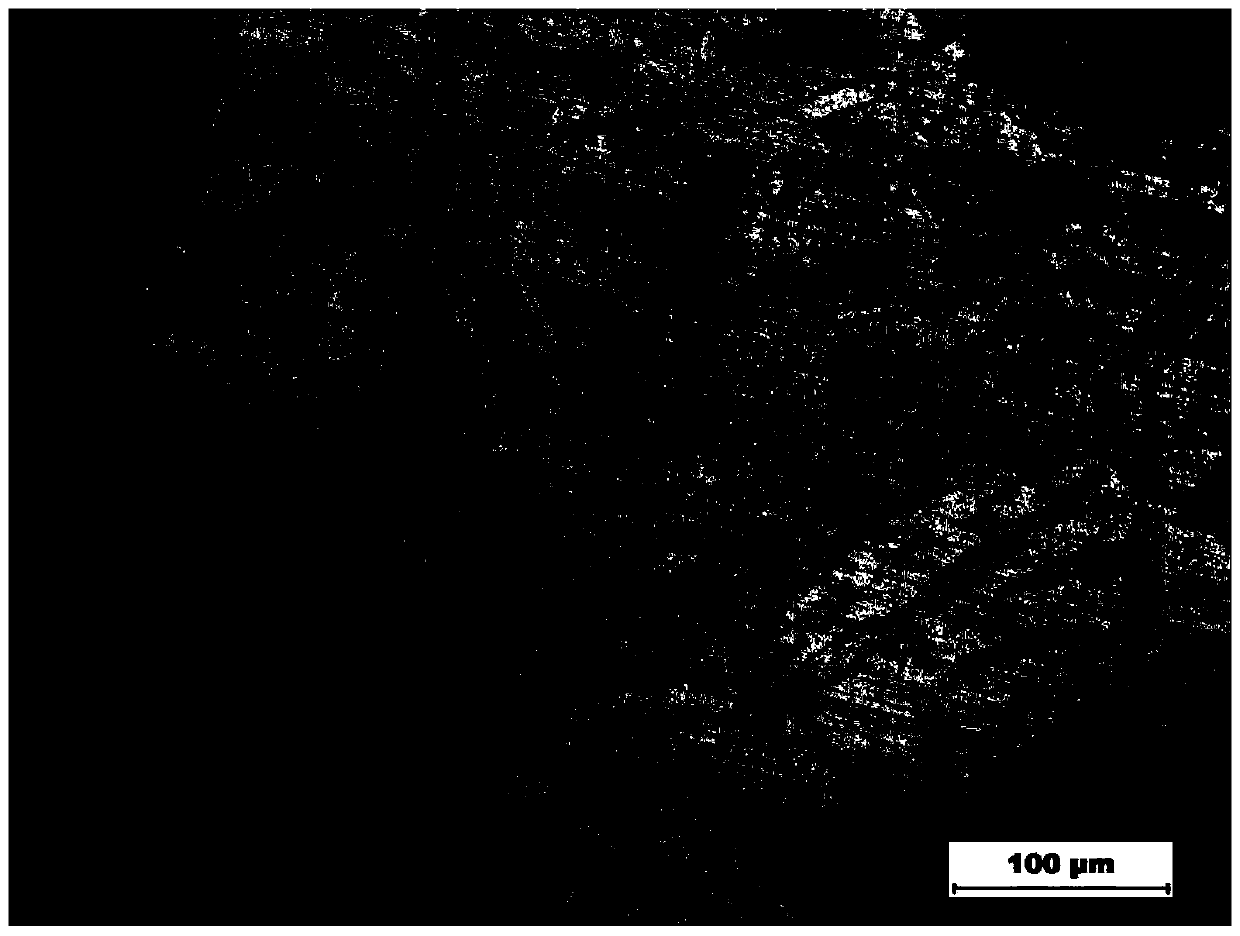

Wolframium (W) doped diamond-like coating and preparation method thereof

InactiveCN103451608AHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingChemical stabilityMaterials science

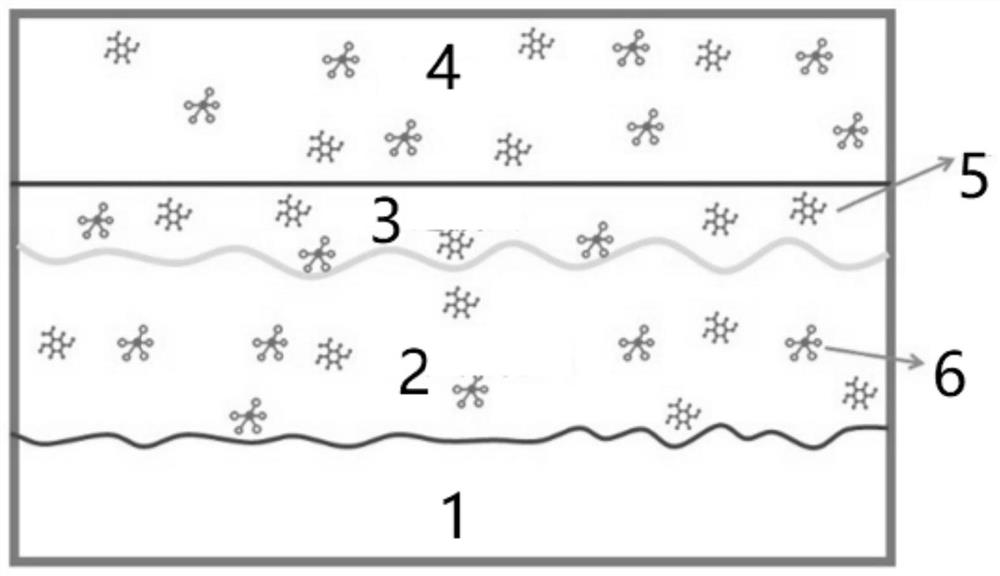

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Lubricating varnish for coating a metal component or applied to a metal component

Owner:SCHAEFFLER TECH AG & CO KG

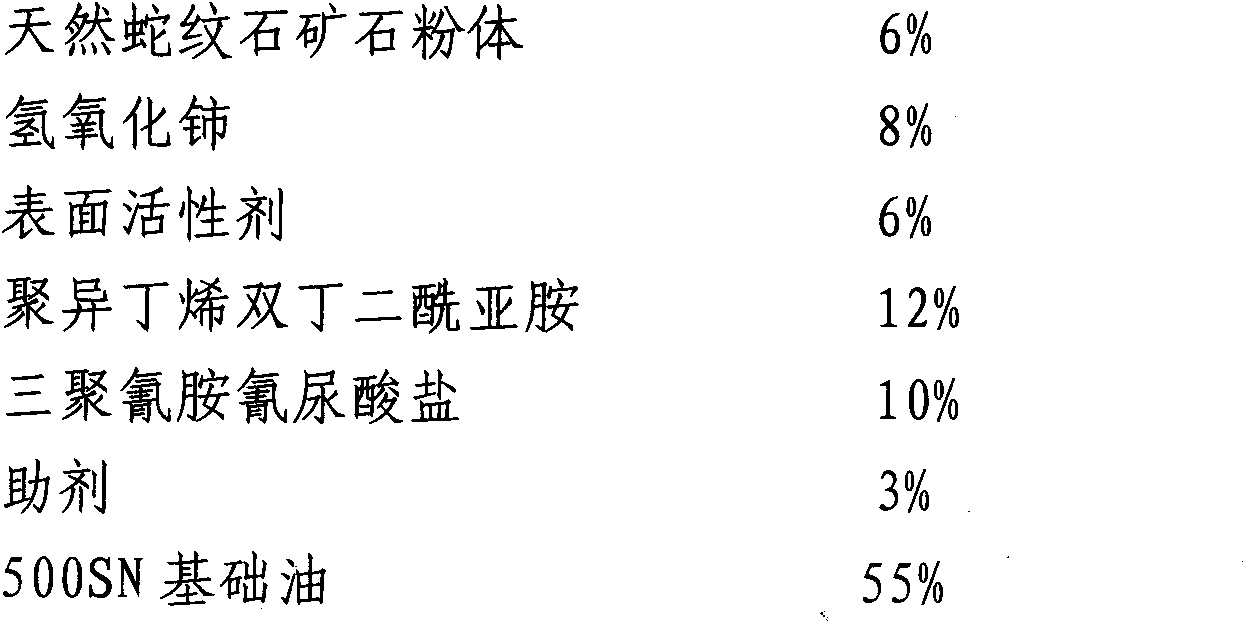

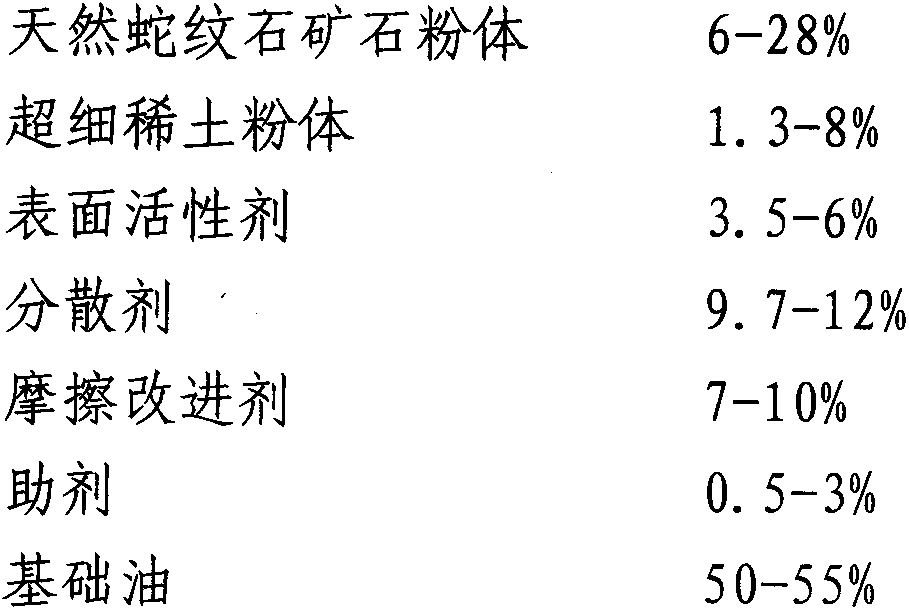

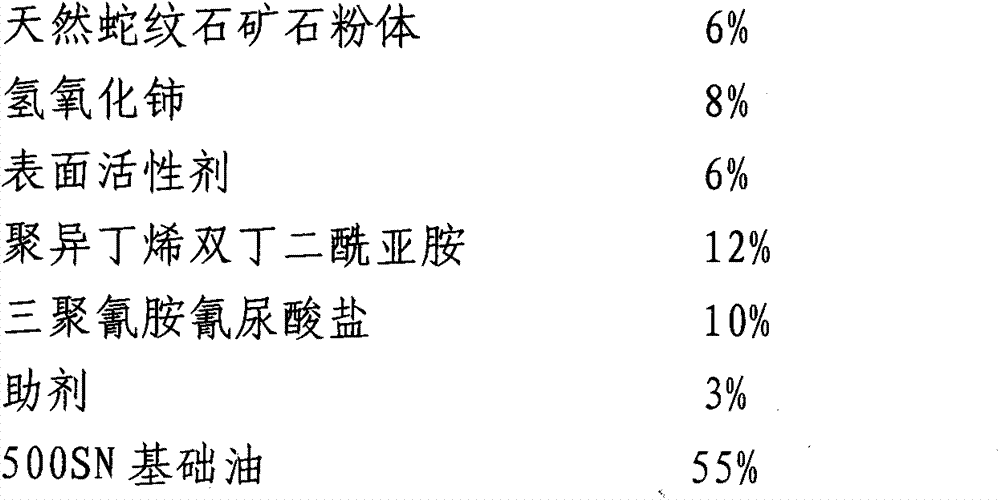

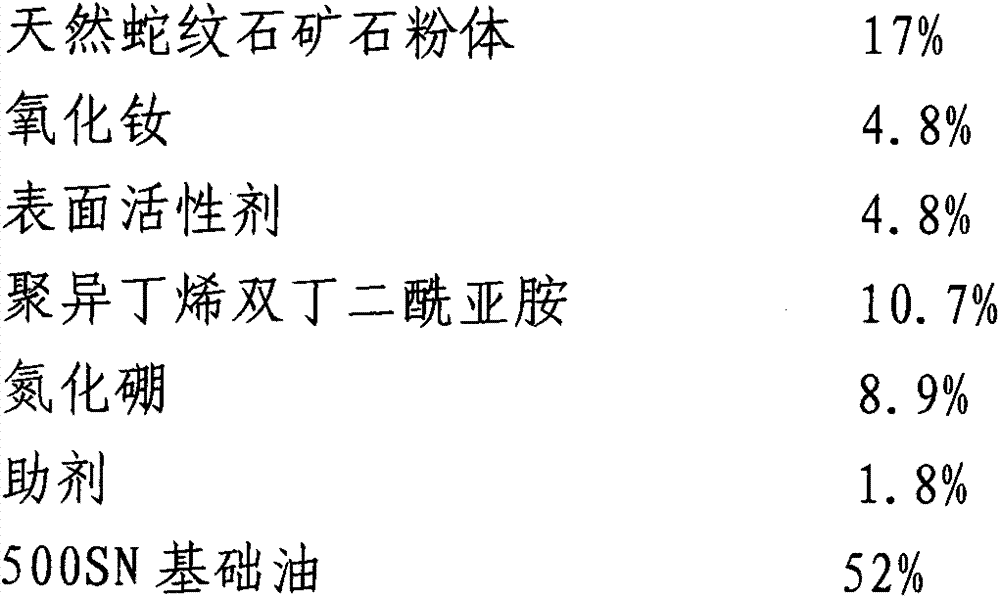

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569AAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Surface treating method for enhancing abrasive resistance and fatigue life of bearing

InactiveCN101307425ADimensionally stableReduce dry friction coefficientVacuum evaporation coatingSputtering coatingGas phaseNitrogen gas

The invention relates to a surface treatment method for improving the abrasion resistance and the fatigue life of a bearing, which is realized through the following steps: a bearing ring part is washed clean and placed into a vapor phase deposition device and is in the vacuum state, and then nitrogen and argon enter into the vapor phase deposition device for protection; and a diamond-like film is formed on the ring part by taking titanium and graphite as target materials to maintain for 0.5 to 4 hours by the physical vapor deposition method, and the deposition depth is between 500 and 1000 nanometers. The method has the advantages that: the dimension of the ring part is stable; the surface hardness of the bearing reaches over HV2500; the dry friction coefficient is reduced to between 0.1 and 0.2; the abrasion resistance is improved by 200 percent; and the fatigue life of the bearing is over 4 times of that of a general heat treatment bearing after an experiment of intensify lifespan.

Owner:C&U CO LTD

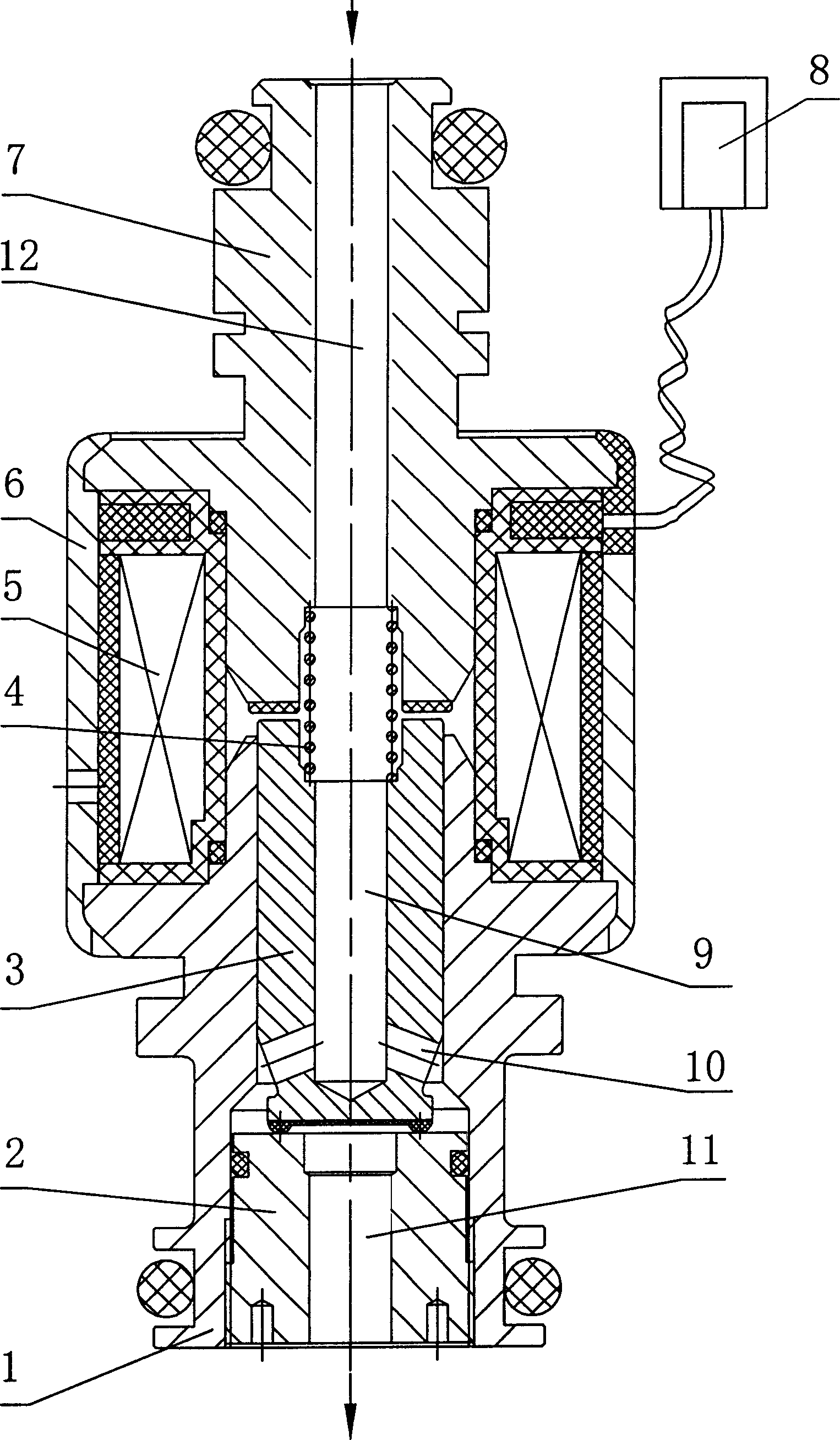

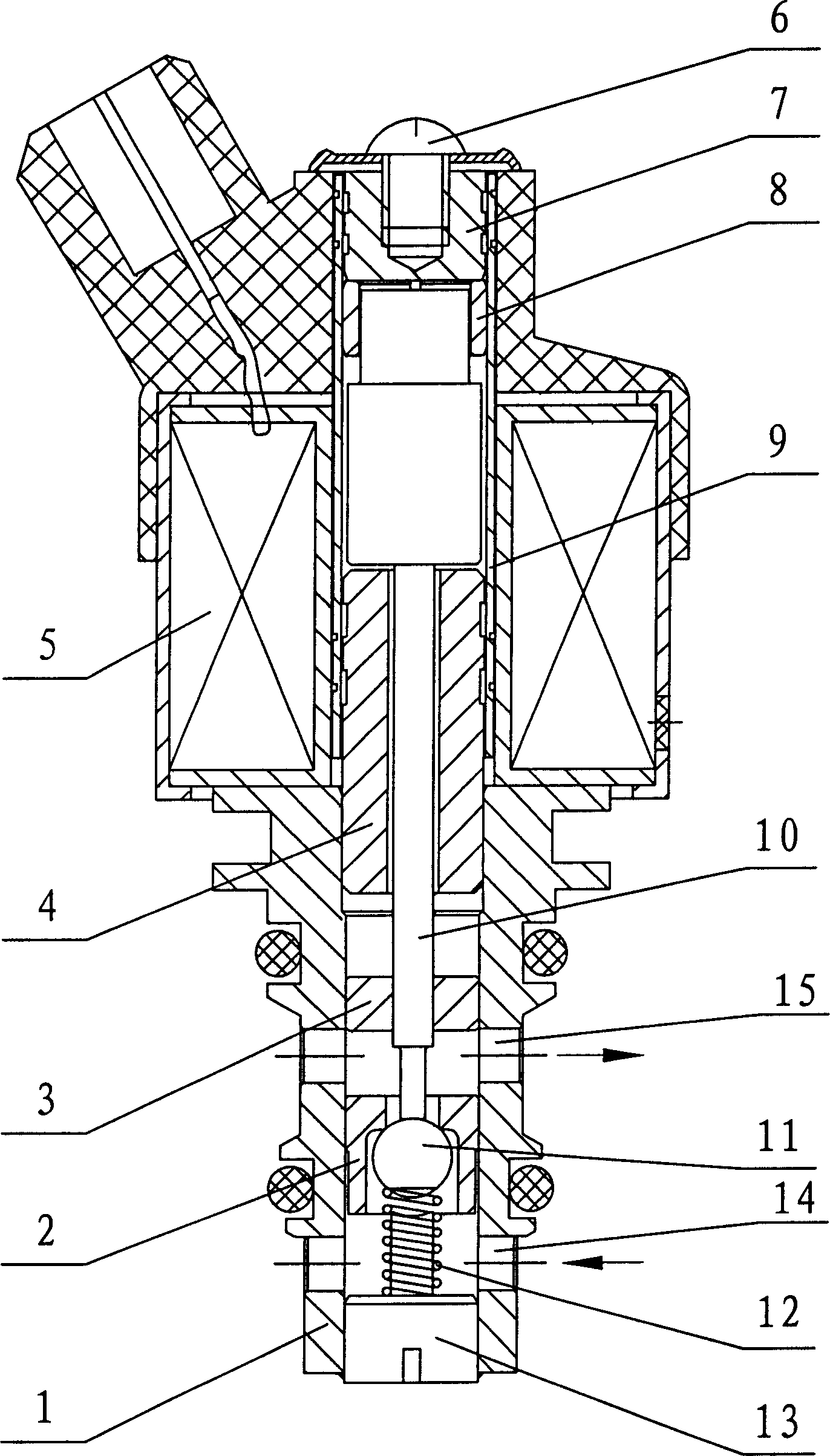

Compressed natural gas injector

InactiveCN1904339AStable jobImprove sealingInternal combustion piston enginesFuel supply apparatusCompressed natural gasEngineering

A compressed natural gas injector comprises a injector casing, a valve seat, an armature, a spring, a coil, a coil covering, a stop iron and an electric plug. The injector casing and the stop iron are inserted into the coil hole. By roll cladding and closing in of two ends of the coil covering, the coil, the coil covering, the stop iron and the injector are connected into one. The valve seat, the armature and the spring are disposed in order in the internal hole of the injector casing. There is an axial through-hole on the stop iron, an axial blind hole on top of the armature, a side hole at the bottom of the armature in communication with the axial blind hole and an axial through-hole on the valve seat. At the bottoms of the armature and the stop iron are sulphurized rubber pieces and in the internal hole of the injector casing and on the cylindrical surface of the armature are sprayed the polytetrafluoro ethylene films.

Owner:BEIJING AINY ELE MECHANICAL

Preparation method of nickel-polytetrafluoroethylene coating

ActiveCN103225098AHigh temperature resistantReduce coefficient of frictionElectrolytic coatingsPolyvinyl chlorideSilica gel

The invention relates to the technical field of electroplating, and particularly relates to a preparation method of a nickel-polytetrafluoroethylene coating. According to the invention, nickel is combined with polytetrafluoroethylene, a fluorinated ethylene-propylene copolymer, a perfluoroalkoxy copolymer and other assistants to be used as an electroplating solution and used for electroplating under certain conditions. The invention can be widely applied to various base materials such as steel, copper alloys, wrought aluminum, cast iron, stainless steel and the like, and can be also perfectly used on various injection molding materials except pure rubber, such as silica gel, TPO0, PVC (polyvinyl chloride) and the like. The coating is favorable in wear resistance and non-corrosibility, has weldability and hardenability, and causes no negative effect on the surfaces of other molds.

Owner:模德模具(东莞)有限公司

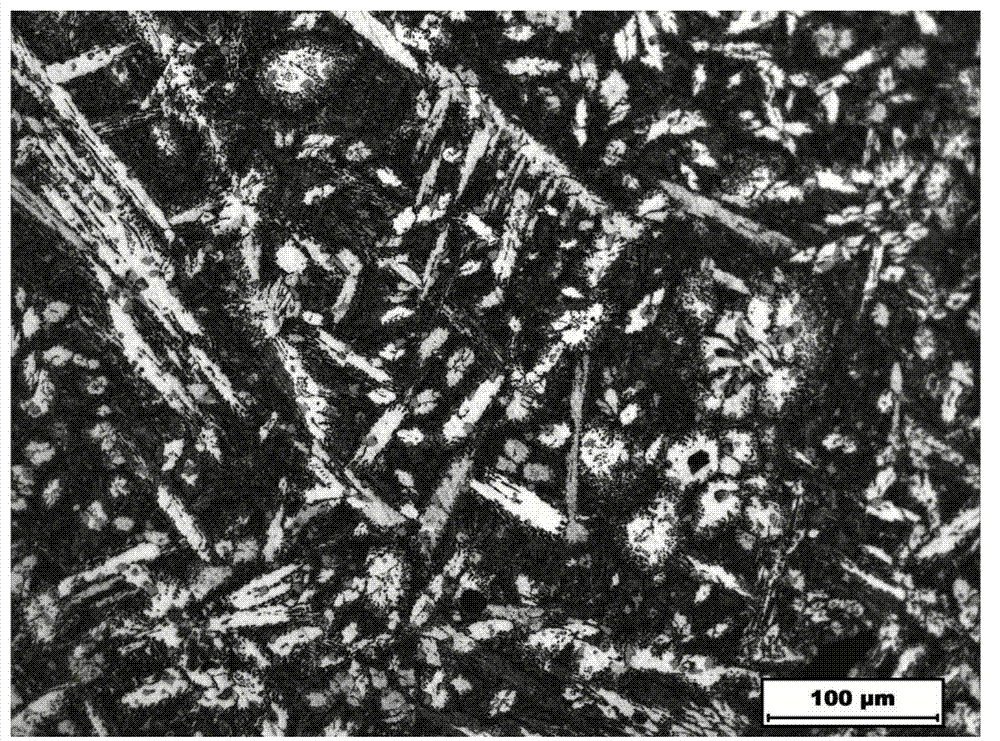

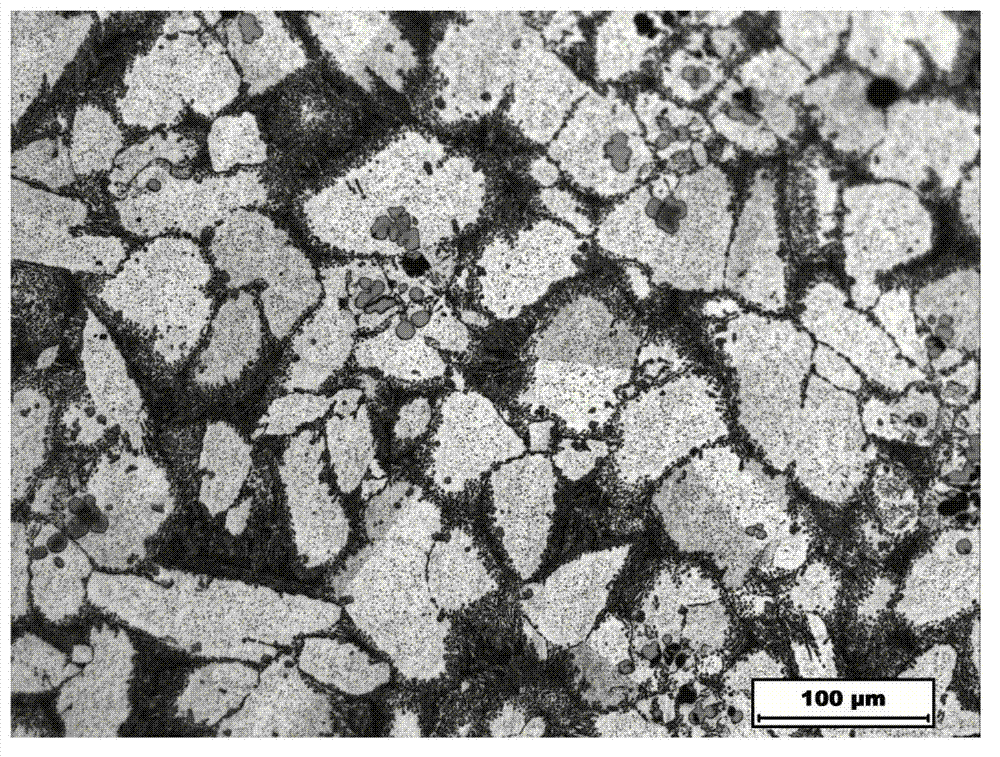

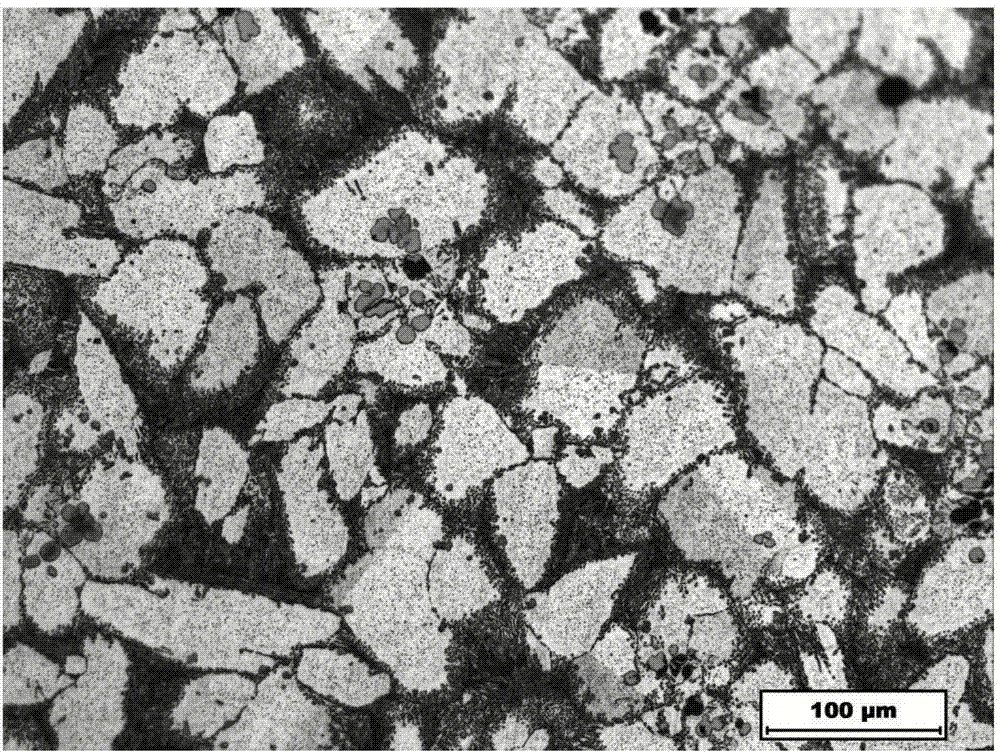

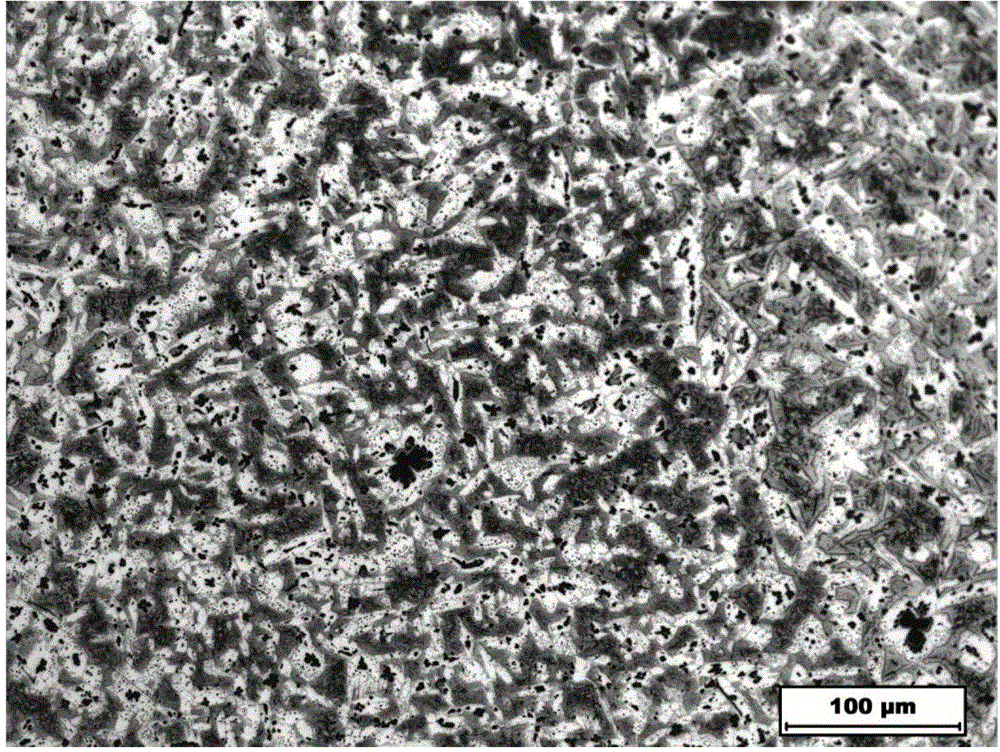

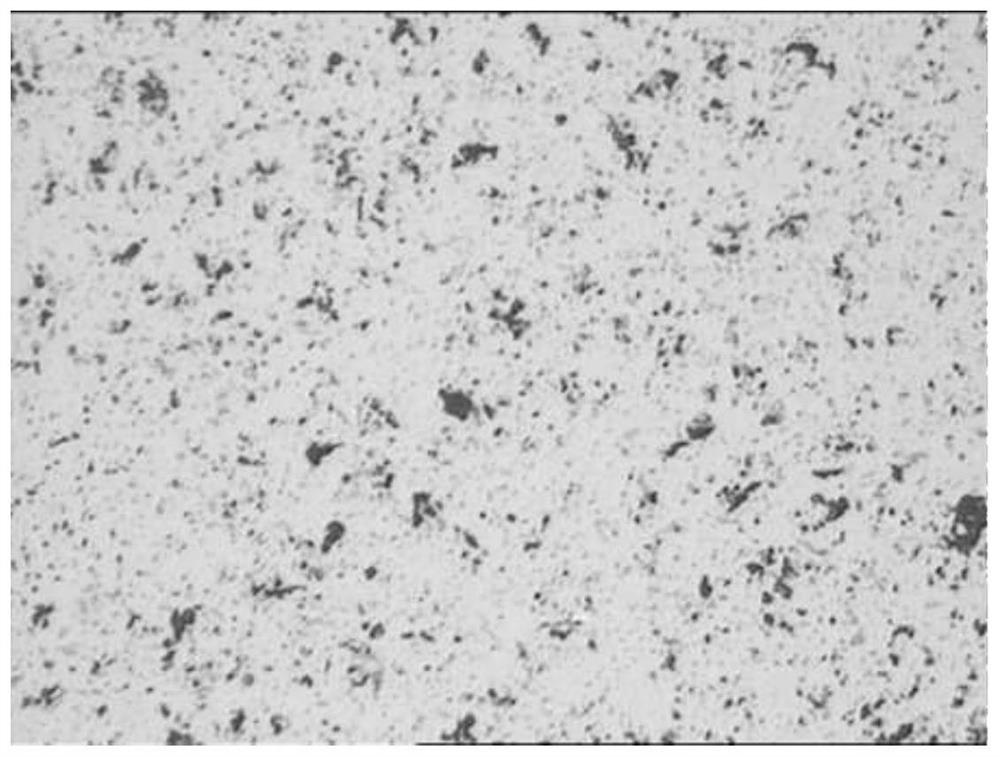

Zirconium and strontium compound micro-alloyed nickel-aluminum bronze and preparation method thereof

The invention relates to a zirconium and strontium compound micro-alloyed nickel-aluminum bronze and a preparation method thereof. The product is characterized by mainly comprising nickel-aluminum bronze, Zr (at the mass percent of 0.02-0.085%) and Sr (at the mass percent of 0.018-0.063%). The preparation process of the alloy is as follows: firstly, fusing the nickel-aluminum bronze, and then adding Al-Sr intermediate alloy and Al-Zr intermediate alloy; secondly, after completely fusing, adding a residue removing agent (for removing impurities), and introducing into high-purity nitrogen for refining; and lastly, pouring into a casting ladle, standing by, removing the residue and casting into an ingot, thereby obtaining the zirconium and strontium compound micro-alloyed nickel-aluminum bronze. Compared with the common nickel-aluminum bronze, the zirconium and strontium compound micro-alloyed nickel-aluminum bronze has the advantages that: the tissue is fine and small; the hardness and the corrosion resistance are increased; the friction coefficient is obviously reduced; and the nickel-aluminum bronze has wide application prospect in the fields of vessel propellers, sea water pumps, offshore oil platforms, seawater pipeline systems, mechanical moulds, bearings working under high speed, high pressure and high environment, lings, turbines, and the like.

Owner:ZHENJIANG JINYE PROPELLER

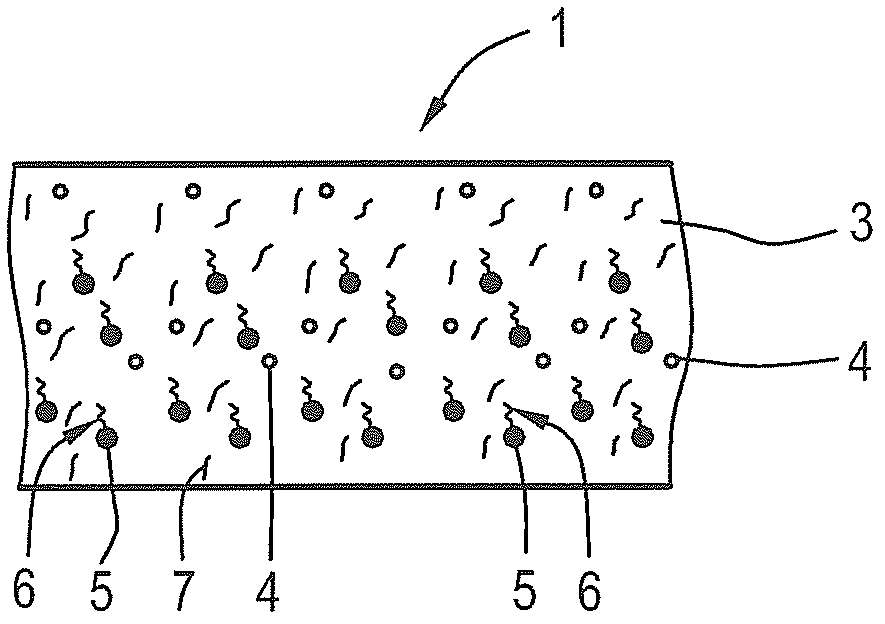

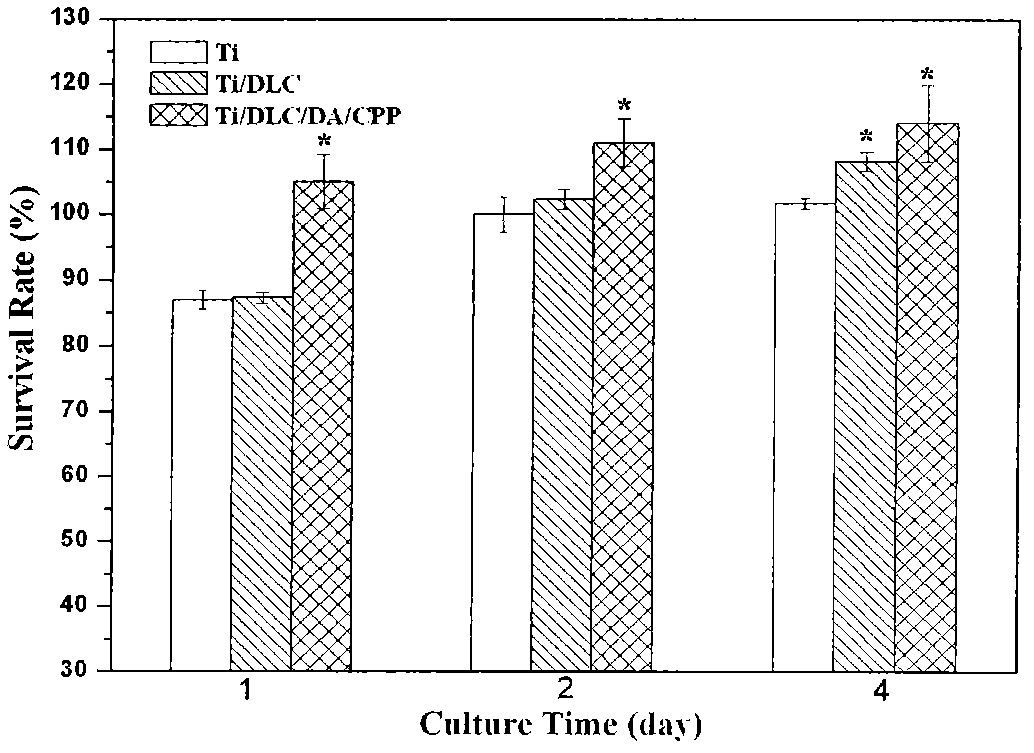

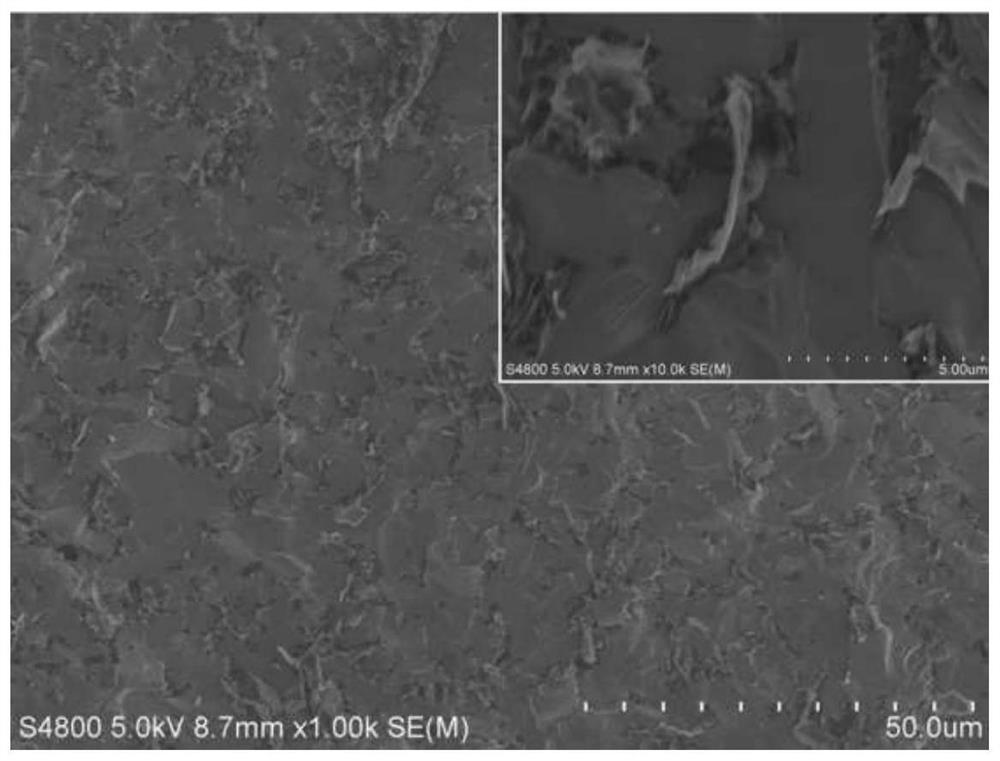

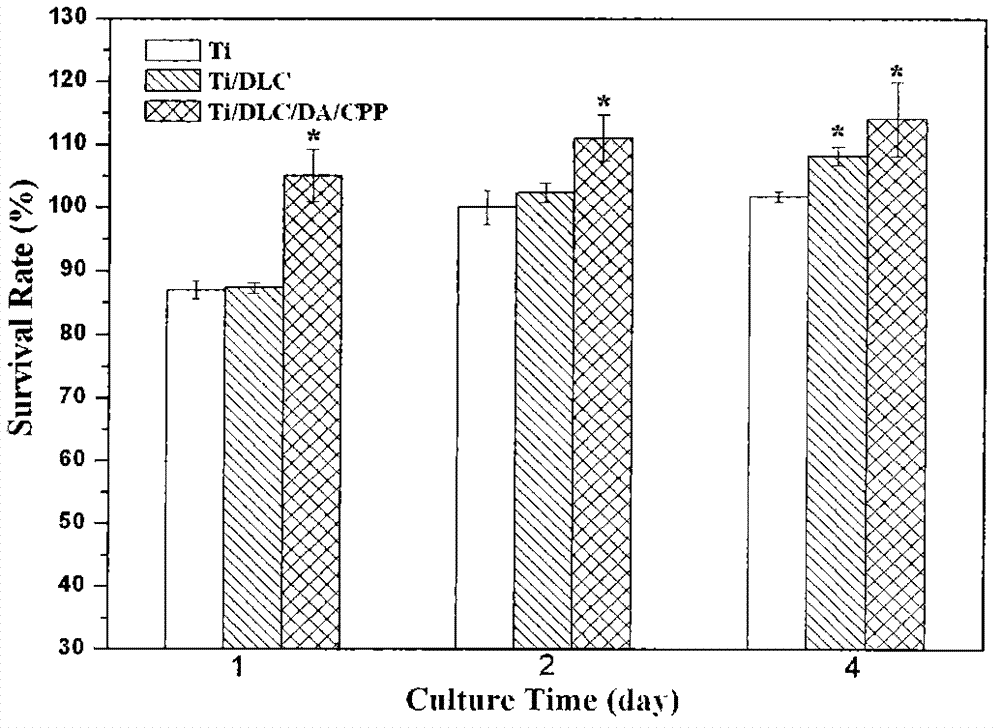

Method of preparing biology activity composite thin film on surface of titanium alloy

ActiveCN103160790AImprove tribological propertiesImprove biological activityVacuum evaporation coatingSputtering coatingComposite filmGas phase

The invention discloses a method of preparing biology activity composite thin film on surface of titanium alloy. Specifically, the titanium alloy which is processed before the convention is placed in a multi-sphere ion plating-magnetic control sputtering composite gas phase sedimentation vacuum system. A data link control (DLC) thin film with Ti as a transition layer is sedimentated. The composite thin film is composed of a titanium alloy base body, the DCL thin film and a casein phosphoric acid peptide activity egg white surface layer in sequence. A series of excellent qualities of the titanium alloy as the base body material are maintained by the thin film. The biology activity and the tribology performance are improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

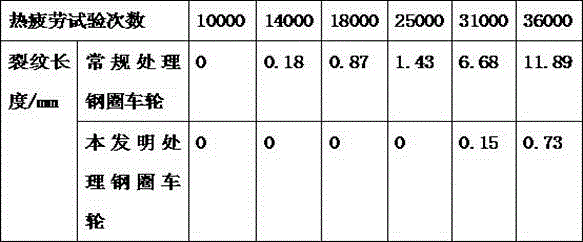

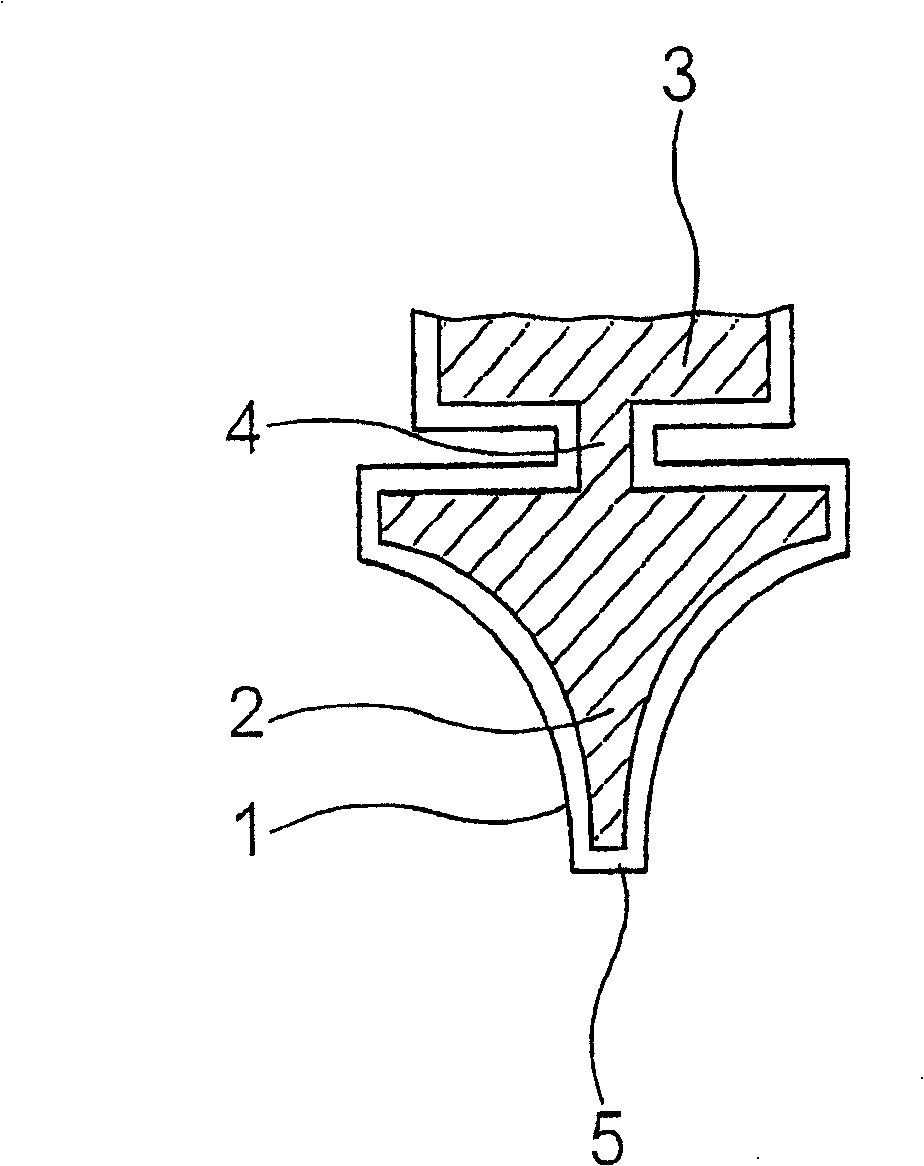

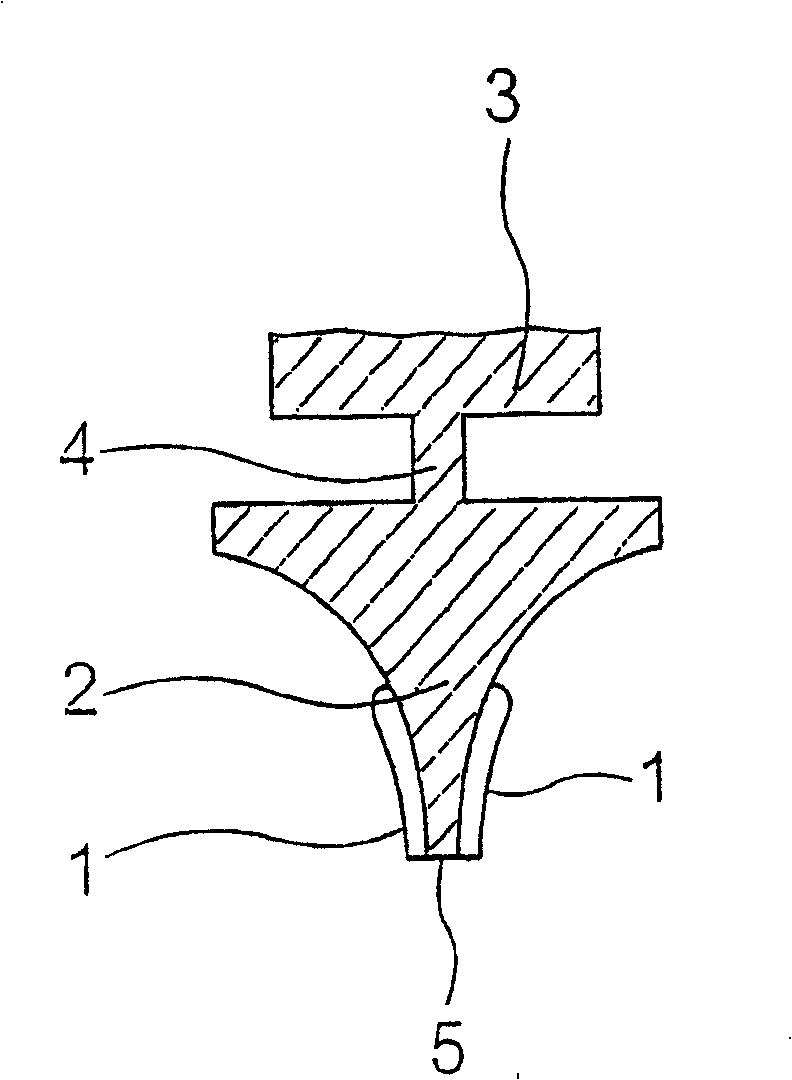

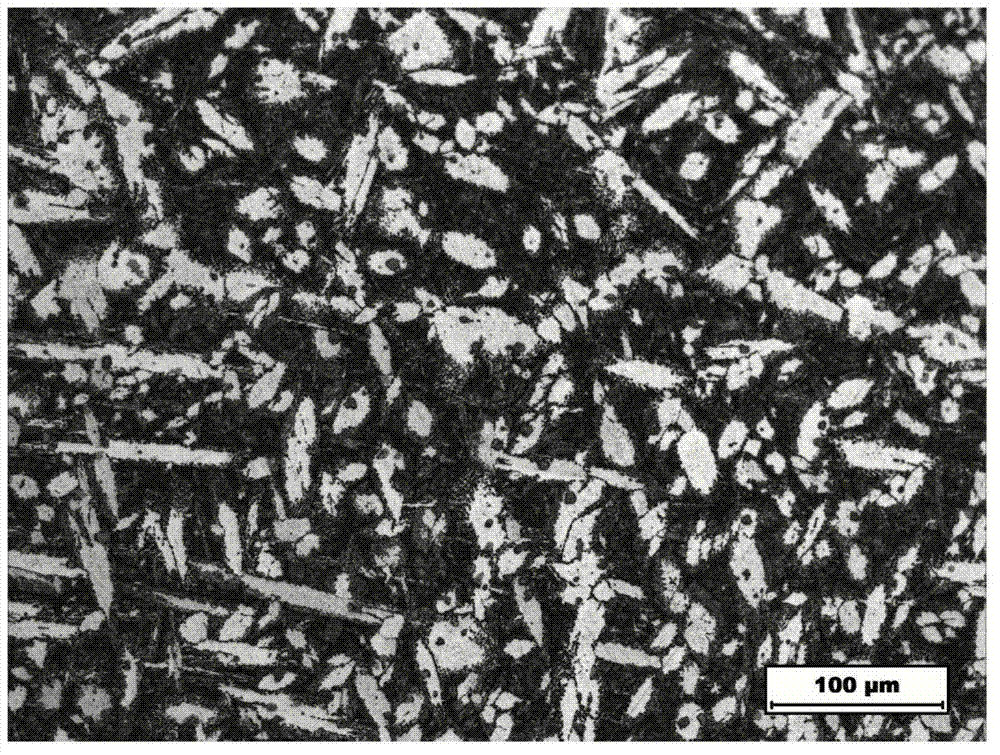

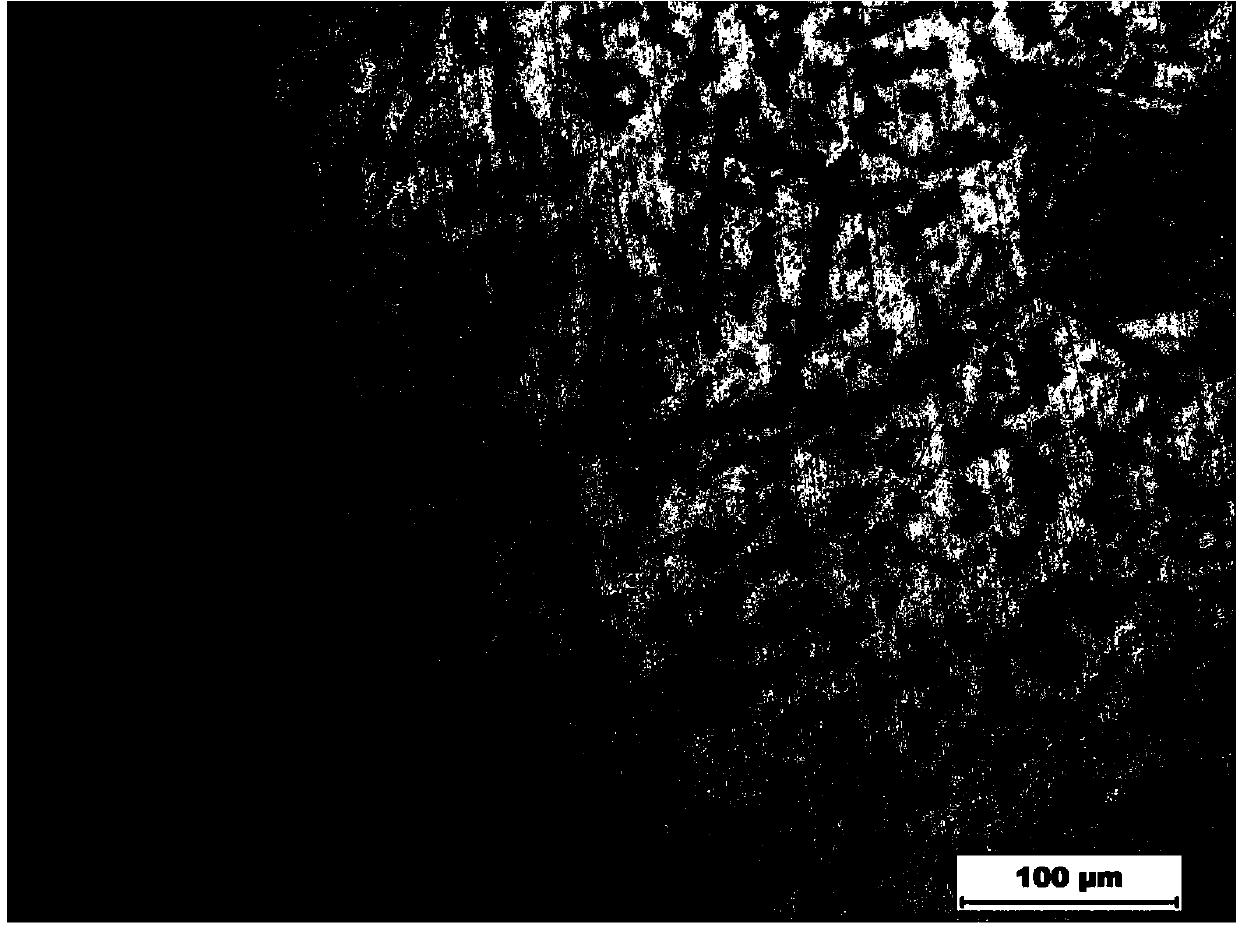

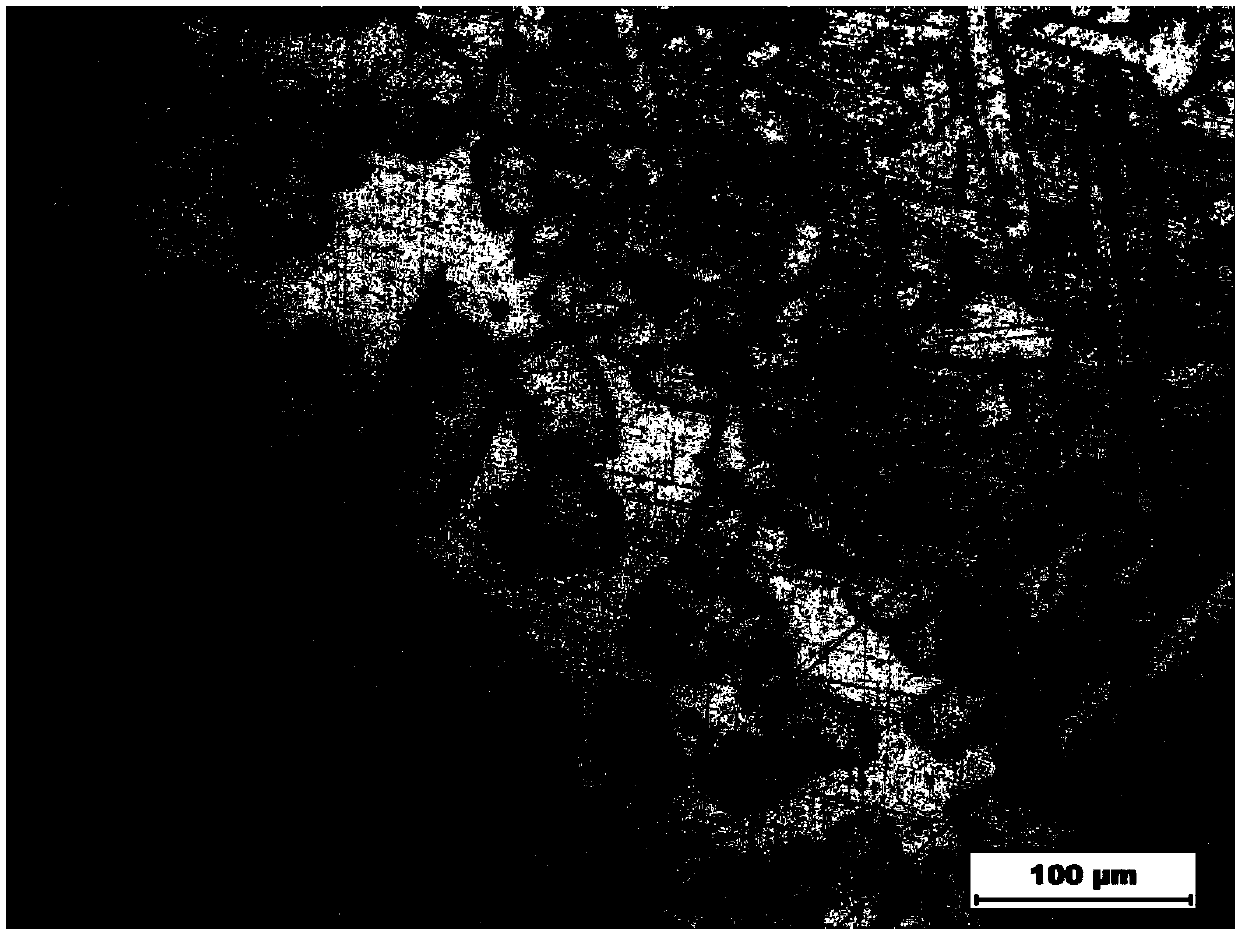

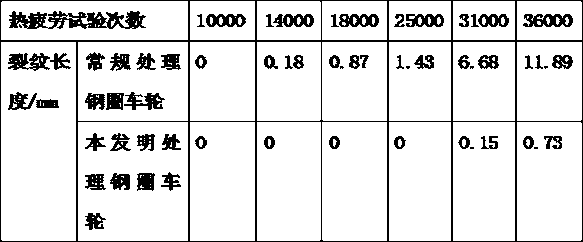

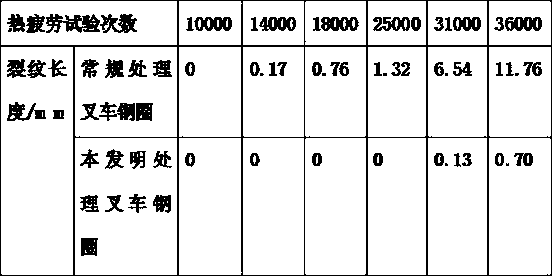

Steel ring car wheel surface treatment process

ActiveCN106222680AEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Method for improving anti-static, anti-abrasion and water lubricating performance of starch capsules

The invention relates to the field of medical accessories, and provides a method for improving the anti-static, anti-abrasion and water lubricating performance of starch capsules. A micromolecular polyhydroxy compound is added into preparation raw materials of the starch capsules, the hygroscopicity of starch membranes is improved by adding the micromolecular polyhydroxy compound, bound water on the surfaces of the starch membranes moves inwards, the content of the bound water on the surfaces of the starch membranes is reduced, thus, the electric charge quantity generated on the surfaces of the starch membranes is reduced, and the anti-static purpose is achieved; meanwhile, as the content of bound water on the surfaces of capsule shells is reduced, the space hindrance of the starch capsules in the water-containing environment can be reduced, and the water lubricity of the starch capsules is improved; the micromolecular polyhydroxy compound enters the starch membranes, hydrogen bonds are formed between the micromolecular polyhydroxy compound and starch molecules, relative sliding between starch molecular chains becomes easier, thus, the dry friction coefficient of the starch membranes can be reduced, and the purposes of reducing friction and resisting abrasion are achieved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

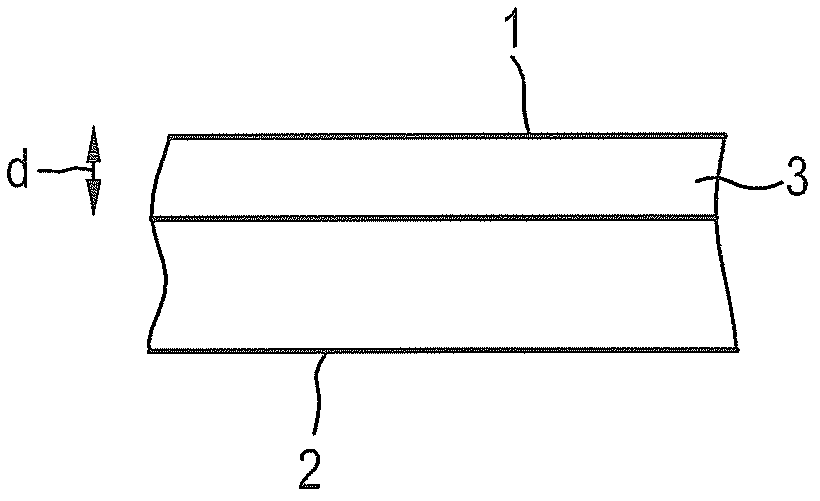

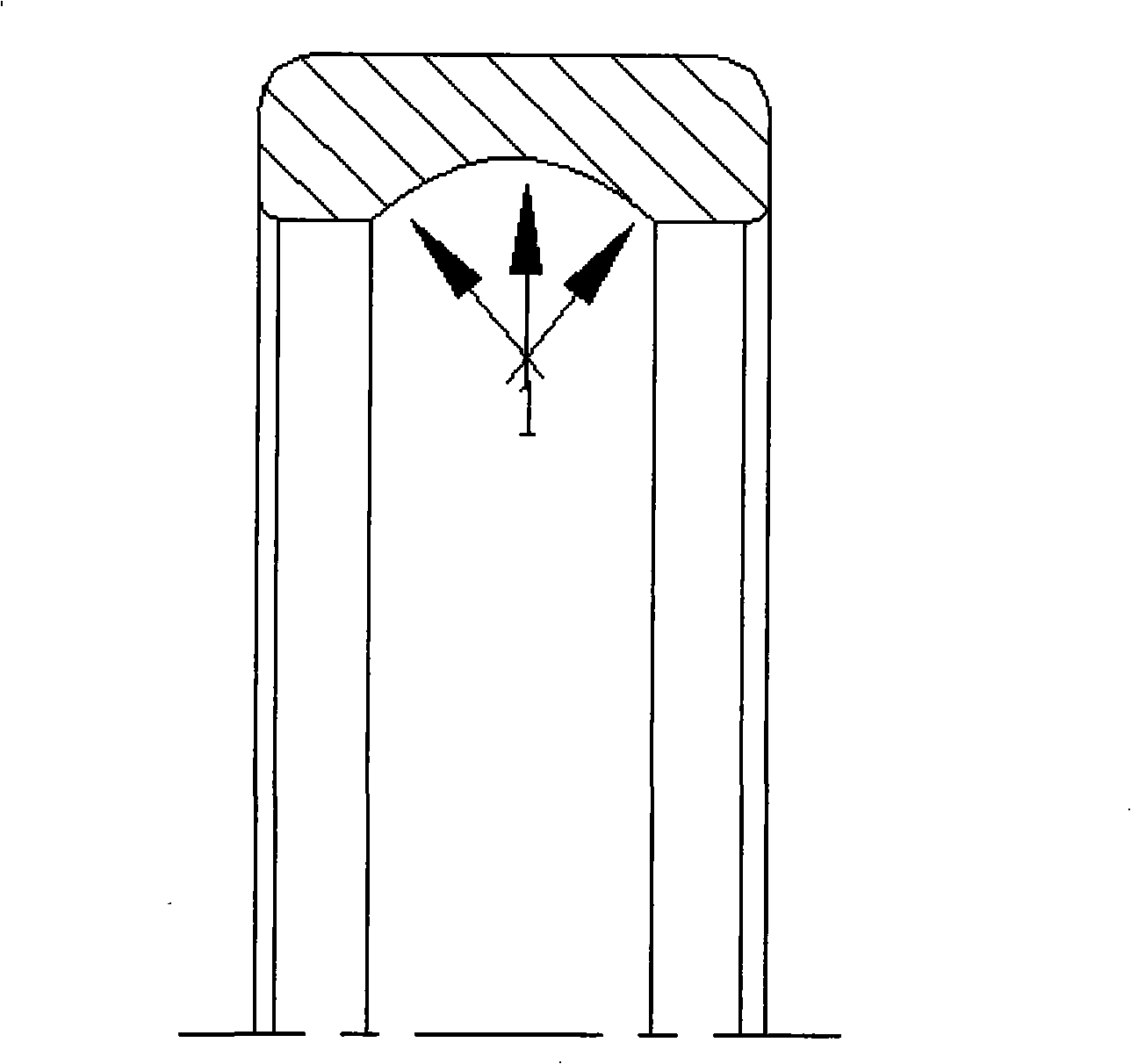

Wiper blade

InactiveCN100418813CHigh molar massReduce dry friction coefficientPretreated surfacesVehicle cleaningEngineeringDry friction

A wiper blade for a windshield wiper, in particular for a windshield wiper of a motor vehicle, is proposed, which has a wiper blade rubber with a wiper blade rubber lip (2). In order to achieve a low dry friction coefficient, the wiper blade rubber lip (2) is fabricated partially of polyethylene.

Owner:ROBERT BOSCH GMBH

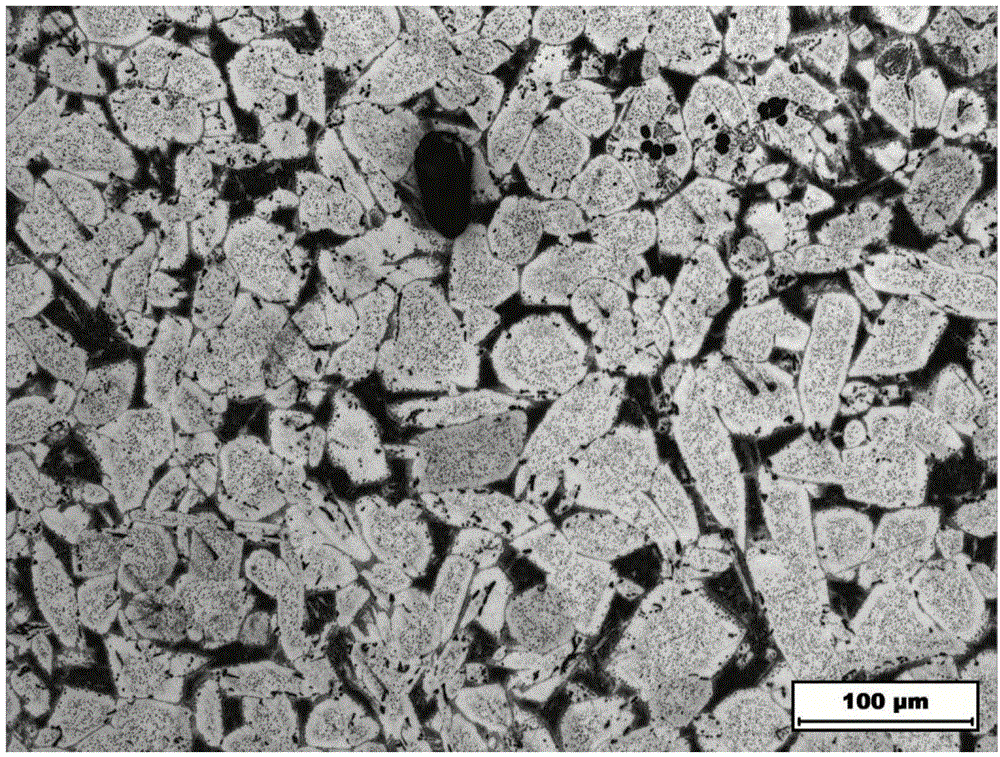

Zirconium micro-alloyed nickel-aluminum bronze

The invention relates to zirconium micro-alloyed nickel-aluminum bronze and a preparation method thereof. The zirconium micro-alloyed nickel-aluminum bronze is characterized in that the alloy mainly comprises nickel-aluminum bronze and zirconium (Zr) with mass percentage of 0.03 to 0.1%. The preparation process flow of alloy comprises the following steps of: firstly, after melting the nickel-aluminum bronze, and then adding Al-Zr intermediate alloy; after completely melting, adding a deslagging agent, and then introducing a high-purity nitrogen gas to refine for 3min; and finally, pouring into a ladle, keeping stand and keeping the temperature for 1-5min, deslagging and casting into ingots. Compared with the conventional nickel-aluminum bronze, the alloy provided by the invention has a fine microstructure, the hardness is increased by 8.1%, the uniform corrosion rate in 3.5% NaCl solution is reduced to 5.3%, and the coefficient of friction is obviously reduced; and the alloy has wide application prospects in fields such as marine ship propellers, seawater pumps, marine oil platforms, seawater piping systems, mechanical molds and bearings, bushings and turbines which work at high speed, high pressure and high temperature.

Owner:ZHENJIANG JINYE PROPELLER

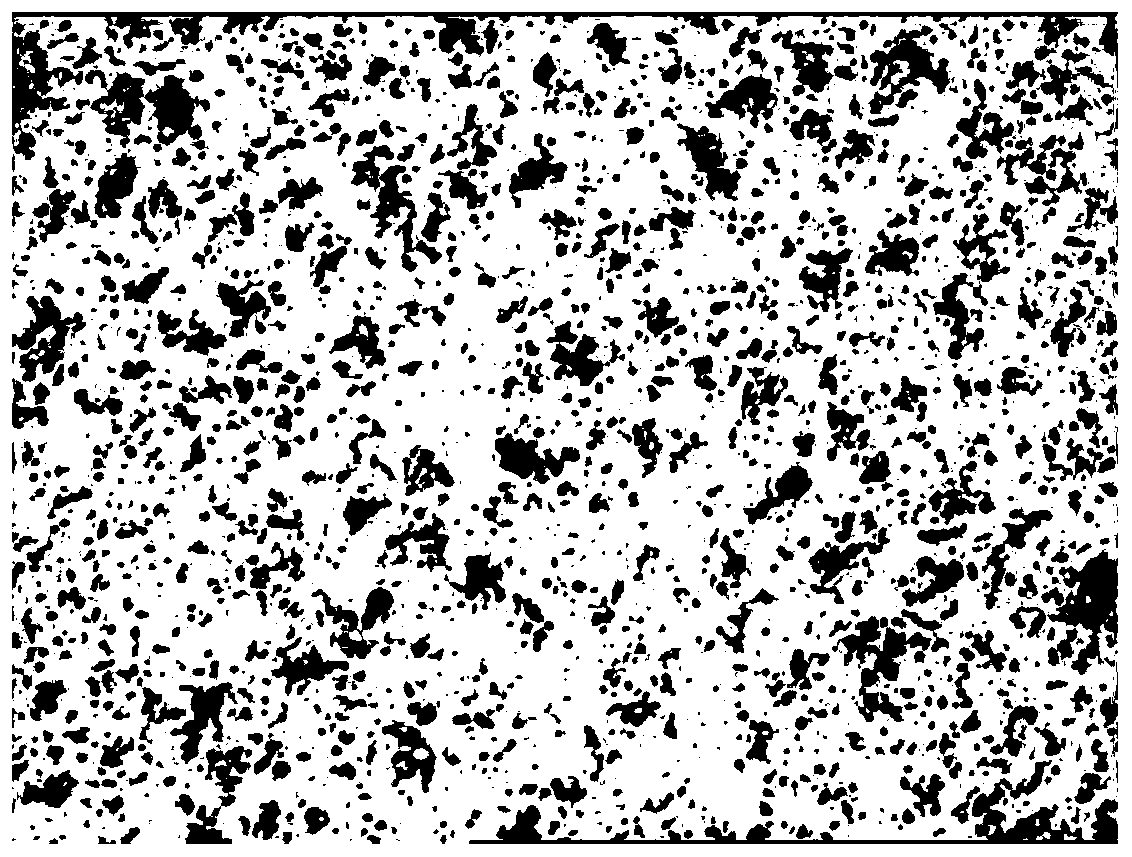

Multiphase composite reinforced low-friction silicon carbide ceramic sealing material and preparation method thereof

ActiveCN111138200AImprove surface smoothnessImproved dry friction propertiesCarbide siliconMechanical properties of carbon nanotubes

The invention discloses a multiphase composite reinforced low-friction silicon carbide ceramic sealing material. The low-friction silicon carbide ceramic sealing material is composed of the followingraw materials in percentage by weight: 86%-88% of silicon carbide, 6%-8% of yttrium aluminum garnet, 1%-2.5% of graphene, 1%-2.5% of nanometer zirconium diboride and 1%-2.5% of silicon carbide whiskers. The invention also provides a preparation method of the low-friction silicon carbide ceramic sealing material. The prepared silicon carbide ceramic sealing material is low in friction coefficient and high in mechanical property.

Owner:浙江东新新材料科技有限公司

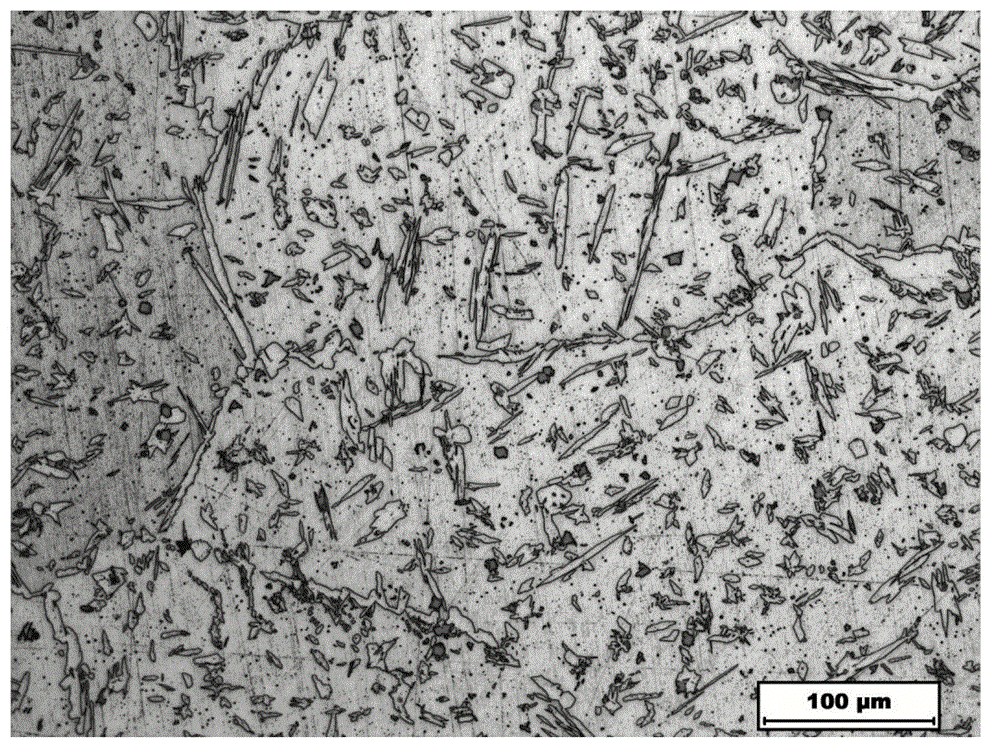

Scandium, zirconium and strontium (Sc-Zr-Sr) compounded micro-alloyed high manganic aluminum bronze and preparation method thereof

The invention discloses Sc-Zr-Sr compounded micro-alloyed high manganic aluminum bronze, which is characterized by mainly comprising the following components in percentage by mass: 0.015-0.058% of Sc, 0.028-0.074% of Zr, 0.012-0.057% of Sr and the balance of high manganic aluminum bronze, wherein the sum of mass percentages of all the components is 100%. The preparation process of the alloy comprises the following steps of: firstly, melting the high manganic aluminum bronze, and sequentially adding an Al-Sr intermediate alloy, an Al-Zr intermediate alloy and pure Sc; then, adding a slag cleaning agent for removing impurities after completely melting the added materials, and feeding high-purity nitrogen for refinement; and finally, pouring into a casting ladle, removing slag after standing, and casting to form ingots. Compared with the conventional high manganic aluminum bronze, the Sc-Zr-Sr compounded micro-alloyed high manganic aluminum bronze is fine and compact in structure, has the hardness which is increased by 46.3%, the uniform corrosion rate in a 3.5% NaCl solution is reduced by 8%, and the friction coefficient is reduced significantly. The Sc-Zr-Sr compounded micro-alloyed high manganic aluminum bronze effectively makes up the defect of insufficient performance of the existing high manganic aluminum bronze on the market, and can meet the requirements on high-performance high manganic aluminum bronze of the rapid development in fields including propellers, seawater pumps, valves, seawater desalination equipment and the like for large ships in our country.

Owner:ZHENJIANG JINYE PROPELLER

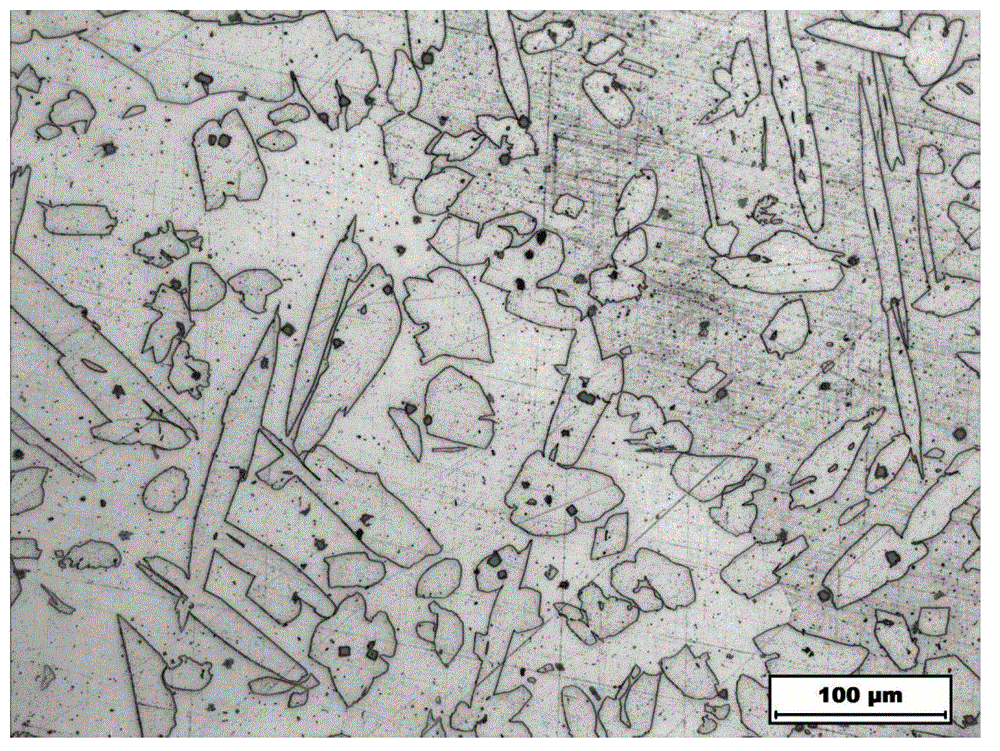

Strontium, titanium and boron composite microalloying manganese brass and preparation method of manganese brass

The invention provides strontium, titanium and boron composite microalloying manganese brass which is mainly prepared from the following components in percentage by weight: 0.01 to 0.03% of strontium (Sr), 0.01 to 0.05% of titanium (Ti), 0.002 to 0.008% of boron (B), and the balance of the manganese brass, wherein sum of mass percentage of the components is of 100%. The preparation method of an alloy comprises the technical processes as follows: melting the manganese brass; adding an Al-Sr intermediate alloy and an Al-Ti-B intermediate alloy in sequence, wherein materials are added based on specified sequence, which means that a following intermediate alloy just can be added after a previous intermediate alloy is melted; transferring into a casting ladle after the ally is completely molten; standing; removing slag; and casting to obtain an ingot, thus obtaining the strontium, titanium and boron composite microalloying manganese brass. Compared with a conventional manganese brass, the strontium, titanium and boron composite microalloying manganese brass provided by the invention has the advantages that texture is small, hardness is improved by 21.6%, an uniform corrosion speed in 3.5% of NaCl solution is reduced by 9.9%, and a frictional coefficient is greatly reduced.

Owner:ZHENJIANG JINYE PROPELLER

A kind of preparation method of nickel-polytetrafluoroethylene coating

The invention relates to the technical field of electroplating, and particularly relates to a preparation method of a nickel-polytetrafluoroethylene coating. According to the invention, nickel is combined with polytetrafluoroethylene, a fluorinated ethylene-propylene copolymer, a perfluoroalkoxy copolymer and other assistants to be used as an electroplating solution and used for electroplating under certain conditions. The invention can be widely applied to various base materials such as steel, copper alloys, wrought aluminum, cast iron, stainless steel and the like, and can be also perfectly used on various injection molding materials except pure rubber, such as silica gel, TPO0, PVC (polyvinyl chloride) and the like. The coating is favorable in wear resistance and non-corrosibility, has weldability and hardenability, and causes no negative effect on the surfaces of other molds.

Owner:模德模具(东莞)有限公司

A surface fatigue-resistant treatment process for slewing bearings

ActiveCN106435467BSurface treatment process optimizationImprove surface wear resistanceSolid state diffusion coatingSurface fatigueEngineering

Owner:安徽省宁国顺昌机械有限公司

Strontium, titanium and boron composite microalloying manganese brass and preparation method of manganese brass

The invention provides strontium, titanium and boron composite microalloying manganese brass which is mainly prepared from the following components in percentage by weight: 0.01 to 0.03% of strontium (Sr), 0.01 to 0.05% of titanium (Ti), 0.002 to 0.008% of boron (B), and the balance of the manganese brass, wherein sum of mass percentage of the components is of 100%. The preparation method of an alloy comprises the technical processes as follows: melting the manganese brass; adding an Al-Sr intermediate alloy and an Al-Ti-B intermediate alloy in sequence, wherein materials are added based on specified sequence, which means that a following intermediate alloy just can be added after a previous intermediate alloy is melted; transferring into a casting ladle after the ally is completely molten; standing; removing slag; and casting to obtain an ingot, thus obtaining the strontium, titanium and boron composite microalloying manganese brass. Compared with a conventional manganese brass, the strontium, titanium and boron composite microalloying manganese brass provided by the invention has the advantages that texture is small, hardness is improved by 21.6%, an uniform corrosion speed in 3.5% of NaCl solution is reduced by 9.9%, and a frictional coefficient is greatly reduced.

Owner:ZHENJIANG JINYE PROPELLER

A kind of steel rim wheel surface treatment process

ActiveCN106222680BEfficient removalImprove surface mechanical propertiesFurnace typesMetallic material coating processesHigh resistanceShock resistance

The invention discloses a steel ring car wheel surface treatment process. The steel ring car wheel surface treatment process comprises the following steps of (1) cleaning, (2) surface preheating, (3) surface modification treatment, (4) cleaning and cold standing and (5) quenching treatment. The steel ring car wheel surface treated through the process has the high abrasion resistance, high hardness, high toughness and high shock resistance, subsequent quenching treatment is matched, the optimal quenching time and quenching temperature are optimized, and the tempering time and tempering temperature are adjusted, so that the impact toughness and hardness of a steel ring car wheel are improved; and inner hardness and outer hardness are balanced, the microhardness of the surface of a steel ring car wheel coating is quite high, the salt corrosion resistance and stress corrosion cracking resistance can be further improved. In addition, the fatigue resistance of the steel ring car wheel is greatly improved, the service life of the steel ring car wheel is prolonged, and the service life of the steel ring car wheel is prolonged by three to four times compared with untreated steel ring car wheels.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Multi-phase composite reinforced low-friction silicon carbide ceramic sealing material and preparation method thereof

ActiveCN111138200BGrowth inhibitionSolve the problem of rapid decline in mechanical propertiesCarbide siliconGraphite

The invention discloses a multi-phase composite reinforced low-friction silicon carbide ceramic sealing material. The raw material of the low-friction silicon carbide ceramic sealing material is composed of the following components in weight percentage: 86% to 88% of silicon carbide, yttrium aluminum garnet 6% to 8%, graphene 1% to 2.5%, nano zirconium diboride 1% to 2.5%, silicon carbide whiskers 1% to 2.5%. The invention also provides a preparation method of the low-friction silicon carbide ceramic sealing material. The silicon carbide ceramic sealing material prepared by the invention not only has a low friction coefficient, but also has high mechanical properties.

Owner:浙江东新新材料科技有限公司

A kind of tungsten-doped diamond-like coating and preparation method thereof

InactiveCN103451608BHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingDlc coatingOxidation resistant

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Method of preparing biology activity composite thin film on surface of titanium alloy

ActiveCN103160790BReduce coefficient of frictionReduce dry friction coefficientVacuum evaporation coatingSputtering coatingO-Phosphoric AcidThin membrane

The invention discloses a method of preparing biology activity composite thin film on surface of titanium alloy. Specifically, the titanium alloy which is processed before the convention is placed in a multi-sphere ion plating-magnetic control sputtering composite gas phase sedimentation vacuum system. A data link control (DLC) thin film with Ti as a transition layer is sedimentated. The composite thin film is composed of a titanium alloy base body, the DCL thin film and a casein phosphoric acid peptide activity egg white surface layer in sequence. A series of excellent qualities of the titanium alloy as the base body material are maintained by the thin film. The biology activity and the tribology performance are improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A surface treatment process for forklift steel ring

ActiveCN106283093BEfficient removalImprove surface mechanical propertiesOrganic detergent compounding agentsAnionic surface-active compoundsFatigue IntensityWear resistant

The invention discloses a fork truck steel ring surface treatment process, which comprises the following steps of (1) cleaning; (2) acid washing; (3) surface preheating; (4) surface deterioration treatment; (5) cleaning and cold placement; (6) quenching treatment; (7) surface treatment agent treatment. When being used for treating the surface of a fork truck steel ring, the fork truck steel ring surface treatment process has the advantages that the wear resistant performance is good; the hardness is high; the toughness is high; the anti-impact performance is high; the subsequent quenching treatment is matched; the best quenching time and quenching temperature are optimized; the tempering time and the tempering temperature are regulated, so that the impact toughness and hardness of the fork truck steel ring are improved; in addition, the inner hardness and the outer hardness are balanced; the micro hardness of the surface of the coating layer of the fork truck steel ring is very high; the slat corrosion resistance and the stress corrosion cracking resistant performance can be further improved; in addition, the anti-fatigue intensity of the fork truck steel ring is greatly improved; the service life is prolonged, and is prolonged by 3 to 4 times through being compared with the service life of the untreated fork truck steel ring.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

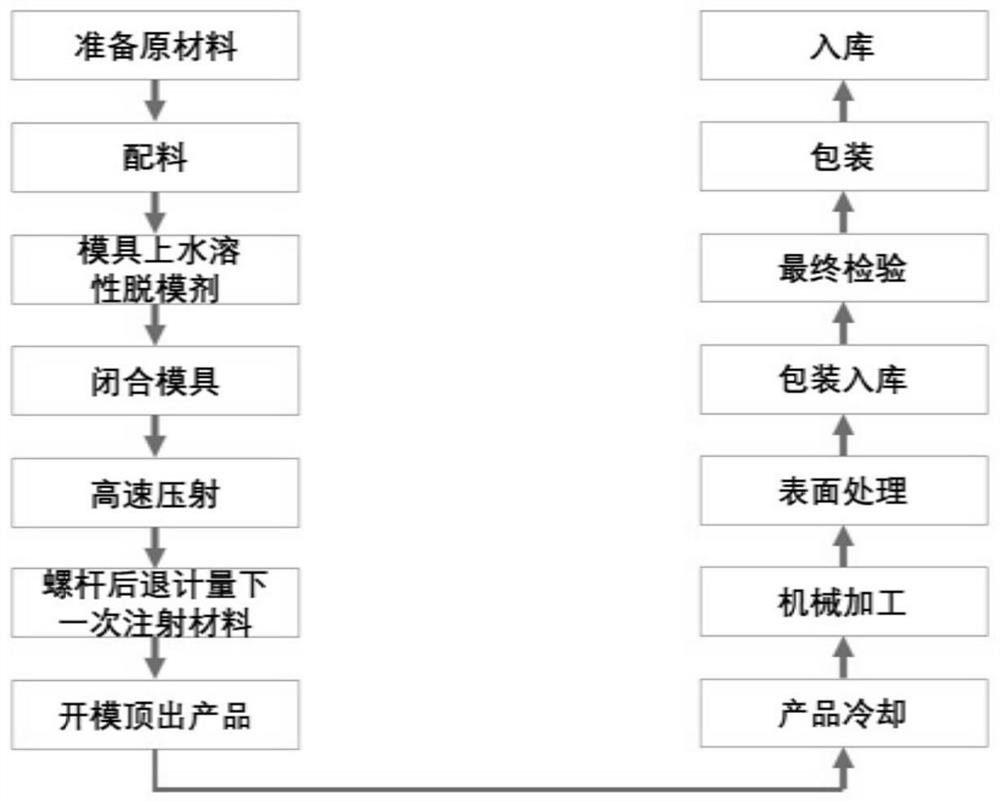

A kind of magnesium alloy building formwork semi-solid die casting and double fluorination joint manufacturing method

ActiveCN112247097BHigh tensile strengthHigh elongationMetallic material coating processesDie castingSemi solid

The invention discloses a semi-solid die-casting and double fluorination joint manufacturing method of a magnesium alloy building formwork, comprising the following steps: step 1, preparing a magnesium alloy building formwork by using a semi-solid die-casting method; step 2, using the magnesium alloy building formwork prepared in step 1 Immerse in the double fluoride treatment solution to carry out double fluoride combined treatment to obtain a double fluoride combined treated magnesium alloy building formwork. The magnesium alloy formwork plate produced by the present invention is flat and free of defects, has high tensile strength, high elongation, high surface hardness, small friction coefficient, excellent scratch resistance and hydrophobicity, and can effectively reduce the risk of concrete aggregates. The friction damage and corrosion damage from the external erosive medium prevent the chemical reaction and physical adsorption caused by cement, and ensure the construction quality and demoulding effect of the building wall.

Owner:重庆建谊祥科技有限公司

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569BAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

A lifting type material tray loading and unloading equipment

ActiveCN105293081BSave spaceGood streamlineStacking articlesDe-stacking articlesEngineeringMechanical engineering

Owner:SUZHOU HEROIC AUTOMATION TECH

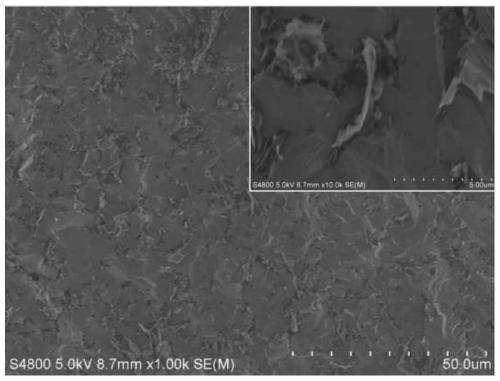

Wear-resistant asphalt resin-based composite material

ActiveCN110452553AReduce wear rateReduce dry friction coefficientBuilding insulationsWear resistantHeat resistance

The invention relates to the technical field of self-lubricating antifriction wear-resistant composite materials, and discloses a wear-resistant asphalt resin-based composite material. The wear-resistant asphalt resin-based composite material includes the following raw materials: in parts by weight, 30-40 parts of asphalt resin with an average particle size of 75 [mu]m, 30-45 parts of graphite powder with an average particle size of 75 [mu]m, 8-15 parts of polymethylmethacrylate (PMMA) powder with an average particle size of 10 [mu]m, 5-10 parts of iron (Fe) powder with an average particle size of not larger than 10 [mu]m and 5-10 parts of nickel (Ni) powder with an average particle size of not larger than 10 [mu]m. The preparation method of the asphalt resin-based composite material includes the steps: mixing the raw materials evenly through mechanical stirring, and then performing hot pressing on the uniformly-mixed composite materials at a temperature of 220-230 DEG C and a pressureof 35-40 MPa so as to obtain the asphalt resin-based composite material. The technical problem that severe abrasion is caused due to low hardness and poor heat resistance at high temperature when a composite material which is prepared through compounding of asphalt resin and graphite works under the condition of dry friction is solved.

Owner:上海振嵘摩擦材料有限公司

Mg-Sr-Ti-B composite micro-alloyed manganese brass and preparation method thereof

The invention discloses an Mg-Sr-Ti-B composite micro-alloyed manganese brass and a preparation method thereof. The Mg-Sr-Ti-B composite micro-alloyed manganese brass is characterized by comprising 0.05 to 0.1% by mass of Mg, 0.005 to 0.03% by mass of Sr, 0.008 to 0.05% by mass of Ti, 0.002 to 0.0075% by mass of B and the balance manganese brass. The preparation method comprises the following steps of melting manganese brass, orderly adding an Al-Sr intermediate alloy, an Al-Ti-B intermediate alloy and pure Mg into the melted manganese brass, after full melting, pouring the fully-melted mixture into a casting ladle, standing, removing dregs, and carrying out casting to obtain a cast ingot of the Mg-Sr-Ti-B composite micro-alloyed manganese brass. Compared with the conventional manganese brass, the Mg-Sr-Ti-B composite micro-alloyed manganese brass has a fine microstructure, hardness improved by 11.6%, a uniform corrosion rate reduced by 7.6% in a NaCl solution having a concentration of 3.5%, and a friction coefficient greatly reduced.

Owner:江苏国鑫铝业有限公司

A low-friction water-lubricated polymer bearing composite material

ActiveCN105419049BReduce dry friction coefficientGood dimensional stabilityDomestic articlesPolymer sciencePolyvinyl alcohol

Owner:WUCHANG SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com