A surface treatment process for forklift steel ring

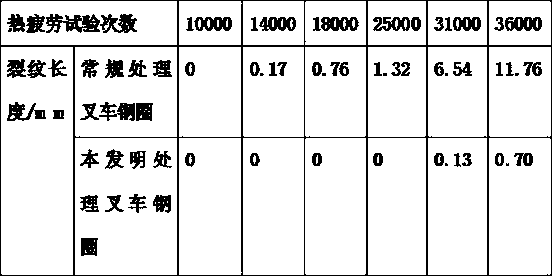

A technology of surface treatment and surface treatment agent, which is applied in the field of surface treatment of forklift rims, can solve problems such as long-time work and large span of use environment, and achieve the effects of balanced internal and external hardness, short cleaning time, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A surface treatment process for a steel ring of a forklift, comprising the following steps:

[0017] (1) cleaning. Put the forklift steel ring into the cleaning agent, soak for 20 minutes first, and then use ultrasonic vibration for 15 minutes at 36-40 ° C, then boil the cleaning agent to boil, let the forklift steel ring soak in the boiling cleaning agent for 30 minutes Minutes later, take out the steel rim of the forklift and dry it at 42-48°C; the cleaning agent is made from the following raw materials in parts by weight: sodium lauryl sulfate 5, sodium N-acylglutamate 2, sodium lactate 3, Sodium lignosulfonate 2, alkyl alcohol amide 1, triethanolamine 3, sodium alginate 0.1, sodium citrate 1, eucalyptus oil 2, maltitol 0.1, chlorophyll 0.01, capsicum 0.01, water 70;

[0018] (2) pickling. Put the steel ring of the forklift into the acid solution, soak it at 36-37°C for 20 minutes, then turn the steel ring of the forklift at 90r / min for 15 minutes, stop the rotatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com