Zirconium and strontium compound micro-alloyed nickel-aluminum bronze and preparation method thereof

A nickel-aluminum bronze and micro-alloying technology, which is applied in the field of zirconium and strontium composite micro-alloyed nickel-aluminum bronze and its preparation, new nickel-aluminum bronze alloy and its preparation, can solve problems such as restricting high-speed development, and achieve friction coefficient Reduced, low coefficient of friction, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

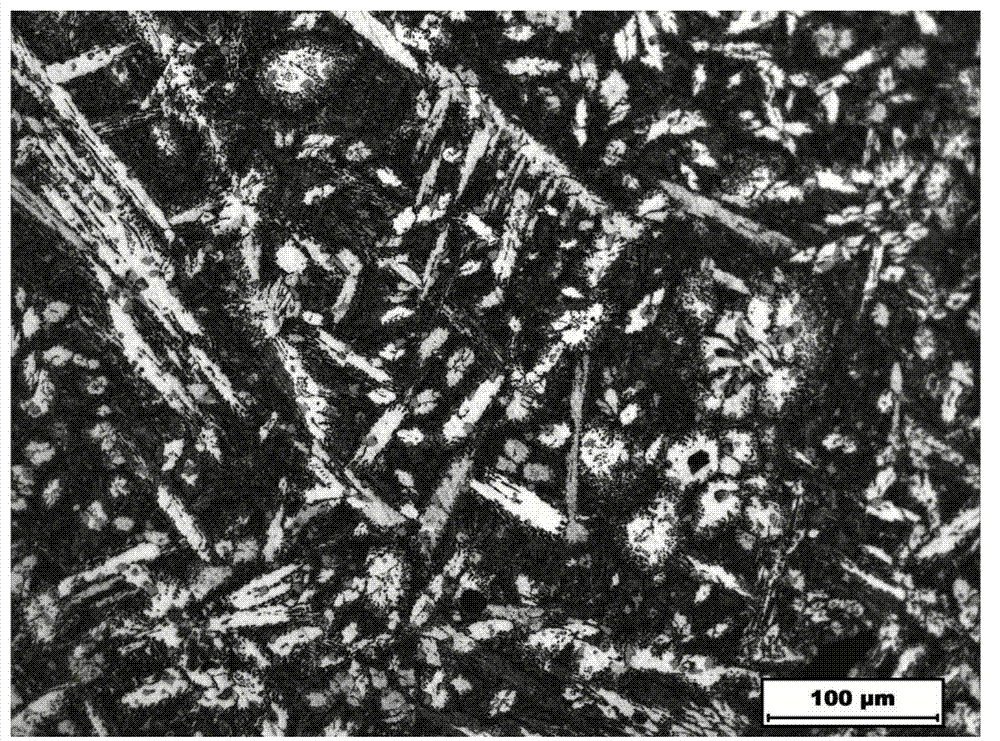

[0022] Such as figure 1 shown.

[0023] A zirconium and strontium composite microalloyed nickel aluminum bronze, its preparation method:

[0024] Take 7.1206kg as an example.

[0025] First, 7 kg of self-made (see Comparative Example 1) or commercially available nickel-aluminum bronze (composition: 78.65Cu, 1.05Mn, 9.94Al, 5.8Fe, 4.54Ni, 0.64Zn, the numbers before all element symbols in the examples indicate mass percentage, the same below) After melting, add 35.4g Al-Sr master alloy (89.85%Al, 9.89%Sr (can also be selected between 8.901%~10.879%, the same below), 0.16%Fe, 0.10%Si) (Sr The loss rate is about 40%), 85.2g Al-Zr master alloy (95.69%Al, 4.11%Zr (can also be selected between 3.699% ~ 4.521%), 0.20%Fe, 0.10%Si ) (Zr loss rate is about 8%), the master alloy can be purchased directly from the market, or can be prepared by yourself by conventional methods. In the melting process, the former master alloy is melted and then added to the latter master alloy; after all ...

Embodiment 2

[0029] A zirconium and strontium composite microalloyed nickel aluminum bronze, its preparation method:

[0030] Take 7.1206kg as an example.

[0031] First, melt 7.005kg of nickel-aluminum bronze (composition: 78.96Cu, 1.09Mn, 9.94Al, 5.02Fe, 4.41Ni, 0.38Zn, the numbers before all element symbols in the examples represent mass percentages, the same below) and add them in sequence 30.4g Al-Sr master alloy (89.85%Al, 9.89%Sr, 0.16%Fe, 0.10%Si) (the loss rate of Sr is about 40%), 85.2g Al-Zr master alloy (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) (the loss rate of Zr is about 8%), described master alloy can be purchased directly from the market, also can adopt conventional method self-preparation, in the melting process, wait for the previous master alloy to melt and then Add the latter master alloy; after it is completely melted, add a slag removal agent (to remove impurities), and then pass high-purity nitrogen to refine for 3 minutes; finally, pour it into a ladle, keep it for 1...

Embodiment 3

[0034] A zirconium and strontium composite microalloyed nickel aluminum bronze, its preparation method:

[0035] Take 7.1206kg as an example.

[0036] First, 7.062kg of homemade (see Comparative Example 1) or commercially available nickel aluminum bronze (composition: 78.65Cu, 1.05Mn, 9.94Al, 5.8Fe, 4.54Ni, 0.64Zn, the numbers before all element symbols in the examples indicate Mass percentage, the same below) After melting, add 21.6g Al-Sr master alloy (89.85%Al, 9.89%Sr (can also be selected between 8.901%~10.879%, the same below), 0.16%Fe, 0.10%Si) ( The loss rate of Sr is about 40%), 37.66 Al-Zr master alloy (95.69%Al, 4.11%Zr (can also be selected between 3.699%~4.521%), 0.20%Fe, 0.10%Si ) (loss of Zr rate is about 8%), the master alloy can be purchased directly from the market, or can be prepared by yourself by conventional methods. In the melting process, the former master alloy is melted and then added to the latter master alloy; after all melting, Add slag agent (to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com