Mg-Sr-Ti-B composite micro-alloyed manganese brass and preparation method thereof

A technology of micro-alloying and manganese brass, which is applied in the field of brass alloys and its preparation, can solve the problems that the performance of manganese brass cannot meet the requirements of high-performance use, and achieve fine grain size, good corrosion resistance and low friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

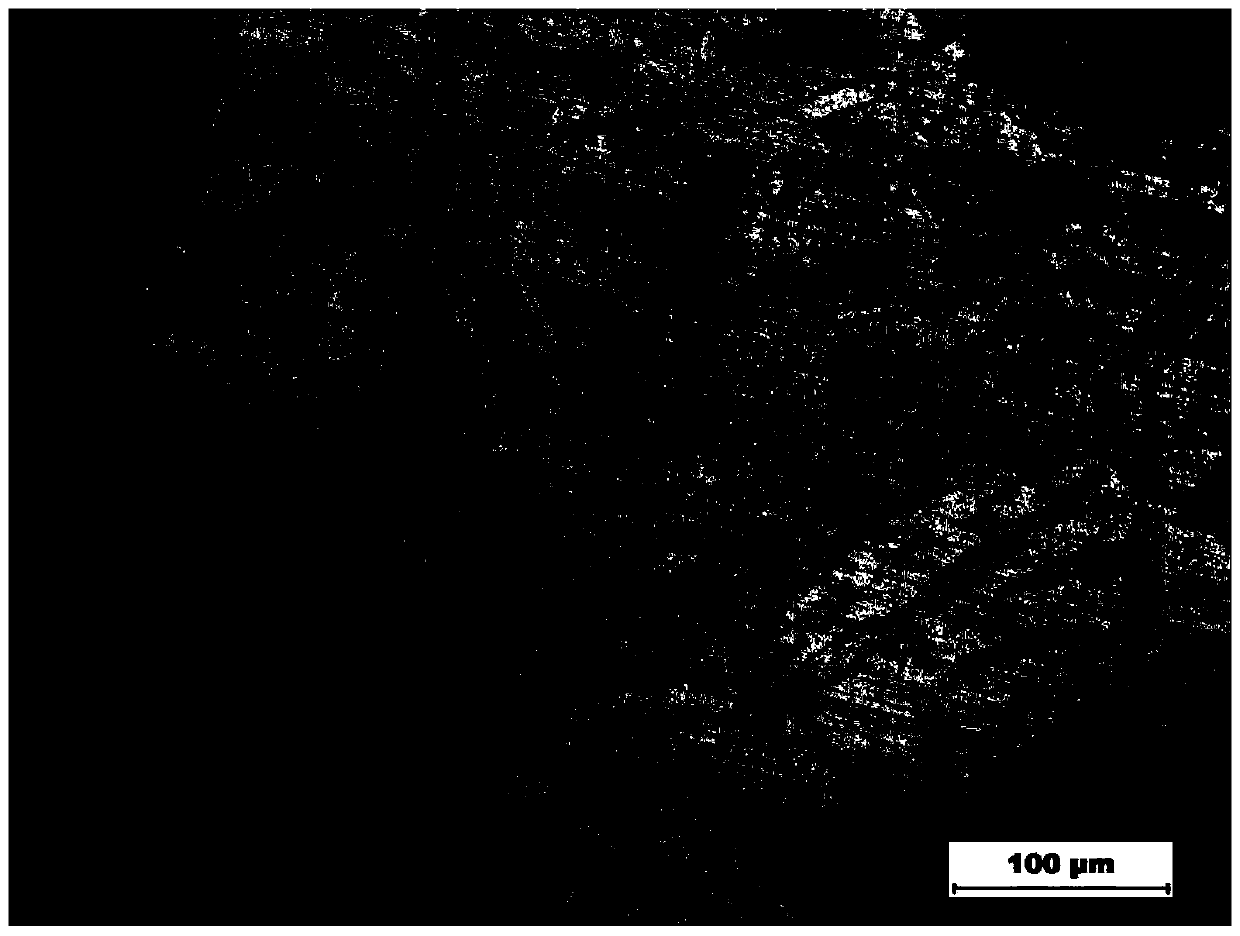

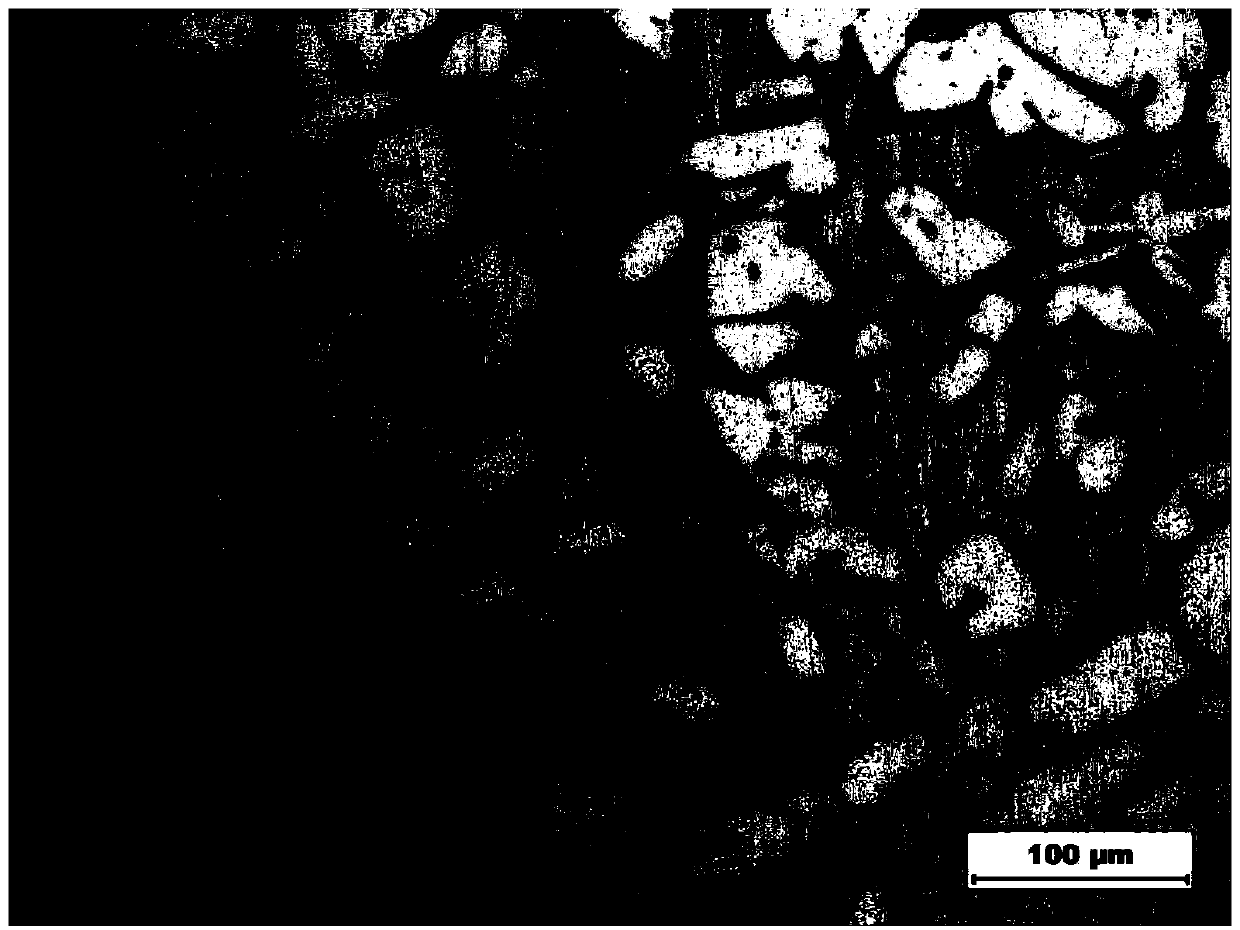

[0021] like figure 1 , 2 shown.

[0022] A magnesium, strontium, titanium and boron composite microalloyed manganese brass, its preparation method:

[0023] Take 8.4715kg as an example.

[0024] First, 8.4025 kg of commercially available manganese brass (mainly composed of copper (Cu), aluminum (Al), manganese (Mn), zinc (Zn), iron (Fe) and nickel (Ni), the mass of zinc (Zn) The percentage is 35~40%, the mass percentage of manganese (Mn) is 0.5~4.0%, the mass percentage of aluminum (Al) is 0.5~3.0%, the mass percentage of iron (Fe) is 0.5~2.5%, nickel (Ni) The mass percentage is £1.0%, the same below) After melting, add in sequence:

[0025] 1. Al-Sr master alloy prefabricated or directly ordered from the market: 21.2g (89.85%Al, 9.89%Sr (strontium content can fluctuate 10% around 9.89%), 0.16%Fe, 0.10%Si) (Sr The loss rate is about 40%),

[0026] 2. Al-Ti-B master alloy prefabricated or directly ordered from the market: 41.9g (93.69% Al, 5.01% Ti (the content of titaniu...

Embodiment 2

[0032] A magnesium, strontium, titanium and boron composite microalloyed manganese brass, its preparation method:

[0033] Take 8.4715kg as an example.

[0034] First, after melting 8.4027kg of manganese brass, add 15.2g of Al-Sr master alloy (89.85%Al, 9.89%Sr, 0.16%Fe, 0.10%Si) (the loss rate of Sr is about 40%), 46.3g Al-Ti-B master alloy (93.69%Al, 5.01%Ti, 0.98%B, 0.19%Fe, 0.13%Si) (Ti loss rate is about 8%), 10g Mg (Mg loss rate is about 20% ), the master alloy can be purchased directly from the market, or can be prepared by yourself by conventional methods; after it is completely melted, it is poured into a ladle, and after standing for 1 to 5 minutes, the slag is removed and cast into an ingot; that is, magnesium, Strontium, titanium and boron composite microalloyed manganese brass

[0035] The composition of the composite microalloyed manganese brass of the present embodiment is actually measured by spectrum: 37.07%Zn, 1.42%Mn, 1.52%Al, 0.73%Fe, 0.32%Ni, 0.094%Mg, 0...

Embodiment 4

[0048] A magnesium, strontium, titanium and boron composite microalloyed manganese brass, its preparation method:

[0049] Take 8.4715kg as an example.

[0050] First, after melting 8.378kg of manganese brass, add 45.6g of Al-Sr master alloy (89.85%Al, 9.89%Sr, 0.16%Fe, 0.10%Si) (the loss rate of Sr is about 40%), 46.3g Al-Ti-B master alloy (93.69%Al, 5.01%Ti, 0.98%B, 0.19%Fe, 0.13%Si) (the loss rate of Ti is about 8%), 4.8g Mg (the loss rate of Mg is about 20 %), the master alloy can be purchased directly from the market, or can be self-prepared by conventional methods; after it is completely melted, it is poured into a ladle, and after standing for 1 to 5 minutes, the slag is removed and cast into an ingot; that is, to obtain magnesium , strontium, titanium and boron composite microalloyed manganese brass

[0051] The composition of the composite microalloyed manganese brass of the present embodiment is actually measured by spectrum: 37.07%Zn, 1.42%Mn, 1.52%Al, 0.73%Fe, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com