Surface strengthening method of extrusion die

An extrusion die and surface strengthening technology, which is applied in the field of extrusion die surface strengthening, can solve the problems that the friction coefficient of the die surface cannot be reduced, the surface of the extrusion die is prone to wear, and the surface oxidation resistance is not high, so as to achieve the performance of protection , reduce the friction coefficient, improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

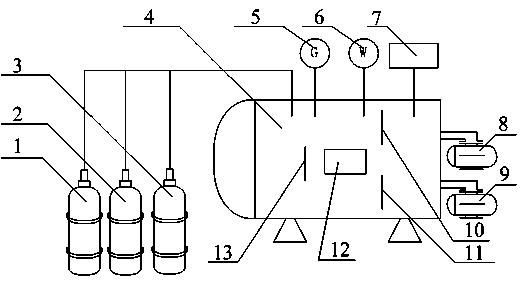

Image

Examples

Embodiment 1

[0054] The remanufacturing and strengthening treatment of the extrusion die surface made of H13 hot work die steel includes the following steps:

[0055] (1) Perform gas nitriding treatment on the surface of the mold to be treated, the nitriding medium is NH3, the nitriding temperature is 550°C, and the holding time is 12h. After the mold temperature drops to room temperature, take out the mold;

[0056] (2) Use a hand-held polishing grinder to polish the surface of the nitriding mold, remove the "white layer" on the nitriding surface of the mold, and at the same time polish the surface so that the surface of the mold is in a mirror state, and the roughness Ra≯0.40μm;

[0057] (3) Put the polished and polished mold into the ultrasonic cleaning equipment, and use the mixed solution of absolute ethanol and acetone to clean the surface of the mold. The mixing volume ratio of absolute ethanol and acetone is 1.5:1 to ensure the mold The surface is free of oil, rust, and impurities...

Embodiment 2

[0068] The remanufacturing and strengthening treatment of the surface of the extrusion die suitable for common aluminum profiles includes the following steps:

[0069] (1) Perform gas nitriding treatment on the surface of the mold to be treated, and the nitriding medium is NH 3 , the nitriding temperature is 510°C, and the holding time is 10h. After the mold temperature drops to room temperature, take out the mold;

[0070] (2) Use a hand-held polishing grinder to polish the surface of the nitriding mold, remove the "white layer" on the nitriding surface of the mold, and at the same time polish the surface so that the surface of the mold is in a mirror state, and the roughness Ra≯0.40μm;

[0071] (3) Put the mold that has been polished and polished into an ultrasonic cleaning device, and use a mixed solution of absolute ethanol and acetone to clean the surface of the mold. The mixing volume ratio of absolute ethanol and acetone is 1:1 to ensure that the mold The surface is f...

Embodiment 3

[0082] The remanufacturing and strengthening treatment of the surface of the extrusion die suitable for common aluminum alloy profiles includes the following steps:

[0083] (1) Perform gas nitriding treatment on the surface of the mold to be treated, and the nitriding medium is NH 3 , the nitriding temperature is 530°C, and the holding time is 12 hours. After the mold temperature drops to room temperature, take out the mold;

[0084] (2) Use a hand-held polishing grinder to polish the surface of the nitriding mold, remove the "white layer" on the nitriding surface of the mold, and at the same time polish the surface so that the surface of the mold is in a mirror state, and the roughness Ra≯0.40μm;

[0085] (3) Put the polished and polished mold into the ultrasonic cleaning equipment, and use the mixed solution of absolute ethanol and acetone to clean the surface of the mold. The mixing volume ratio of absolute ethanol and acetone is 1.2:1 to ensure the mold The surface is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com