Method for preparing zirconium diboride coating

A technology of zirconium diboride and coating, which is applied in the field of preparation of ceramic coatings, can solve the problems of high requirements for gas flow meters, achieve the effects of preventing oxidation, increasing deposition speed, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

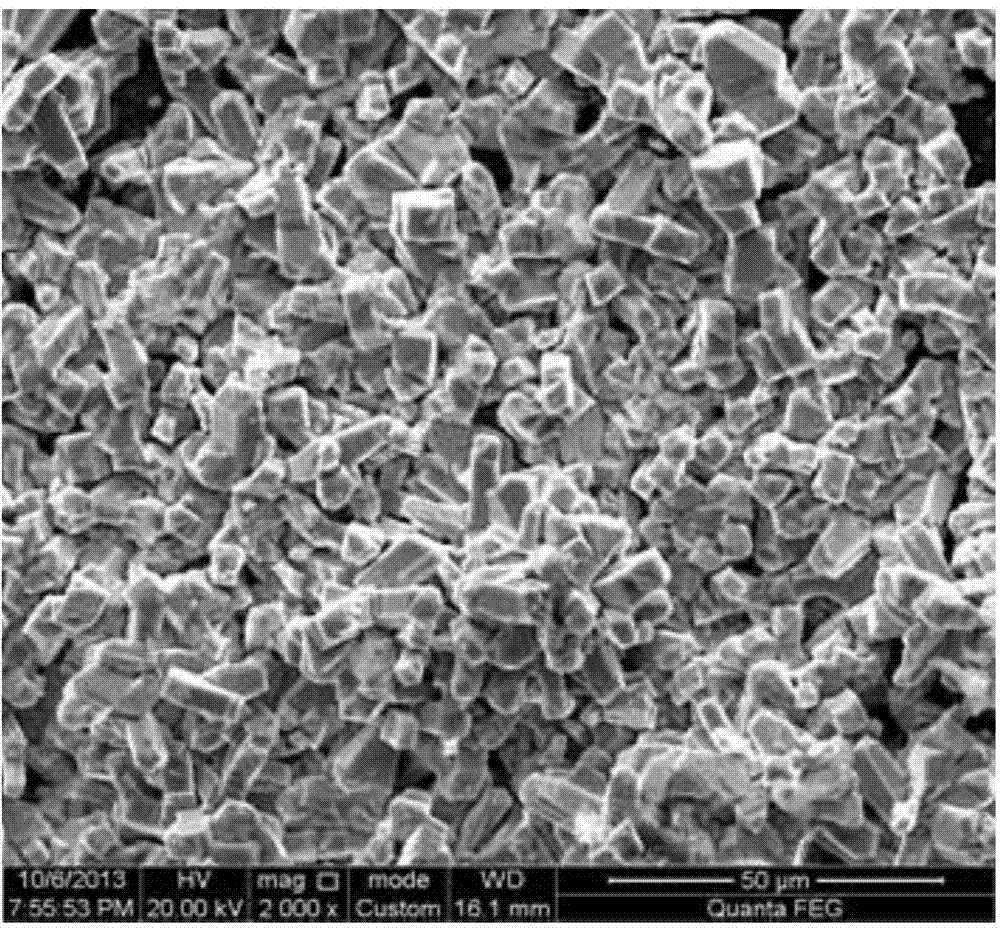

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of a kind of zirconium diboride coating of this embodiment is carried out according to the following steps:

[0021] One, the ZrCl 4 Placed in one temperature zone of the reaction chamber, the substrate material is placed in another temperature zone of the reaction chamber, the reaction chamber is first evacuated by a vacuum system, and then Ar gas or N 2 , to get rid of the air in the reaction chamber;

[0022] 2. Use the heating system 2 to heat up the temperature zone where the substrate material is placed at a rate of 1°C / min to 20°C / min. During the temperature rise process, Ar gas or N 2 Protection, after the temperature rises to 500 ° C ~ 1600 ° C, the reaction gas BCl is introduced 3 、H 2 , while utilizing the heating system 1 to place the ZrCl 4 The temperature of the temperature zone is heated to 300°C ~ 1000°C, and then BCl is heated at a temperature of 500°C ~ 1600°C 3 、H 2 and ZrCl 4 The gas is deposited...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the substrate material in step 1 is graphite, zirconium alloy or copper. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the BCl that passes into the reaction chamber per unit time described in step two 3 with ZrCl 4 The molar ratio is (0.1~20):1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com