A kind of preparation method of c/c composite material and its surface anti-oxidation composite coating

A composite material and composite coating technology, which is applied in the field of preparation of C/C composite materials and their surface anti-oxidation composite coating, can solve the problems of long preparation cycle, unfavorable double SiC composite coating, long heat preservation time, etc., and achieve The effect of short preparation cycle, good combination and lower preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

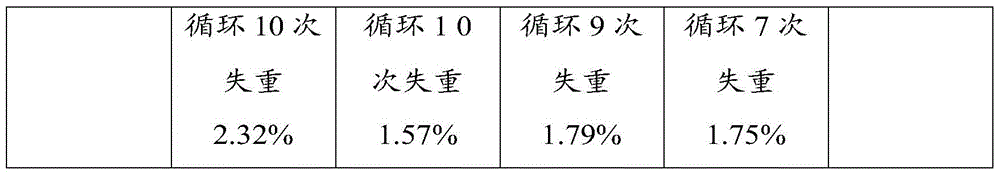

Examples

Embodiment 1

[0030] The preparation method of the anti-oxidation composite coating on the surface of C / C composite material comprises the following steps:

[0031] The first step: first spread the inner layer of anti-oxidation powder on the surface of the C / C composite material, and then spread the outer layer of anti-oxidation powder to obtain a blank;

[0032] Step 2: put the blank into a discharge plasma sintering furnace, heat-preserve and sinter at 1200°C in a vacuum environment for 1 min, and then take it out of the furnace to obtain the product;

[0033] Wherein, the first layer of anti-oxidation powder is composed of the following components: by weight, 70 parts of elemental Si and 30 parts of elemental C; the second layer of anti-oxidation powder is SiC powder.

Embodiment 2

[0035] The preparation method of the anti-oxidation composite coating on the surface of C / C composite material comprises the following steps:

[0036] The first step: first spread the inner layer of anti-oxidation powder on the surface of the C / C composite material, and then spread the outer layer of anti-oxidation powder to obtain a blank;

[0037] Step 2: Put the blank into a discharge plasma sintering furnace, heat-preserve and sinter at 1250°C for 1 minute in a vacuum environment, and then take it out of the furnace to obtain the product;

[0038] Wherein, the first layer of anti-oxidation powder is composed of the following components: by weight, 70 parts of elemental Si and 30 parts of elemental C; the second layer of anti-oxidation powder is SiC powder.

Embodiment 3

[0040] The preparation method of the anti-oxidation composite coating on the surface of C / C composite material comprises the following steps:

[0041] The first step: first spread the inner layer of anti-oxidation powder on the surface of the C / C composite material, and then spread the outer layer of anti-oxidation powder to obtain a blank;

[0042] Step 2: put the blank into a discharge plasma sintering furnace, heat-preserve and sinter at 1300°C for 1 min in a vacuum environment, and then take it out of the furnace to obtain the product;

[0043] Wherein, the first layer of anti-oxidation powder is composed of the following components: by weight, 70 parts of elemental Si and 30 parts of elemental C; the second layer of anti-oxidation powder is SiC powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com