Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Act as a "plasticizer"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluororubber rubber compound and preparation method thereof

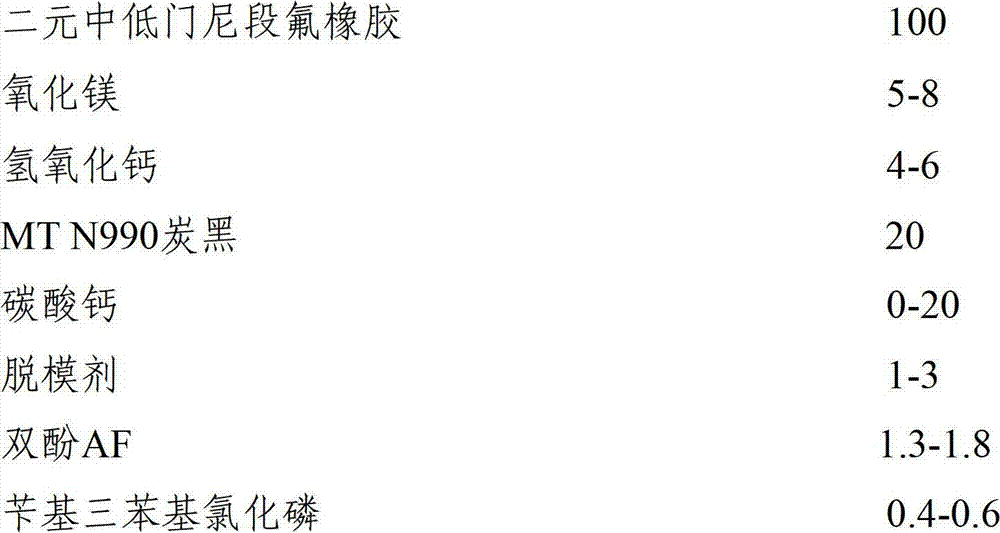

The invention provides a fluororubber rubber compound and a preparation method thereof. The fluororubber rubber compound is prepared by mixing binary intermediate-low monney sectional fluororubber rubber, reinforcing system (MT N990 carbon black and inorganic filler), acid absorbing system (active magnesium oxide and superfine calcium hydroxide), vulcanizing system (benzyl triphenyl phosphorus chloride and bisphenol AF), releasing agent (alfux and / or carnauba wax), and multifunctional bisphenol vulcanizing composite assistant vulcanizing agent L; the obtained fluororubber rubber compound has high stretching strength, and high extending rate, increases the scorching time by improving the liquidity of the rubber, therefore, high adaptability of the rubber to different manufacture technical environments and the vulcanizing environments can be ensured, the safety in vulcanizing can be improved, and as a result, the rejection rate of the products can be reduced. The fluororubber rubber compound provided by the invention is applicable to industries such as aerospace, aviation, car, metallurgy, petrochemical industry and electron and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Coating composite material and preparation method thereof

InactiveCN110117911AImprove insulation performanceImprove flame retardant performanceCoatingsTextiles and paperFiberPolyester

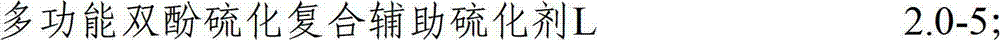

The invention relates to a coating composite material, in particular to a coating composite material with high heat insulation and high peeling strength taking polyvinyl chloride and polyester fiber base cloth as main base materials and a preparation method of the material, and belongs to the technical field of new materials. The composite material comprises a polyester fiber fabric base materiallayer, wherein a coating surface layer and a back layer are respectively arranged on both sides of the base material layer; the back layer comprises a flame-retardant PVC primer layer and a flame-retardant PVC heat insulation layer from inside to outside; and the coating surface layer comprises a flame-retardant PVC primer layer, a flame-retardant PVC heat insulation layer, a PVC high reflection layer and an infrared reflection heat insulation transparent layer from inside to outside, and is prepared by adopting a specific preparation method. The coating composite material has good heat insulation, high peeling strength and wicking resistance characteristics, and has excellent flame resistance, weather resistance and ultraviolet resistance.

Owner:NINGBO XIANFENG NEW MATERIAL

Low-viscosity alkoxy terminated polysiloxane and preparation method thereof

The present invention relates to an organic silicon rubber material, and in particular to a low-viscosity alkoxy terminated polysiloxane and a preparation method thereof. The low-viscosity alkoxy terminated polysiloxane is prepared by polymerization of the following raw materials, in parts by weight: 50 to 100 parts of base rubber and 0.1-50 parts of alkoxy silane. The preparation method has the advantages of low cost, high yield and simple process; and the low-viscosity alkoxy terminated polysiloxane not only reduces the viscosity of products, but also improves the mechanical properties of the products, and solves the defects that physical plasticizers exude oil and are easy to volatilize and migrate.

Owner:文仁光

High-strength and anti-impacting natural rubber cable sheathing material

ActiveCN106117644AHigh strengthGood compatibilityInsulated cablesInsulated conductorsLow-density polyethylenePolymer science

The invention discloses a high-strength and anti-impacting natural rubber cable sheathing material. The high-strength and anti-impacting natural rubber cable sheathing material is prepared from the following raw materials: natural rubber, polyvinyl chloride, low-density polyethylene, an ethylene-vinyl acetate copolymer, zinc oxide, stearic acid, sulfur, high-abrasion-resisting furnace black, carbon nanotubes, nano calcium carbonate, montmorillonoid, zirconium diboride, calcium sulfate whiskers, lignocellulose short fibers, cotton short fibers, an accelerant M, an accelerant BZ, a poly-3-hydroxybutyrate-4-hydroxybutyrate, epoxy soybean oil, an anti-aging agent RD, an anti-aging agent MB, p-aminodiphenyl amine, gamma-epoxypropoxy propyltrimethoxysilicane and vinyltriethoxysilane. The high-strength and anti-impacting natural rubber cable sheathing material disclosed by the invention is high in strength, good in anti-impacting performance, excellent in anti-aging performance and long in service life.

Owner:ANHUI ELECTRIC GRP SHARES

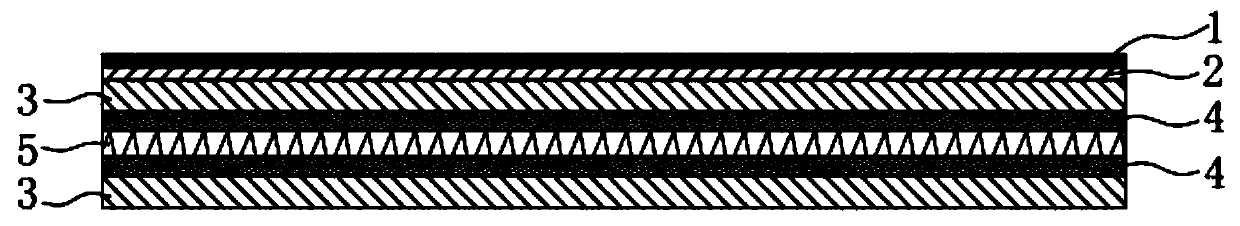

Process for preparing moulded zeolite by utilizing coal ash

InactiveCN101870477ASolve the reuse problemReduce pre-activation processMolecular-sieve and base-exchange compoundsPolymer scienceCoal

The invention discloses a process for preparing moulded zeolite by utilizing coal ash. The concrete method includes: coal ash, regulator, exciting agent, additive and water are fully mixed, ageing is carried out, and extrusion moulding is carried out; moulding material is subject to autoclave maintenance and then is subject to heat treatment in a programmed heating furnace, finally the moulding material is subject to zeolitization in NaOH aqueous solution, and washing and drying are carried out, thus obtaining the moulded zeolite. In the method, coal ash moulding and coal ash zeolitization are combined together, thus not only saving raw material and reducing energy consumption but also shortening process period. The moulded coal ash zeolite prepared by the method has the characteristics of high mechanical strength, simple preparation method, various shapes, low cost, corrosion resistance, light weight and a plurality of three-dimensional through pore canals, thus being capable of being widely applied to the fields of absorbing material, catalyst carrier, wall material and building material.

Owner:NANJING UNIV OF SCI & TECH

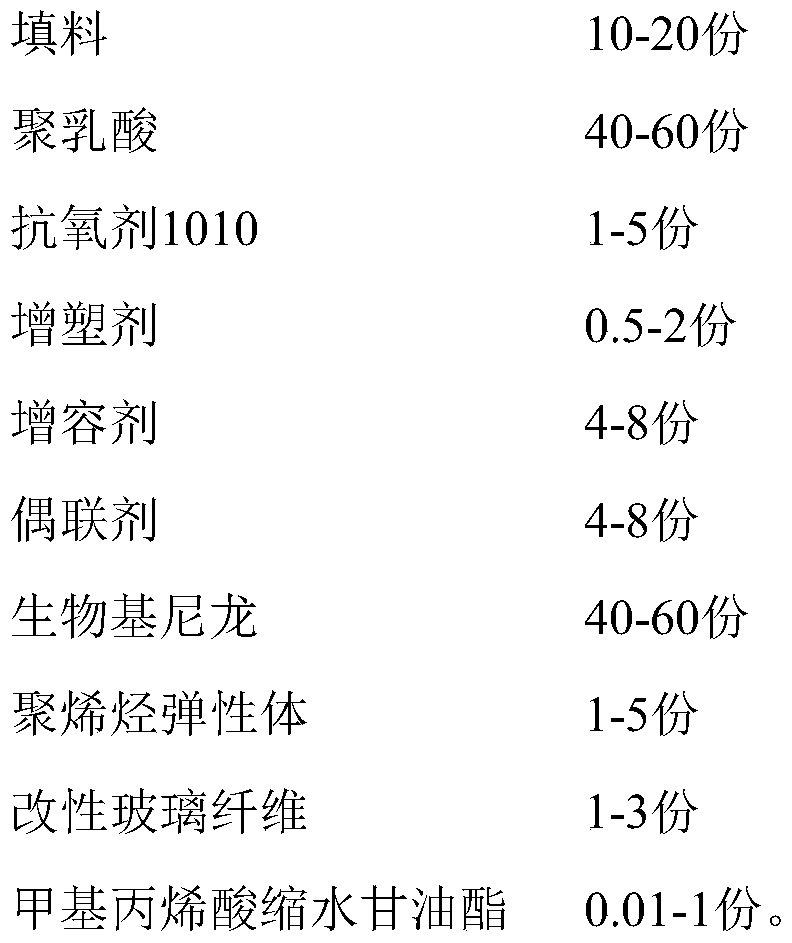

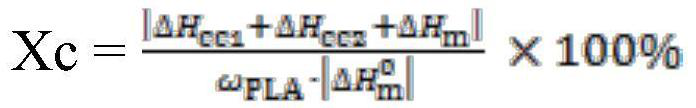

Bio-based nylon composite PLA material and preparation method thereof

ActiveCN110467804AProtects against thermo-oxidative degradationHigh mechanical strengthElastomerGlycidyl methacrylate

The invention relates to the technical field of biomaterials, particularly to a bio-based nylon composite PLA material and a preparation method thereof, wherein the raw materials comprise, by weight,10-20 parts of a filler, 40-60 parts of polylactic acid, 1-5 parts of an antioxidant1010, 0.5-2 parts of a plasticizer, 4-8 parts of a compatibilizer, 4-8 parts of a coupling agent, 40-60 parts of a bio-based nylon, 1-5 parts of a polyolefin elastomer, 1-3 parts of modified glass fiber, and 0.01-1 part of glycidyl methacrylate. According to the present invention, the mechanical strength and the size stability of the PLA material are improved by filling the modified glass fiber with the bio-based nylon and the polylactic acid while the bio-based nylon and polylactic acid compounding process isfilled and grafted by using the filler and the high-toughness grafting agent glycidyl methacrylate, such that the bio-based nylon composite PLA material meets the performance requirements of engineering plastics and has good degradability.

Owner:DONGGUAN ZHONGYI NEW MATERIAL TECH CO LTD

Synthesis method of polyether ester plasticizer

The present invention discloses a method for preparation of a novel polyether ester green plasticizer from adipic acid, C4-C6 dihydric alcohols, and ether-bond-containing C4-C6 dihydric alcohols as main raw materials by addition of a catalyst for three-step esterification, neutralization, water washing, bleaching, reduced pressure distillation, and purification, wherein the catalyst is n-tetrabutyl titanate, stannous octoate and stannous chloride. The designed preparation process is simple and efficient, and rich in source of raw materials. The designed novel polyether ester exhibits better durability, and anti-migration property, and large-scale industrial production can be performed.

Owner:TIANJIN UNIV OF SCI & TECH

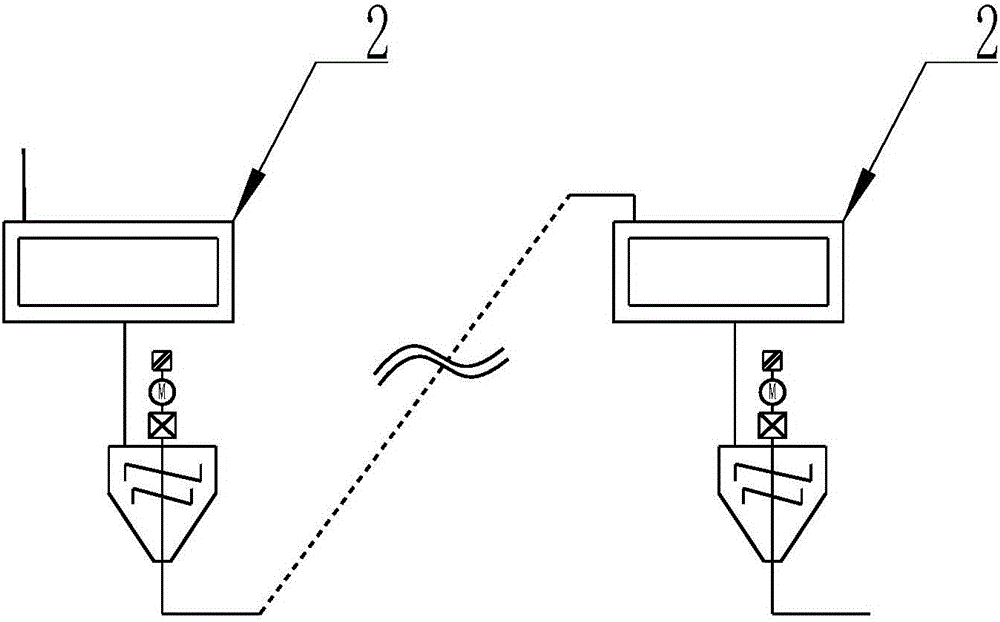

Preparation method of lithium ion phosphate power battery cathode plate

The invention provides a preparation method of a lithium ion phosphate power battery cathode plate. The method comprises the following steps: (1) adding an adhesive for preparing a cathode material to a solvent, and stirring and fully dissolving the adhesive to prepare a solution; (2) adding a conductive agent, an additive and lithium ion phosphate to the solution prepared in the step (1) respectively, and stirring the conductive agent, the additive and the lithium ion phosphate evenly at a high speed to prepare cathode slurry; (3) coating a cathode current collector with the slurry prepared in the step (2) to form a cathode material layer; and (4) coating the cathode material layer with a coating layer for improving the safety of the cathode plate, and carrying out drying, rolling and slitting to prepare the lithium-ion battery cathode plate. The additive is prepared from the following raw materials in percentage by weight: 1%-20% of ethanol, 10%-30% of N-methylpyrrolidone and 50%-85% of ethylene carbonate. The preparation method can obviously improve dusting of the lithium ion phosphate cathode plate and improves gram volume development of the lithium iron phosphate; the cost is low; and the operation is simple and easy.

Owner:HUBEI YUNENG POWER CO LTD

Offset printing black ink formula

InactiveCN104987766AChange viscosityChange acid value and even glossInksMicrocrystalline waxKerosene

The present invention discloses an offset printing black ink formula, wherein the materials in the formula comprise resin oil, colloid oil, a long oil alkyd resin, phthalocyanine blue B, a Reflex Blue slurry, high pigment carbon black, furnace pigment carbon black, poly ethylene microcrystalline wax, polytetrafluoroethylene microcrystalline wax, cobalt isooctanoate, manganese isooctanoate, zirconium isooctanoate, butyraldehyde oxime, and high boiling point kerosene. According to the present invention, the phthalocyanine blue B, the Reflex Blue slurry, the high pigment carbon black and the furnace pigment carbon black are adopted as the ink pigment so as to provide the coloration effect; the resin oil, the colloid oil and the long oil alkyd resin are adopted as the connection material so as to disperse the pigment; the poly ethylene microcrystalline wax and the polytetrafluoroethylene microcrystalline wax are the ink filler and can be filled in the ink so as to reduce the cost; and the remaining cobalt isooctanoate, the manganese isooctanoate, the zirconium isooctanoate, the butyraldehyde oxime and the high boiling point kerosene are the additional material of the ink.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

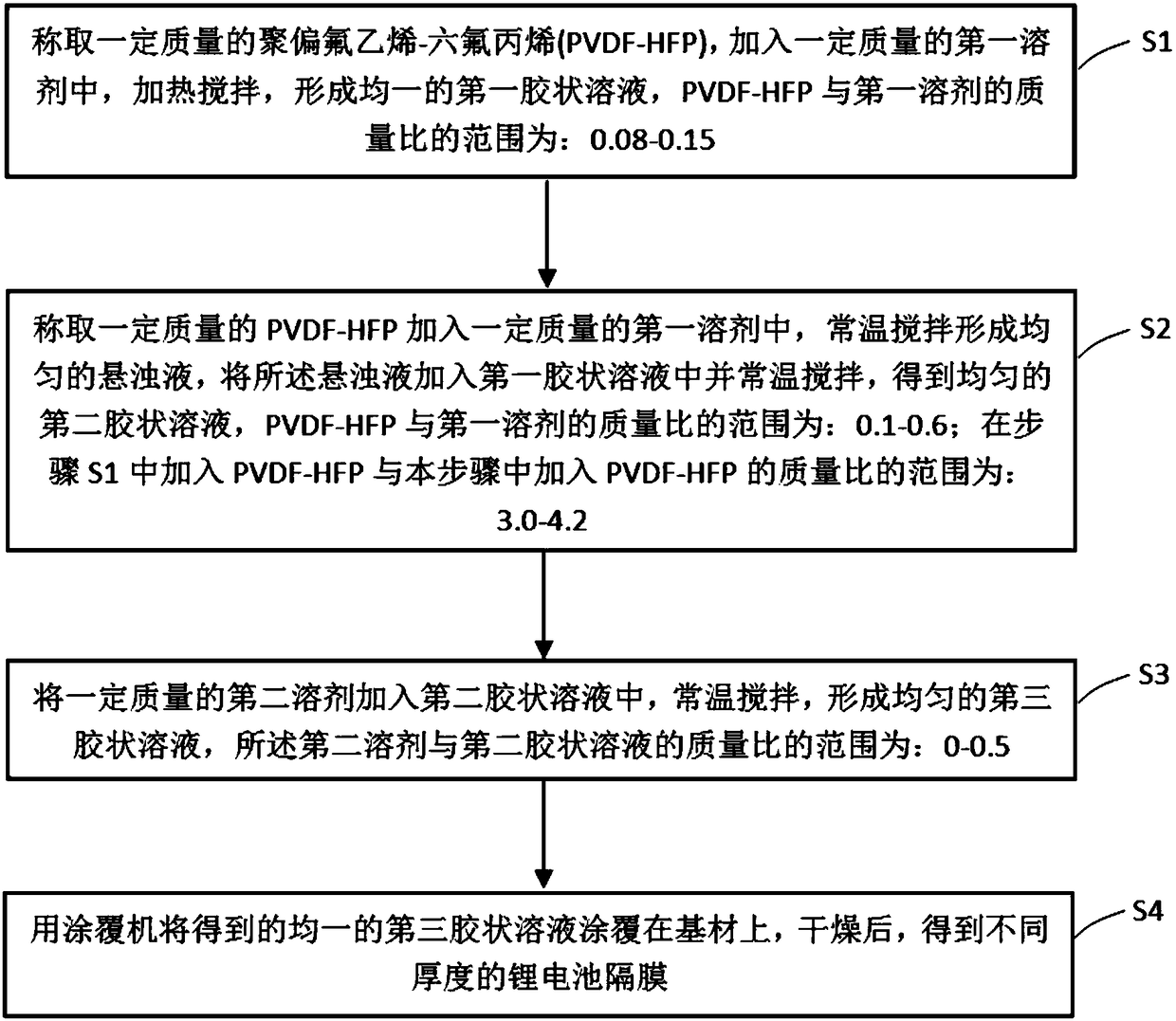

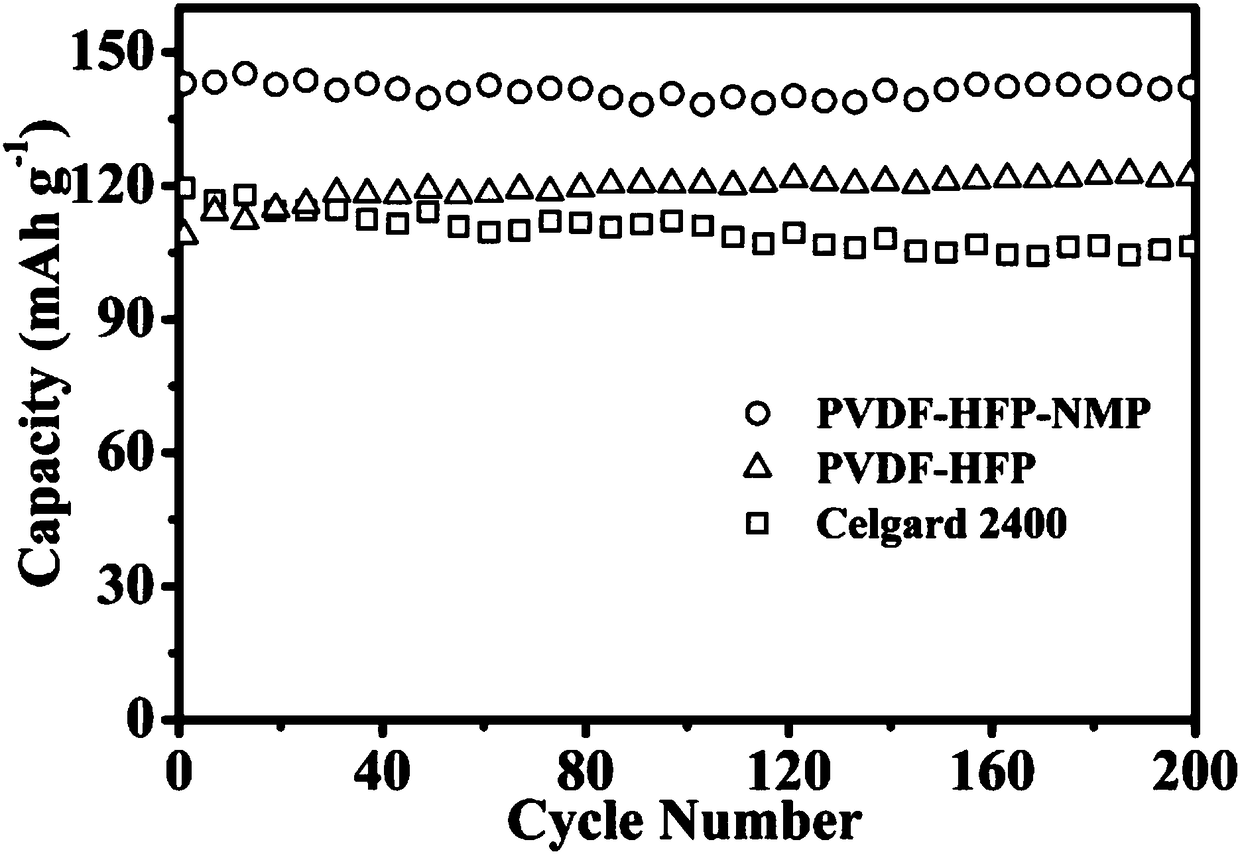

Lithium battery diaphragm preparation method based on mixed solvent multi-stage volatilization mechanism

ActiveCN108134034AImprove structural strengthImprove toughnessCell component detailsCoatingsCrystallographyCross-link

The invention discloses a lithium battery diaphragm preparation method based on a mixed solvent multi-stage volatilization mechanism. The preparation method comprises the steps of performing heating dissolution on a certain mass of PVDF-HFP in a certain mass of first solvent, performing normal temperature dissolution on a certain mass of PVDF-HFP in a certain mass of first solvent, enabling the above two parts to be mixed uniformly and then adding a certain mass of second solvent, performing uniform mixing and than coating a base material, and carrying out drying to obtain the lithium batterydiaphragm. According to the preparation method, the PVDF-HFP is added into the first solvent in two times to form a cross-linked network structure with link; then the second solvent is added to dissolve a part of the link, and the dissolved partial link forms the cross-linked network structure to wind around the linkage; after drying, the first solvent is volatilized to form main lithium ion transmission holes; and the second solvent is volatilized to form holes in the cross-linked network structure around the link, so that the surrounding strength of the link of the lithium battery thin filmis reinforced, and the strength of the lithium battery diaphragm is further reinforced.

Owner:SHENZHEN LI S TECH CO LTD

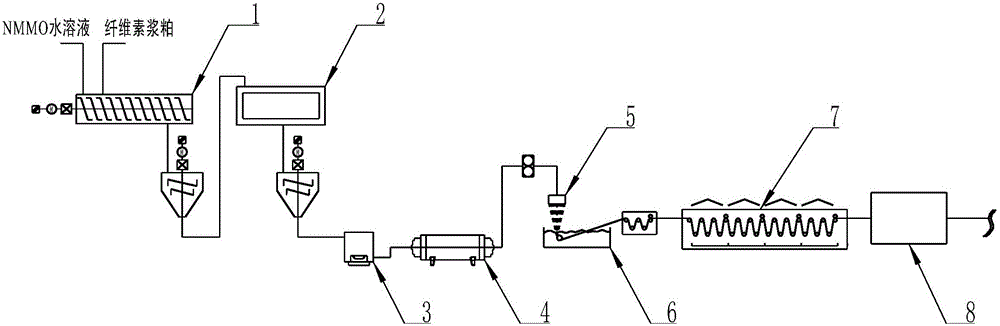

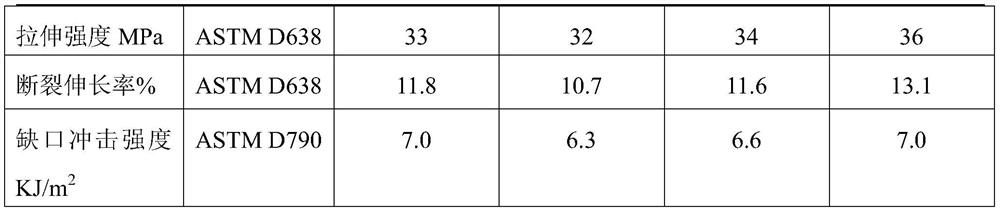

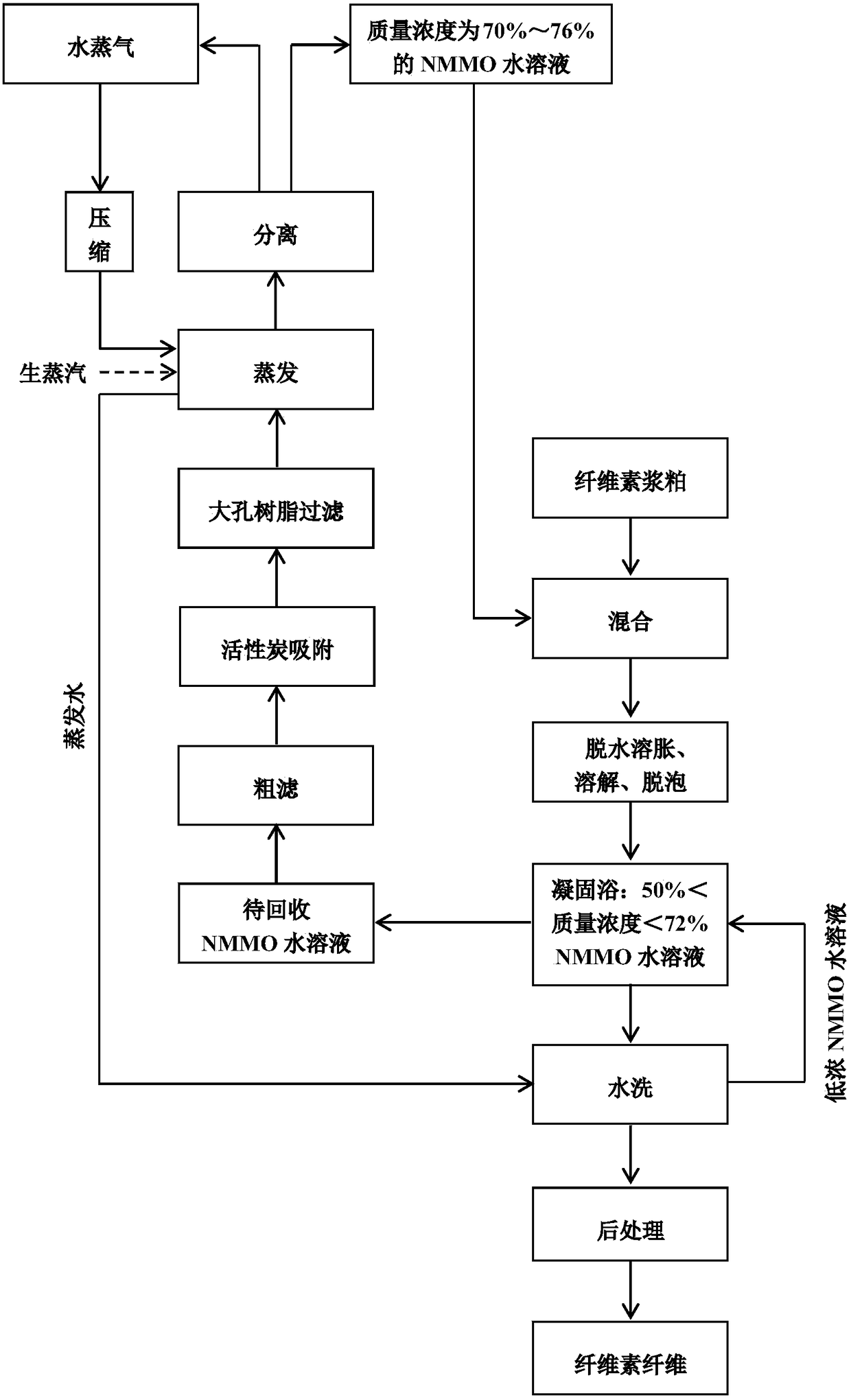

Preparation method of cellulosic fibers

ActiveCN106222771ASimple preparation processEliminate security risksArtificial filament recoveryArtificial filament washing/dryingCellulose fiberDissolution

The invention discloses a preparation method of cellulosic fibers. The preparation method includes the following steps that 1, cellulose pulp is mixed with an NMMO water solution with the mass concentration of 60%-85%, preferably 70%-76% to obtain a uniform mixture; 2, the obtained uniform mixture is subjected to dehydration swelling and dissolution defoaming to obtain a cellulose spinning solution; 3, the obtained cellulose spinning solution is filtered and subjected to heat exchange and then enters a spinning machine, after the cellulose spinning solution is extruded through a spinning assembly and air-cooled, the cellulose spinning solution enters a solidification system and is solidified in an NMMO solidification bath with the mass concentration larger than 50% and smaller than 72%, and nascent fibers are obtained; 4, the obtained nascent fibers are washed to obtain cellosilk bundles, and then the cellulosic fibers are obtained through subsequent section treatment. Equipment investment can be greatly reduced, the process is simplified, energy consumption and industrialization cost are reduced, safety production is promoted, the homogeneity and mechanical performance of the fibers are improved, and therefore the preparation method is more suitable for efficient low-consumption industrial production.

Owner:CHINESE TEXTILE ACAD

High-heat-resistance modified PGA material and preparation method thereof

The invention provides a high-heat-resistance modified PGA material and a preparation method thereof. The modified PGA material is prepared from the following raw materials in parts by weight: 70-80 parts of polyglycolic acid resin, 5-15 parts of filler, 10-30 parts of castor oil mixture and 0.5-1 part of nucleating agent; wherein the castor oil mixture is a mixture of castor oil with purity of 90% and methanol, and the mass ratio of castor oil to methanol is 7.5-8.5:2. The nucleating agent is selected from one or more of talcum powder, inositol and sebacic acid dimethylbenzene hydrazide; the filler is selected from one or more of nano montmorillonite, nano calcium carbonate and edible starch. The castor oil mixture, the nucleating agent and the filler are used for modifying the polyglycolic acid resin, so that the modified PGA material has high crystallization performance and can be used for preparing high-heat-resistance products.

Owner:海南赛高新材料有限公司

High-anti-permeability cement-based repair material for tunnel engineering and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a high-anti-permeability cement-based repair material for tunnel engineering. The repair material consists of portland cement, coal ash, silica fume, steel slag powder, rock powder, tailing sand, quartz sand, attapulgite, acrylate emulsion, cellulose ether, polyacrylamide, PVA fibers, PET fibers, a polycarboxylic acid water reducer and a defoaming agent. The repair material has the characteristics of easy construction, good working performance, good water retention performance, high compressive strength, high anti-permeability level, high toughness and adhesion, excellent durability and the like; and the repair material can be suitable for construction initial protection or engineering later maintenance and repair of lining concrete in the tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

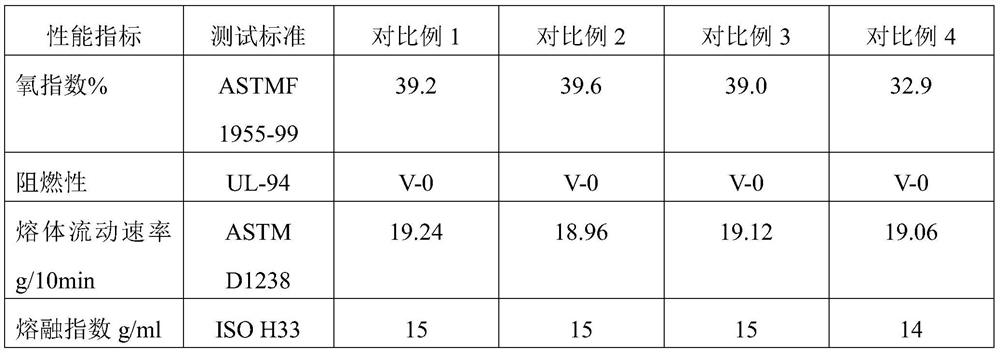

Low-odor high-weld-line-strength flame-retardant PC/ABS (polycarbonate/acrylonitrile butadiene styrene) composite

InactiveCN105778463AAvoid problems such as precipitationImprove flame retardant performancePolymethyl methacrylateUltimate tensile strength

The invention relates to a low-odor high-weld-line-strength flame-retardant PC / ABS (polycarbonate / acrylonitrile butadiene styrene) composite which comprises PC, a phosphorus-containing flame retardant, ABS, PMMA (polymethyl methacrylate) and an impact resistant modifier. The low-odor high-weld-line-strength flame-retardant PC / ABS composite is prepared by means of preparing the ABS, PMMA and impact resistant modifier into a one-step material YBL-ABS through physical extrusion prior to mixing the one-step material YBL-ABS with waste materials. The composite has the advantages that the one-step material used is simple and easy to obtain, the preparation process is simple, cost is low, small molecules in material molecules can be removed effectively, meanwhile, weld line strength of the material is improved, and mechanical properties of the material can be improved significantly; the material can be applied to industries such as automobiles, refrigerators and televisions.

Owner:TIANJIN KINGFA NEW MATERIAL

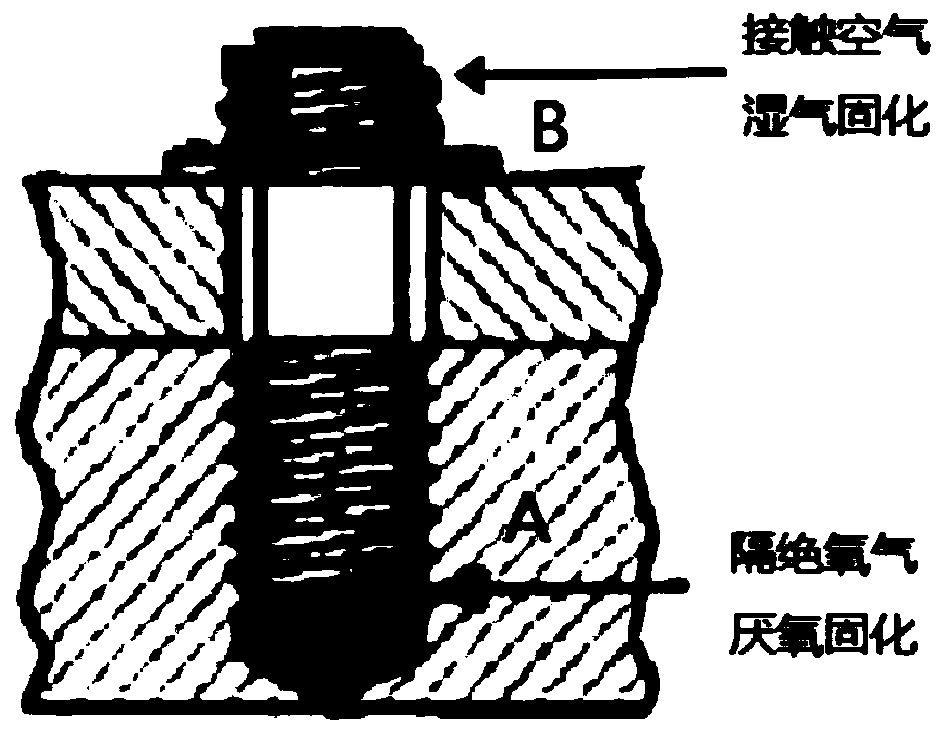

Moisture-curable anaerobic adhesive and preparation method thereof

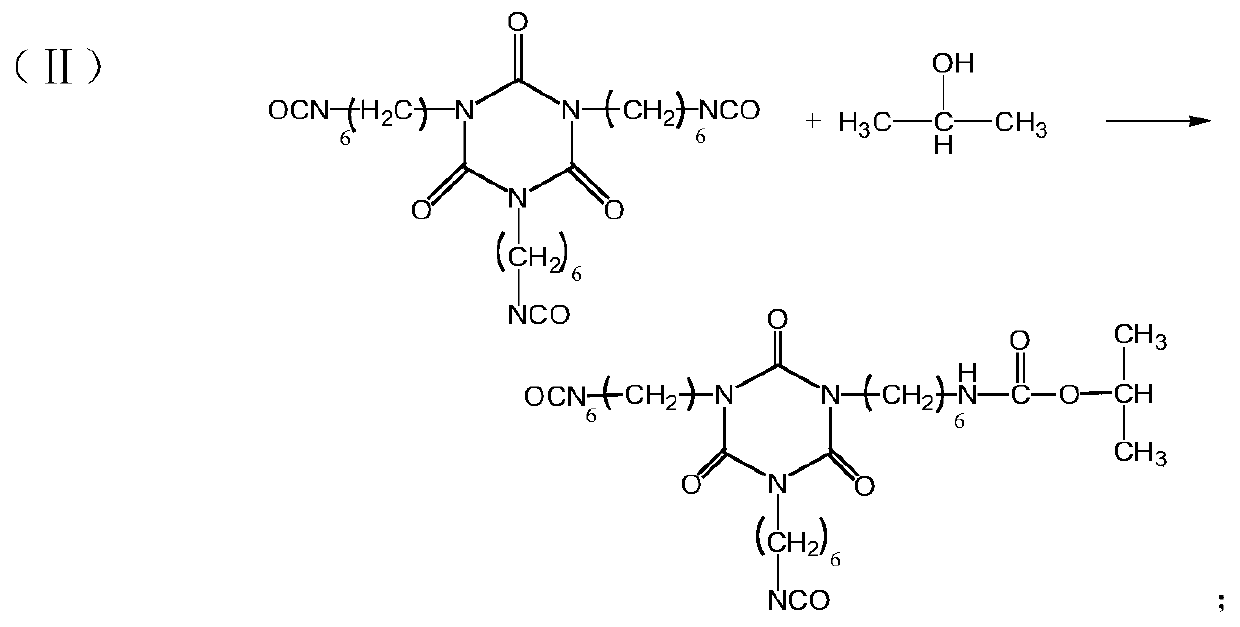

PendingCN110128994AImprove initial tackReduce bond strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemical reactionAdhesive

The invention relates to a moisture-curable anaerobic adhesive and a preparation method thereof. According to the present invention, when a metal material is adhered, the closed anoxic environment ofthe adhered surface can cause a chemical reaction between the isocyanate group-containing monomer pr prepolymer in an anaerobic adhesive and the polar group on the surface of the metal substrate to generate bridging effect so as to improve the initial adhesion of the anaerobic adhesive to the metal substrate, and the(meth)acryloyloxy group contained in the anaerobic adhesive is subjected to rapidradical polymerization, and the monomer or prepolymer containing more than or equal to 2 isocyanate groups in the system can provide plasticizing effect to maintain the adhesion of the system at a high level so as to achieve the effects of curing and firm adhesion, such that the bonding strength of the anaerobic adhesive is greatly improved; and a small amount of the isocyanate group contained inthe moisture-curable anaerobic adhesive overflowing from the seam of the adhered surface chemically reacts with the water in the air to dry the surface, such that the defect of the contamination on the metal material is avoided while the excess curing glue can be conveniently cut off by using a cutter blade.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

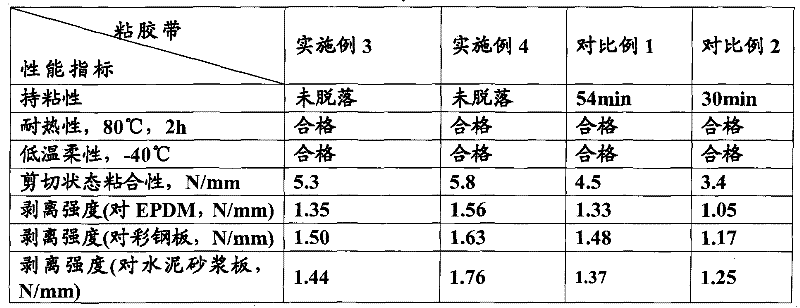

Butyl rubber composition and method for producing butyl rubber adhesive tape by using same

InactiveCN101824288BHigh peel strengthLow viscosityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention discloses a butyl rubber composition and a method for producing a butyl rubber adhesive tape by using the same. Based on the total weight of the composition, the butyl rubber composition comprises the following components: 15 to 40 percent of butyl rubber matrix, 5 to 12 percent of styrenic thermoplastic elastomer, 8 to 20 percent of plasticizer, 20 to 40 percent of tackifying resin, 0.2 to 2 percent of vulcanizing agent and 10 to 30 percent of inorganic filler. The method for producing the adhesive tape comprises the steps of extrusion molding and vulcanizing. The adhesive tapeprepared by the butyl rubber composition has high peel strength and adhesiveness stability, and the process for producing the adhesive tape is simple and easy to control and is suitable for popularization and application.

Owner:中建材苏州防水研究院有限公司

Preparation method of polyoxyethylene water-soluble film

The invention relates to a preparation method of a polyoxyethylene water-soluble film. According to the method, polyoxyethylene serves as a raw material, additives are added, and the polyoxyethylene water-soluble film is prepared by an extruding and blow molding method. Compared with the prior art, the thickness of the prepared PEO film is 20-50 micrometers, the tensile strength of the film is higher than or equal to 10Mpa, the breaking elongation of the film is higher than or equal to 500%, and the dissolve time of the film is 20-150 seconds at the water temperature of 30 DEG C.

Owner:SHANGHAI RES INST OF CHEM IND +2

Organic silicon polymer composite emulsion and preparation method thereof

The invention discloses an organic silicon polymer composite emulsion and a preparation method thereof. The organic silicon polymer composite emulsion is prepared from the following components in parts by weight: 5-500 parts of ethylene vinyl acetate, 90-110 parts of organic silicon and 1-5 parts of a catalyst, wherein the organic silicon is one or more of phenethyl methyl polysiloxane, phenethylmethyl hydrogen-containing polysiloxane, substituted phenethyl methyl polysiloxane or substituted phenethyl methyl hydrogen-containing polysiloxane. The organic silicon polymer composite emulsion disclosed by the invention is a white viscous emulsion, and the organic silicon and the ethylene vinyl acetate form a cross-linked structure or an interpenetrating network structure, so that the originalphenomena of scattering, sand lost and spalling of pervious concrete can be effectively improved, and properties such as compressive strength of the pervious concrete can be increased.

Owner:南通福伦利新材料有限公司

Preparation method of Vitrimer material based on carboxyl-containing polysaccharide and dynamic ester bond

The invention belongs to the technical field of vitrimer material preparation, and designs a preparation method of a dynamic ester bond vitrimer material based on carboxyl-containing biomass polysaccharide. According to the preparation method, carboxyl-containing polysaccharide and biomass polyol are used as preparation raw materials, so that the use of petrochemical products in related fields isreduced, the problem of environmental pollution caused by large-scale use of petrochemical raw materials is relieved, and the problems of resource waste and environmental pollution caused by non-reusability of common plastic are solved. According to the method, biomass polysaccharide containing carboxyl and biomass polyol are used as raw materials, glycidyl ether is used as a cross-linking agent,and a three-dimensional network structure rich in a large number of ester groups is formed under the catalytic action of a catalyst through esterification reaction of carboxyl and epoxy groups. The biomass polysaccharide vitrimer material prepared by the preparation method disclosed by the invention is a novel, green and renewable vitrimer material.

Owner:DALIAN UNIV OF TECH

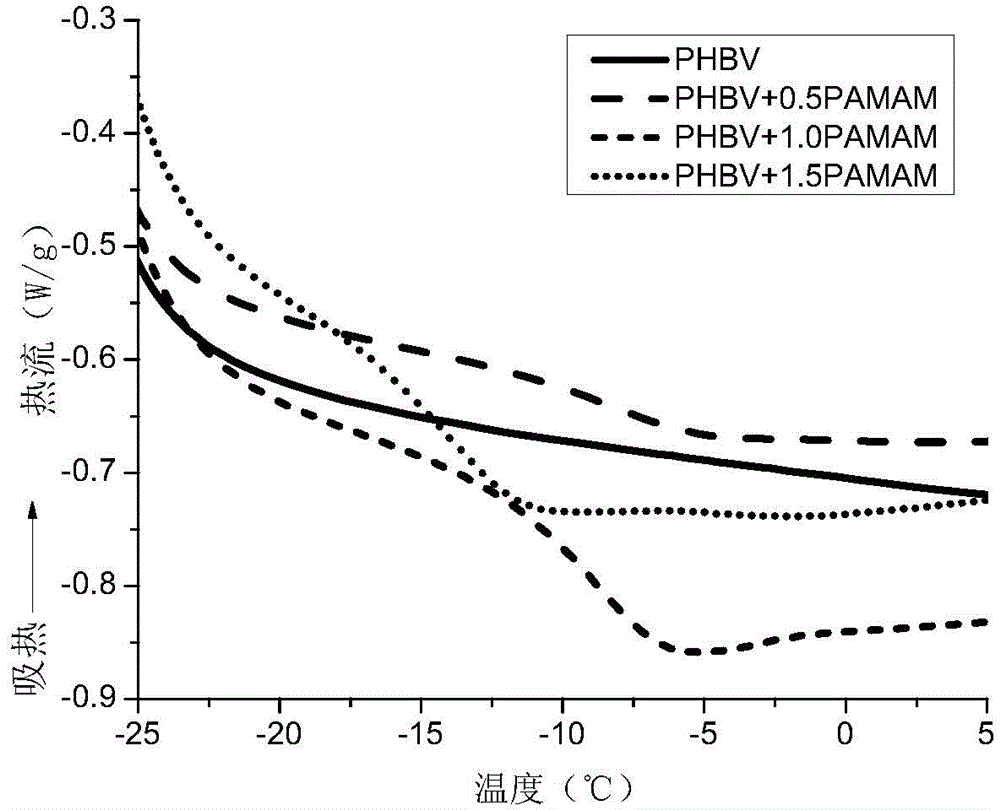

PHBV (poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) composite material as well as preparation method and applications thereof

The invention discloses a PHBV (poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) composite material as well as a preparation method and applications thereof. The preparation method comprises the following steps: adding PHBV resin in a solvent, stirring at the temperature of 55-65 DEG C, and performing condensation reflux for 3-5 hours to prepare a PHBV solution; adding a polyamide-amine dendrimer solution in the PHBV solution, heating and stirring for 4-6 hours to prepare a mixed solution of PHBV / polyamide-amine dendrimer; pouring the mixed solution of PHBV / polyamide-amine dendrimer into a mould, spreading a film and volatilizing the solvent to obtain the PHBV composite material. According to the preparation method of the PHBV composite material, the special three-dimensional structure of PAMAM (polyamide-amine) dendrimer and a large number of cavity structures in the PAMAM dendrimer are utilized to destroy the regularity of PHBV, and the molecular chain segments of PHBV are allowed to extend towards all directions to reduce the crystallinity of PHBV, so that the toughness of the PHBV composite material is enhanced.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

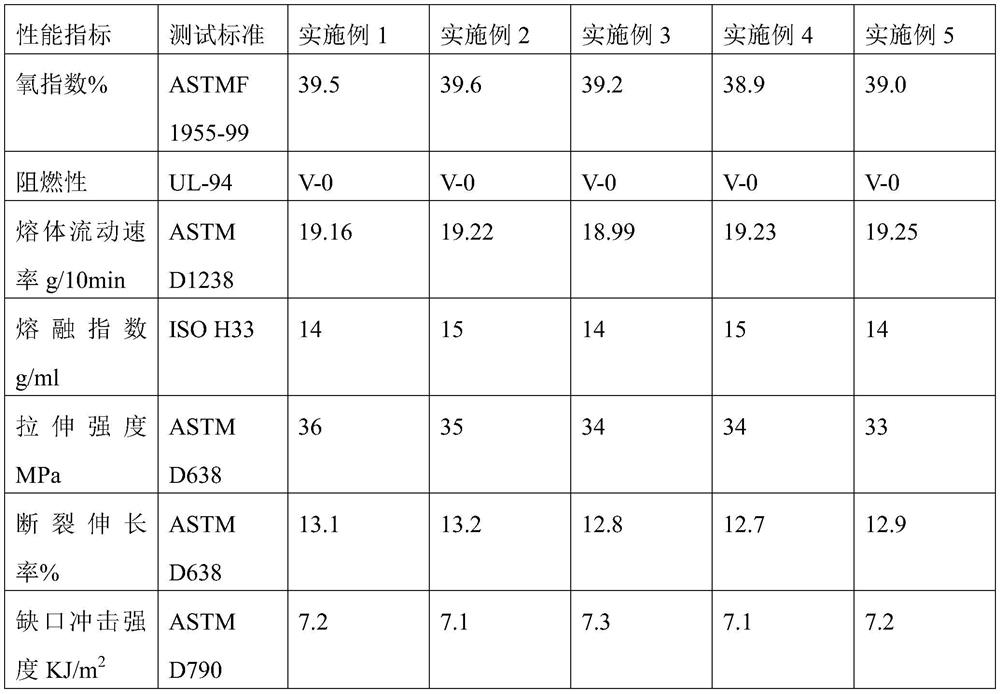

Polylactic acid plastic containing composite flame retardant and preparation method of polylactic acid plastic

The invention provides polylactic acid plastic containing a composite flame retardant. The polylactic acid plastic is prepared from the following raw materials in parts by weight: 100 to 120 parts of polylactic acid, 10 to 20 parts of plant fiber, 1 to 3 parts of pentaerythritol, 1 to 2 parts of starch, 10 to 15 parts of ammonium polyphosphate, 3 to 5 parts of melamine, 1 to 3 parts of modified white carbon black, 4 to 6 parts of ethylene oxide, 0.2 to 0.8 part of sorbitol, 1 to 2 parts of talcum powder, 1 to 2 parts of octadecanamide, and 0.1 to 0.4 part of an antioxidant. The polylactic acid plastic has the advantages of being environmentally friendly and high in flame retardant level; and meanwhile the influence of addition of the flame retardant on the physical and mechanical properties of the polylactic acid body material is reduced to the maximum extent.

Owner:孚莱孚(上海)新材料有限公司

A kind of preparation method of cellulose fiber

ActiveCN106222771BIncrease mass concentrationSimple preparation processArtificial filament recoveryArtificial filament washing/dryingCellulose fiberCoagulation system

The invention discloses a preparation method of cellulose fiber, comprising the following steps: 1) mixing cellulose pulp with an NMMO aqueous solution with a mass concentration of 60% to 85%, preferably 70% to 76%, to obtain a uniform mixture; 2) ) The obtained homogeneous mixture is dehydrated, swelled, dissolved and defoamed to obtain a cellulose spinning stock solution; 3) The obtained cellulose spinning stock solution enters the spinning machine after filtration and heat exchange, is extruded through the spinneret assembly, and after air cooling, enters The coagulation system is coagulated in an NMMO coagulation bath of 50%<mass concentration<72% to obtain nascent fibers; 4) the obtained nascent fibers are washed with water to obtain fiber tows, and then processed in subsequent stages to obtain the cellulose fibers. The invention can greatly reduce equipment investment, simplify process, reduce energy consumption and industrialization cost, facilitate safe production, improve fiber homogeneity and mechanical properties, and thus be more suitable for high-efficiency and low-consumption industrialized production.

Owner:CHINESE TEXTILE ACAD

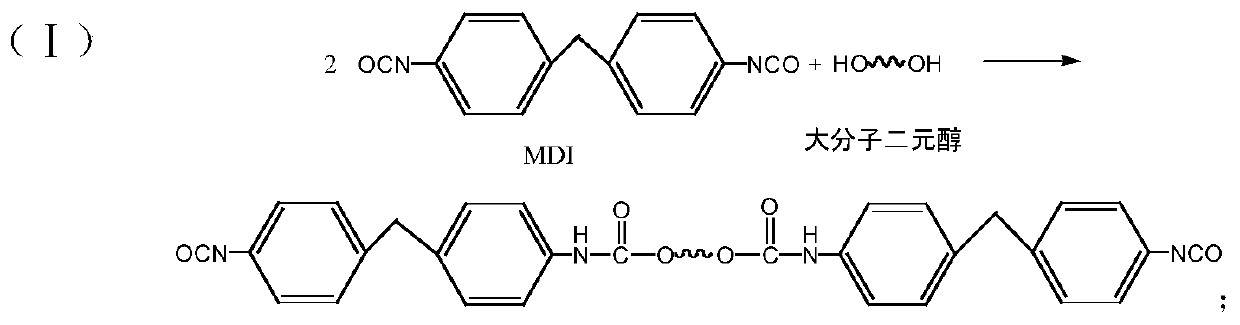

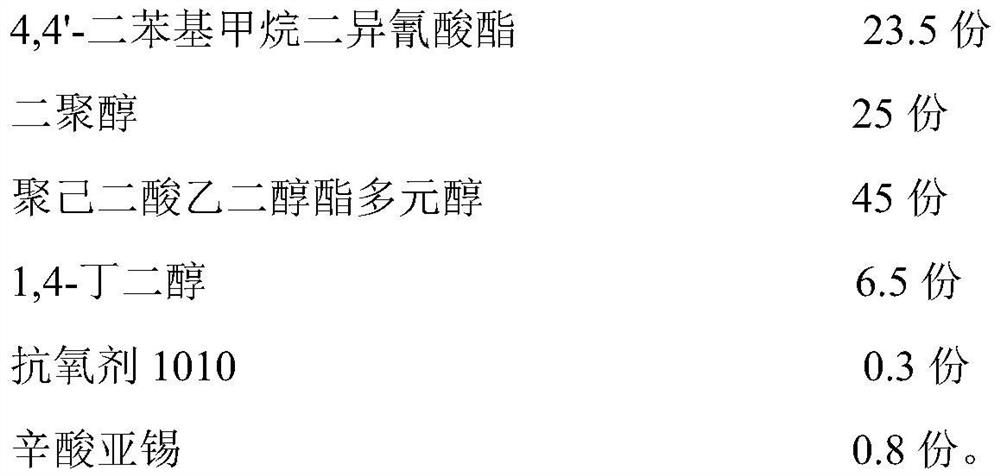

Non-polar modified TPU for shoe materials and preparation method thereof

The invention belongs to the technical field of thermoplastic polyurethane, and particularly relates to non-polar modified TPU for shoe materials and a preparation method of the non-polar modified TPU. The TPU is prepared from the following raw materials in parts by weight: 20-40 parts of diisocyanate, 20-30 parts of dihydric alcohol with a non-polar side chain, 30-50 parts of polyester polyol, 5-10 parts of a chain extender, 0.1-0.5 parts of an antioxidant and 0.5-1 part of a catalyst. According to the invention, dimer alcohol with a non-polar side chain is introduced, dimer alcohol and polyester polyol are used as soft segments to react with diisocyanate and a small molecular chain extender, meanwhile, a fast forming process of premixing dimer alcohol, polyester polyol and a chain extender is used, the prepared TPU not only has the advantages of excellent wear resistance, good mechanical strength and excellent oil resistance and oxidation resistance of the urethane elastomer, but also has excellent hydrolytic stability, low-temperature performance, processing fluidity and elasticity, and meanwhile, can avoid the problems of precipitation, odor and the like caused by addition of aplasticizer.

Owner:SHANDONG INOV POLYURETHANE

TPU blend and use thereof

ActiveCN109517361AImprove wear resistanceReduce hardnessWindow cleanersEndless track vehiclesCross-linkFoaming agent

The invention relates to a thermoplastic polyurethane elastomer blend and use thereof in the preparation of caterpillar bands. By utilizing a liquid anti-UV agent, a liquid heat stabilizer and at least one of a liquid direct dye and a hardness regulator (being selected from one of a chain extender or a cross-linking agent and a foaming agent), the blend has good yellowing resistance and wear resistance and low hardness.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Preparation method of novel rubber additive

The invention discloses a preparation method of a novel rubber additive. The novel rubber additive is prepared from the following components in parts by weight: 20-30 parts of vinyl resin, 18-25 parts of unsaturated polyester resin, 12-16 parts of unsaturated fatty acid, 1.5-2 parts of zinc oxide and 6-9 parts of trifluoropropyl methyl dichlorosilane. The preparation method comprises the steps of adding unsaturated fatty acid into a container, heating to the temperature of 80-90 DEG C for melting, stirring, then adding zinc oxide, raising the temperature to 120-130 DEG C, and reacting for 2-3 hours to obtain viscous liquid; and adding the viscous liquid obtained in the step S1 into vinyl resin, unsaturated polyester resin and trifluoropropyl methyl dichlorosilane, raising the temperature to 110-115 DEG C, and carrying out melt blending for 3-5 hours to obtain the additive.

Owner:赣州晶鑫新材料有限公司

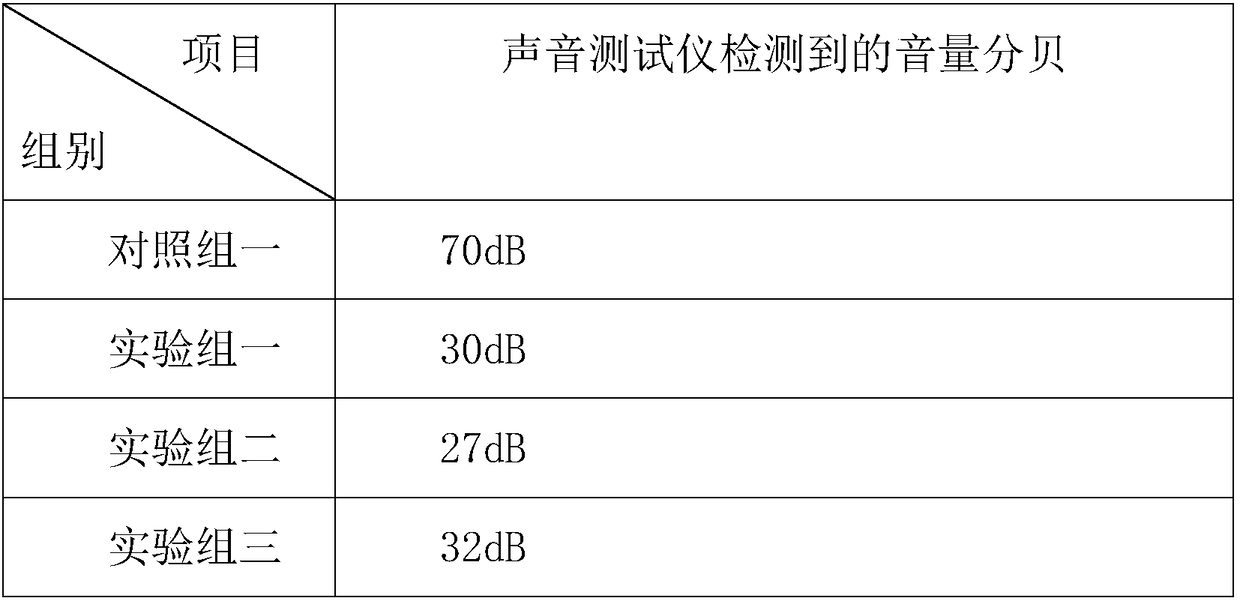

Compound sound insulation material and preparation method thereof

The invention discloses a compound sound insulation material and a preparation method thereof. The compound sound insulation material contains the following materials by weight percent: 40% of vinyl chloride acetate resin, 10-20% of low-density polyethylene, 20-30% of methyl vinyl silicone rubber, 5-10% of a high molecular compatilizer, 2-3% of a diluent, 1-5% of superfine fiber, and 1-2% of an antioxidant. The preparation method comprises the following steps: S1, weighing and preparing materials: weighing the materials according to weight percentage and marking for storage; S2, feeding and blending; S3, plastifying; and S4, performing extrusion molding. According to the invention, due to the setting of components including vinyl chloride acetate resin, low-density polyethylene, methyl vinyl silicone rubber, high molecular compatilizer, diluent, superfine fiber and antioxidant, so that the sound insulation effect of the compound sound insulation material is improved; and due to the setting of preparation procedures of weighing and preparing materials, feeding and blending, plastifying and performing extrusion molding. Therefore, the quality of the sound insulation material is promoted, and further the market competitiveness of the product is promoted.

Owner:王立菊

Raw materials and process for manufacturing rubber floor tile

The invention discloses a process for manufacturing a rubber floor tile. Raw materials include polyoxypropylene polyether glycol, toluene diisocyanate and waste rubber particles. A prepolymer method is adopted in an isocyanate production process. The physical and mechanical performances of a material prepared by using a one-step method are poorer than those of the prepolymer method, and particularly the tensile strength difference is relatively high. The reasons are as follows: polyether glycol is only simply mixed with TDI in the one-step method, a prepolymerization process is omitted, and part of free TDI does not react with polyether glycol, but directly reacts with water or active hydrogen on the surfaces of rubber particles, so that polyether glycol is relatively surplus to play a role of a plasticizer, macromolecules cannot be formed, and the adhesiveness is poor. By using the prepolymer method, polyether glycol reacts with TDI to generate a prepolymer containing a -NCO group and reacts with water and active groups on the surfaces of the rubber particles to form macromolecules, so that the adhesiveness is good, and the tensile strength is remarkably enhanced.

Owner:ANHUI MEIXIANG IND

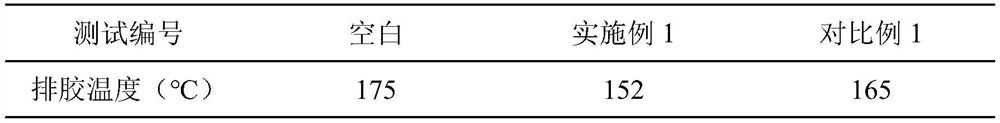

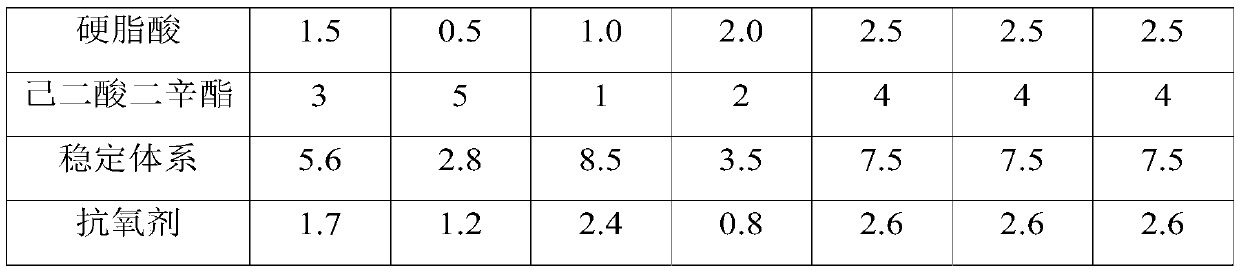

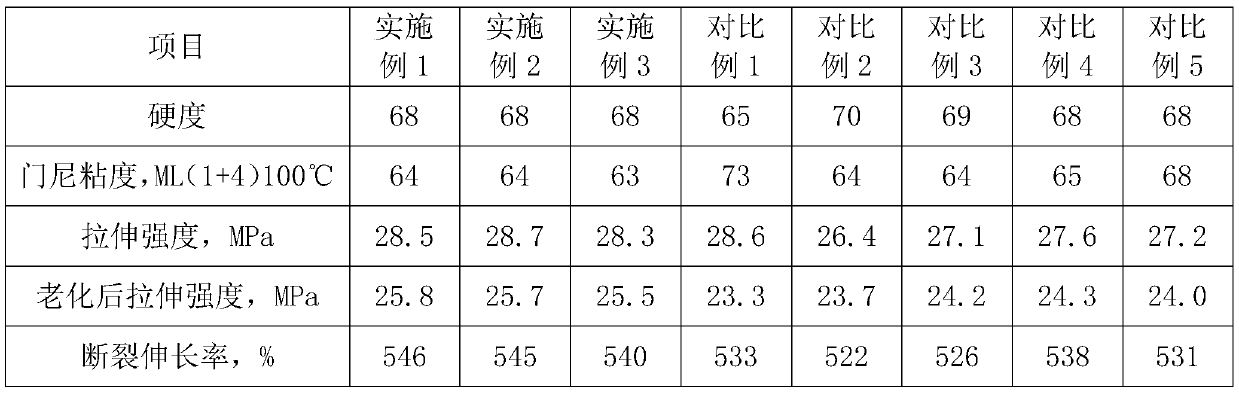

Corrosion-resistant high-temperature-resistant PVC-C pipe and preparation method thereof

The invention discloses a corrosion-resistant and high-temperature-resistant PVC-C pipe and a preparation method thereof. The corrosion-resistant high-temperature-resistant PVC-C pipe is prepared fromthe following raw materials in parts by weight: 100 parts of chlorinated polyvinyl chloride, 4 to 12 parts of acrylonitrile-butadiene-styrene copolymer, 12 to 20 parts of modified filler, 0.2 to 1.2parts of carbon black, 1.5 to 6.5 parts of silicon dioxide, 0.5 to 2.5 parts of stearic acid, 1 to 5 parts of dioctyl adipate, 2.8 to 8.5 parts of stable system and 0.8 to 2.6 parts of antioxidant. The corrosion-resistant and high-temperature-resistant PVC-C pipe prepared by the invention has the advantages of high Vicat softening temperature, excellent thermal aging resistance and high corrosionresistance and can be widely applied to the field with high comprehensive requirements, the preparation process is simple and feasible, and the corrosion-resistant and high-temperature-resistant PVC-Cpipe is suitable for industrial production.

Owner:泉州兴源新材料科技有限公司

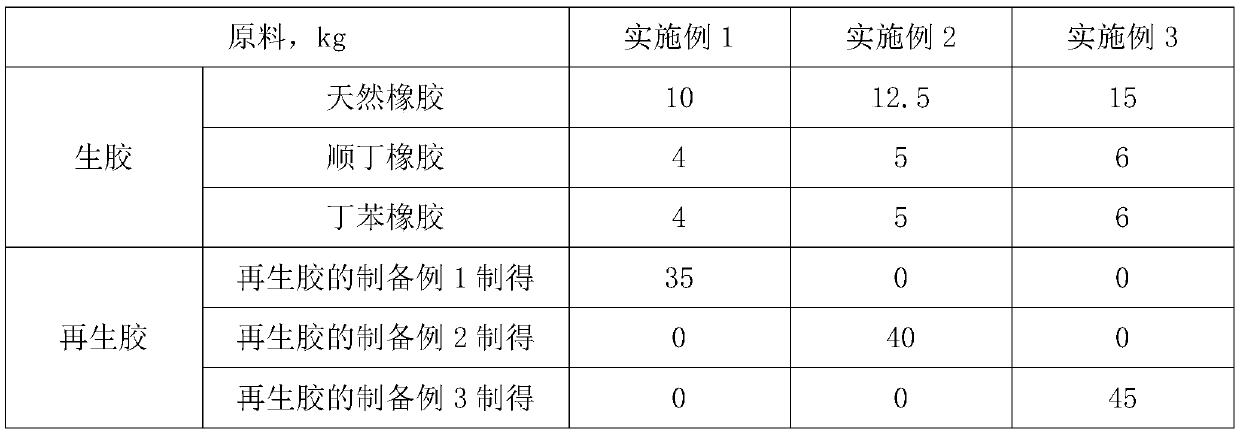

Tread rubber for tire of dune buggy

The invention discloses tread rubber for the tire of a dune buggy. The rubber comprises the following components in parts by weight: 10-15 parts of natural rubber, 8-12 parts of synthetic rubber, 35-45 parts of reclaimed rubber, 0.6-1 parts of sulfur, 0.6-1 parts of zinc oxide, 0.2-0.4 parts of stearic acid, 0.4-0.6 parts of an accelerant, 2-3 parts of carbon black, 2-3 parts of a reinforcing agent and 1.5-2 parts of an anti-aging agent. The reclaimed rubber is prepared by the following method: a, crushing waste tires to obtain waste rubber powder; b, adding a softener and a regenerant into the waste rubber powder, and performing banburying for 10-15 min at the temperature of 110-130 DEG C; and adding the reinforcing agent and the plasticizer to mix for 10-15 minutes at the temperature of50-60 DEG C, and performing cooling to obtain the reclaimed rubber. The tread rubber provided by the invention has the advantages of low cost, good wear resistance and good tear resistance.

Owner:宁波市骏凯橡胶工贸有限公司

Method for preparing calcium-zinc epoxy copolymer core-shell emulsion and modified wood-plastic material

The invention relates to a method for preparing calcium-zinc epoxy copolymer core-shell emulsion and a modified wood plastic material. The method for preparing the calcium-zinc epoxy copolymer core-shell emulsion comprises the following steps: (1) emulsifying shell emulsion; (2) emulsifying core emulsion; (3) preparing the calcium-zinc epoxy copolymer core-shell emulsion through a seeded emulsion polymerization method. The method for preparing the modified wood plastic material comprises the following steps: (1) drying WF (Wood Flour) and PVC (Polyvinyl Chloride); (2) carrying out spray drying on the calcium-zinc epoxy copolymer core-shell emulsion; (3) weighing dried polymer powder, the PVC and the WF, uniformly mixing on a high-speed dispersion machine, and carrying out blending extrusion in a double-screw extruder, thus obtaining composite material particles. The method disclosed by the invention has the advantages that (1) generation of micromolecular hydrogen chloride during a PVC heating process is effectively inhibited, so that the thermal stability of resin is increased; (2) the brittleness of the PVC can be reduced, and the impact resistance is increased; (3) the problems of cracking, non-uniform size and the like of a PVC wood plastic wallboard during a using process are solved.

Owner:贵州华锐达环保装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com