Polylactic acid plastic containing composite flame retardant and preparation method of polylactic acid plastic

A technology of polylactic acid and flame retardant, applied in the field of degradable plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

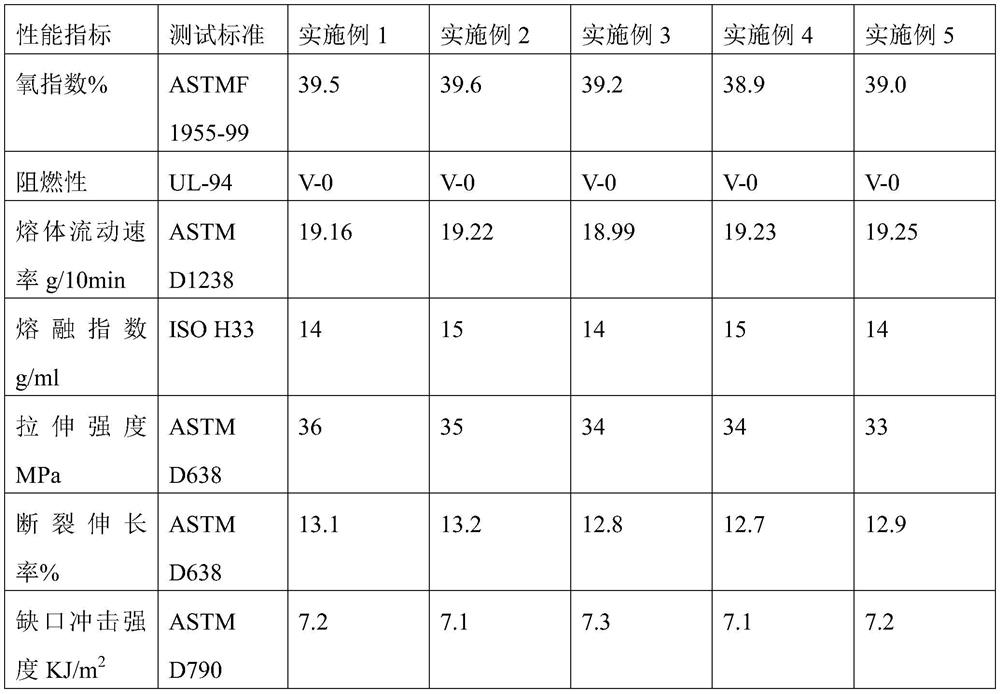

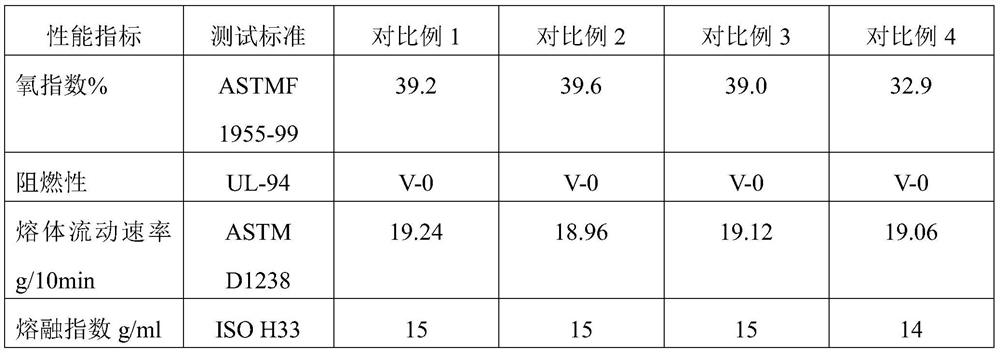

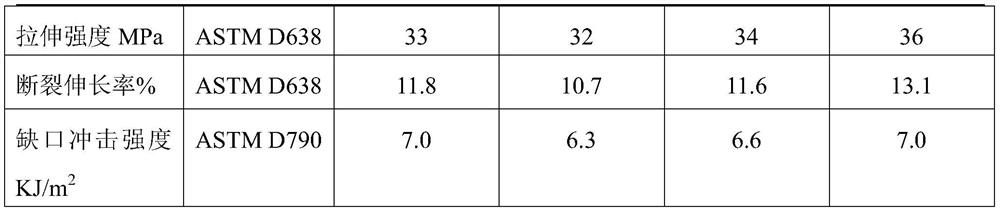

Examples

Embodiment 1

[0026] This embodiment provides a polylactic acid plastic containing a composite flame retardant, which is made of the following raw materials in parts by weight: 110 parts of polylactic acid, 15 parts of plant fiber, 2 parts of pentaerythritol, 1.5 parts of starch, and 12 parts of ammonium polyphosphate. part, 4 parts of melamine, 2 parts of modified white carbon black, 5 parts of ethylene oxide, 0.5 part of sorbitol, 1.5 parts of talcum powder, 1.5 parts of stearic acid amide, 10100.25 parts of antioxidant.

[0027] Wherein, the plant fiber is made through the following surface treatment:

[0028] (1) Take 3.5 g of sodium alginate, add it to 100 ml of water, stir to dissolve, and then adjust the pH value to 7 with acetic acid to obtain a sodium alginate solution.

[0029] (2) Take plant fibers and pulverize them, and then carry out air-explosion loosening treatment; add the plant fibers after air-explosion loosening treatment into sodium alginate solution and soak for 4 hour...

Embodiment 2

[0037] This embodiment provides a polylactic acid plastic containing a composite flame retardant, which is made of the following raw materials in parts by weight: 100 parts of polylactic acid, 20 parts of plant fiber, 1 part of pentaerythritol, 2 parts of starch, and 10 parts of ammonium polyphosphate 5 parts of melamine, 1 part of modified white carbon black, 6 parts of ethylene oxide, 0.2 part of sorbitol, 2 parts of talcum powder, 1 part of stearic acid amide, 0.4 part of antioxidant 1010.

[0038] Wherein, the plant fiber is made through the following surface treatment:

[0039] (1) Take 2 g of sodium alginate, add it to 100 ml of water, stir to dissolve, and then adjust the pH value to 9 with acetic acid to obtain a sodium alginate solution.

[0040] (2) Take the plant fiber and pulverize it, and then carry out air-explosion loosening treatment; add the plant fiber after the air-explosion loosening treatment into sodium alginate solution and soak for 5 hours, filter and d...

Embodiment 3

[0048]This embodiment provides a polylactic acid plastic containing a composite flame retardant, which is made of the following raw materials in parts by weight: 120 parts of polylactic acid, 10 parts of plant fiber, 3 parts of pentaerythritol, 1 part of starch, and 15 parts of ammonium polyphosphate 3 parts, 3 parts of melamine, 3 parts of modified white carbon black, 4 parts of ethylene oxide, 0.8 part of sorbitol, 1 part of talcum powder, 2 parts of stearic acid amide, 0.1 part of antioxidant 168.

[0049] Wherein, the plant fiber is made through the following surface treatment:

[0050] (1) Take 5 g of sodium alginate, add it to 100 ml of water, stir to dissolve, and then adjust the pH value to 5 with acetic acid to obtain a sodium alginate solution.

[0051] (2) Take plant fibers and pulverize them, and then carry out air-explosion loosening treatment; add the plant fibers after air-explosion loosening treatment into sodium alginate solution and soak for 3 hours, filter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com