Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Lower the mixing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Warm-mixed asphalt mixture and preparation method thereof

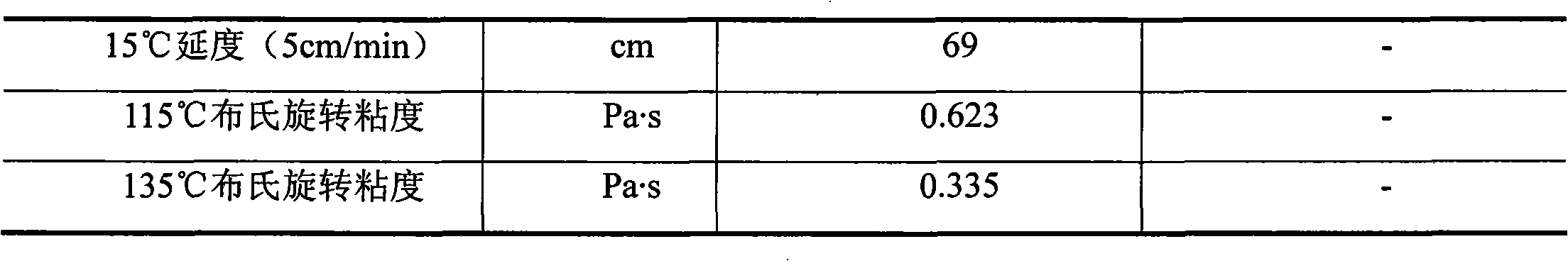

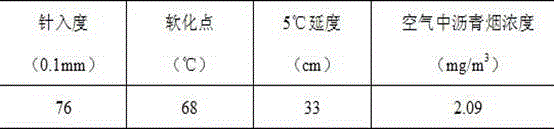

ActiveCN102092988ALower the mixing temperatureHigh tensile strengthClimate change adaptationAdhesive cementHigh concentration

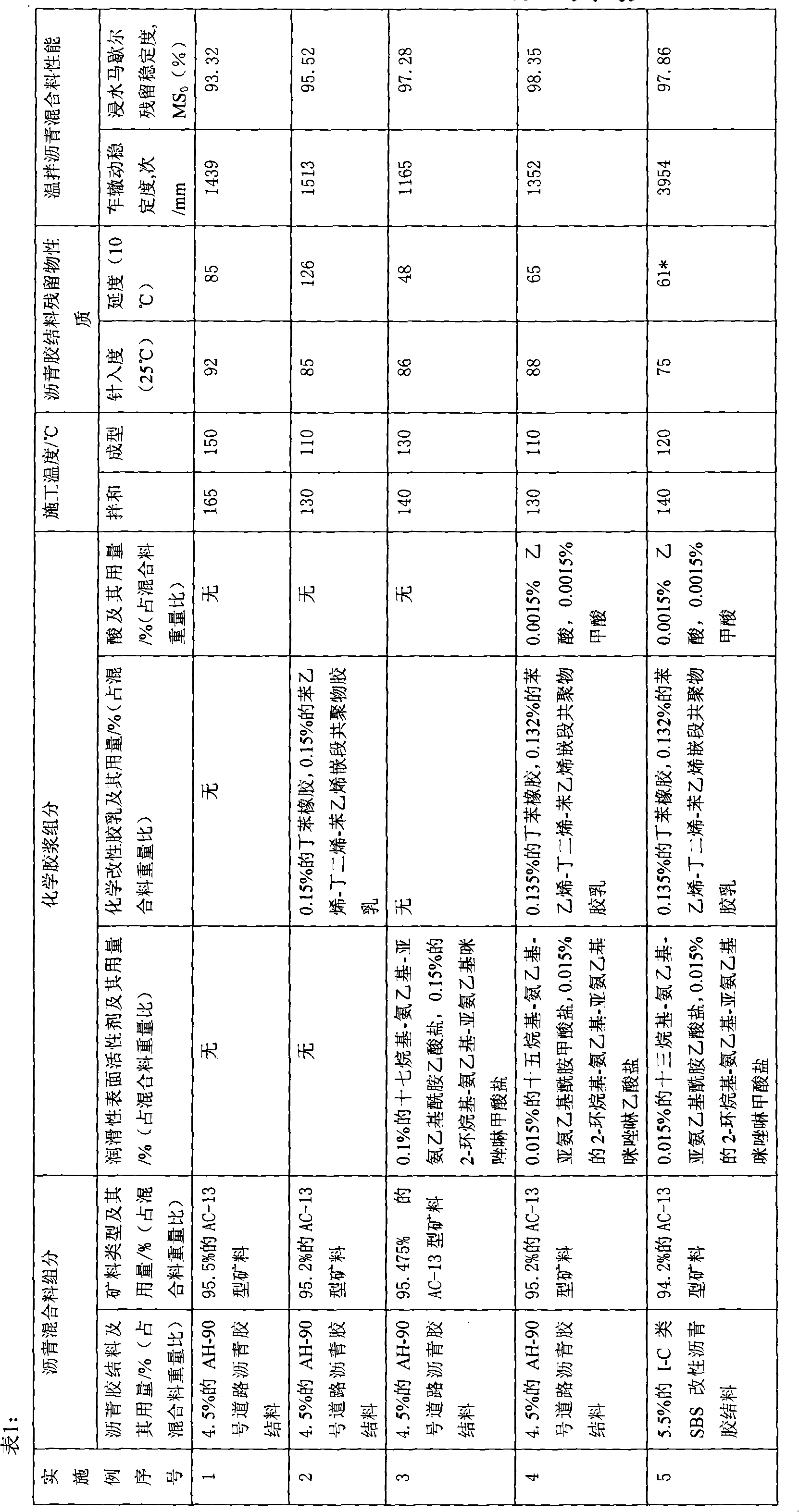

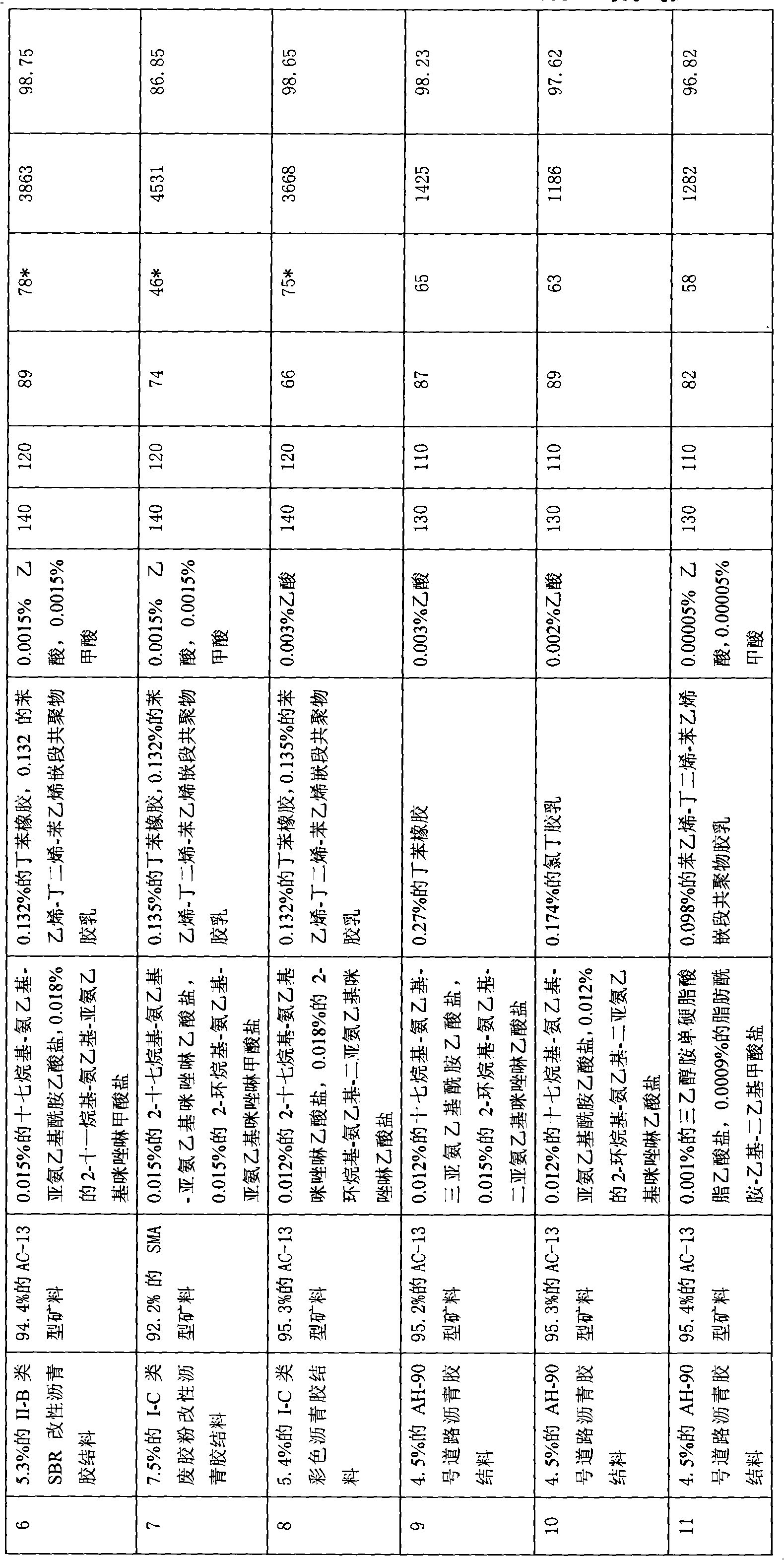

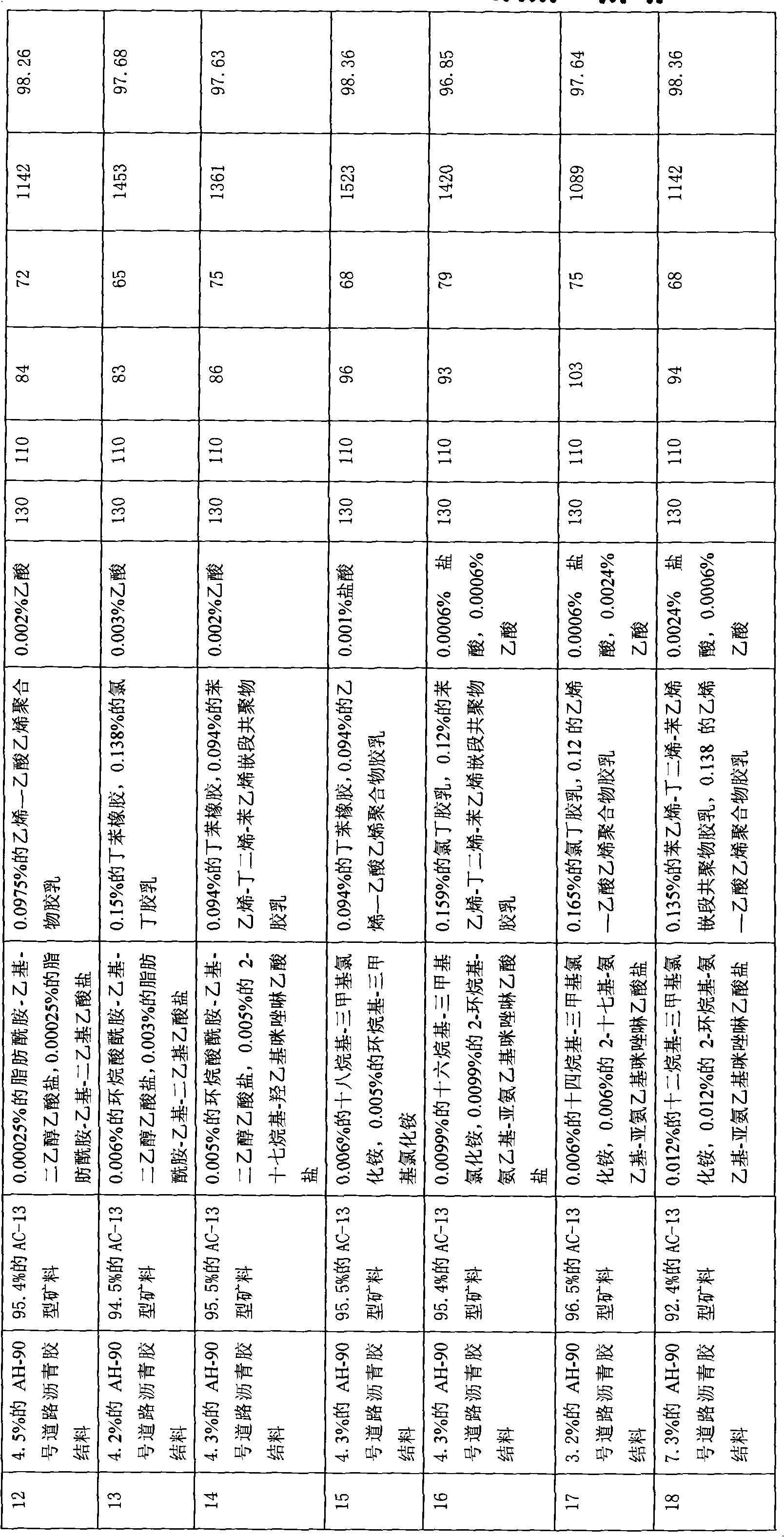

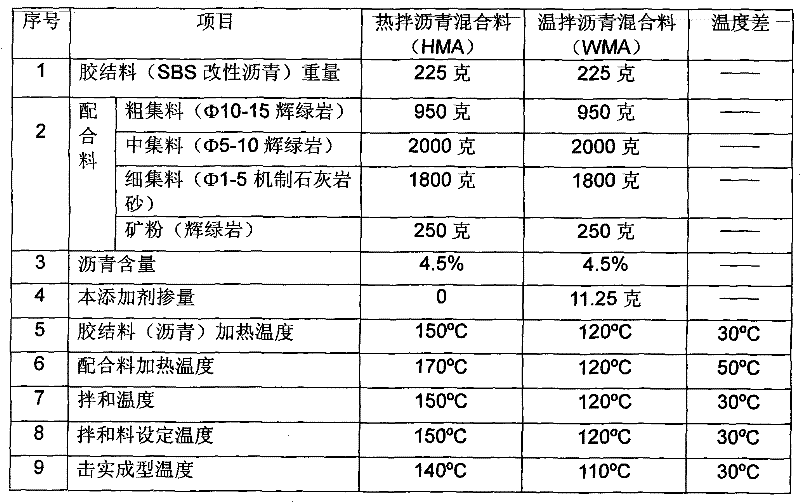

The invention relates to a warm-mixed asphalt mixture and a preparation method thereof. The warm-mixed asphalt mixture is mainly applied to new construction and maintenance of high-grade roads and common roads, and is particularly suitable for cities, parks, tunnels and the like with high environmentally-friendly requirements. The warm-mixed asphalt mixture mainly comprises about 92.4-96.5 percent by weight of mineral, about 3.4-7.5 percent by weight of asphalt cement and 0.05-1.0 percent by weight of chemical modified adhesive cement. The preparation method comprises the following steps of: simultaneously pumping the chemical modified adhesive cement and the hot asphalt cement to the spraying port of a foam generator, fully mixing to generate a foam-containing hot asphalt mixture, spraying the foam-containing hot asphalt mixture into a mixing pan, and further mixing the foam-containing hot asphalt mixture and the hot mineral to form the warm-mixed asphalt mixture. The chemical modified adhesive cement can effectively reduce the mixing, spreading and rolling temperature of the asphalt mixture, and solves the problems of environmental pollution, high energy consumption, asphalt ageing regression and the like. By selecting high-concentration cationic chemical modified latex as a matrix stock of the chemical modified adhesive cement and simultaneously matching a proper proportion of cationic surfactant with lubricating effect and peeling resistance, the influence of the conventional warm-mixed asphalt additive on poor reducing performance and poor adhesive performance of the asphalt cement is solved, and the properties of the warm-mixed asphalt mixture such as water damage resistance, rutting resistance, fatigue resistance, low temperature resistance and the like are improved.

Owner:PETROCHINA CO LTD

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144ALow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

The invention relates to an in-situ warm-mixing regenerant for a bituminous pavement, and a preparation method and a construction method of the in-situ warm-mixing regenerant. The strength of a cold-regenerating mixture is longer in formation time; a finish coat in a certain thickness is required to be paved additionally; the property of the regenerated mixture is poorer; a lower level cold mixing technology is used generally; and cement is required to be added generally, so that the durability of the level is reduced. The in-situ warm-mixing regenerant for the bituminous pavement comprises the following raw materials in parts by mass: 10-30 parts of naphthenic hydrocarbon, 20-40 parts of furfural extract oil, 30-50 parts of deionized water, 10-20 parts of microwave absorption agent, 5-10 parts of surfactant, 5-10 parts of dispersing agent and 1-5 parts of antiaging agent. According to the in-situ warm-mixing regenerant, the preparation method and the construction method, the mixing cost can be lowered; the construction efficiency is improved; a use ratio of old materials is increased; compared with in-situ heat regeneration, the ageing of a bituminous mixture is reduced; the service life of the pavement is prolonged; a cooling rate is reduced; the discharge amount of harmful gas and dust is decreased; new aggregates and new bitumen are not required to be added; and the material cost is lowered.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application

InactiveCN102234432AImprove the degree of adhesionLower working conditionsClimate change adaptationBuilding insulationsPolyvinyl alcoholFatty acid

The invention, belonging to the field of construction engineering, relates to an anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application. The anti-stripping warm mix asphalt additive agent disclosed in the invention comprises polyvinyl acetal, polyacrylamide, fatty acid anhydride ester surfactant, polyoxyethylene acid ester surfactant and water. The warm mix asphalt additive agent disclosed in the invention can enhance the bonding of stone, rock flour and asphalt, so as to get the purposes of high strength and preventing stripping. The requirements of the technical characteristics of the warm mix asphalt is realized by spraying the additive agent with the content of 5-6% of the weight of the asphalt when the temperature of the asphalt reaches 120-130 DEG C, and then carrying out blending and operation as routine asphalt. The warm mix asphalt additive agent disclosed in the invention has no substances which are harmful to the human body and environment, with being environmentally friendly, and is an excellent product with energy saving and emission reduction.

Owner:SHANGHAI YITAI ENERGY TECH

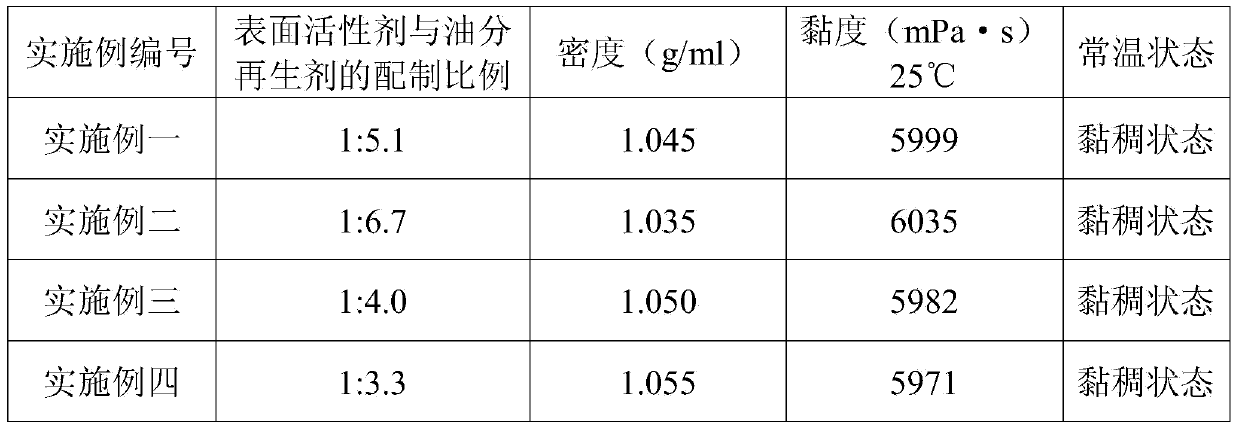

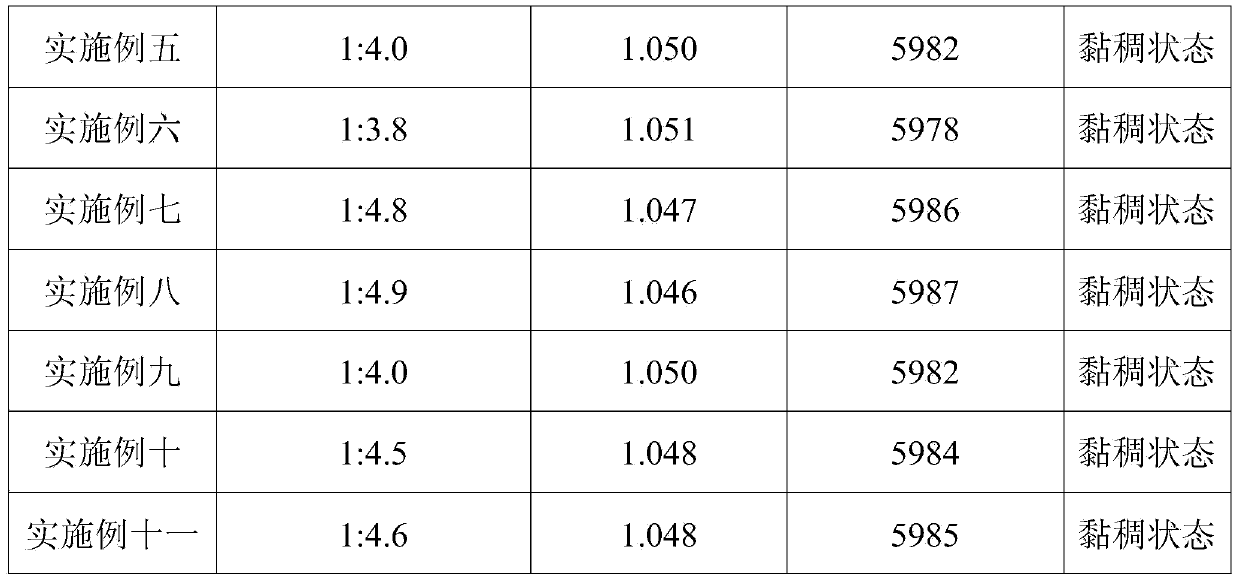

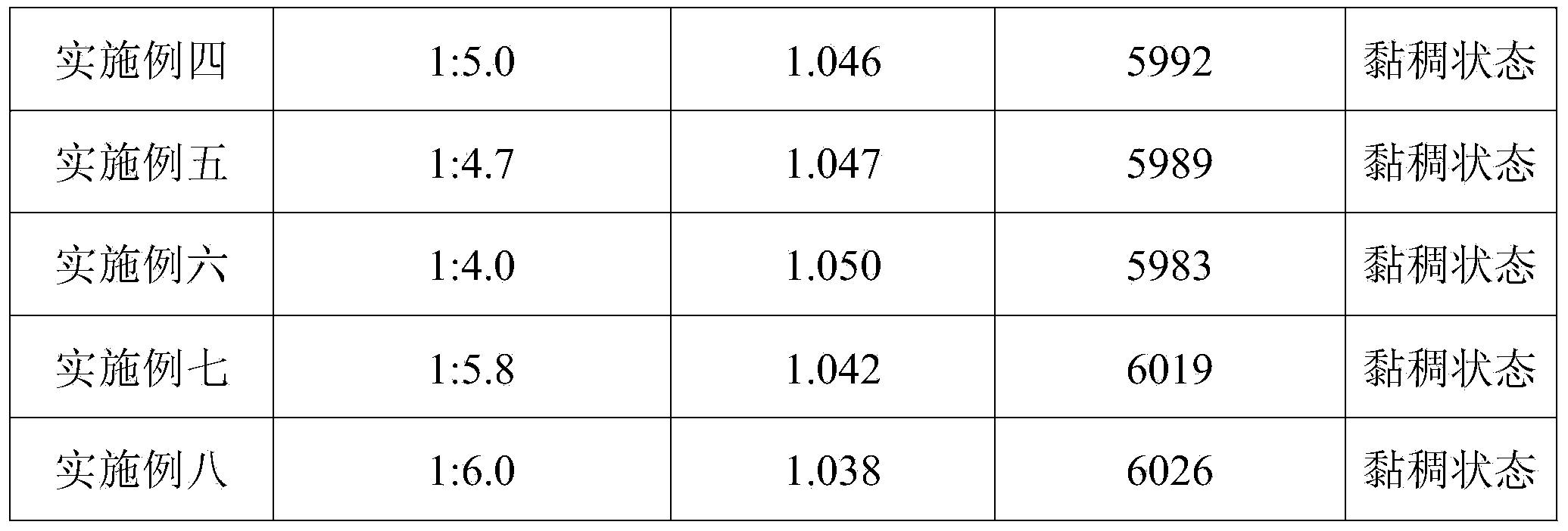

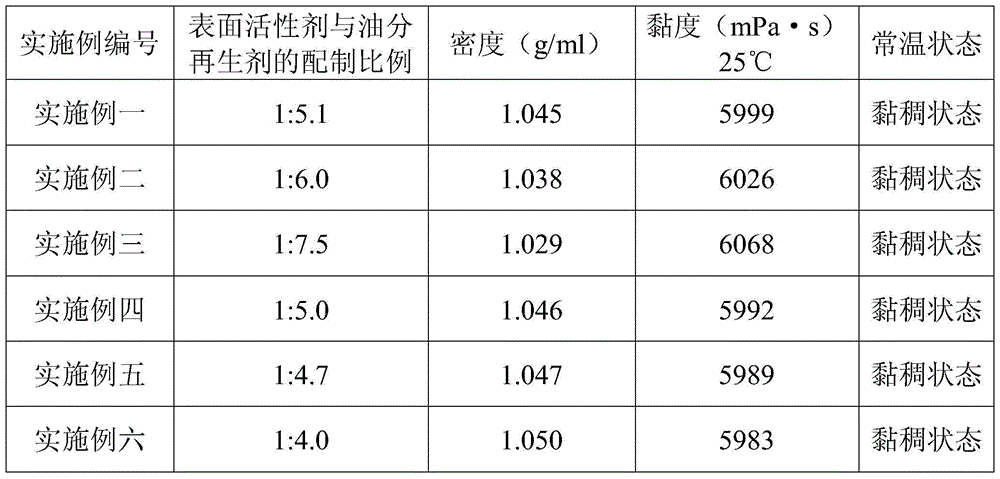

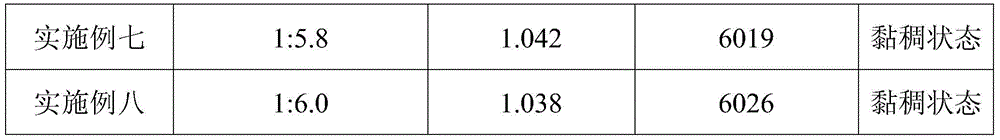

Warm-mixing regenerated asphalt and preparation method thereof

InactiveCN104194358AEasy to prepareLower the mixing temperatureClimate change adaptationBuilding insulationsAsphaltMaterials science

The invention discloses a warm-mixing regenerated asphalt which is mixed from asphalt and a composite warm-mixing regenerant, wherein the composite warm-mixing regenerant is a surfactant-oil regenerant composite material. The warm-mixing regenerated asphalt has the advantages of favorable function effect, no pollution and low cost. The composite warm-mixing regenerant organically combines the warm-mixing agent with the regenerant to fully display the overall functions. The invention also discloses a preparation method of the warm-mixing regenerated asphalt, which comprises the following steps: heating the asphalt to mixing temperature; and adding the composite warm-mixing regenerant to the asphalt, and mixing. The preparation method is simple, and is implemented by directly adding the composite warm-mixing regenerant into the asphalt at one time and uniformly mixing; the mixing temperature is obviously lowered, thereby reducing the discharge of the harmful gas and lowering the cost; and the warm-mixing regenerated asphalt has favorable pavement performance.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE +1

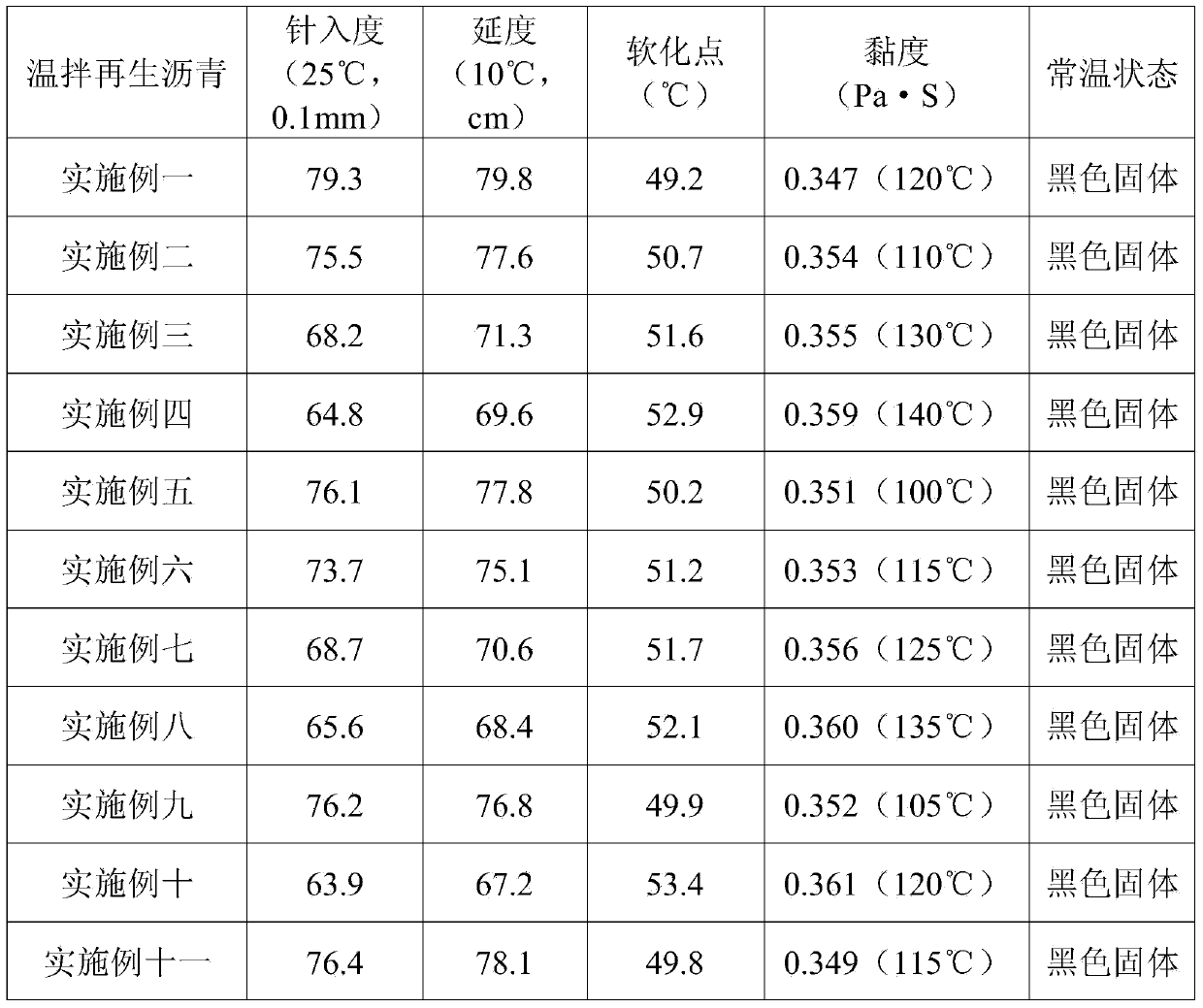

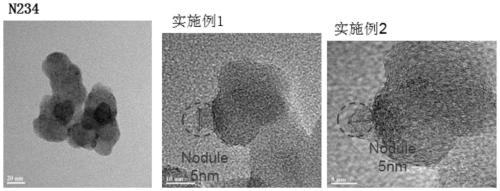

Preparation method for high-dispersion deposition white carbon black

ActiveCN105273442AImprove hydrophobicityImprove wear resistancePigment treatment with organosilicon compoundsRolling resistanceCoupling

The invention relates to a preparation method for white carbon black, and concretely relates to a preparation method for high-dispersion deposition white carbon black. A white carbon black suspension, an umbrella-shaped siloxane dispersant and a siloxane coupling agent containing sulfydryls or carbon-carbon double bonds are mixed, the pH value is adjusted to 2-7 after mixing, the mixture is heated to 30-79 DEG C and reacted for 1-6h, and high-dispersion deposition white carbon black is obtained. The umbrella-shaped siloxane dispersant and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The siloxane coupling agent and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The prepared white carbon black has superstrong hydrophobicity, the processing performance in subsequent preparation of rubber compounds can be raised effectively, dynamic mechanical properties of vulcanized rubber as tyre tread rubber can be improved effectively, the rolling resistance of tread rubber is lowered effectively, and the wear resistant performance of tread rubber is raised.

Owner:SHENYANG RES INST OF CHEM IND

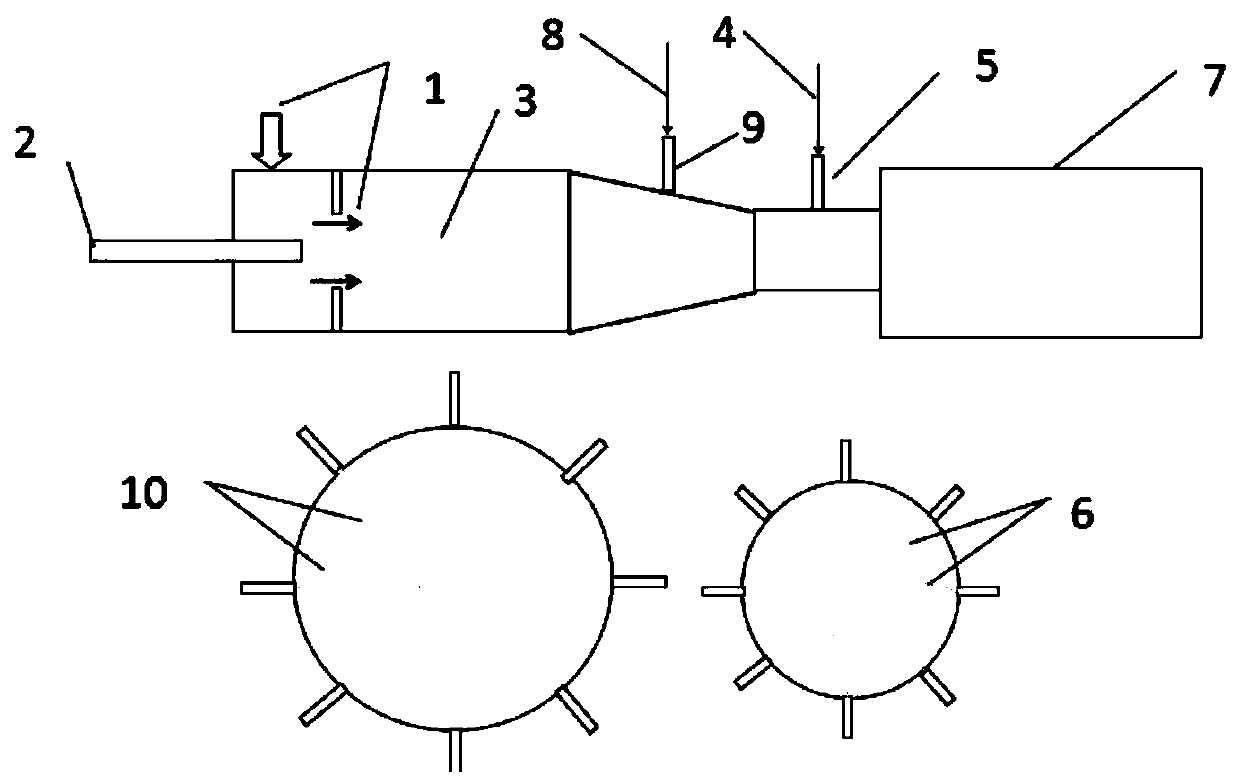

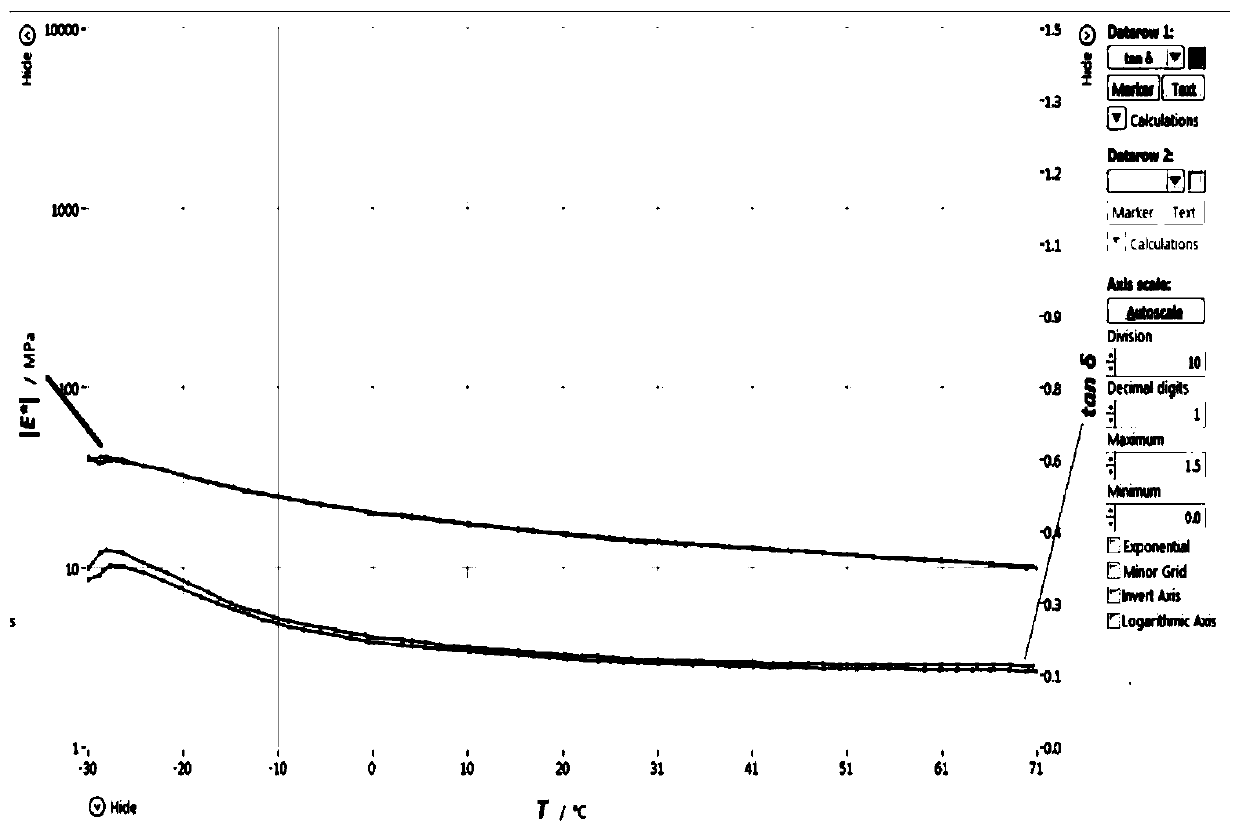

High-modulus asphalt mixture additive and preparation method thereof

ActiveCN106633269AHigh temperature sensitivityGood low temperature flexibilityBuilding insulationsEpoxyMolecular sieve

The invention discloses a high-modulus asphalt mixture additive and a preparation method thereof. The additive comprises, by weight, 100 parts of plastic, 10-20 parts of EVA resin, 15-25 parts of butadiene-styrene rubber and / or derivative thereof, 10-20 parts of ethylene tar and 10-20 parts of composite modifier, wherein the composite modifier is composed of a mesoporous molecular sieve coated with epoxy grafted polyethylene wax. The additive has high compatibility with asphalt and a mixture, so that resistance to low-temperature cracking of a high-modulus asphalt mixture is improved remarkably, the additive has excellent resistance to track and water damage, and the mixture is low in blending temperature and high in construction peaceability.

Owner:CHINA PETROLEUM & CHEM CORP +1

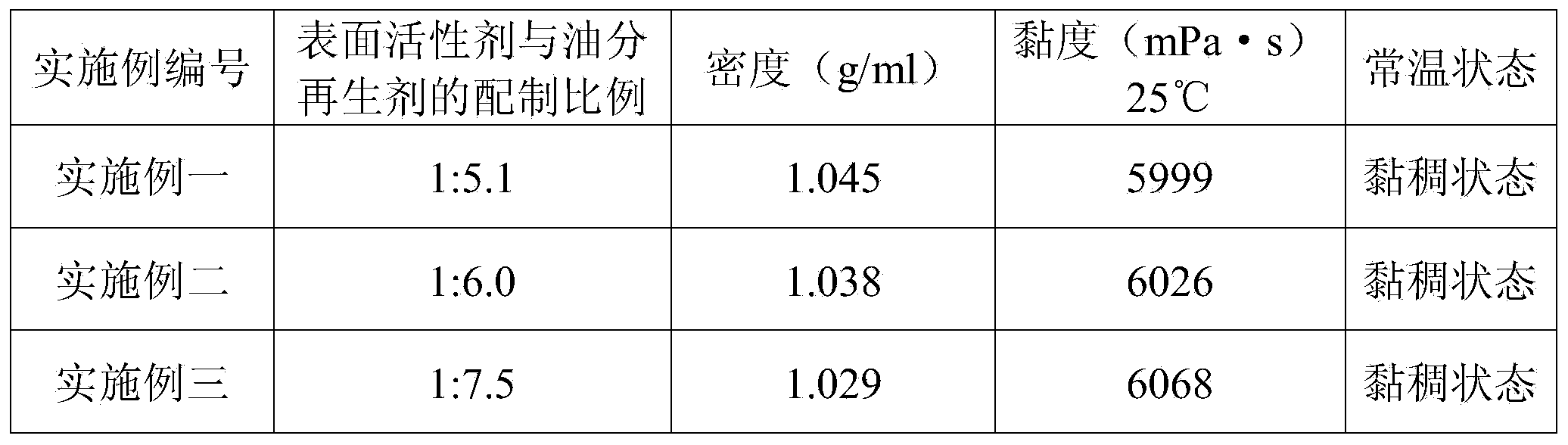

Composite warm-mixing regenerant and preparation method thereof

ActiveCN104177850AEasy to prepareImprove road performanceClimate change adaptationChemical recyclingFatty acid glycerol estersRoad surface

The invention discloses a composite warm-mixing regenerant. The composite warm-mixing regenerant is a composite material of a surfactant and an oil regenerant, wherein the surfactant is one or more of fatty acid glyceride, fatty acid sorbitan, polysorbate and sucrose ester and the oil regenerant is one or more of extracted oil obtained by refining lubricating oil, lubricating oil, engine oil and heavy oil. The invention also discloses a preparation method of the composite warm-mixing regenerant. The preparation method comprises the following steps of weighing the surfactant and the oil regenerant at a certain ratio, loading the surfactant and the oil regenerant into a mixing device and mixing. According to the composite warm-mixing regenerant disclosed by the invention, by organically combining the surfactant and the oil regenerant, the composite warm-mixing regenerant for an asphalt pavement material is produced, the reduction in the mixing temperature of asphalt and an asphalt mixture and the recycling of an old asphalt mixture can be simultaneously achieved, no pollution is generated in the preparation process and the problems that the environmental pollution, waste of resources and like caused by high mixing temperature of traditional asphalt and the asphalt mixture and low utilization ratio of the old asphalt mixture are solved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +1

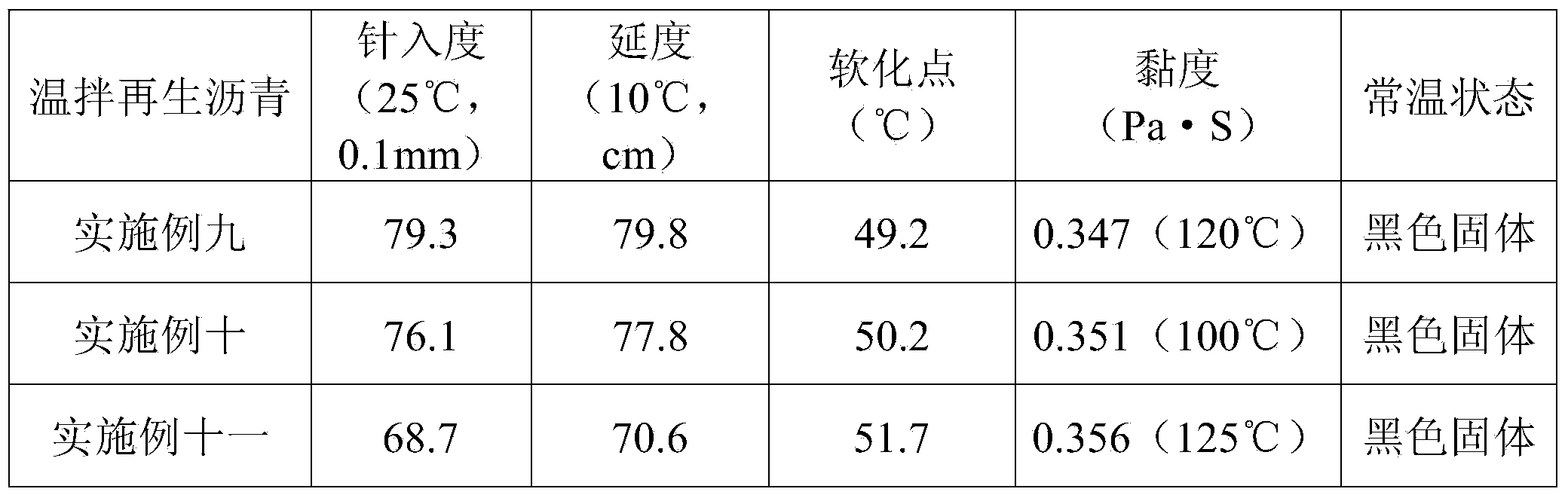

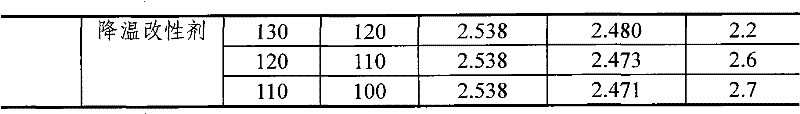

Warm-mix modified asphalt and method for preparing asphalt mixture by using same

InactiveCN102504553AImprove high temperature stabilityHigh temperature stability hasClimate change adaptationBuilding insulationsPolyolefinAsphalt

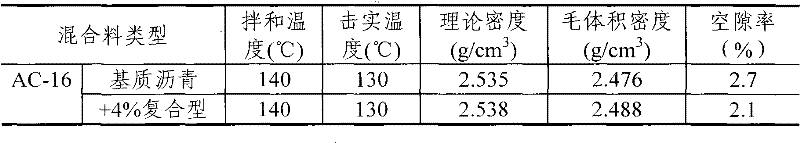

The invention discloses warm-mix modified asphalt and a method for preparing asphalt mixture by using the same. The warm-mix modified asphalt comprises matrix asphalt and a composite modified cooling agent, the adding weight of the composite modified agent is 3% to 6% of the weight of the matrix asphalt, and the composite modified agent is a polyolefin cooling agent. The method for preparing the asphalt mixture by using the warm-mix modified asphalt includes the following steps: the asphalt is heated to 110 DEG C to 130 DEG C and dehydrated, mineral aggregate is heated, hot mineral aggregate with 85%-90% weight ratio and hot matrix asphalt with 7% to 9% weight ratio are put into a mixing cylinder to be mixed, the mixing time is T1 5 seconds to 30 seconds, the polyolefin cooling agent with the weight occupying 3% to 6% of the weight of the matrix asphalt is added and mixed, the mixing time is T2 2 minutes to 5 minutes, and the mixture of the warm-mix asphalt is obtained. The warm-mix modified asphalt and the mixture of the same have low mixing, paving and compacting temperature, and can effectively retain the original performance of hot mix asphalt mixture while solving the problems of environment pollution, large energy consumption, aging and decline of the asphalt and the like.

Owner:JIANGYIN TAIFU ASPHALTUM

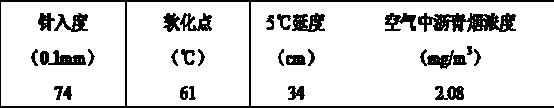

Hot mix asphalt pavement smoke suppressant and preparation method of smoke-suppressing asphalt

ActiveCN104194356ALower the mixing temperatureReduce releaseBuilding insulationsPigment treatment with organosilicon compoundsAluminium hydroxideEnvironmental engineering

The invention discloses a hot mix asphalt pavement smoke suppressant, comprising the following components in percentage by weight: 7%-9% of a warm mixing agent and 91%-93% of aluminium hydroxide subjected to surface modification treatment. The invention also discloses a preparation method of smoke-suppressing asphalt. The method comprises the following steps: a) heating asphalt to 100-130 DEG C, and then adding the warm mixing agent in the smoke suppressant according to the ratio in claim 1, and stirring until the warm mixing agent is uniform; and b) adding the aluminium hydroxide subjected to surface modification treatment, and stirring until the aluminium hydroxide is uniform, wherein the percentage of the asphalt is 95%-97%, and the percentage of the smoke suppressant is 3%-5%. According to the smoke suppressant disclosed by the invention, release of asphalt smoke in the construction process of a hot mix asphalt pavement can be obviously reduced, the mixing temperature of the smoke suppressant is low, the construction and ecological environments are greatly improved, the physical health of constructors is protected, the smoke suppressant has significant social benefits and environmental protection benefits, meanwhile, energy conservation can also be achieved, asphalt ageing is relieved, the pavement performances such as the integrality, the strength and the durability of the asphalt pavement are improved, and the smoke suppressant has obvious technical and economic benefits.

Owner:重庆建工建筑产业技术研究院有限公司 +2

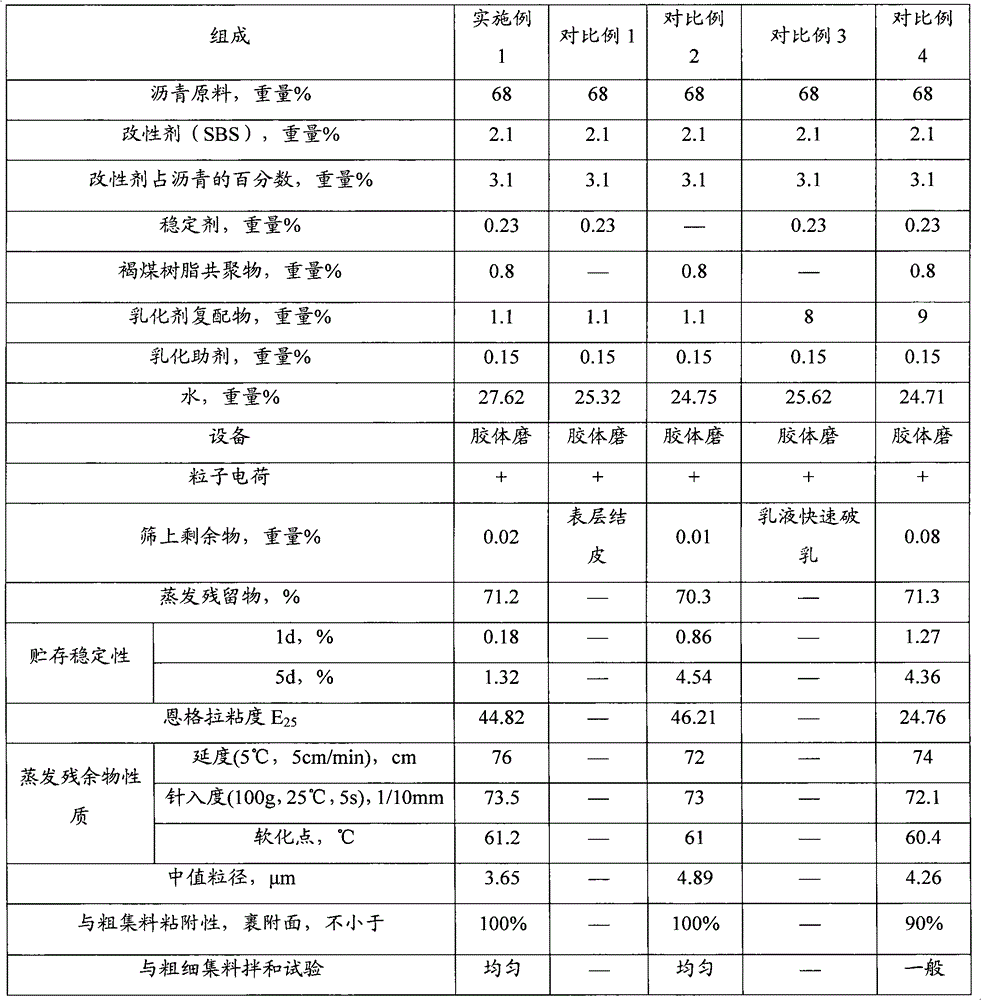

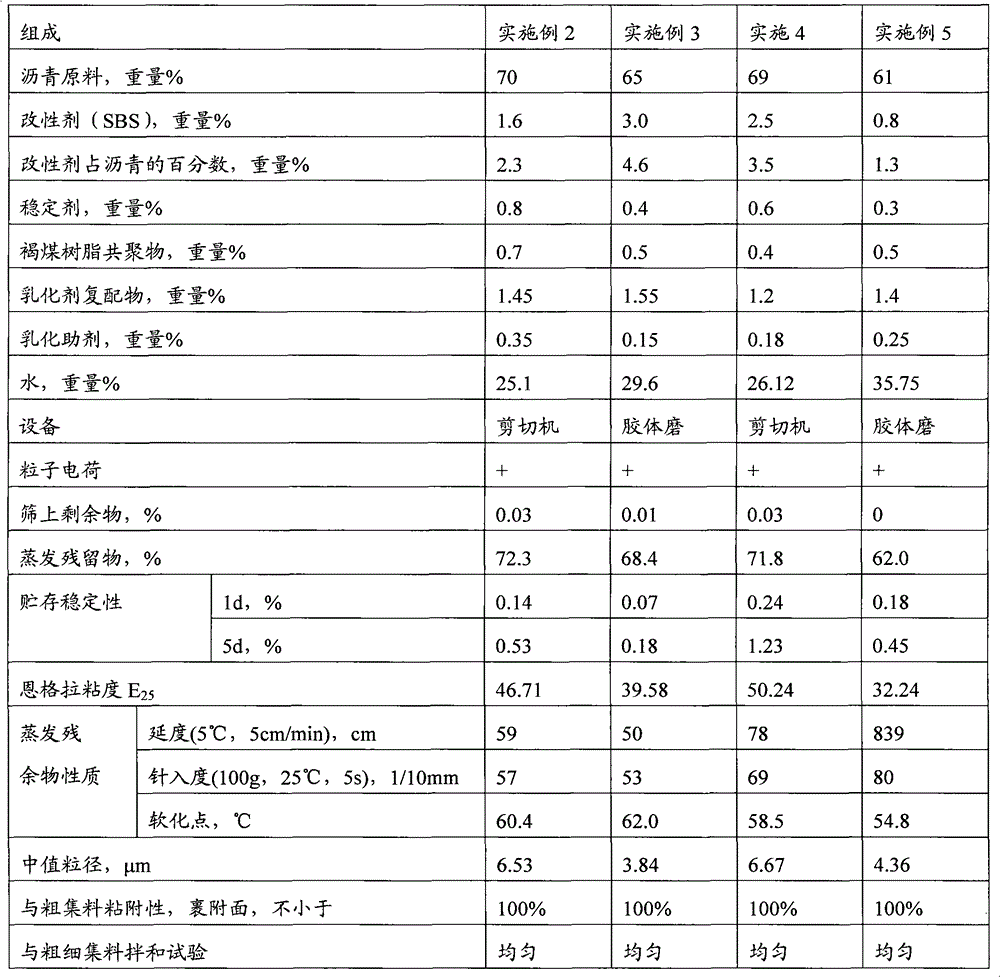

Wet-mixing modified asphalt emulsion and preparation method

ActiveCN103059584AIncrease concentrationEasy to useIn situ pavingsClimate change adaptationHigh concentrationEmulsion

The invention relates to a wet-mixing modified asphalt emulsion and a preparation method, the modified asphalt emulsion comprises 60-75wt% of modified asphalt, 0.01-2wt% of brown coal resin copolymer, 0.05-5wt% of emulsifier compound, 0.02-2wt% of emulsification auxiliary agent and 23-35wt% of water; the emulsifier compound is composed of a lignin emulsifier, an amphiphilic surfactant and a nonionic surface activity, wherein the weight ratio of lignin emulsifier to amphiphilic surfactant to nonionic surface activity is 0.5-4:0.1-2:0.5-2. The emulsion preparation method is characterized in that the brown coal resin copolymer is mixed with modified asphalt, and then emulsified, or the brown coal resin copolymer is mixed with the emulsifier solution and then mixed with the modified asphalt for emulsification. The wet-mixing modified asphalt emulsion has the advantages of high concentration, good storage stability, good adhesiveness with a mineral aggregate, simple production technology and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-smoke asphalt and method for reducing smoke generated during asphalt concrete road surface construction

InactiveCN101700967ANo reduction in road performanceReduce smokeIn situ pavingsRoad surfaceAsphalt concrete

The invention discloses low-smoke asphalt comprising base asphalt, smoke inhibitor SBS and lipophilic type nanometer calcium carbonate, wherein the weight of the smoke inhibitor SBS is 3-4% of that of the base asphalt; and the weight of the lipophilic type nanometer calcium carbonate is 4-5% of that of the base asphalt. The invention also discloses a method for reducing the smoke generated during asphalt concrete road surface construction. The invention can reduce about 28-30% of asphalt smoke under the precondition without reducing the blending temperature and the road surface performance of asphalt mixing materials in the asphalt concrete road surface construction process.

Owner:CHONGQING COMM CONSTR GRP

Preparation method of high-flame-retardant smoke-suppression LVT floor wear-resistant layer

InactiveCN111761772AGuaranteed uniformityIncrease concentrationFlat articlesFlooring insulationsPolymer sciencePlasticizer

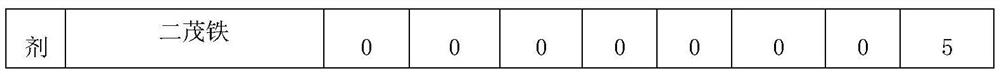

The invention discloses a preparation method of a high-flame-retardant smoke-suppression LVT floor wear-resistant layer. The preparation method comprises the following steps of: (1) taking the following production raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 0-40 parts of a plasticizer, 0-50 parts of a flame retardant, 0-8.0 parts of a smoke suppression agent, 1.0-6.0 parts of a stabilizer and 0.5-3.0 parts of a processing aid; and (2) mixing the production raw materials, performing internal mixing, performing open milling, calendering, cooling, drawing and discharging to obtain the high-flame-retardant smoke-suppression LVT floor wear-resistant layer. According to the LVT floor wear-resistant layer prepared by the method disclosed by the invention, the wear-resistant layer has excellent flame-retardant smoke-suppression performance by reasonably proportioning the components of the plasticizer, the flame retardant and the smoke suppression agent; and by controlling the mixing, internal mixing and other parameters, the light transmittance and flexibility of the wear-resistant layer are greatly improved, the pattern of a color film can be displayed to thegreatest degree when the wear-resistant layer is applied to the LVT floor, the pattern diversity of the LVT floor is reflected, and the wear-resistant layer can be applied to ships, rail transit and other places with relatively strict operating requirements.

Owner:宜宾天亿新材料科技有限公司 +1

Composite binder for powder injection moulding and preparation and application method

ActiveCN105860886AImprove liquidityGood liquidity lowNon-macromolecular adhesive additivesTransportation and packagingMicrocrystalline waxInjection moulding

The invention discloses composite binder for powder injection moulding and a preparation and application method. The composite binder for powder injection moulding comprises raw materials including furfuryl alcohol, trimethylolpropane, polypropylene, o-hydroxybenzoic acid, polyacrylamide, palm wax, microcrystalline wax and epoxidized soybean oil and further comprises boric acid and water. The composite binder combining thermoplasticity and a thermosetting system is adopted, advantages of thermoplasticity and the thermosetting system are utilized, on one hand, the problems that conventional binder is excessively long in thermal degreasing time and low in production efficiency are solved, and the degreasing rate can reach 90% or above within 6 hours; on the other hand, the yield rate of a powder injection moulding product is raised, and quality of a finished product is improved.

Owner:ANHUI SANLIAN UNIV

Reparation method and construction method of warm mix asphalt mixture

InactiveCN104386949AImprove performanceReduce high temperature viscosityClimate change adaptationPerformance indexEvaluation system

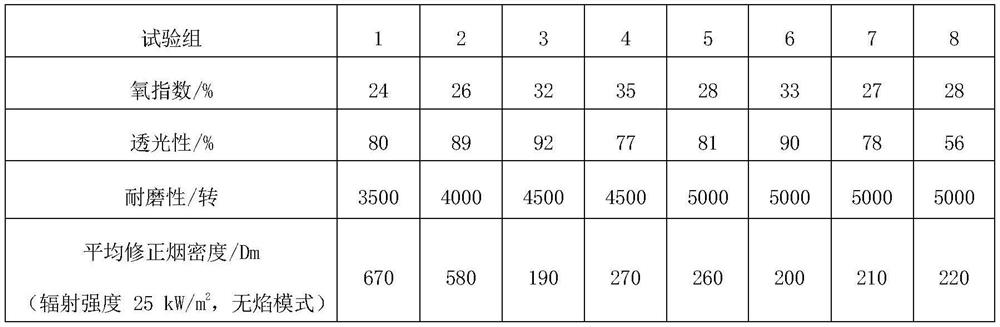

The invention discloses a preparation method and a construction method of a warm mix asphalt mixture. The preparation method comprises the following steps: testing all performance indexes of a warm mixing agent and matrix asphalt; adding different addition amounts of the warm mixing agent into the matrix asphalt to prepare warm mix asphalt; commonly testing all performance indexes of the warm mix asphalt by adopting a penetration grading evaluation system and a PG grading evaluation system, and determining the best addition amount of the warm mixing agent; and preparing the warm mix asphalt mixture. The warm mixing agent is a Sasobit warm mixing agent, and the best addition amount of the warm mixing agent is 2.5-3.5% of the mass of the matrix asphalt. The construction method comprises the steps of warm mix asphalt mixture mixing, transportation, spreading and compaction. The preparation method and the construction method of the warm mixing asphalt mixture are simple, the mixing temperature substantially decreases, the discharge of harmful gases is substantially reduced, the cost is reduced, and the road performances of the asphalt and the asphalt mixture are comprehensively improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

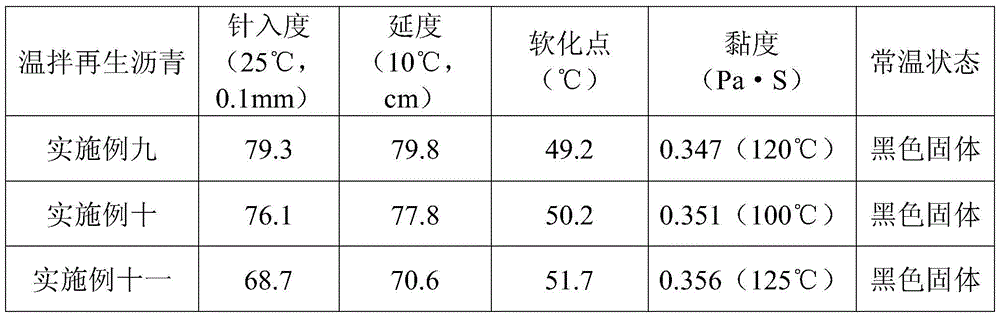

Asphalt mixture additive and preparation method thereof

ActiveCN104559258APerformance is easy to controlImprove road performanceBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt mixture additive and a preparation method thereof. The asphalt mixture additive comprises the following components in parts by mass: 10-20 parts of a polymer, 5-10 parts of a cross linker, 10-20 parts of padding, 0.5-2 parts of a smog inhibitor, 1-2 parts of a plasticizer, 0.1-1 part of an antioxidant and 50-70 parts of matrix asphalt, wherein the matrix asphalt is one of Shell 70#, Shell 90#, SK70# or SK90#. Compared with the prior art, the asphalt mixture additive has the advantages that the anti-rutting performance and water damage resistance of an asphalt mixture can be significantly improved, the low-temperature cracking resistance and ageing resistance of asphalt concrete can be effectively improved, and the service life of asphalt roads is prolonged; meanwhile, the asphalt mixture additive can substitute about 15-25% of asphalt raw materials in the asphalt mixture, so that the production temperature is reduced to 140 DEG C, then the smoking phenomenon in the production and spreading processes is effectively reduced, and the asphalt mixture additive is energy-saving and environment-friendly; and the production method is simple, low in cost and suitable for industrialized production.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

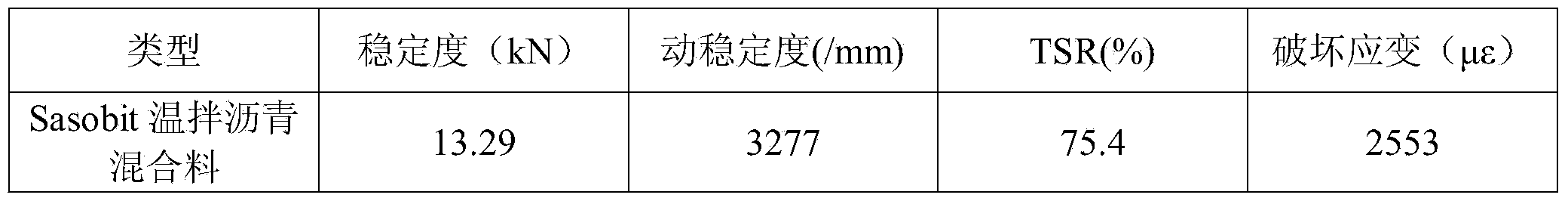

Rubber master batch and preparation method thereof

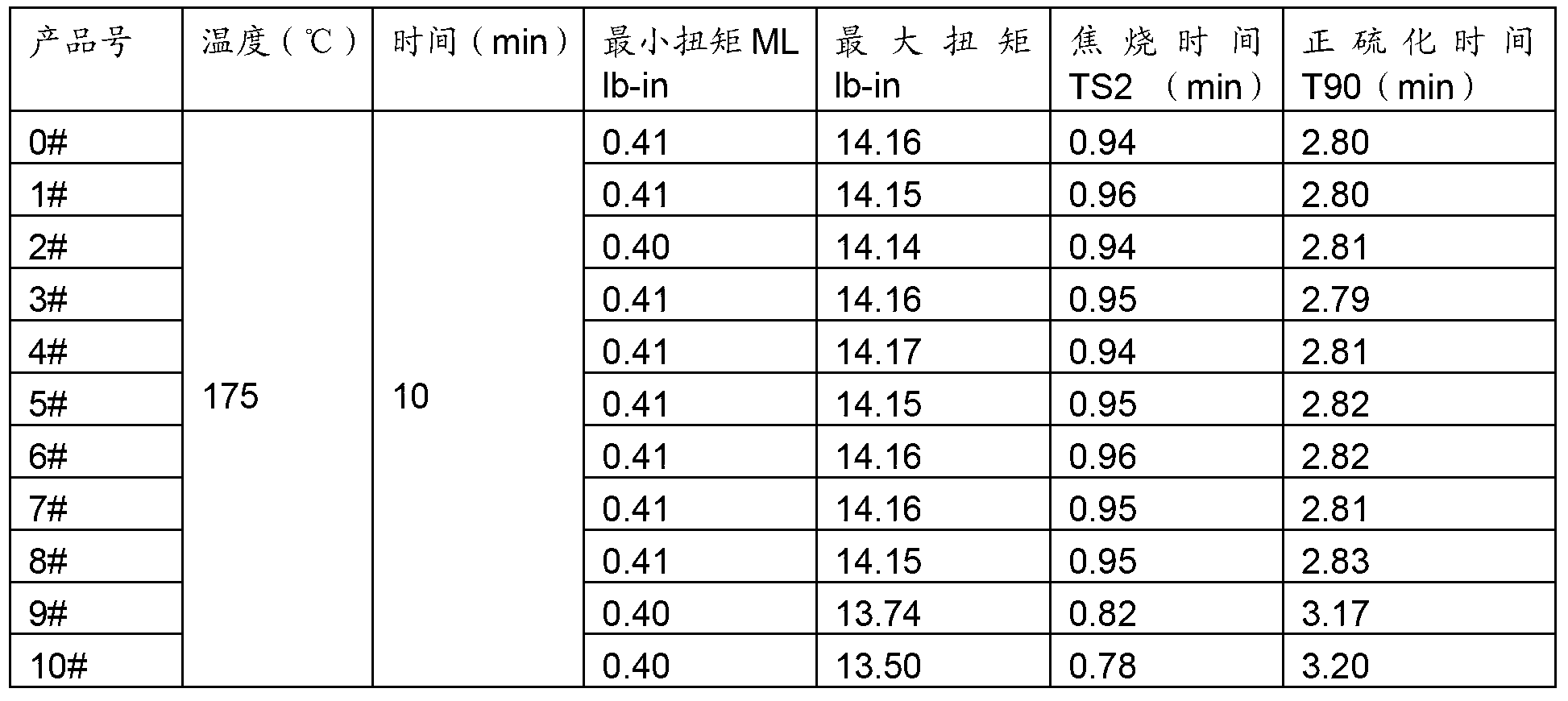

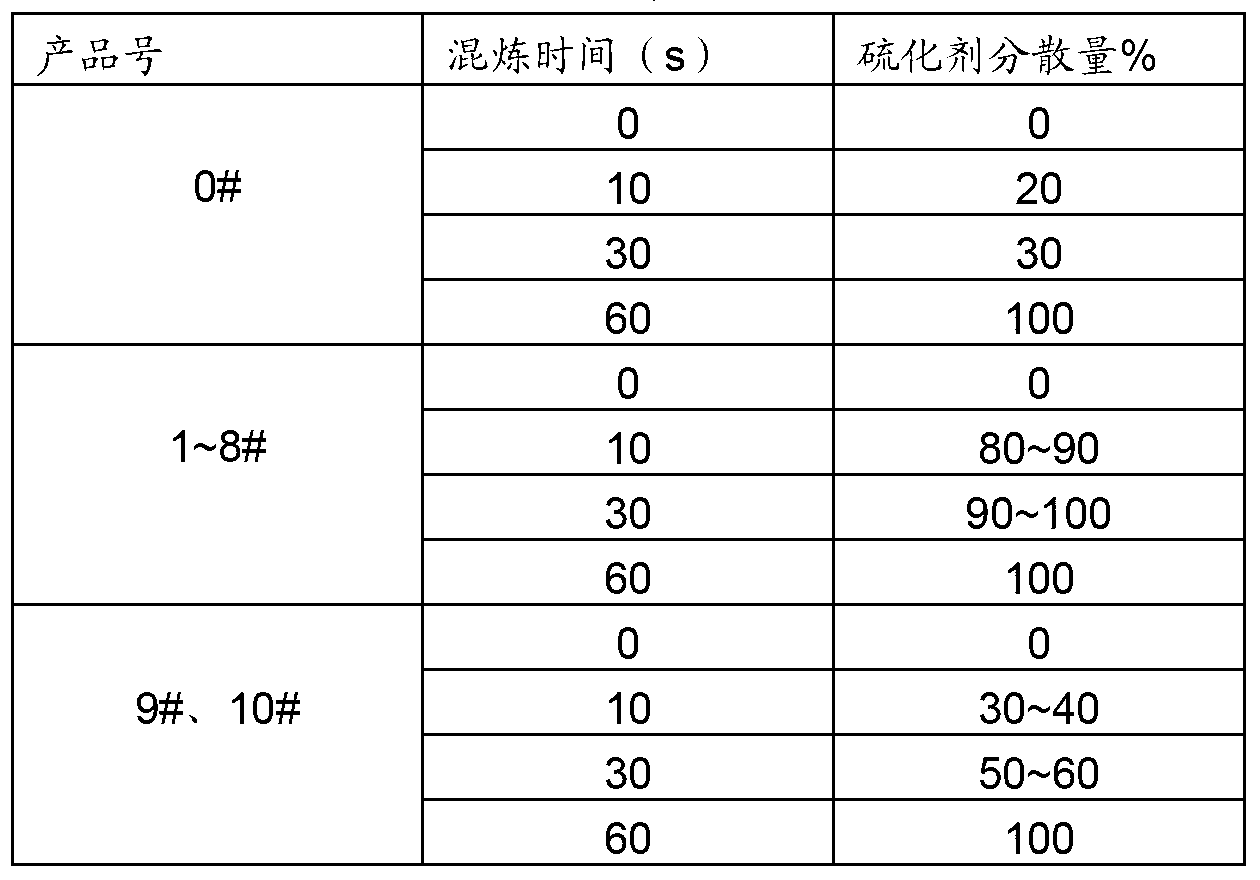

The invention relates to rubber master batch which comprises sulfur powder, filling oil, a dispersant and natural rubber NR. The mass ratio of the sulfur powder to the filling oil is (9-13):1. The mixture of the sulfur powder and the filling oil is mixed sulfur powder. The mass ratio of the mixed sulfur powder to the dispersant is (20-30):1. The mass ratio of the dispersant to the NR is 1: (2-5). The master batch prepared by the invention can be used as a rubber vulcanizer, and is quick in mixing and dispersing, short in mixing time and low in mixing temperature.

Owner:QINGDAO LINK OIL PROD

Low-odor rubber asphalt mixture used for road engineering

The invention discloses a low-odor rubber asphalt mixture used for road engineering. The mixture is prepared from the following components: 85-92 parts of aggregate, 1-3 parts of zeolite particles, 8-12 parts of zeolite powder, 4-8 parts of rubber asphalt, and 0.2-0.4 part of a warm-mixed additive. The mixture is prepared by the following steps: firstly preheating the aggregate, the zeolite particles and the zeolite powder to 160-170 DEG C, and performing heat preservation for 2-4 h; preheating the rubber asphalt to 145-155 DEG C; adding the aggregate and the zeolite particles sequentially into a mixing pot, performing mixing for 90 s at 150-155 DEG C, adding the warm-mixed additive and the rubber asphalt, performing mixing for 90 s, finally adding the zeolite powder, and continuing mixing for 90 s to obtain the finished product of the target mixture. According to the mixture provided by the invention, the zeolite is innovatively applied to the rubber asphalt mixture, the zeolite powder is used to replace mineral powder in an original mixture, the zeolite particles with a same particle size are used to replace aggregate with a corresponding specification in the original mixture, so that the content of the zeolite in the mixture is improved under the premise that road performance of the mixture is ensured, harmful gas is absorbed more effectively, and emission of the harmful gases during mixing and transportation of the rubber asphalt mixture is greatly reduced.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +2

Waste grease premixed reinforced asphalt mixture and preparation method thereof

InactiveCN107500611AEasy constructionImprove workabilityClimate change adaptationGreenhouse gasHigh energy

The invention discloses a waste grease premixed reinforced asphalt mixture and a preparation method thereof. The preparation method comprises the following steps: step 1, adding 1.5 to 2.5 percent o waste grease into matrix asphalt, uniformly stirring, developing, and obtaining waste grease soft asphalt; step 2, premixing aggregates by using the waste grease soft asphalt prepared in step 1, and obtaining a premixed material; step 3, re-mixing the premixed material obtained in step 2 by using rock asphalt powder, and obtaining a remixed material; step 4, adding mineral powder into the remixed material obtained in step 3, and uniformly mixing, thus obtaining the waste grease premixed reinforced asphalt mixture. The waste grease premixed reinforced asphalt mixture can well use the waste grease and can solve the problems in the asphalt mixture pavement laying process such as high energy consumption, emission of a great amount of greenhouse gas and harmful gas and the like.

Owner:CHANGAN UNIV +1

Bituminous mixture preparation method capable of implementing warm mixing

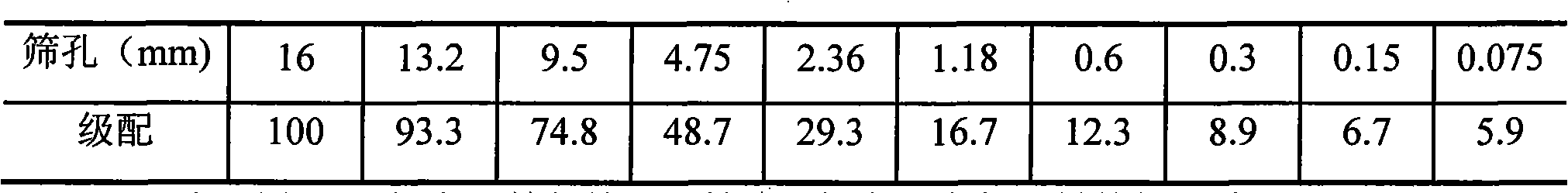

InactiveCN109503030AReduce production capacityReduce the temperatureBituminous materialsUltimate tensile strength

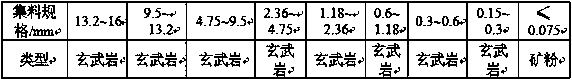

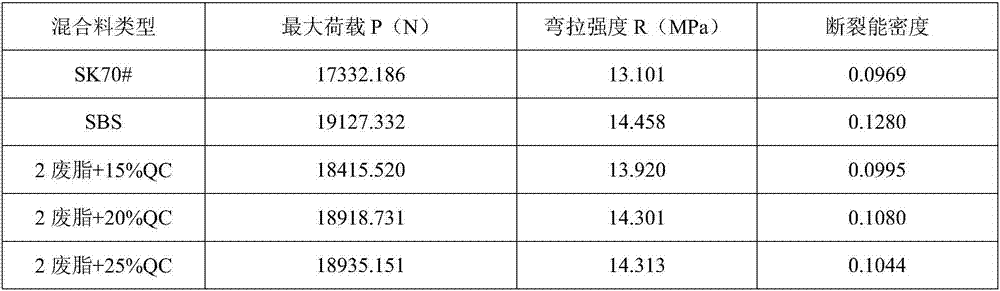

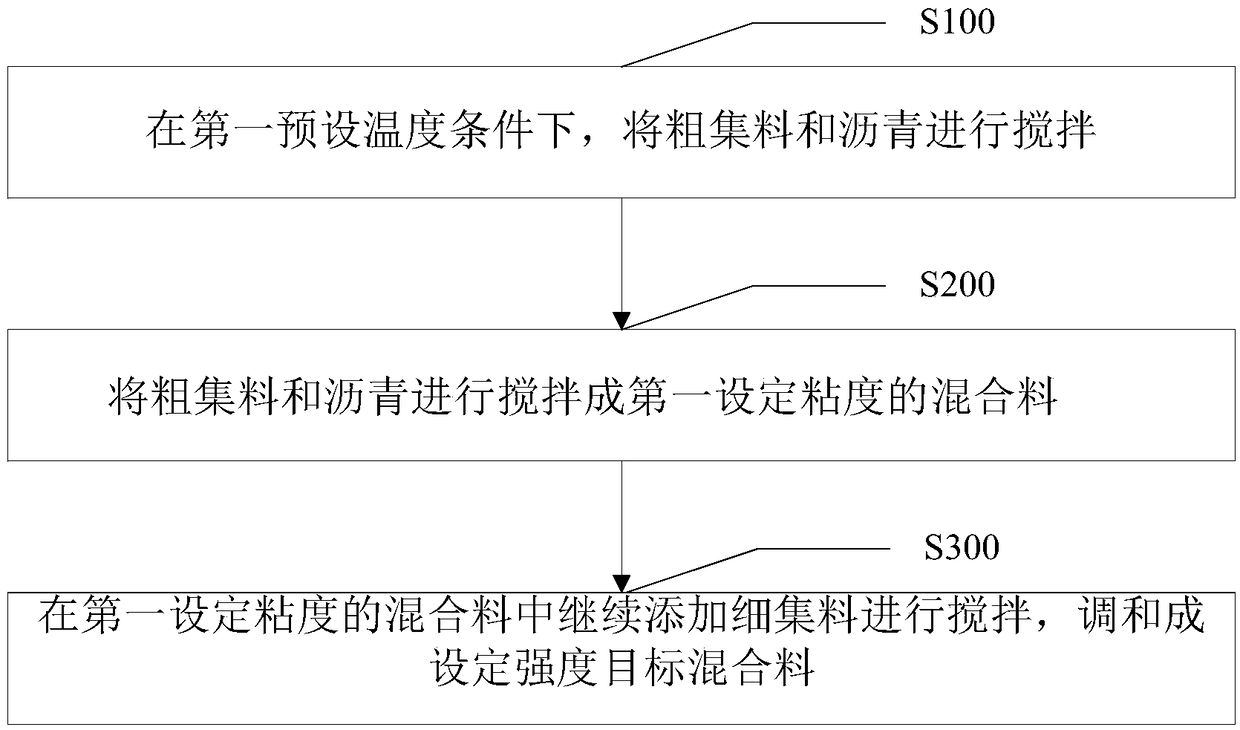

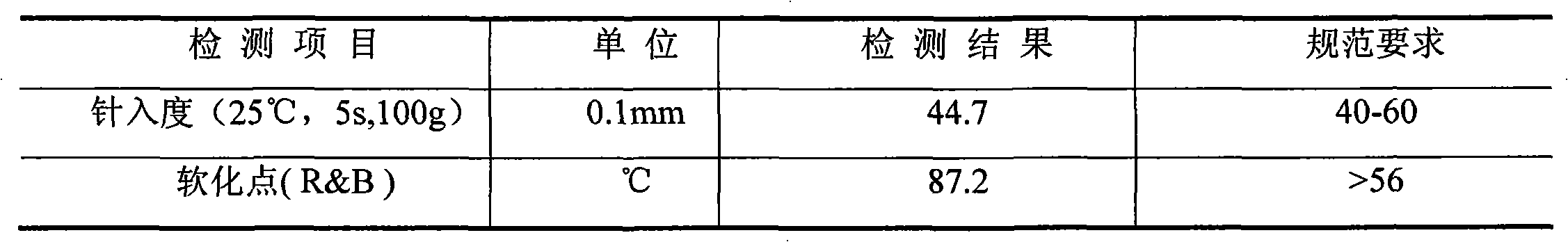

The invention discloses a bituminous mixture preparation method capable of implementing warm mixing. The bituminous mixture preparation method capable of implementing warm mixing comprises the following steps: stirring coarse aggregates and bitumen under the condition of a first preset temperature; stirring the coarse aggregates and the bitumen into a mixture with a first set viscosity; and keeping adding fine aggregates in the mixture with the first set viscosity and stirring to obtain a target mixture with set strength. According to the bituminous mixture which is prepared by warm mixing, abitumen material replaces materials such as Sasobit, Evotherm in the prior art, meanwhile, the production blending temperature of the mixture can be reduced under the condition that a warm mixing agent is not added, and a warm mixing effect is achieved.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD +1

Preparation method of low-carbon asphalt mixture

ActiveCN101837603AReasonable dosageOptimum Oil QuantityCeramic shaping apparatusPavement engineeringMaterials science

The invention belongs to the technical field of highways and urban roads, and in particular relates to a preparation method of a low-carbon asphalt mixture. The preparation method comprises the concrete step of directly adding a low-carbon agent into modified asphalt or substrate asphalt, which reduces the emission of carbon dioxide, the mixing temperature and the paving temperature of the asphalt mixture and the consumption of energy sources. The mixing temperature is generally 110-140DEG C and the compaction temperature is generally 80-100DEG C; and compared with the hot mixing asphalt mixture, the emission of the carbon dioxide is reduced by over 45 percent and the consumption of the energy sources can be reduced by 12-18 percent. The preparation method can play roles of reducing the emission of the carbon dioxide and saving the energy sources, is a preparation method of the asphalt mixture with greenness, environmental protection and energy saving and can be applied to paving the urban roads, various grades of highways and other pavement engineering.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

Heat-resisting smell-cleaning and warm-mixing multifunctional asphalt modifier and preparation method and application thereof

ActiveCN108585605ALower mixing temperatureEvenly dispersedClimate change adaptationDiseaseRoad surface

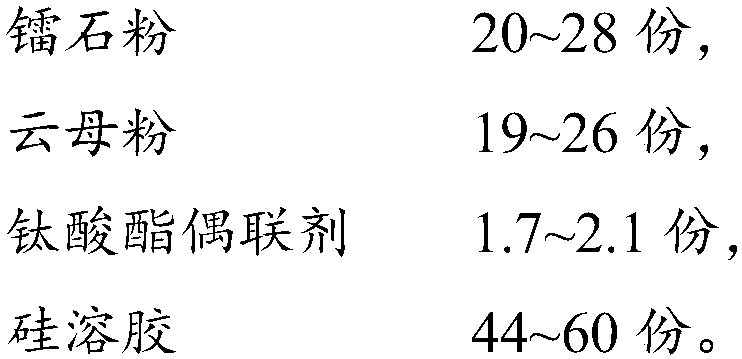

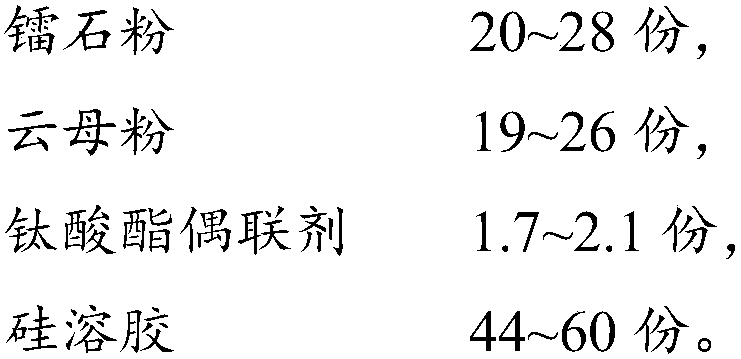

The invention provides a heat-resisting smell-cleaning and warm-mixing multifunctional asphalt modifier. The modifier comprises, by mass, 20-28 parts of thunderstone power, 19-26 parts of mica powder,1.7-2.1 parts of coupling agent of organic titanate and 44-60 parts of silica sol. The modifier has an obvious smell purification function, the releasing amount of asphalt fume during the mixing process of an asphalt mixing material can be effectively reduced, the temperature of an asphalt road surface can be effectively reduced to reduced the generation high-temperature diseases, the mixing temperature of the asphalt mixing material can be greatly reduced, and energy is saved.

Owner:CHANGAN UNIV +1

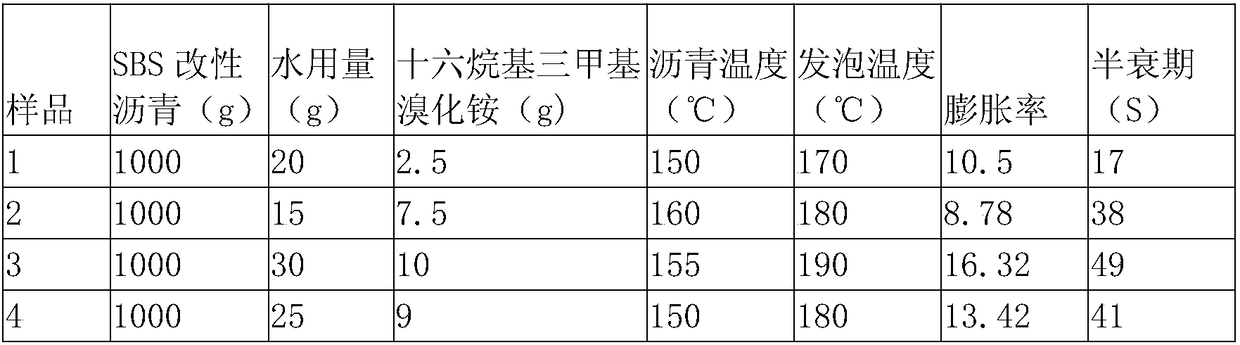

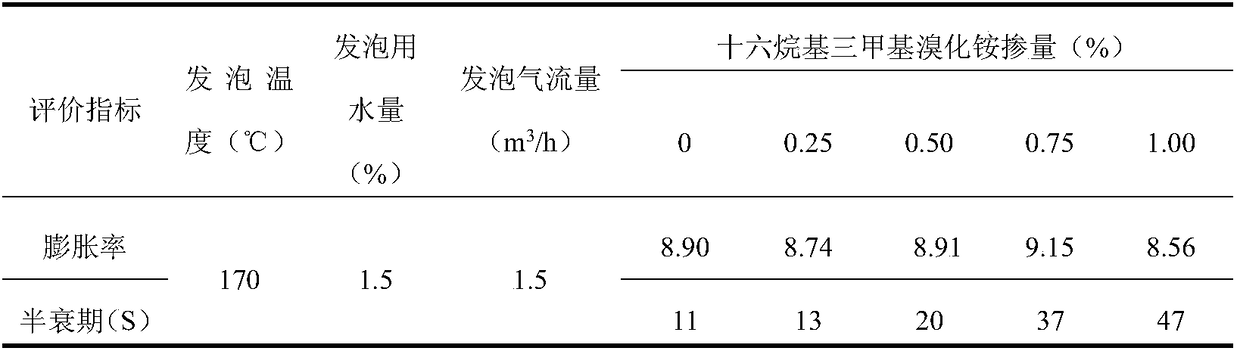

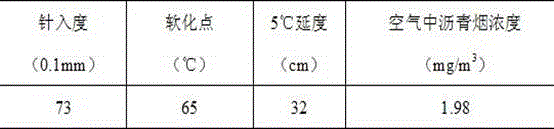

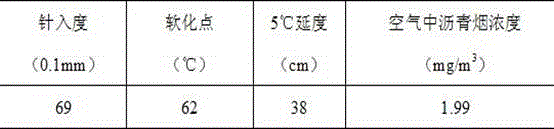

SBS (Styrene-Butadiene-Styrene) modified foam warm mix asphalt and preparation method thereof

PendingCN108504113AImprove foam stabilityMaximum expansion rate has no effectClimate change adaptationBuilding insulationsAmmonium bromideAsphalt

The invention discloses an SBS (Styrene-Butadiene-Styrene) modified foam warm mix asphalt, which is prepared from the following raw materials in parts by weight: 100 parts of SBS modified asphalt, 1.5-3 parts of water and 0.25-1.0 part of hexadecyl trimethyl ammonium bromide. The invention also discloses a preparation method for the asphalt. The preparation method comprises the following steps: (1) heating the SBS modified asphalt to a fusion state, and pouring the asphalt tank of a foaming machine; (2) adding hexadecyl trimethyl ammonium bromide into the asphalt tank, and stirring; (3) when the SBS modified asphalt reaches a foaming temperature, issuing a foaming instruction to the foaming machine, injecting water into hot asphalt to be foamed, and finally, obtaining the SBS modified foamasphalt. The half-life period of the foam asphalt is obviously improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

Normal temperature regenerant for asphalt pavement recycled mixture

ActiveCN109232974APlay the role of diluting asphaltImprove road performancePlastic recyclingBuilding insulationsRoom temperatureRoad surface

The invention discloses a normal temperature regenerant for an asphalt pavement recycled mixture and relates to the technical field of production of auxiliary materials for processing asphalt. The regenerant is prepared from the following component in percentage by weight: 20 to 70 percent of heavy traffic paving asphalt, 2 to 10 percent of a latex modifier, 2 to 9 percent of a surfactant, 15 to 40 percent of water, 0 to 5 percent of an organic aid and 0 to 3 percent of aromatic oil. The normal temperature regenerant prepared by the invention is used for recycling a pavement recycled mixture;the performance of the obtained recycled mixture meets existing specifications and standards and the standards of national renewable asphalt concrete; the problem that the performance of an existing pavement recycled mixture cannot meet national standard requirements at present is solved.

Owner:合肥孚成活性材料技术开发有限公司

A kind of hot mix asphalt pavement smoke suppression agent and preparation method of smoke suppression asphalt

ActiveCN104194356BLower the mixing temperatureReduce releaseBuilding insulationsPigment treatment with organosilicon compoundsEcological environmentAluminium hydroxide

The invention discloses a hot mix asphalt pavement smoke suppressant, comprising the following components in percentage by weight: 7%-9% of a warm mixing agent and 91%-93% of aluminium hydroxide subjected to surface modification treatment. The invention also discloses a preparation method of smoke-suppressing asphalt. The method comprises the following steps: a) heating asphalt to 100-130 DEG C, and then adding the warm mixing agent in the smoke suppressant according to the ratio in claim 1, and stirring until the warm mixing agent is uniform; and b) adding the aluminium hydroxide subjected to surface modification treatment, and stirring until the aluminium hydroxide is uniform, wherein the percentage of the asphalt is 95%-97%, and the percentage of the smoke suppressant is 3%-5%. According to the smoke suppressant disclosed by the invention, release of asphalt smoke in the construction process of a hot mix asphalt pavement can be obviously reduced, the mixing temperature of the smoke suppressant is low, the construction and ecological environments are greatly improved, the physical health of constructors is protected, the smoke suppressant has significant social benefits and environmental protection benefits, meanwhile, energy conservation can also be achieved, asphalt ageing is relieved, the pavement performances such as the integrality, the strength and the durability of the asphalt pavement are improved, and the smoke suppressant has obvious technical and economic benefits.

Owner:重庆建工建筑产业技术研究院有限公司 +2

Low-hysteresis carbon black and production method thereof

InactiveCN111534128AReduce rolling resistanceLow heat generationPigmenting treatmentPhysical chemistryEngineering

The invention provides low-hysteresis carbon black and a production method thereof. The low-hysteresis carbon black has the characteristics that the oil absorption value is 131-145 ml / 100 g, the compression oil absorption value is 102-114 ml / 100 g, the iodine absorption value is 115-131 mg / g, and the nitrogen adsorption specific surface area is 119-130 m < 2 > / g. A tire manufactured using the low-hysteresis carbon black has low rolling resistance and low heat accumulation under use conditions.

Owner:CHAOYANG BLACK CAT WUXINGQI CARBON BLACK CO LTD

Composite pavement sealing layer and preparation method and application thereof

ActiveCN109133728AImprove wear resistanceImprove high temperature stabilityIn situ pavingsEmulsionSurface layer

The invention provides a composite pavement sealing layer and a preparation method and application thereof and belongs to the technical field of road maintenance. The composite pavement sealing layerprovided by the invention comprises a bottom layer arranged on the surface of a to-be-treated road and a surface layer arranged on the surface of the bottom layer, wherein the bottom layer is formed by a normal temperature modified asphalt mixture which comprises asphalt, an asphalt modifier and aggregate; the surface layer is formed by a sand-containing fog seal layer mixture which comprises a waterborne concentrated cover material, an acrylic resin emulsion, fine sand and water; and the waterborne concentrated cover material comprises asphalt, emulsifier, argil and water. The composite pavement sealing layer provided by the invention has the beneficial effects that the softening point of the asphalt is reduced by utilizing the asphalt modifier, so that the mixing of the normal temperature modified asphalt mixture and the paving of the bottom layer can be realized under normal temperature conditions; and meanwhile, by utilizing the surface layer formed by the sand-containing fog sealing layer mixture, water on the road surface can be effectively prevented from sinking in road and damaging the bottom layer, so that the waterproof performance of the road surface is improved.

Owner:北京路凯泰公路养护工程有限公司

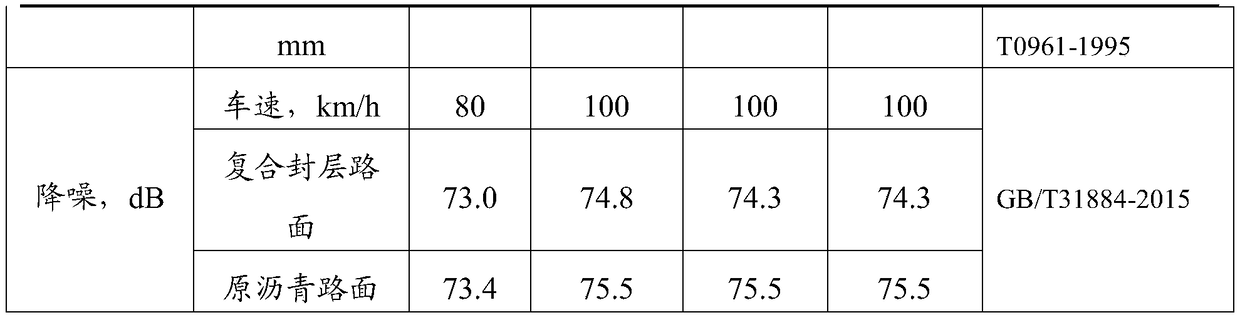

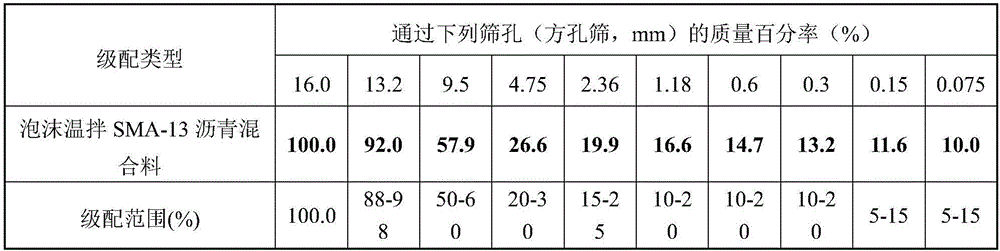

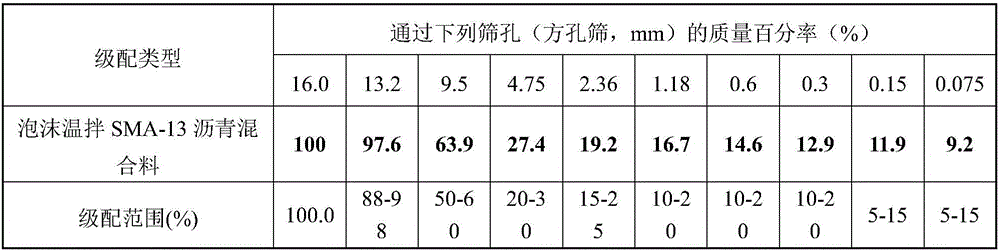

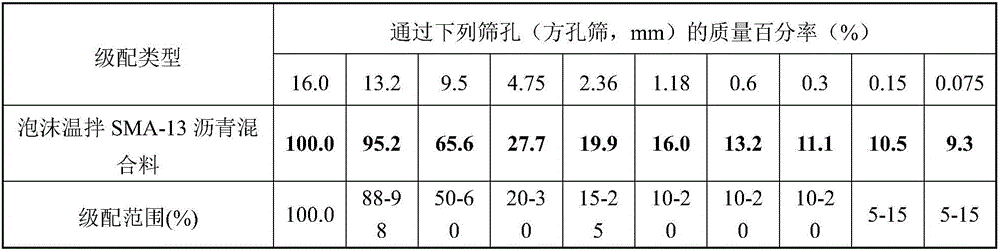

Foam warm-mixing SMA-13 asphalt mixture, preparation method and performance evaluation method thereof

InactiveCN106083177ALower the mixing temperatureReduce agingClimate change adaptationCeramicwareFiberVaporization

The invention discloses a foam warm-mixing SMA-13 asphalt mixture, a preparation method and a performance evaluation method thereof. The preparation method comprises the following steps: performing mechanical foaming processing on the modified asphalt to prepare the foam-modified asphalt; screening an aggregate, taking the required grade of a coarse aggregate and a fine aggregates; mixing the selected aggregates, adding flocculent lignin fibers and the foam-modified asphalt, and uniformly stirring the material to obtain a target product. Middle-high temperature asphalt, gas and water are simultaneously introduced into an asphalt foaming apparatus for rapid vaporization, foam asphalt is generated through rapid expansion, volume of the formed asphalt is temporarily increased, and the viscosity is temporarily minimized, the aggregates can be fully coated under low temperature, workability is increased, mixing temperature of the foam warm-mixing SMA-13 asphalt mixture is reduced from the temperature of 180-185 DEG C to about 160 DEG C, mixing temperature is reduced, and aging degree of the SMA-13 asphalt mixture is reduced, and the generation of the harmful gas is reduced.

Owner:JSTI GRP CO LTD

A kind of composite warm mixing regeneration agent and preparation method thereof

ActiveCN104177850BEasy to prepareImprove road performanceBuilding insulationsAgent CombinationActive agent

The invention discloses a composite warm-mix regeneration agent, which is a composite material of a surfactant and an oil regeneration agent, and the surfactant is one or more of fatty acid glyceride, fatty acid sorbitan, polysorbate, and sucrose ester. The oil component regeneration agent is one or more of extracted oil, lubricating oil, engine oil and heavy oil when refining lubricating oil. The invention also discloses a preparation method of the composite warm-mixing regeneration agent, which comprises the following steps: weighing the surfactant and the oil regeneration agent according to a certain ratio; putting the two into mixing equipment for stirring. The present invention will show that the active agent is organically combined with the oil regeneration agent, and a composite warm-mix regeneration agent for asphalt pavement materials is invented, which can realize the reduction of the mixing temperature of asphalt and asphalt mixture and the recycling of old asphalt mixture, and the preparation process is free It solves the problems of environmental pollution and waste of resources caused by the high mixing temperature of traditional asphalt and asphalt mixture and the low utilization rate of old materials.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +1

Warm mixing type track-resistant compound modification agent and preparation method thereof

ActiveCN106147249AProlonged viscosity at 60°CIncrease viscosity at 60°CClimate change adaptationBuilding insulationsActive agentOil sludge

The invention discloses a warm mixing type track-resistant compound modification agent and a preparation method thereof and belongs to the technical field of road asphalt. The warm mixing type track-resistant compound modification agent is prepared from a special warm mixing agent, a powdery solid, polyethylene wax, sulfur and hard asphalt according to a formula, wherein the special warm mixing agent is prepared from a fluorocarbon surfactant, alkyl glycoside and carlo amine, the powdery solid is a solid product separated after oily sludge is treated by adopting a sludge thermal-extraction dehydration process. The components in the warm mixing type track-resistant compound modification agent have a synergistic effect, the effect of additive synergism can be played, the mixing and forming temperatures of a warm mixing type asphalt mixed material prepared by applying the warm mixing type track-resistant compound modification agent are lower than 135 DEG C, the warm mixing type track-resistant compound modification agent has the advantages of obviously reducing the mixing and forming temperatures, and the properties of the mixed material are equivalent to the properties of warm mixing asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of asphalt concrete warm mixing rutting and cracking resisting agent

The invention relates to a preparation method of an asphalt concrete warm mixing rutting and cracking resisting agent. The preparation method concretely comprises the following steps: fully mixing wax, resin and a cross-linking agent in a reaction kettle to obtain a modifying mixture; and adding a surfactant, a plasticizer and assistant to the modifying mixture, carrying out melt blending, and granulating the mixture through a granulating tower or a rotary belt condensation granulator to obtain the warm mixing rutting and cracking resisting agent. Compared with the prior art, the preparation method disclosed in the invention has the advantages of simplicity in operation, easiness in industrial generation, facilitation of reduction of the mixing temperature and the compacting temperature of asphalt concrete, reduction of the discharge of harmful gases, improvement of the moisture resistance, and high-temperature viscosity reducing and low-temperature viscosity increasing effects on asphalt; and the prepared warm mixing rutting and cracking resisting agent obviously improves the softening point, the ductility and the 60 DEG C viscosity of the asphalt, reduces the mixing and lying temperature, and improves the rutting resistance, the low-temperature cracking resistance and the water damage resistance of the asphalt concrete.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com