Anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application

A technology of surfactant and warm-mix asphalt, which is applied in the fields of climate change adaptation, building insulation materials, building components, etc., can solve problems such as the inability to completely avoid harmful gas emissions, unfavorable large-scale promotion, and complex composition ratios. Improvement of conditions, reduction of damage to workers' health, effects of less ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

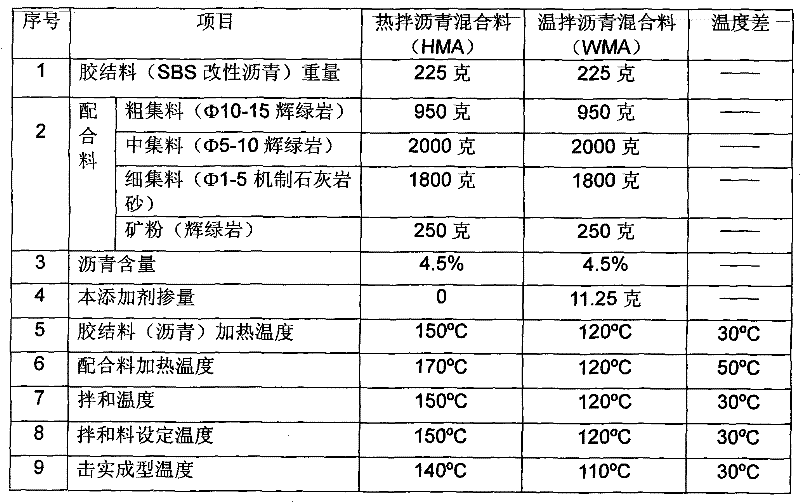

Image

Examples

Embodiment 1

[0040] 1. Preparation of polyvinyl acetal:

[0041] The number average molecular weight of 100 parts by weight is 1×10 4~5×10 4 Polyvinyl acetate, 200 parts by weight of acetic acid and 70 parts by weight of water are mixed and heated to 60 ° C, stirred until completely dissolved, and then 60 parts by weight of formaldehyde solution is added (based on the weight of the formaldehyde solution, the weight percentage of formaldehyde is 30%) and 4 parts by weight of sulfuric acid, react at 80°C for 24 hours, then neutralize with ammonium acetate, add water to precipitate polyvinyl acetal, wash and dry to obtain polyvinyl acetal product.

[0042] 2. Preparation of anti-stripping warm mix asphalt additive:

[0043] 1) dissolving polyvinyl acetal with water as a solvent to form a polyvinyl acetal mixed solution with a solid content of 20% (percentage by weight);

[0044] 2) using water as a solvent to prepare polyacrylamide into a polyacrylamide mixture with a solid content of 10%...

Embodiment 2

[0060] 1. Preparation of polyvinyl acetal:

[0061] The number average molecular weight of 80 parts by weight is 1×10 4 ~5×10 4 Polyvinyl acetate, 250 parts by weight of acetic acid and 100 parts by weight of water are mixed and heated to 80°C, stirred until completely dissolved, and then 80 parts by weight of formaldehyde solution is added (based on the weight of the formaldehyde solution, the weight percentage of formaldehyde is 50%) and 6 parts by weight of sulfuric acid, react at 60°C for 30 hours, then neutralize with ammonium acetate, add water to precipitate polyvinyl acetal, wash and dry to obtain polyvinyl acetal product.

[0062] 2. Preparation of anti-stripping warm mix asphalt additive:

[0063] 1) dissolving polyvinyl acetal with water as a solvent to form a polyvinyl acetal mixed solution with a solid content of 50% (weight percent);

[0064] 2) Polyacrylamide is prepared into a polyacrylamide mixed solution with a solid content of 15% (weight percent);

[0...

Embodiment 3

[0074] 1. Preparation of polyvinyl acetal:

[0075] The number average molecular weight of 120 parts by weight is 1×10 4 ~5×10 4 Polyvinyl acetate, 150 parts by weight of acetic acid and 50 parts by weight of water are mixed and heated to 70°C, stirred until completely dissolved, and then 50 parts by weight of formaldehyde solution (based on the weight of the formaldehyde solution, the weight percentage of formaldehyde is 40%) and 3 parts by weight of sulfuric acid, react at 70°C for 20 hours, then neutralize with ammonium acetate, add water to precipitate polyvinyl acetal, wash and dry to obtain polyvinyl acetal product.

[0076] 2. Preparation of anti-stripping warm mix asphalt additive:

[0077] 1) dissolving polyvinyl acetal in water as a solvent to form a polyvinyl acetal solution with a solid content of 20% (percentage by weight);

[0078] 2) polyacrylamide is prepared into a polyacrylamide mixed solution with a solid content of 5% (weight percent);

[0079] 3) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com