Positive pole piece and preparation method and application thereof

A technology of positive pole piece and positive current collector, which is applied in the field of positive pole piece and its preparation, can solve the problems of lithium-ion battery safety hazards, low safety, and internal short circuit, so as to reduce internal short circuit phenomenon, improve safety, and energy The effect of less density loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

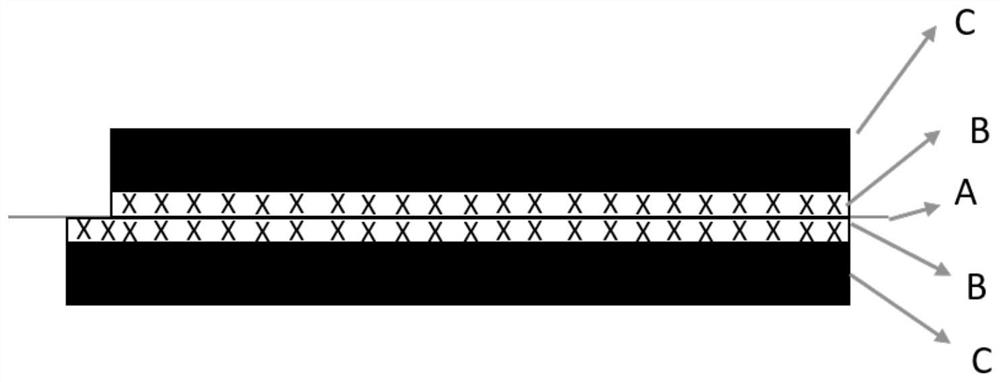

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the above-mentioned positive pole piece, the method comprising the following steps:

[0041] Prepare a positive electrode slurry including a positive electrode active material, the ratio [003] / [006] of the diffraction intensity [003] of the 003 crystal plane to the diffraction intensity [006] of the 006 crystal plane of the positive electrode active material in X-rays is less than 20;

[0042] The positive electrode sheet is prepared by coating the positive electrode slurry on the positive electrode current collector through a coating device, drying, cutting, and sheeting.

[0043] According to the present invention, described method specifically comprises the following steps:

[0044] (1-1) Prepare the first positive electrode slurry including the first positive electrode active material, wherein the diffraction intensity [003] of the first positive electrode active material in the X-ray of the 003 crystal plan...

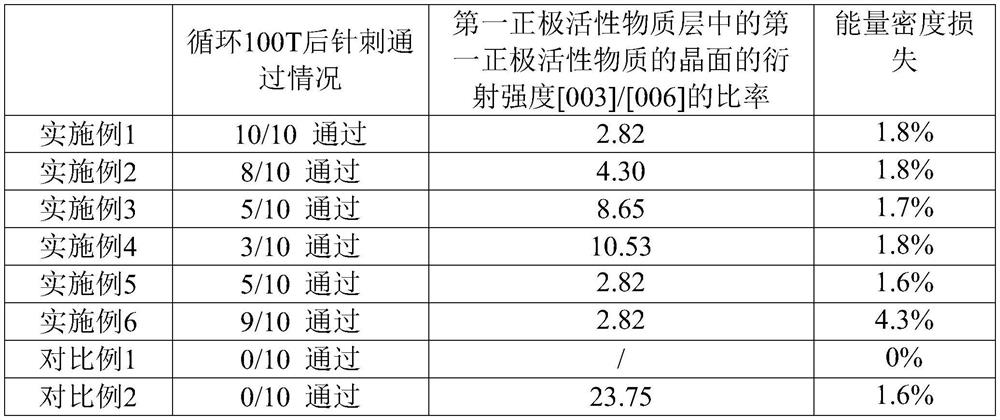

Embodiment 1

[0061] (1) Preparation of positive electrode sheet

[0062] (1-1) Preparation of the first positive electrode slurry

[0063] 88wt% of the first positive electrode active material (median particle diameter D 50 Lithium cobalt oxide LiCoO with a layered structure of 4-6 μm 2 , and the ratio [003] / [006] of the diffraction intensity [003] of the first positive electrode active material in the first positive electrode active material layer in the X-ray to the diffraction intensity [006] of the 006 crystal plane is: 2.82), 1.2wt% of the first conductive agent (conductive carbon black) and 10.8wt% of the first binder (polyvinylidene fluoride) were mixed, and then N-methylpyrrolidone was added to stir and disperse to make the first positive electrode slurry.

[0064] (1-2) Preparation of the second positive electrode slurry

[0065] 97.8wt% of the first positive electrode active material (median particle diameter D 50 Lithium cobalt oxide LiCoO with a layered structure of 5-20 μ...

Embodiment 2

[0074] Others are the same as in Example 1, except that the ratio of the diffraction intensity [003] of the first positive electrode active material in the first positive electrode active material layer to the diffraction intensity [006] of the 006 crystal plane in X-rays [ 003] / [006] is 4.30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com