Lithium battery positive plate and preparation method and application thereof

A lithium battery and positive electrode technology, which is applied in the field of lithium battery positive electrode and its preparation, can solve problems such as safety problems, the reduction of acupuncture pass rate of lithium batteries, melting and burning of binders, etc., so as to improve elasticity and improve mixing Uniformity, the effect of improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

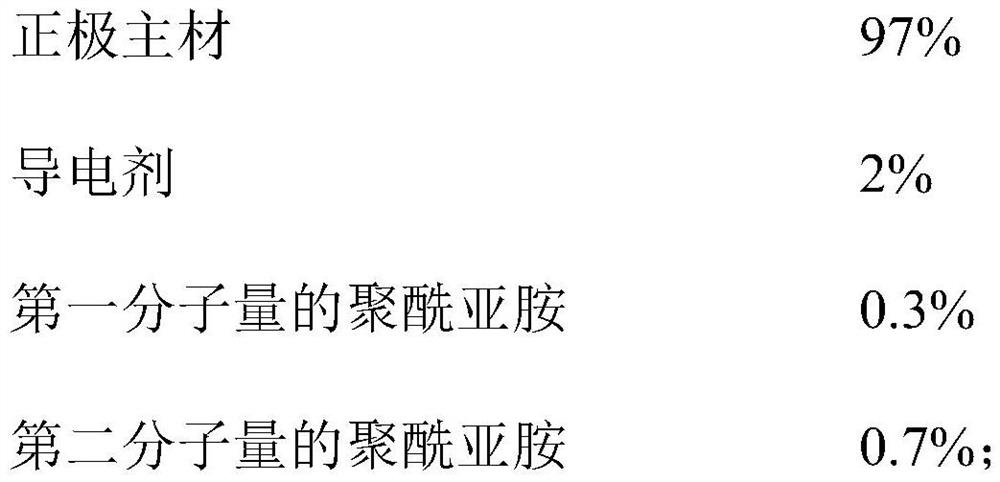

[0045] Taking the mass of the active material layer as 100%, the composition of the active material layer on the positive electrode sheet of the lithium battery in this embodiment includes the following components:

[0046]

[0047] Among them, the main material of the positive electrode is NCM622, and the conductive agent is conductive graphite.

[0048] The molecular weight of the polyimide with the first molecular weight is 115,000; the molecular weight of the polyimide with the second molecular weight is 50,000.

Embodiment 2

[0050] Taking the mass of the active material layer as 100%, the composition of the active material layer on the positive electrode sheet of the lithium battery in this embodiment includes the following components:

[0051]

[0052] Among them, the main material of the positive electrode is NCM622, and the conductive agent is conductive graphite.

[0053] The molecular weight of the polyimide with the first molecular weight is 105,000; the molecular weight of the polyimide with the second molecular weight is 35,000.

Embodiment 3

[0055] Taking the mass of the active material layer as 100%, the composition of the active material layer on the positive electrode sheet of the lithium battery in this embodiment includes the following components:

[0056]

[0057] Among them, the main material of the positive electrode is NCM622, and the conductive agent is conductive graphite.

[0058] The molecular weight of the polyimide with the first molecular weight is 130,000; the molecular weight of the polyimide with the second molecular weight is 40,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com