Rubber master batch and preparation method thereof

A masterbatch and rubber technology, applied in the field of rubber additives, can solve the problems of high mixing temperature, slow dispersion speed, long mixing time, etc., and achieve the effect of low mixing temperature, no risk of explosion, and short mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

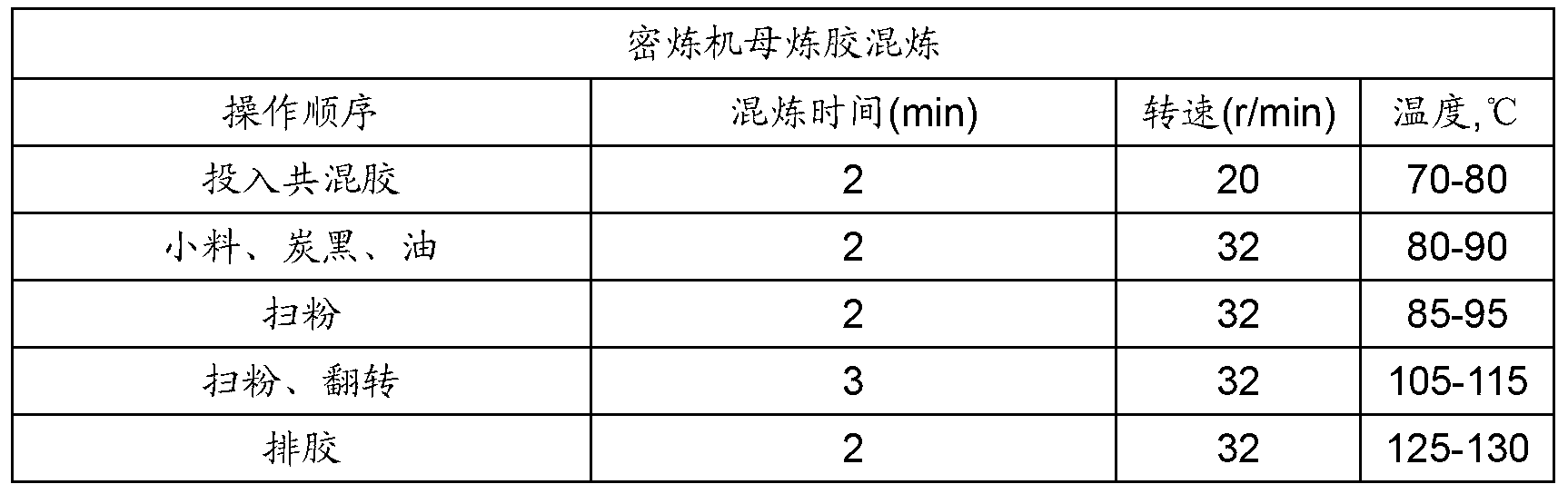

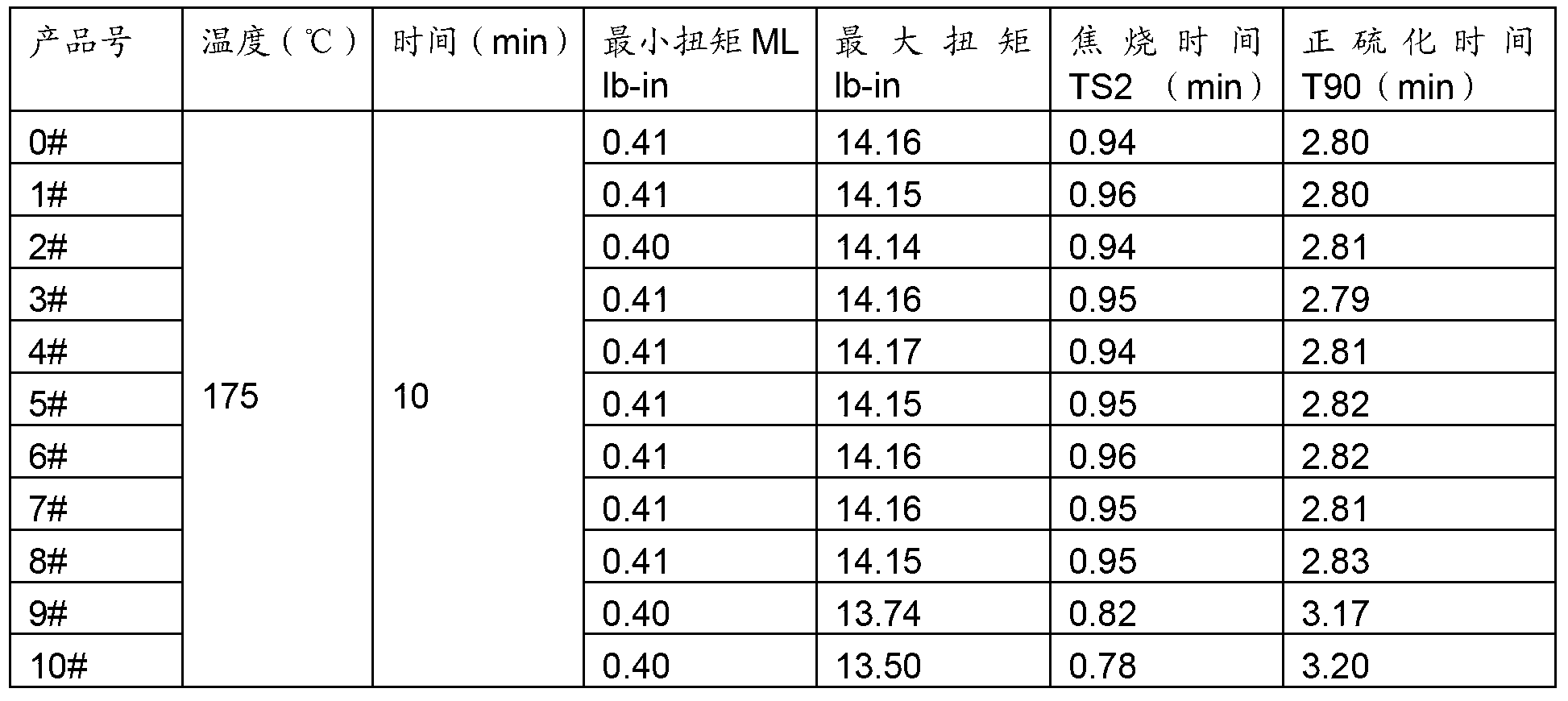

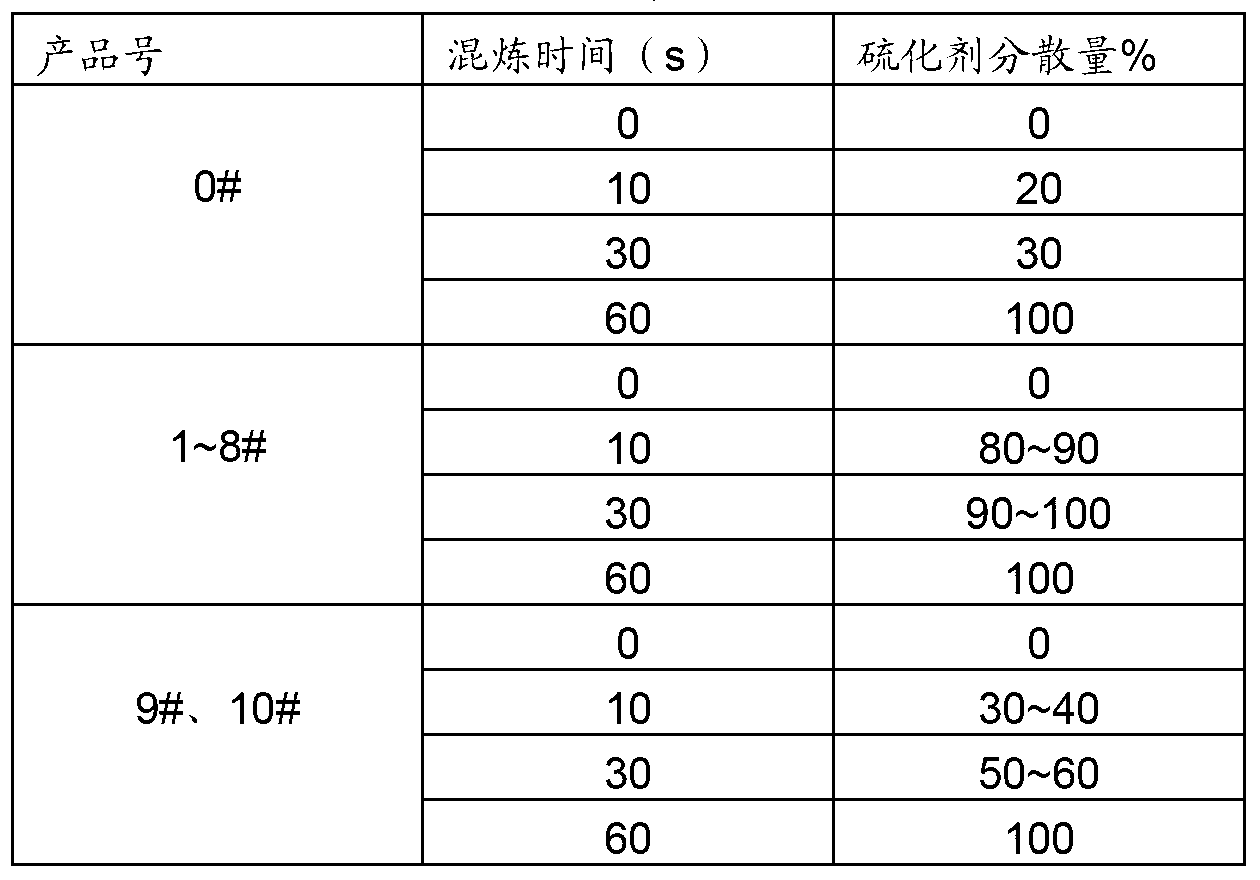

Method used

Image

Examples

Embodiment 1

[0023] Add sulfur powder into the mixer and stir. While stirring, spray naphthenic oil into the mixer through the upper oil hole according to the weight required by the formula. The temperature is 60°C, the mass ratio of sulfur powder to naphthenic oil is 9:1, and stir for 20 minutes to get Mix in sulfur powder.

[0024] Add the mixed sulfur powder into the internal mixer, and add the dispersant fatty acid zinc and natural rubber (Nitrite Reductase, NR). The mass ratio of the mixed sulfur powder to the dispersant is 20:1; the mass ratio of the dispersant to NR is 1: 5. Mix for 15 minutes. After the sulfur powder, dispersant, and NR are all uniformly dispersed, discharge the material. The discharge temperature is 40-60°C to obtain the masterbatch.

[0025] Heat the extruder to 50°C, add the masterbatch into the extruder, adjust the feeding, extrusion, and cutter speed of the extruder so that the length of the cut particles is 3mm-5mm, and the rubber masterbatch S-80 is obtaine...

Embodiment 2

[0027] Add sulfur powder into the mixer and stir. While stirring, spray spindle oil into the mixer according to the weight required by the formula through the upper oil hole. The temperature is 40°C, the mass ratio of sulfur powder to spindle oil is 13:1, and stir for 40 minutes to obtain mixed sulfur. pink.

[0028] Add the mixed sulfur powder into the internal mixer, and add the dispersant PETS and natural rubber (Nitrite Reductase, NR). The mass ratio of the mixed sulfur powder to the dispersant is 30:1; the mass ratio of the dispersant to NR is 1:4 . Mix for 30 minutes. After the sulfur powder, dispersant, and NR are all uniformly dispersed, discharge the material. The discharge temperature is 80°C to obtain the masterbatch.

[0029] Heat the extruder to 40-60°C, add the masterbatch into the extruder, adjust the feeding, extrusion, and cutter speed of the extruder so that the length of the cut particles is 3mm-5mm, and the rubber masterbatch S-80 is obtained .

Embodiment 3

[0031] Add sulfur powder into the mixer and stir. While stirring, spray transformer oil into the mixer through the upper oil hole according to the weight required by the formula. The temperature is 50°C, the mass ratio of sulfur powder to transformer oil is 11:1, and stir for 30 minutes to obtain mixed sulfur. pink.

[0032] Add the mixed sulfur powder into the internal mixer, and add the dispersant paraffin and natural rubber (Nitrite Reductase, NR). The mass ratio of the mixed sulfur powder to the dispersant is 25:1; the mass ratio of the dispersant to NR is 1:2 . Mix for 21 minutes. After the sulfur powder, dispersant, and NR are all uniformly dispersed, discharge the material. The discharge temperature is 70°C to obtain the masterbatch.

[0033] Heat the extruder to 40-60°C, add the masterbatch into the extruder, adjust the feeding, extrusion, and cutter speed of the extruder so that the length of the cut particles is 3mm-5mm, and the rubber masterbatch S-80 is obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com