SBS (Styrene-Butadiene-Styrene) modified foam warm mix asphalt and preparation method thereof

A technology of modified asphalt and warm-mix asphalt, which is applied in building insulation materials, building components, climate change adaptation, etc., and can solve the problems of poor construction workability, unsatisfactory foaming effect, and reduced road performance of foamed asphalt mixtures. , to achieve the effect of improving road performance, improving mixing and compacting effect, and increasing foaming stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] One, prepare SBS modified foam warm mix asphalt of the present invention

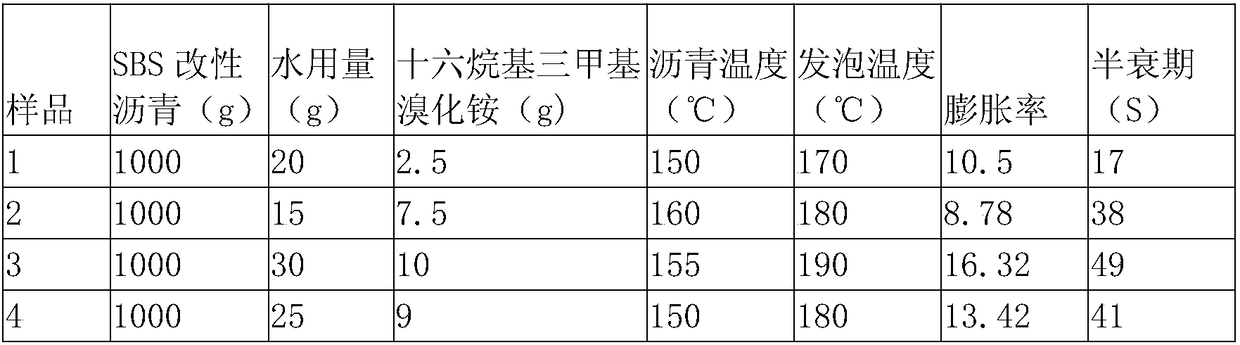

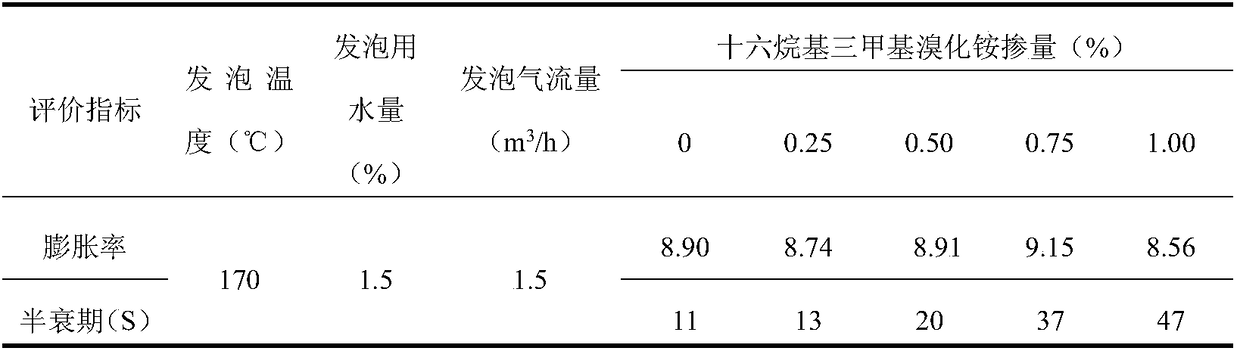

[0020] The asphalt is made of water, SBS modified asphalt, and cetyltrimethylammonium bromide. The water content is 1.5% to 3% of the mass of SBS modified asphalt. It is 0.25% to 1.00% of the mass of SBS modified asphalt. Concrete preparation is operated according to the following steps:

[0021] (1) Heat the SBS modified asphalt to a molten state (150°C-160°C), then pour it into the asphalt tank of the foaming machine, and the asphalt in the asphalt tank starts to circulate under the drive of the circulating pump;

[0022] (2) Add cetyltrimethylammonium bromide with a mass of 0.25% to 1.00% of SBS modified asphalt into the asphalt tank, and stir with a glass rod for 3 to 5 minutes, and then let the hot asphalt flow under the drive of the circulation pump for 5 minutes Foam again for ~7 minutes to promote cetyltrimethylammonium bromide and SBS modified asphalt to mix evenly until the SBS modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com