Preparation method of compound protein effervescing agent

A compound protein and foaming agent technology, applied in the field of food biology, to achieve the effects of good food safety, production promotion, good market prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

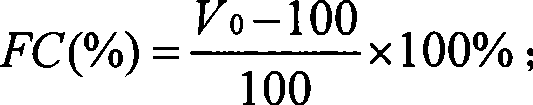

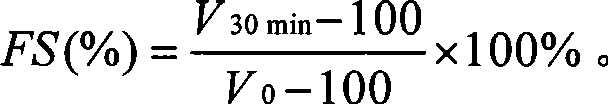

[0026] Accurately weigh 50g of soybean protein isolate, add water and stir to dissolve, make 80g / L protein solution, adjust the pH value to 8.0 with 1mol / L NaOH solution, keep the temperature at 55°C, add alkaline protease Alcalase with a solution volume of 0.2% Carry out the hydrolysis reaction, maintain the pH value of the protein solution at 8.0 during the period, when the degree of protein hydrolysis reaches 3%, the reaction is terminated, the hydrolyzate is heated in a boiling water bath for 15 minutes to inactivate the enzyme, and the supernatant is collected after centrifugation at 5000r / min for 20 minutes. The hydrolysis procedure of wheat gluten, rice protein and whey protein is the same as soybean protein isolate.

[0027] Mix the hydrolyzate of soybean protein isolate, wheat gluten protein, rice protein and whey protein in a ratio of 3:3:3:1 (v / v / v / v), and use a polysulfone ultrafiltration membrane with a molecular weight cut-off of 10kDa to separate the mixture The...

Embodiment 2

[0031] According to the operation steps of Example 1, graded hydrophobic peptides and hydrophilic peptides were prepared.

[0032] The fractionated hydrophobic peptides and hydrophilic peptides were mixed 1:1 (w / w) as the enzyme reaction substrate. The substrate polypeptide content was 50g / L, and 4g / L TGase was added to the substrate solution. Carry out cross-linking reaction, the reaction temperature is 40°C, pH6.5, after reacting for 3 hours, put it in a water bath at 80°C for 30 minutes to inactivate the enzyme, then cool it in a water bath at 25°C, the cross-linked product is concentrated in vacuum at 45-50°C, and placed in - The composite protein foaming agent product was obtained after freeze-drying at a temperature of 50-55°C. The foaming ability of the cross-linked product was measured to be 284%, the foam stability was 96%, and the foaming ability was 18% higher than that of egg white protein.

Embodiment 3

[0034] According to the operation steps of Example 1, graded hydrophobic peptides and hydrophilic peptides were prepared.

[0035] The fractionated hydrophobic peptides and hydrophilic peptides were mixed 1:1 (w / w) as the enzyme reaction substrate. The substrate polypeptide content was 50g / L, and 4g / L TGase was added to the substrate solution. Carry out cross-linking reaction, the reaction temperature is 45°C, pH 6.5, after 3.5 hours of reaction, put it in a water bath of 80°C for 30 minutes to inactivate the enzyme, then cool it in a water bath of 25°C, and the cross-linked product is concentrated in a vacuum at 45-50°C. The complex protein foaming agent product was obtained after freeze-drying at the temperature of -50~-55°C. The foaming ability of the cross-linked product was measured to be 293%, the foam stability was 97%, and the foaming ability was 22% higher than that of egg white protein .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com